Experimental device for closed dynamic cyclic salt fog corroding compressor blades

A dynamic cycle, salt spray corrosion technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of not meeting the test requirements of compressor blades, increasing the complexity of equipment and construction costs, and the inability to reflect external conditions. problems such as actual working conditions, to achieve the effect of reducing the interference of temperature changes, reducing the amount of salt spray, and the device is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further describe the present invention below in conjunction with accompanying drawing:

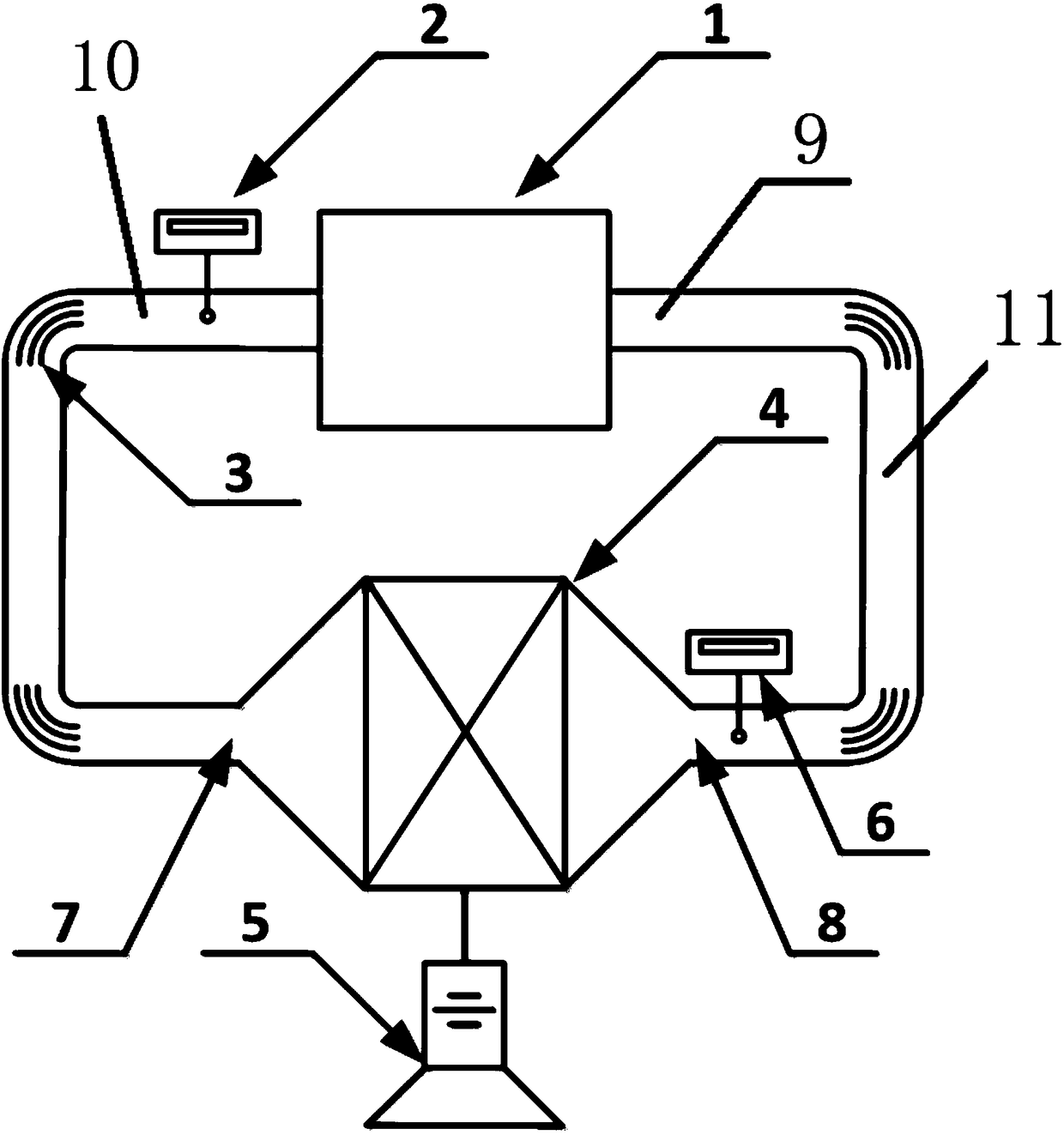

[0017] Such as figure 1 , a closed dynamic cycle salt spray corrosion compressor blade test device: including a salt spray generator 1, a salt spray generator outlet flow meter 2, an arc-shaped guide plate 3, a compressor 4, a compressor motor 5, a compressor Exit multi-probe pressure flowmeter 6, compressor inlet 7, compressor outlet 8, salt mist generator inlet 9, salt mist generator outlet 10, pipeline 11; salt mist generator 1 salt mist generator The outlet 10 is connected to the compressor air inlet 7 of the compressor 4 through the pipeline 11, the salt mist generator inlet 9 of the salt mist generator 1 is connected to the compressor gas outlet 8 of the compressor 4 through the pipeline 11, and the pipeline 11 It is a rectangle, the salt mist generator 1 and the compressor 4 are located on the two sides of the rectangle, the outlet flowmeter 2 of the salt mist generator is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com