Novel fish meal dryer

A drying machine and fishmeal technology, applied in the direction of drying machine, drying solid materials, drying, etc., can solve the problems of mildew, easy to stink, powder sticking, etc., and achieve the effect of increasing the drying speed and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now do further detailed explanation in conjunction with accompanying drawing.

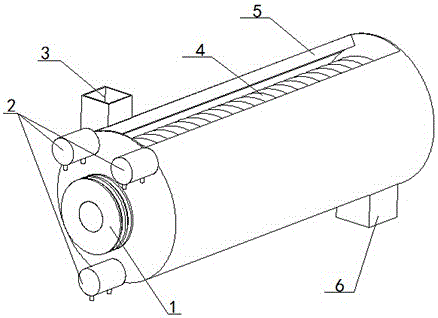

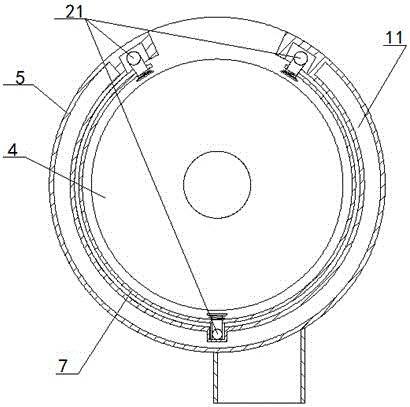

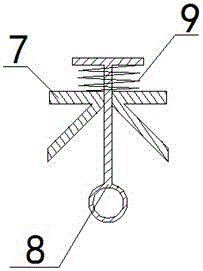

[0025] like figure 1 As shown, the new fish meal dryer includes: pulley 1, hydraulic motor 2, screw rod 21, feed port 3, blade 4, cylinder 5, discharge port 6, scraper knife 7, sleeve rod 8, spring 9 , Trapezoidal blade 10, interlayer 11.

[0026] The working principle of a new type of fishmeal dryer is mainly to put a powdery object with high humidity through the feed port 3, and after drying at high temperature, obtain a powdery object with low humidity from the discharge port 6. The drying principle is as follows: high-temperature and high-pressure steam is introduced into the interlayer 11, the pulley 1 drives the blade 4 to rotate, and the blade 4 and the cylinder 5 form an inclination angle of 5-10 degrees, thereby pushing the fish meal to move forward at a uniform speed on the inner wall of the drying cylinder , so as to achieve the drying effect.

[0027] The principle of removing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com