Continuous automatic energy-saving and efficient agricultural product drying device

A drying device and technology for agricultural and sideline products, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of low drying efficiency, recycling of drying trays, and low space utilization, and improve the circulation flow efficiency , Improve drying efficiency, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

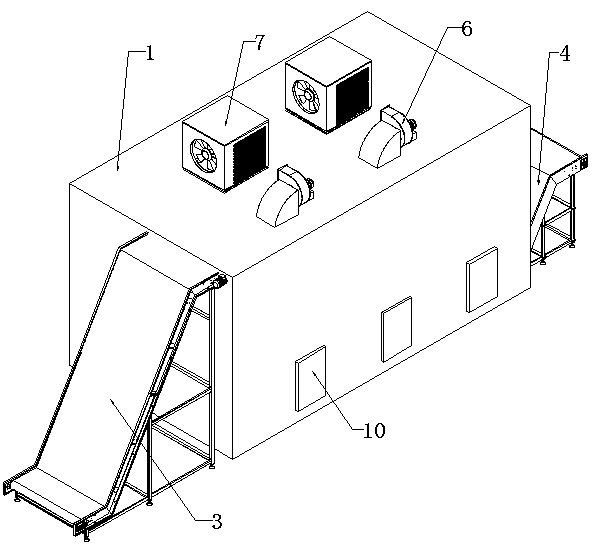

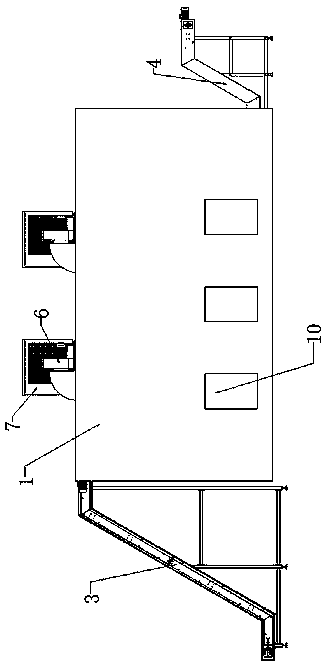

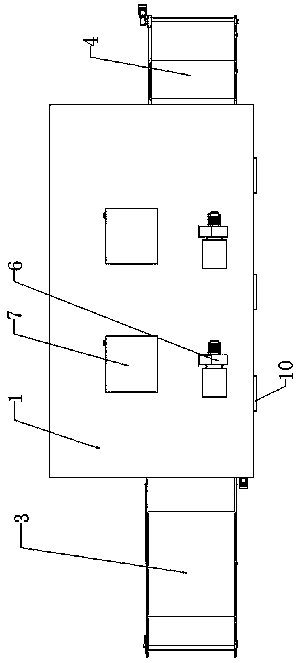

[0028] as attached Figure 1-9 As shown, a continuous automatic energy-saving and high-efficiency agricultural and sideline product drying device includes a box body 1, a skeleton 2, a feeder 3, a discharger 4, a transmission device 5, a dehumidification centrifugal fan 6, a heat pump 7, and a surface cooler 8 and an axial flow fan 9, the box 1 is a hollow cubic structure, the skeleton 2 and the transmission device 5 are installed side by side in the box 1, and the lower part of the skeleton 2 is fixedly installed with a heat pump 7 A surface cooler 8, the upper part of the framework 2 is arranged with an axial flow fan 9, the transmission device 5 is fixedly installed on the front side of the framework 2, and the humidity-discharging centrifugal fan 6 is installed above the box 1 A heat pump 7 with an air inlet corresponding to the air outlet of the dehumidifying centrifugal fan 6 is installed above the box 1, the feeder 3 is installed on the left side of the box 1, and the r...

Embodiment 2

[0047] Using this device to dry 1500Kg of fresh wolfberry, the comparison of time and energy consumption from fresh wolfberry (about 80% water content) to dry wolfberry (water content 10%) is shown in the following table:

[0048]

[0049] Power consumption in this example: heat pump performance coefficient cop is 3.5, and the power consumption of a drying cycle is converted according to 0.33Kg (standard coal) / (kW h), which is equivalent to standard coal: M 1 =27.06×10 5 ÷(3.5×3600)×0.33=70.9Kg (standard coal)

[0050] Existing coal-fired drying energy consumption: the existing coal-fired combustion efficiency is 80%, and the calorific value of 1Kg standard coal is 29306KJ, then the standard coal consumption in one drying cycle is: M 2 =27.06×10 5 ÷(29306×80%)=102.6Kg (standard coal)

[0051] The entire drying time of the existing equipment is 24 hours of drying + 3 hours of manual loading, giving a total of about 27 hours.

[0052] Compared with the existing coal-fired...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com