Automatic horizontally-moving conveyer for aluminum profile packaging

A technology for packaging and aluminum profiles, applied to conveyors, transportation and packaging, etc., can solve the problems of automatic adjustment of the tension of the conveyor belt, and achieve the effects of flexible use, avoiding slipping, and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

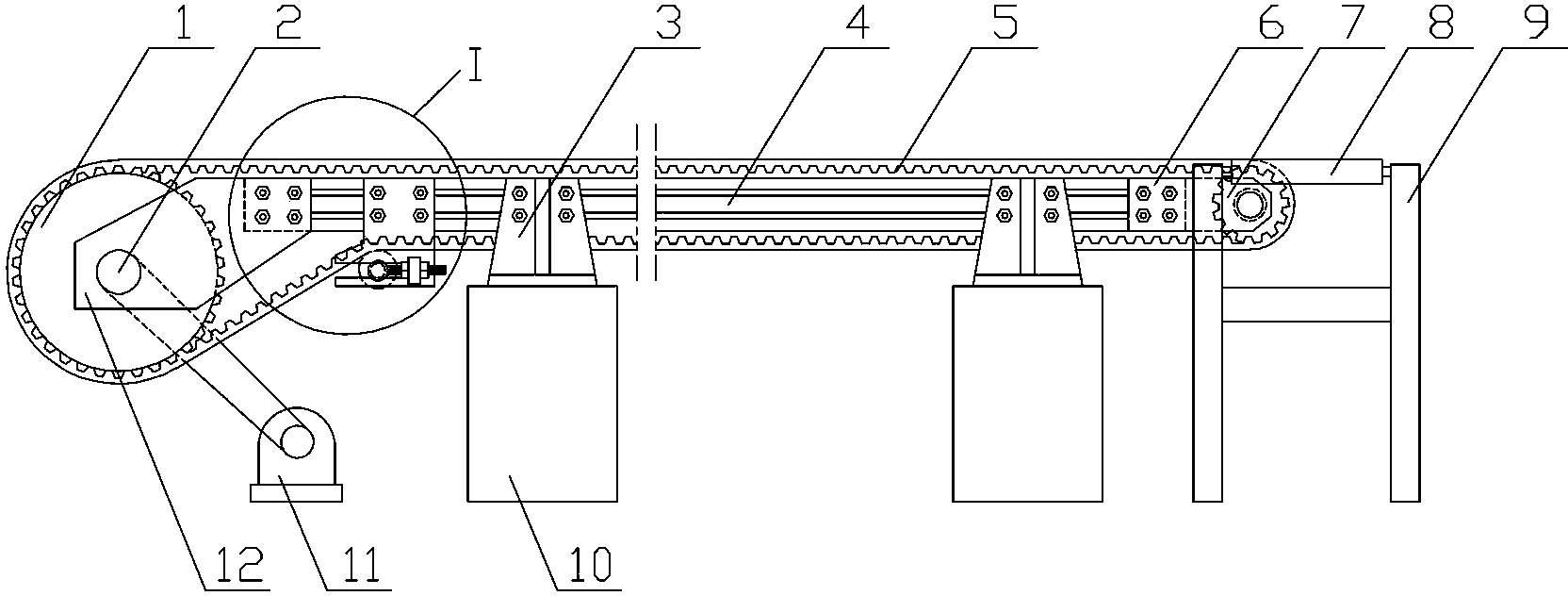

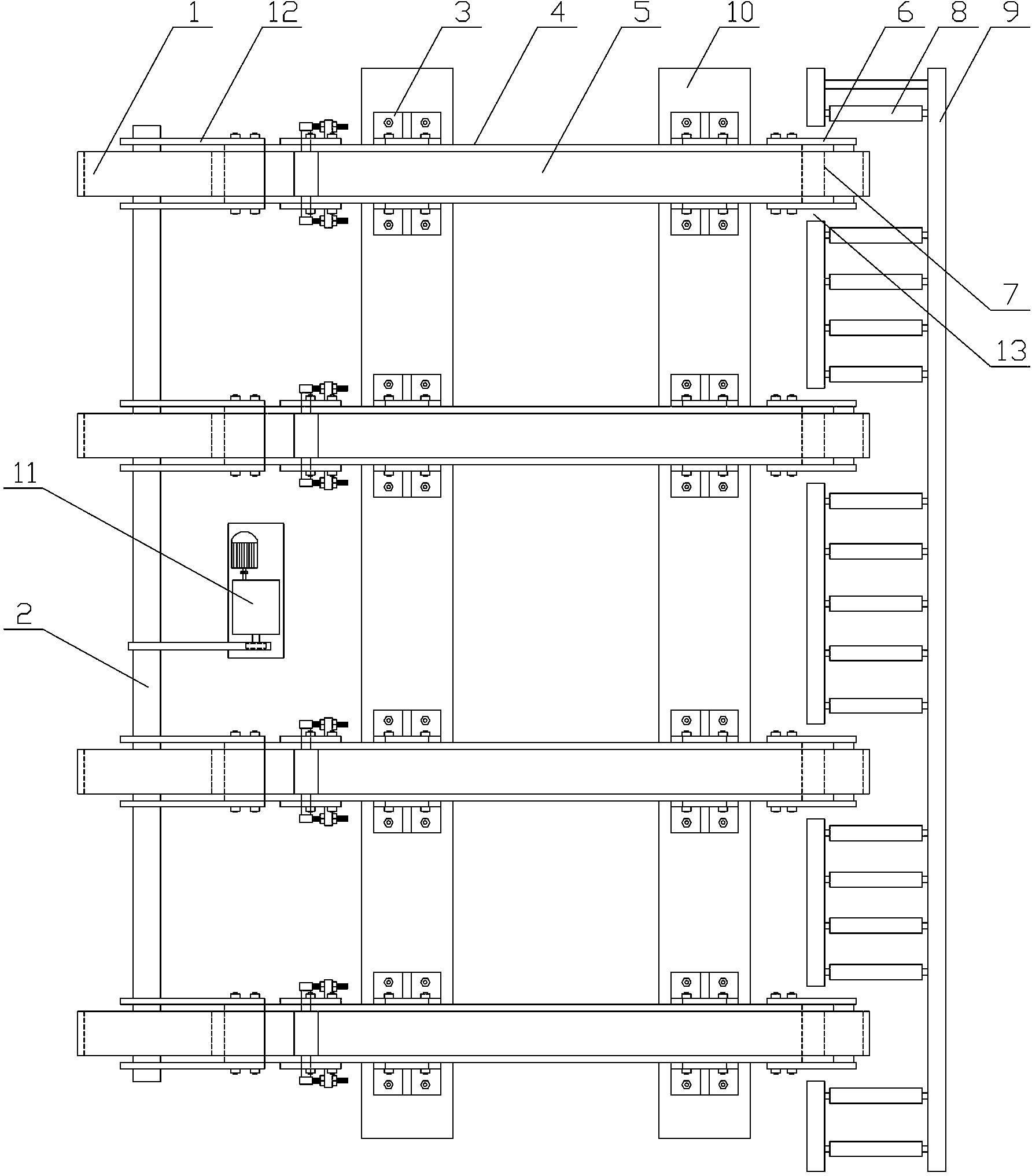

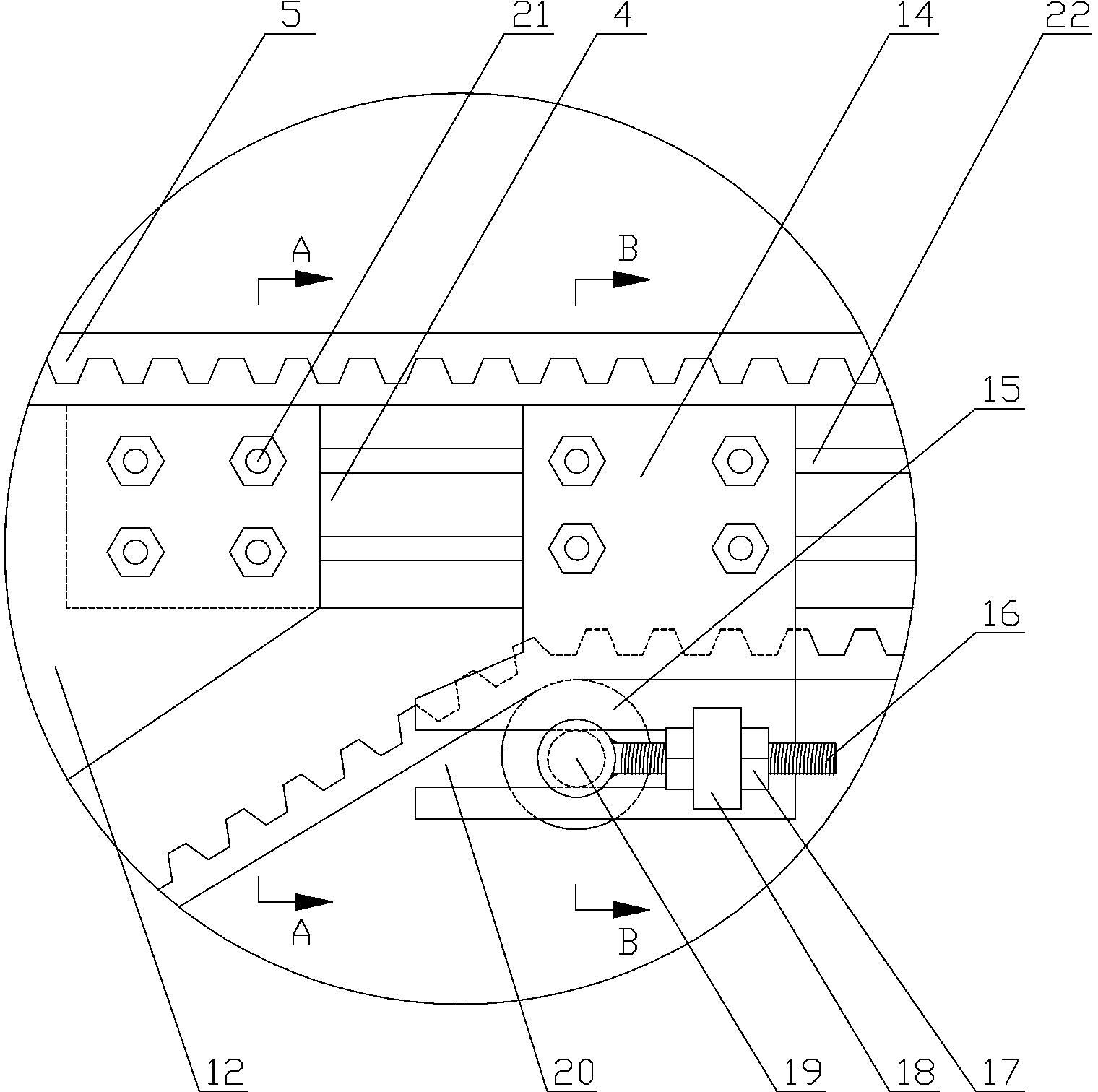

[0016] See figure 1 , figure 2 with Figure 4 The present invention has a frame 10, the top of the frame 10 is equipped with four conveyor belt devices arranged symmetrically forward and backward, the conveyor belt device has a support beam 4 installed on the top of the frame 10, the left and right ends of the support beam 4 are respectively installed A conveyor belt 5 is connected between the driving wheel 1 and the driven wheel 7, and the driving wheel 1 and the driven wheel 7 are connected. The driving wheels 1 of each conveyor belt device are connected together by an input shaft 2 which is connected to an external power device 11. On the right side of the driven wheel 7 is also arranged a supporting frame 9, and sixteen supporting rollers 8 are mounted on the supporting frame 9. The diameter of the driving wheel 1 is larger than the diameter of the driven wheel 7 and the tops of the driving wheel 1 and the driven wheel 7 are located on the same horizontal plane. See imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com