A tooling structure for three-phase inductance coil combination

An inductance coil and three-phase technology, which is applied in the tooling structure field of three-phase inductance coil combination, can solve the problems of combination installation difficulty, installation size not in place, lower production efficiency, etc., achieve fast installation speed, easy installation, and improve installation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

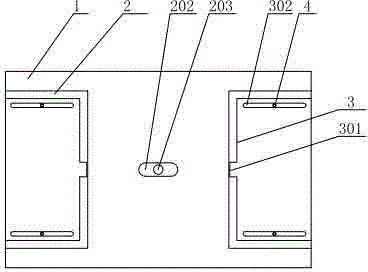

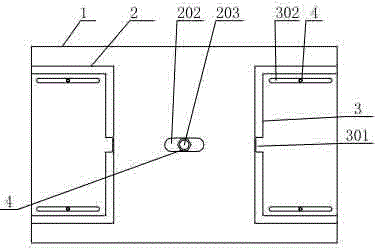

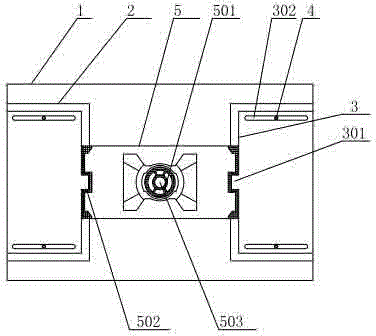

[0021] like figure 1 As shown, the present invention comprises base plate 1, and groove 2 is symmetrically arranged on the base plate 1, and mounting bracket 3 is installed in groove 2, and waist-shaped groove 302 is symmetrically opened on mounting bracket 3, and mounting bracket is fixed by nut 4 and fastener. 3 is fixedly connected to the bottom plate 1, and one side of the mounting bracket 3 extends outward to form a second boss 301. Located between the two installation brackets 3 , a first boss 202 is installed on the bottom plate 1 , the first boss 202 is waist-shaped, and a first installation hole 203 is opened in the middle of the first boss 202 . like image 3 As shown, a plurality of buffer pads 5 arranged at intervals are embedded between two mounting brackets 3 , and a space for installing a three-phase inductance coil 7 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com