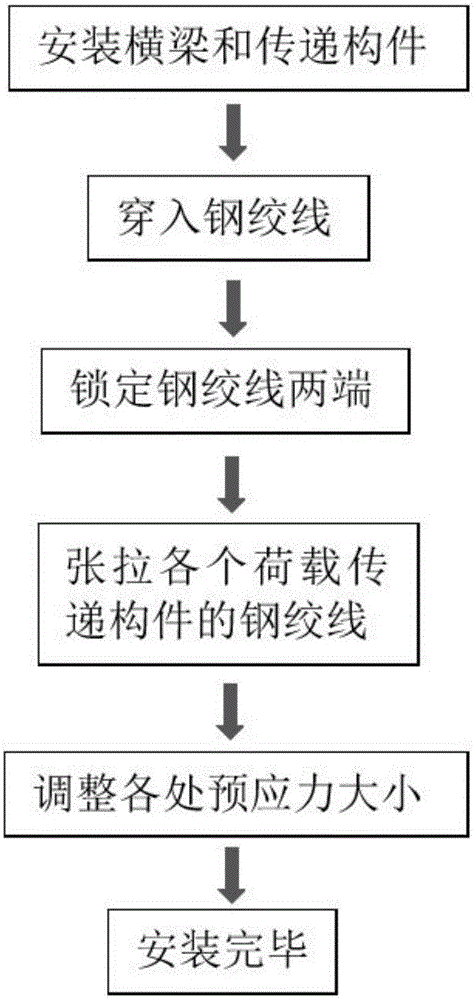

Novel detachable foundation pit bracing system and construction mounting method thereof

A foundation pit support, a new type of technology, applied in the direction of basic structure engineering, excavation, construction, etc., can solve the problems of construction difficulties, increased costs, and reduced support effects, etc., to save steel and joints, high site adaptability, Avoid the effect of foundation pit instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

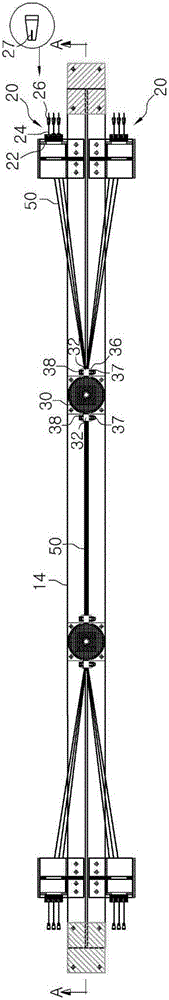

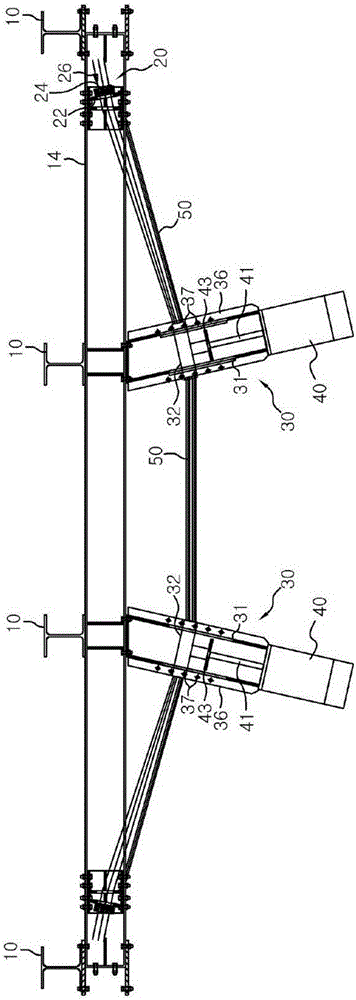

[0031] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0032] Such as figure 2 , image 3 As shown, the present invention provides a novel detachable foundation pit support system and its construction and installation method. line 50, the crossbeam 14 is installed on a plurality of H-shaped steel piles 10, and the H-shaped steel piles 10 are the supporting structure of the foundation pit. , the two ends of the crossbeam 14 are provided with steel strand locking devices 20, the crossbeam is fixed with an intermediate load transfer member 30, the steel strand 50 passes through the tunnel provided on the intermediate load transfer member 30, and the steel strand 50 The two ends are respectively fixed on the locking device 20 at the two ends of the crossbeam 14. A pressure sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com