Method and device for removing oxide skin of polycrystalline silicon reduction furnace bell jar through laser

A technology of polysilicon and oxide skin, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficulty in handling and transportation, manpower, large volume of electrochemical equipment, increased labor costs, etc., and achieve fast removal speed, Excellent mobility and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

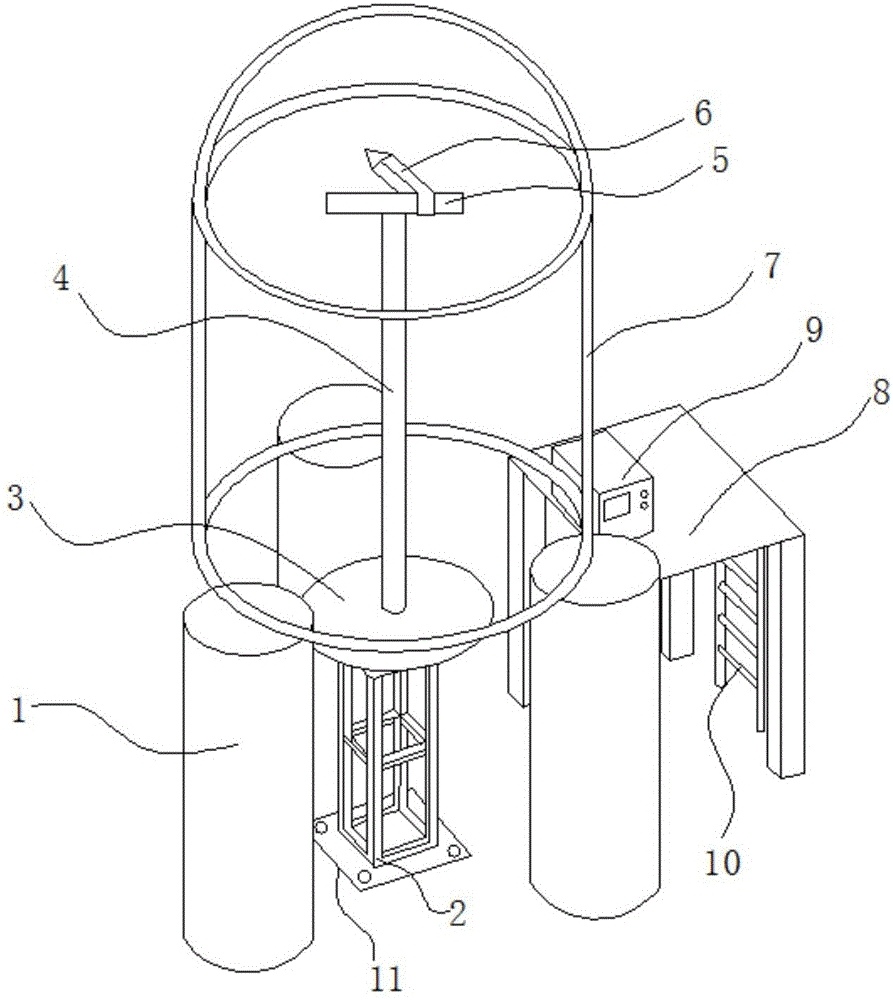

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0029] Example. A method for laser removing bell jar oxide skin of a polysilicon reduction furnace, comprising the following steps:

[0030] S1. Hoist the bell jar of the polysilicon reduction furnace and place it on the support column;

[0031] S2. Start the laser generator, rotate the working disk to drive the Z-axis slide rail to rotate, and the X-axis slide rail slides from bottom to top on the Z-axis slide rail, through the Z-axis slide rail, X-axis slide rail and rotation The working disk automatically scans the polysilicon reduction furnace bell jar from bottom to top;

[0032] S3. Use the laser emitting head to irradiate the inner wall of the polysilicon reduction furnace bell jar with laser light, quickly and conveniently remove the oxide skin attached to the inner wall of the polysilicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com