Method for replacing rotating furnace

A converter and furnace body technology, applied in the field of converter replacement, can solve the problems of difficulty in controlling the quality of new converter assembly, long working hours, and high-altitude operations, so as to avoid operating procedures and high-altitude operations, good quality and good construction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

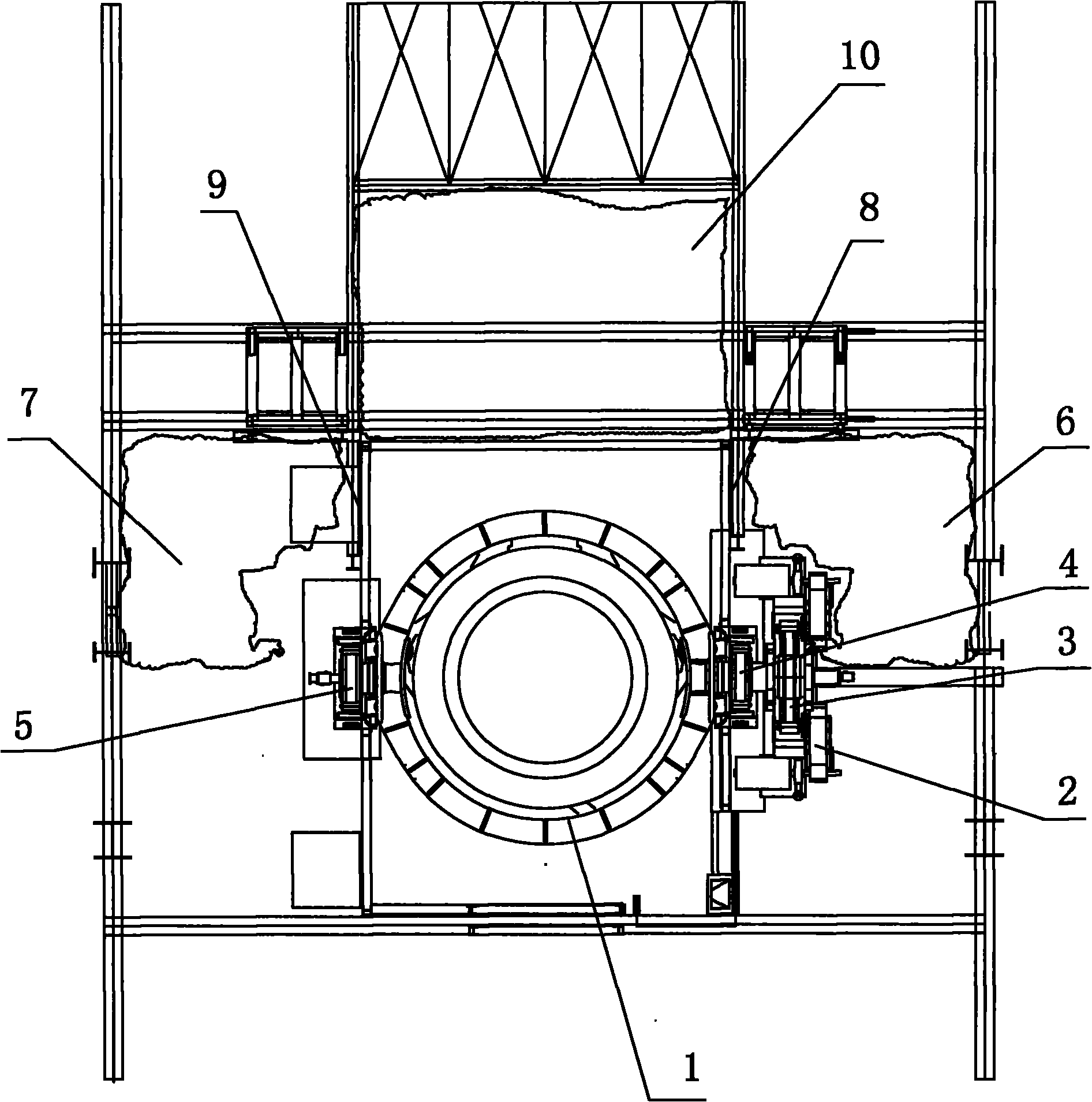

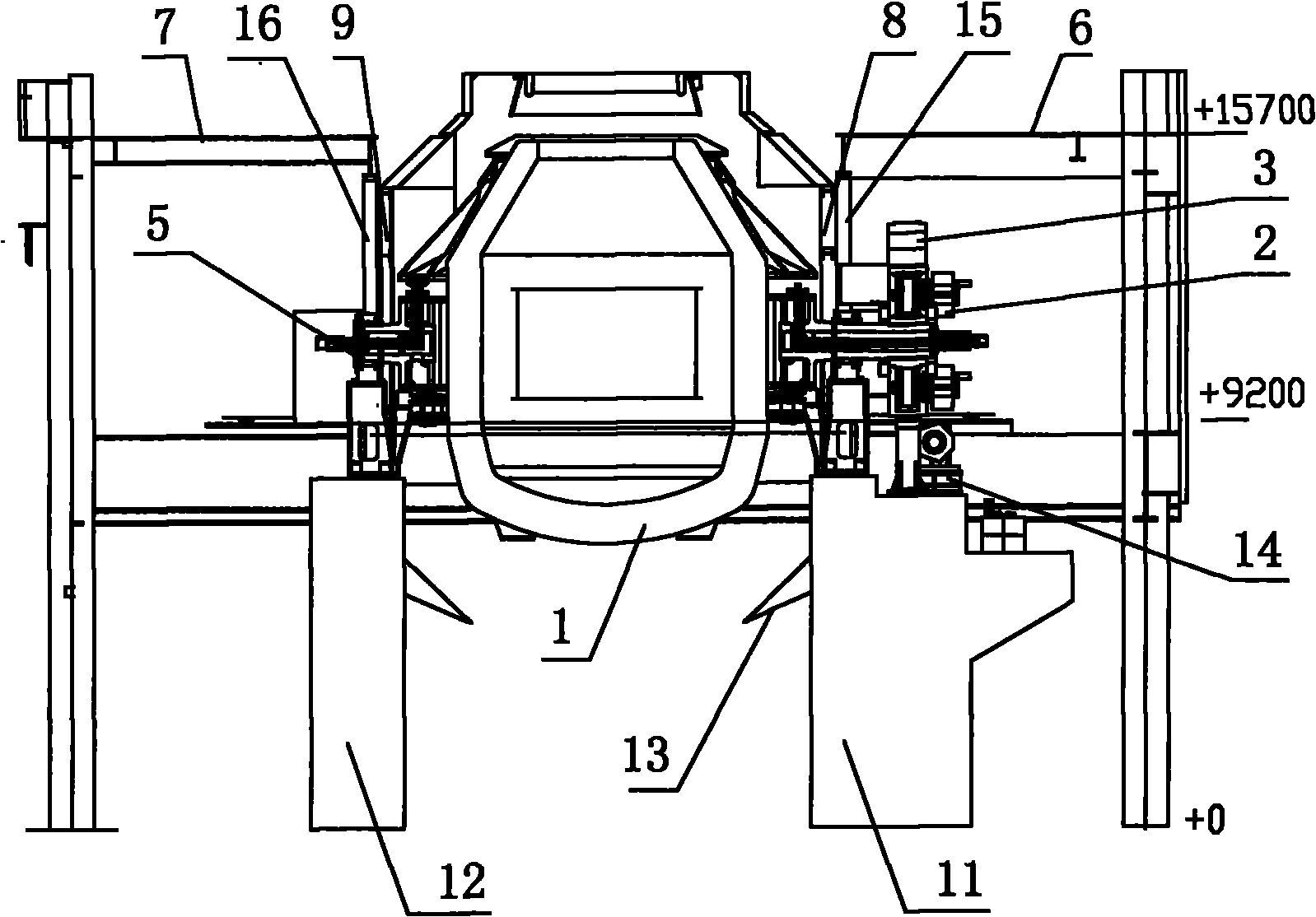

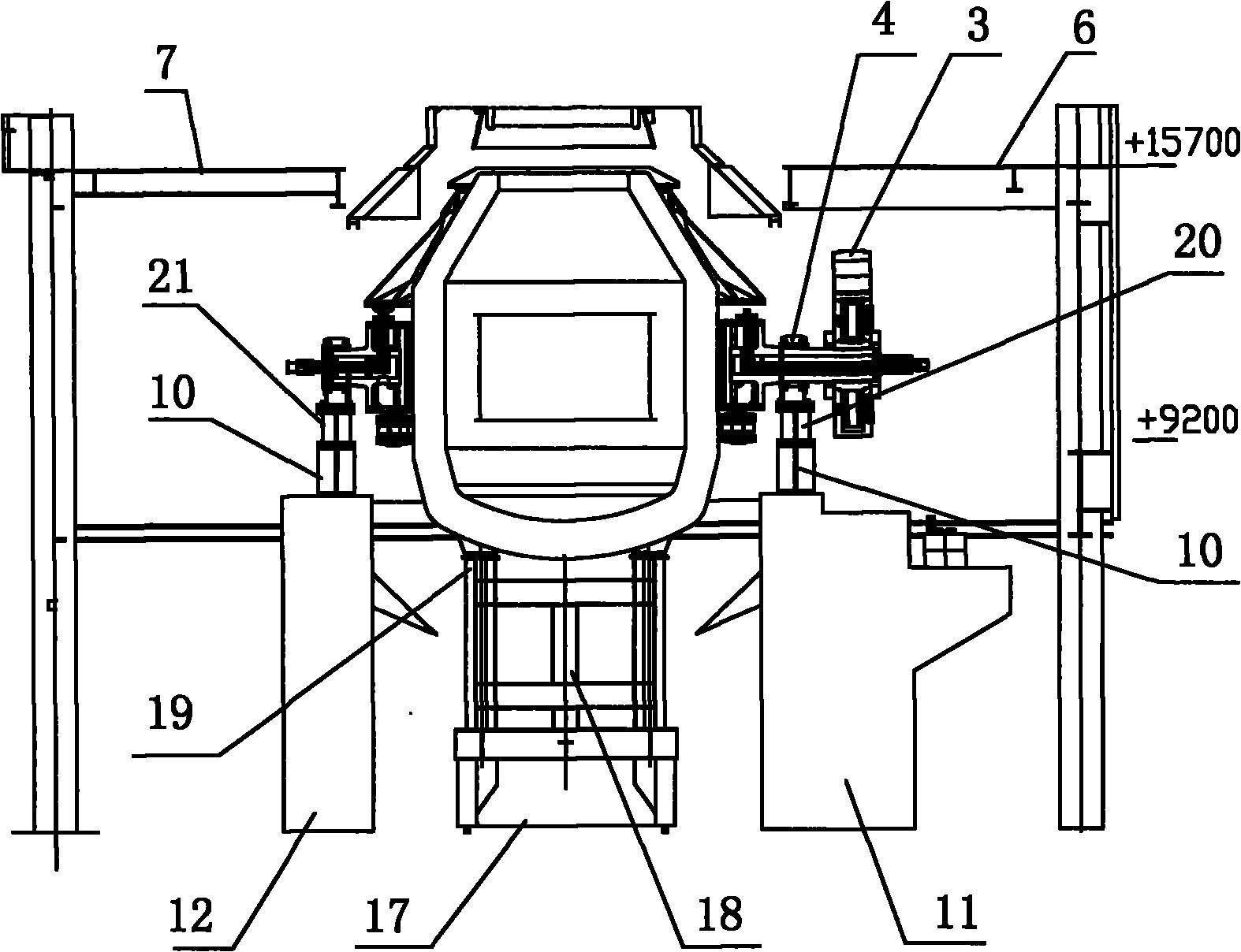

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the method for replacing the converter includes the following steps:

[0024] 1) Before the old converter is dismantled, assemble the new converter in the span where the crane used for hoisting after the old converter is dismantled {furnace body, support ring, skirt plate, furnace mouth flange, bearing seat, dumping device (secondary reducer ) etc. for overall assembly}, leaving the primary reducer and torsion bar of the new converter to be installed; these tasks need to be completed in the preparatory stage before the start of maintenance. After the position is completed, the assembly direction should be the same as the installation direction of the new converter, because the direction cannot be rotated when the two cranes are lifted;

[0025] 2) Fix the carrier platform 18 on the ladle car 17, and fix four hydraulic jacks 19 (each 200t) on the carrier platform 18; then run the ladle car 17 to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com