A device for removing burrs from the metal braiding layer of cables

A technology of metal braiding layer and cleaning device, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of leakage of conductive layer, high labor intensity, heavy workload, etc., to prevent shrinkage and wrinkle, and reduce labor Strength, Ease of Use and Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

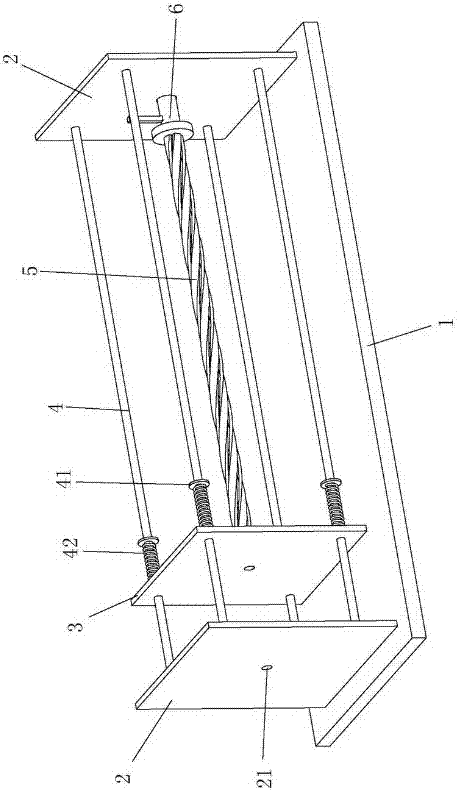

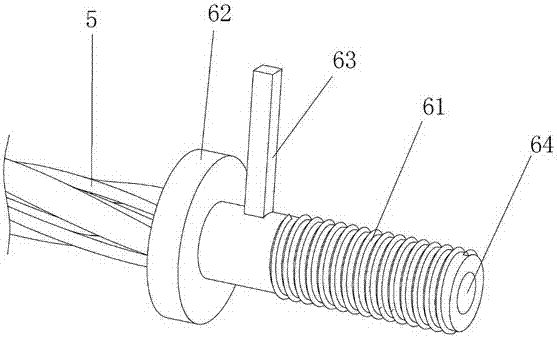

[0021] Embodiment 1: as Figure 1 to Figure 3 As shown, a cable metal braid deburring device includes a base 1, a clearing assembly 5 and a tensioning plate arranged at both ends of the clearing assembly 5 to tension it, and the tensioning plate includes two fixed plates 2 arranged at intervals and The movable plate 3 arranged between the fixed plates 2, the fixed plate 2 is fixedly connected on the base 1, a guide rod 4 connecting the fixed plates 2 is arranged between the two fixed plates 2, and the movable plate 3 is sleeved on the guide on pole 4. One end of the clearing assembly 5 is connected to one of the fixed plates 2, the other end is connected to the movable plate 3, and the guide rod 4 is provided with a tensioning assembly, including a baffle plate 41 fixed on the guide rod 4 and a sleeve guide. The elastic piece 42 on the bar 4 is a spring, which is arranged between the movable plate 3 and the baffle plate 41, and one end thereof is in contact with the movable p...

Embodiment 2

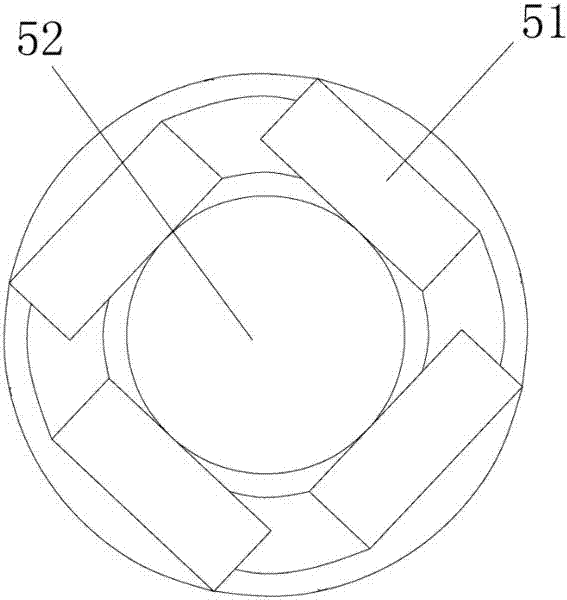

[0023] Embodiment 2: as Figure 4 As shown, the difference from the above embodiment is that the cleaning assembly 5 is composed of eight friction strips 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com