Rotating disc type vacuum perforating apparatus

A punching device and turntable technology, applied in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve problems such as laborious, low processing efficiency, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

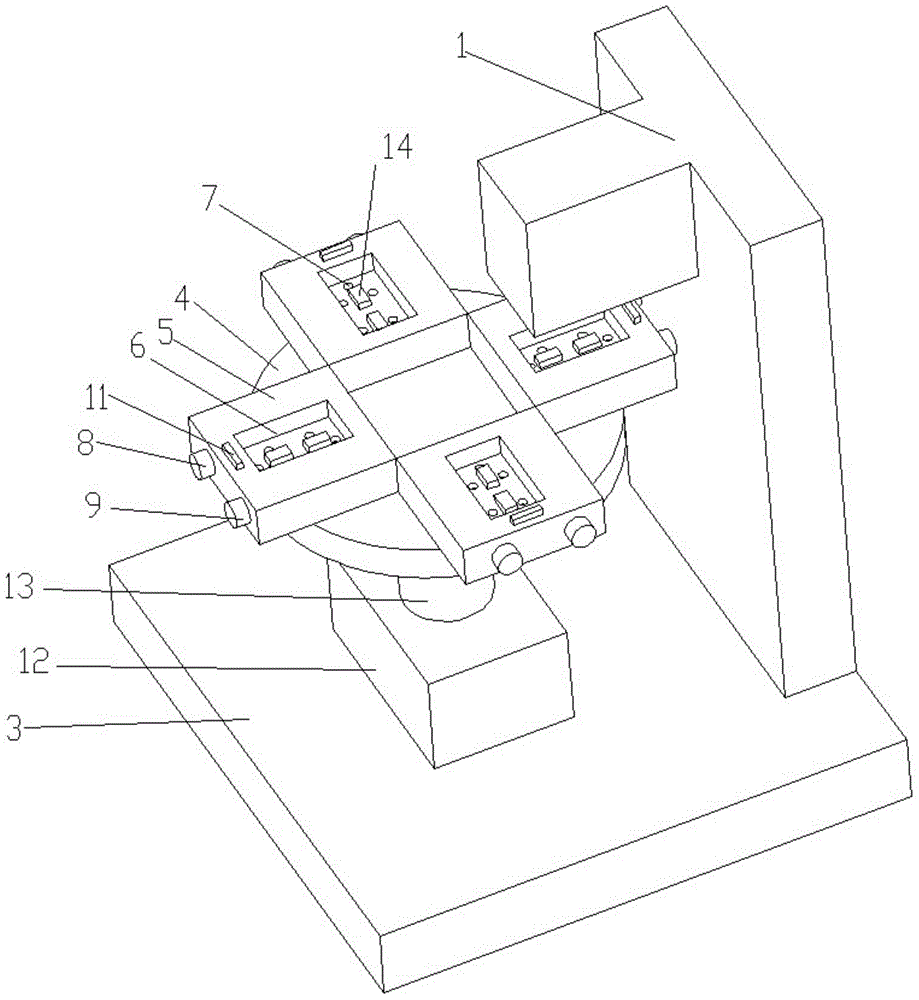

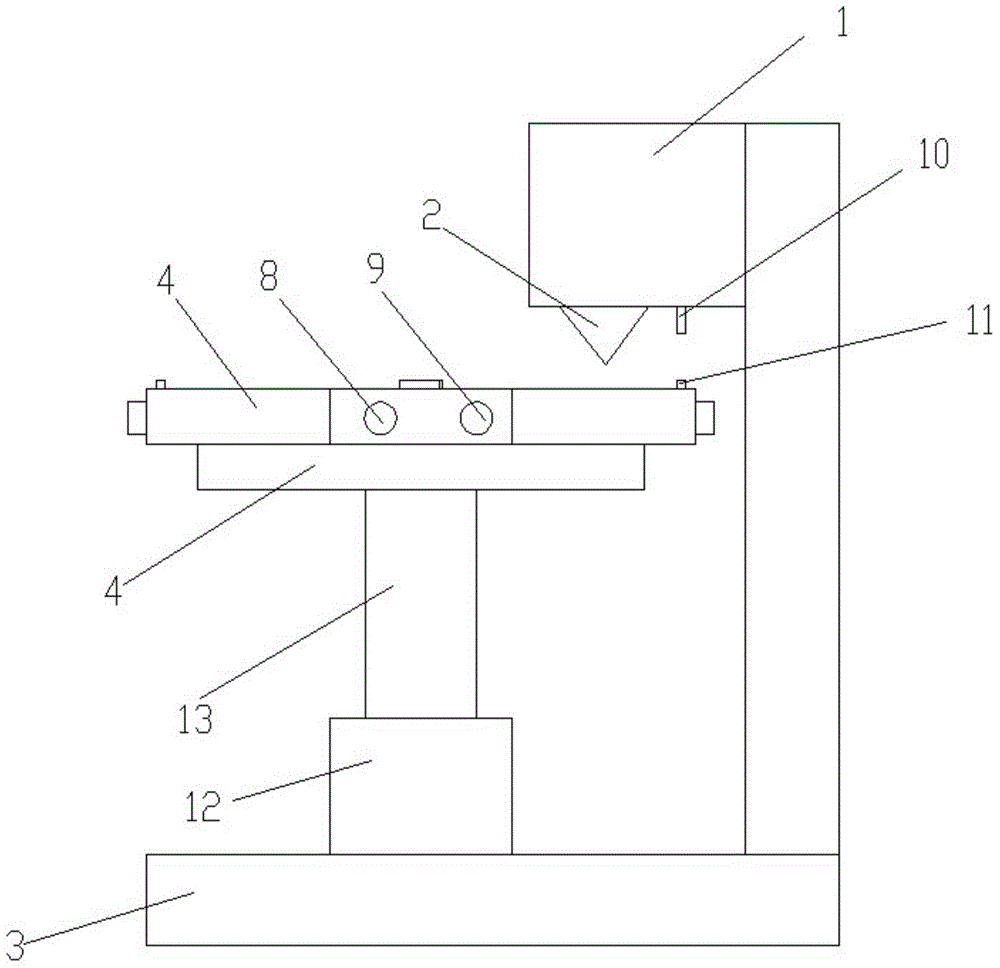

[0017] Embodiment: a rotary table type vacuum punching device, comprising a punching machine body 1, a punching drill bit 2 is installed on the punching machine body, a workbench 3 is arranged on the punching machine body, and a punching machine body is also included. Turntable 4 and several hollow positioning blocks 5, the rotating disk is positioned above the workbench, the positioning block is fixed on the rotating disk, a positioning groove 6 is provided in the middle of the positioning block, and in the positioning groove A plurality of small holes 7 are provided, and the side wall of the positioning groove is provided with an air extraction port 8 and an air charging port 9, and an infrared emitter 10 is fixed on the position of the drilling machine body near the drill bit, and on the positioning block An infrared sensor 11 is fixed, and the infrared sensor is located below the infrared emitter. The parts that need to be punched can be placed through the positioning groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com