Novel whole moving device of drilling machine

A mobile device and drilling rig technology, which is applied to support devices, drilling equipment, earthwork drilling and production, etc., can solve the problems of inconvenient operation, narrow space, increased cost, etc., and achieve the effect of simple installation, stable movement, quick and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

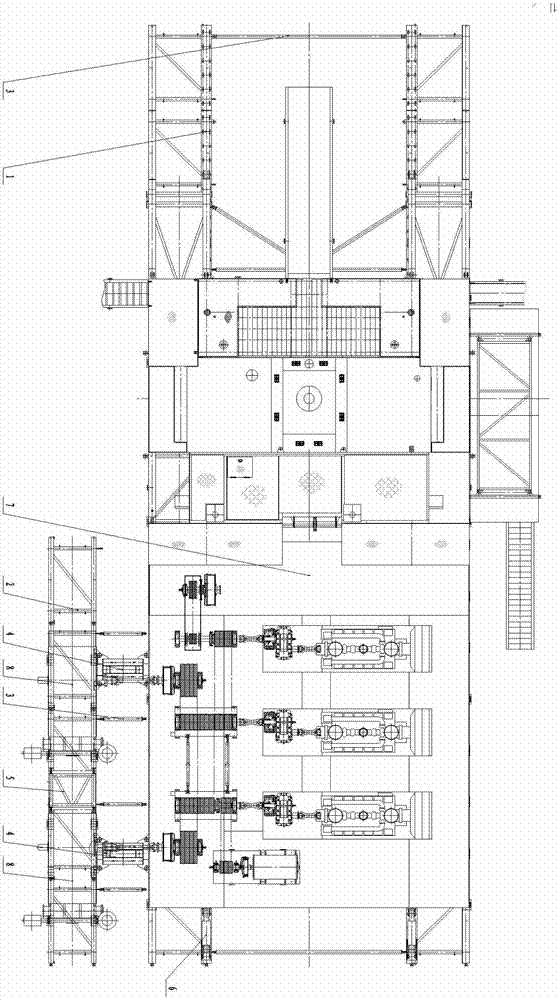

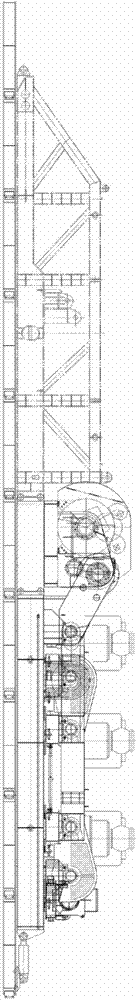

[0015] like figure 1 , 2 Specific embodiments of the invention are given. The new type of drilling rig mobile device is characterized by two rows of main rails 1 installed under the main body of the drilling rig, and connecting struts 3 are arranged between the two rows of main rails 1; at the same time, it also has a row of auxiliary rails installed under the two mud pumps 2. There is also a connecting strut 3 between a row of auxiliary rails 2 and two rows of main rails 1; at the same time, there is a rigid connecting frame 4 arranged on the main body of the drilling rig and connected to two mud pumps. A connecting frame 5 is arranged between them, and two oil cylinders 6 are located at the end of the main rail 1 to push the main body 7 of the drilling rig. The rigid connection frame 4 between the mud pump and the main body of the drilling rig is in the form of a pin shaft ear plate. The drilling rig transmission device of the present invention uses three diesel engines a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com