Patents

Literature

104results about How to "Clear fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

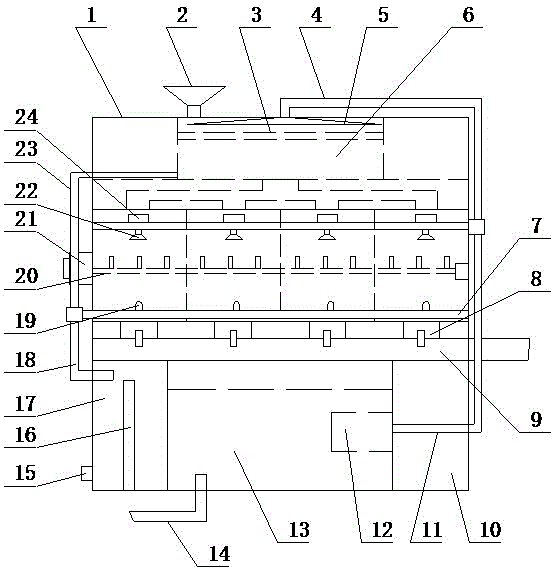

Wall surface old ceramic tile dismantling machine

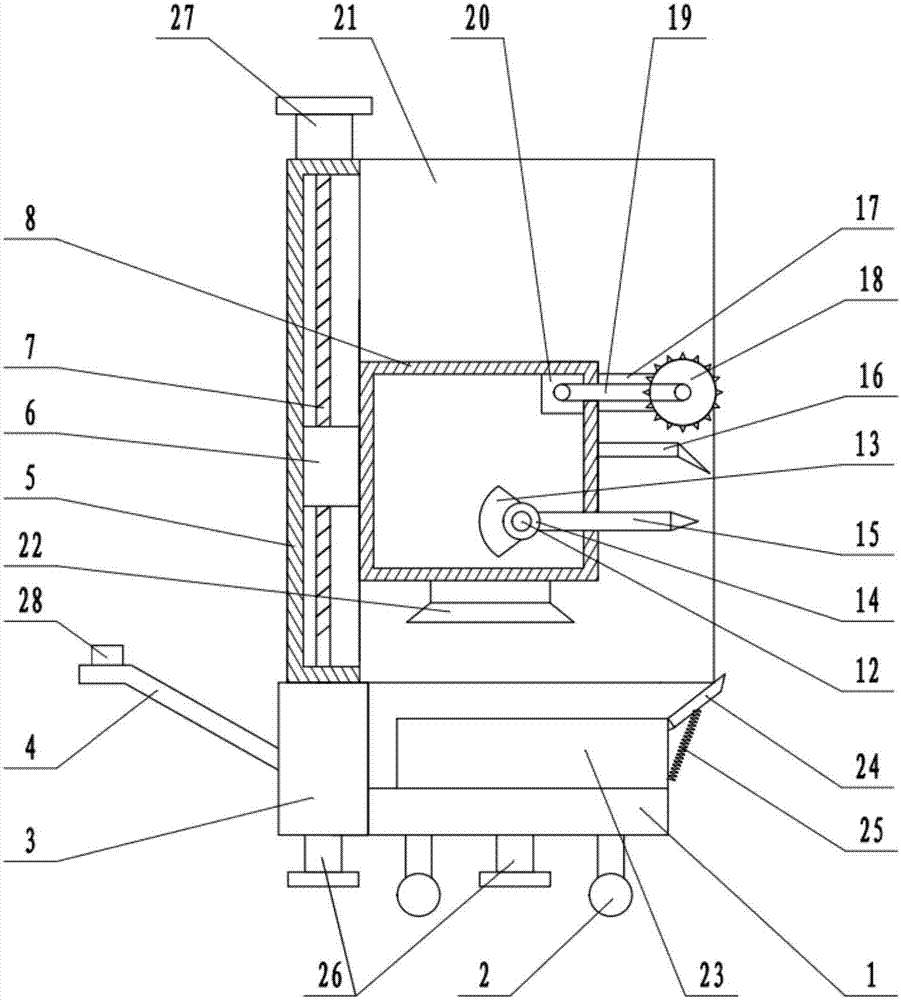

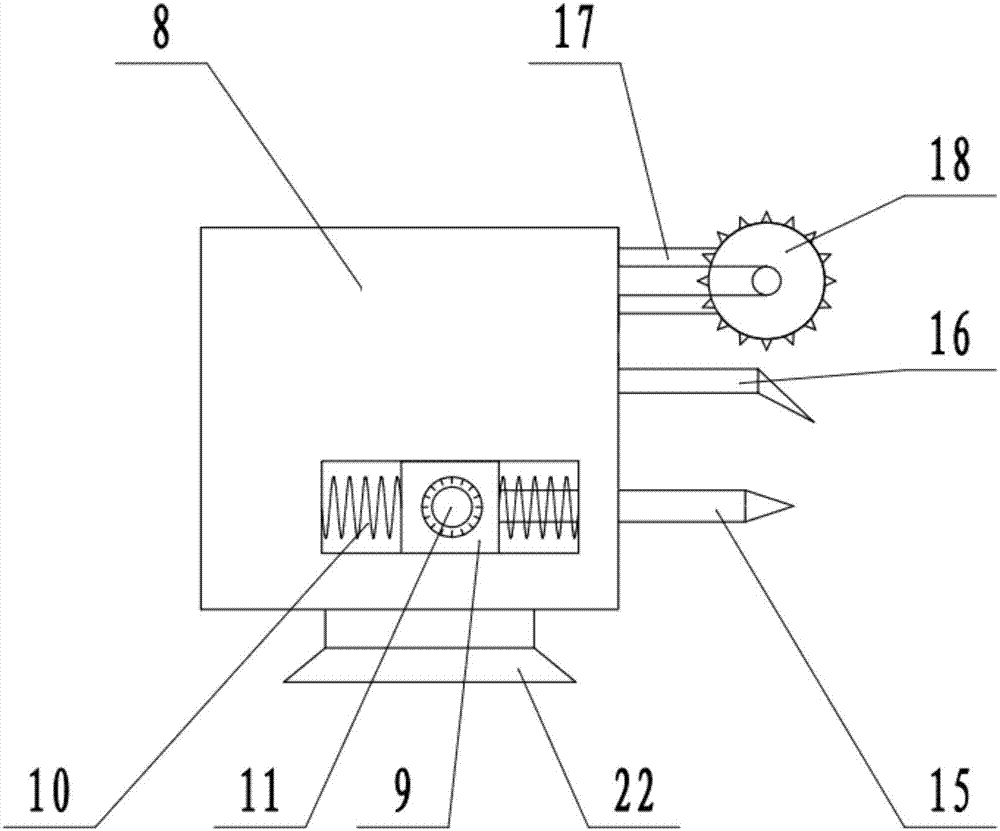

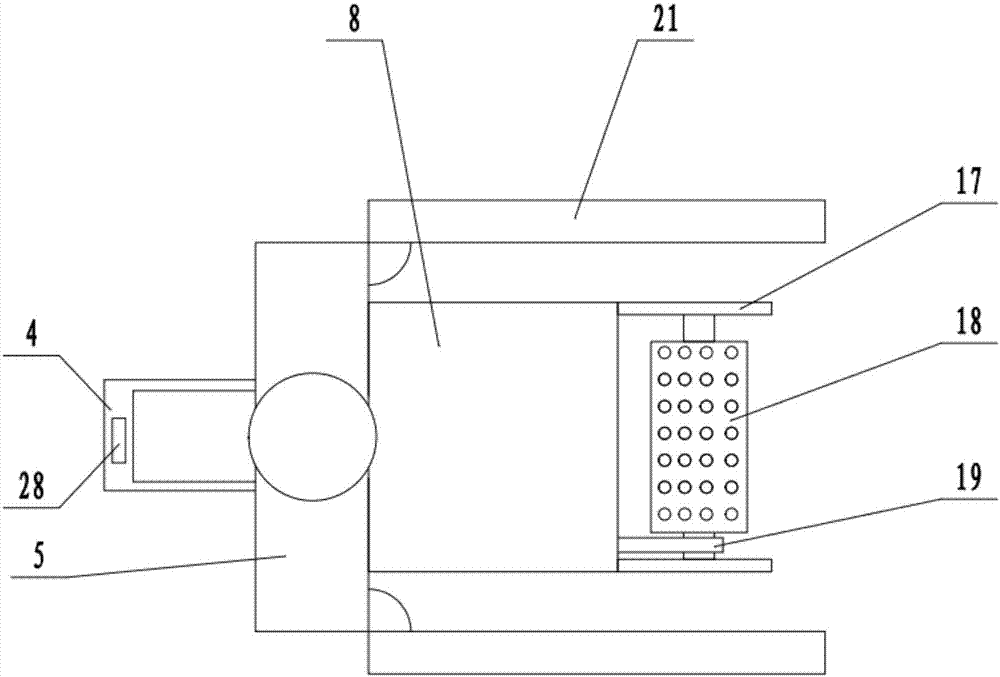

The invention discloses a machine for removing old wall tiles, which comprises a base, a universal wheel, a lifting motor, a push rod, a vibrating motor, a crushing knife and a collecting box; the left end of the base is fixedly connected with a lifting motor, and the top of the lifting motor is fixedly connected There is a support plate, the right side wall of the support plate is provided with a slide rail, the slide rail is slidingly connected with a slider, the right side wall of the slider is fixedly connected with a moving box, and the two symmetrical side walls of the moving box are provided with a chute. A vibrating block is slidably connected in the chute, and a vibrating motor is fixedly connected to the vibrating block. The shaft extension end of the vibrating motor is fixedly connected to a rotating shaft. A collection box is installed on the upper surface, the top of the collection box is hinged with a guide plate, and the lower surface of the guide plate is fixedly connected with a guide spring. Use a broken knife to knock the old tiles on the wall to break and peel off the old tiles, and use a grinding roller to polish the wall. , so that the wall is flat, the work efficiency is high, and the manpower is greatly saved.

Owner:张宇霞

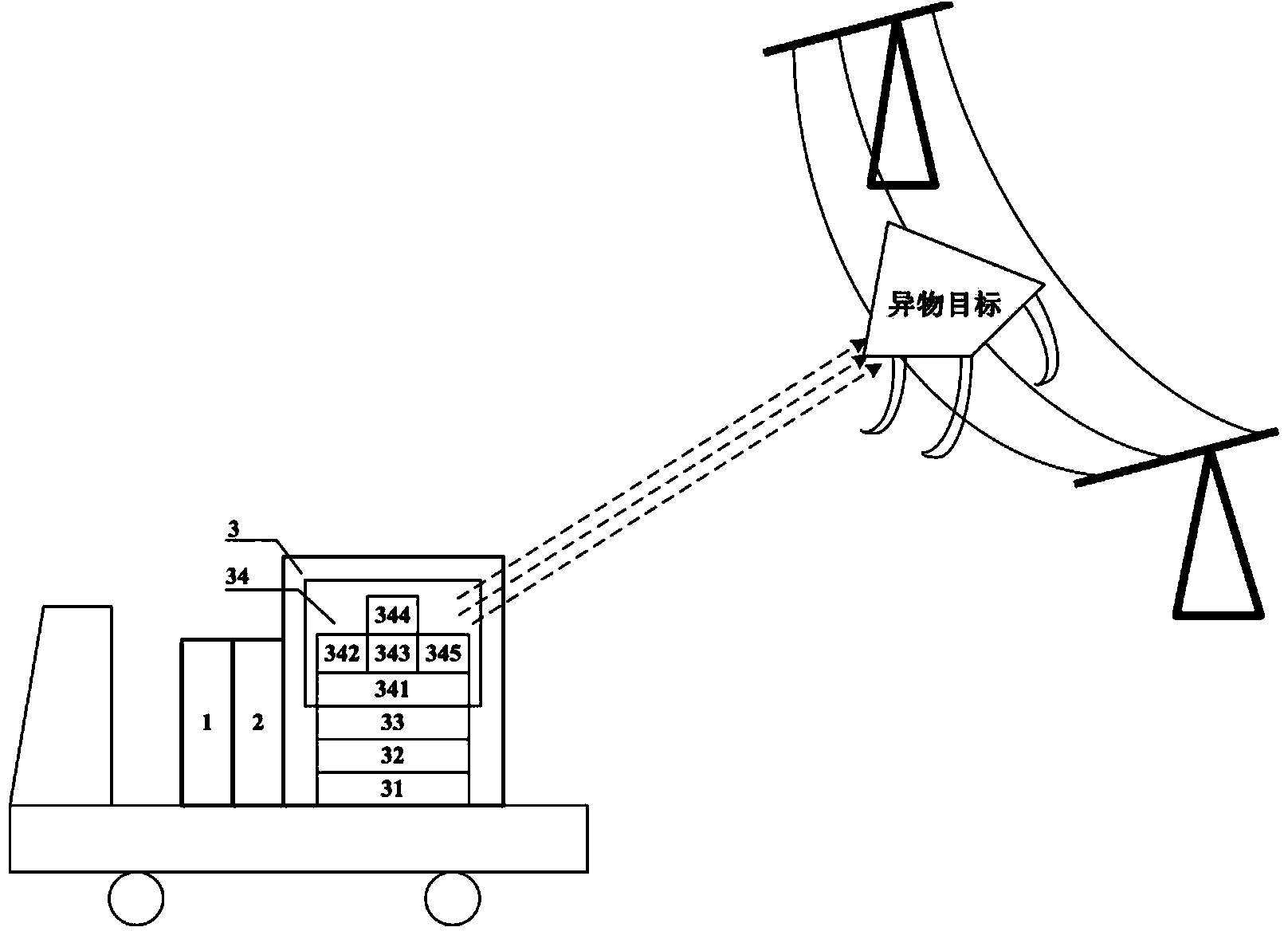

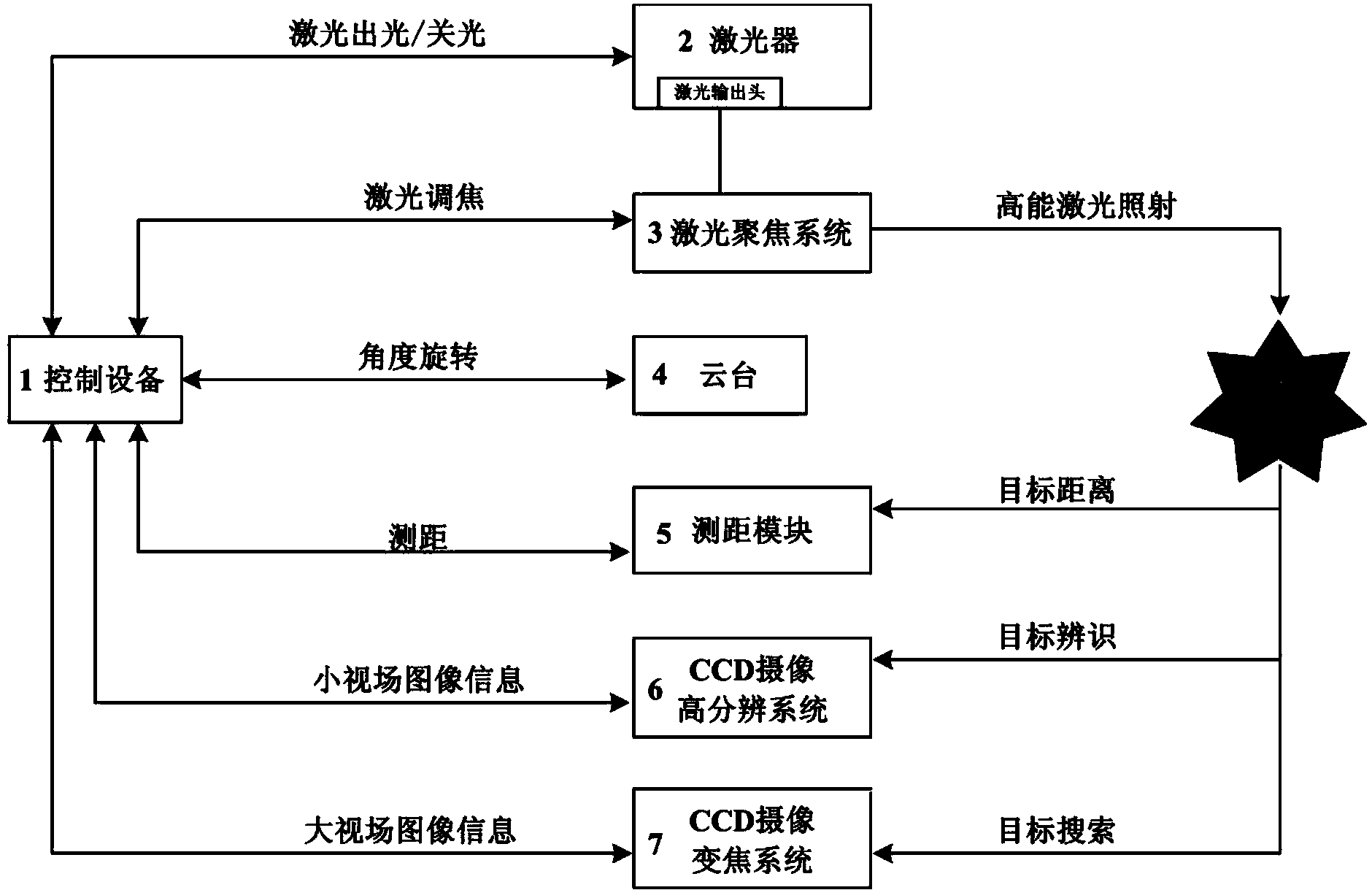

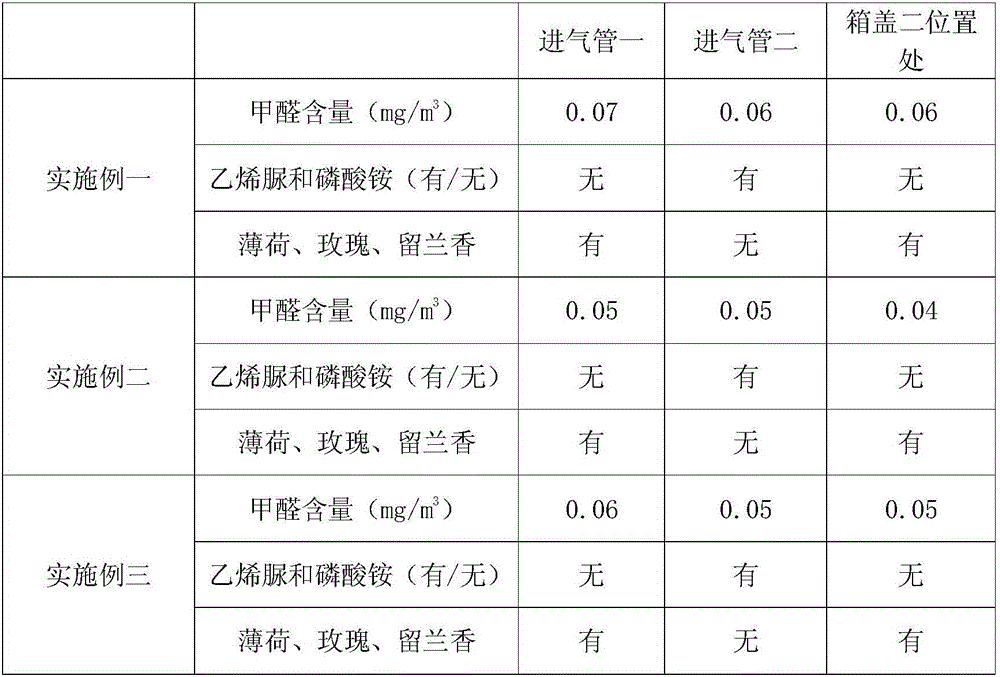

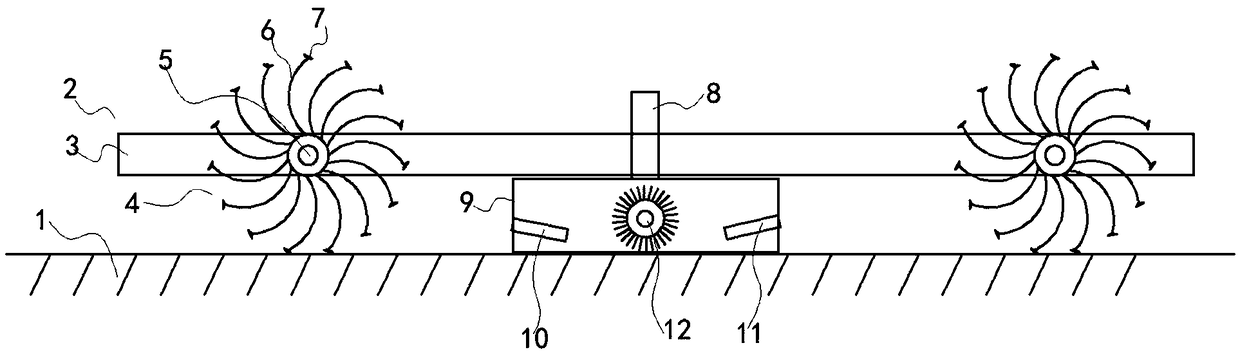

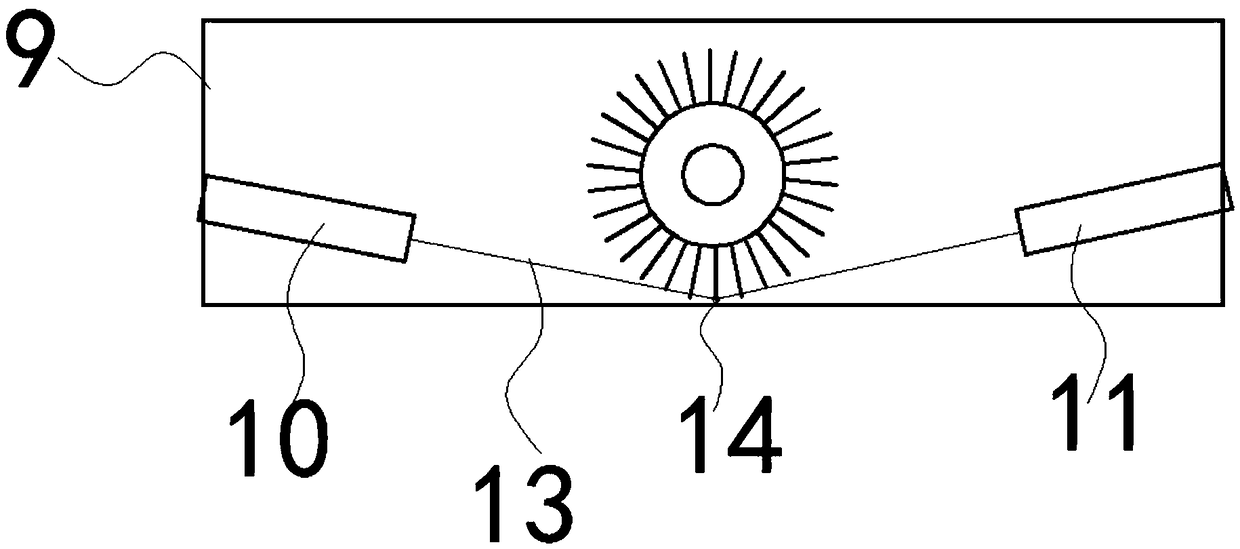

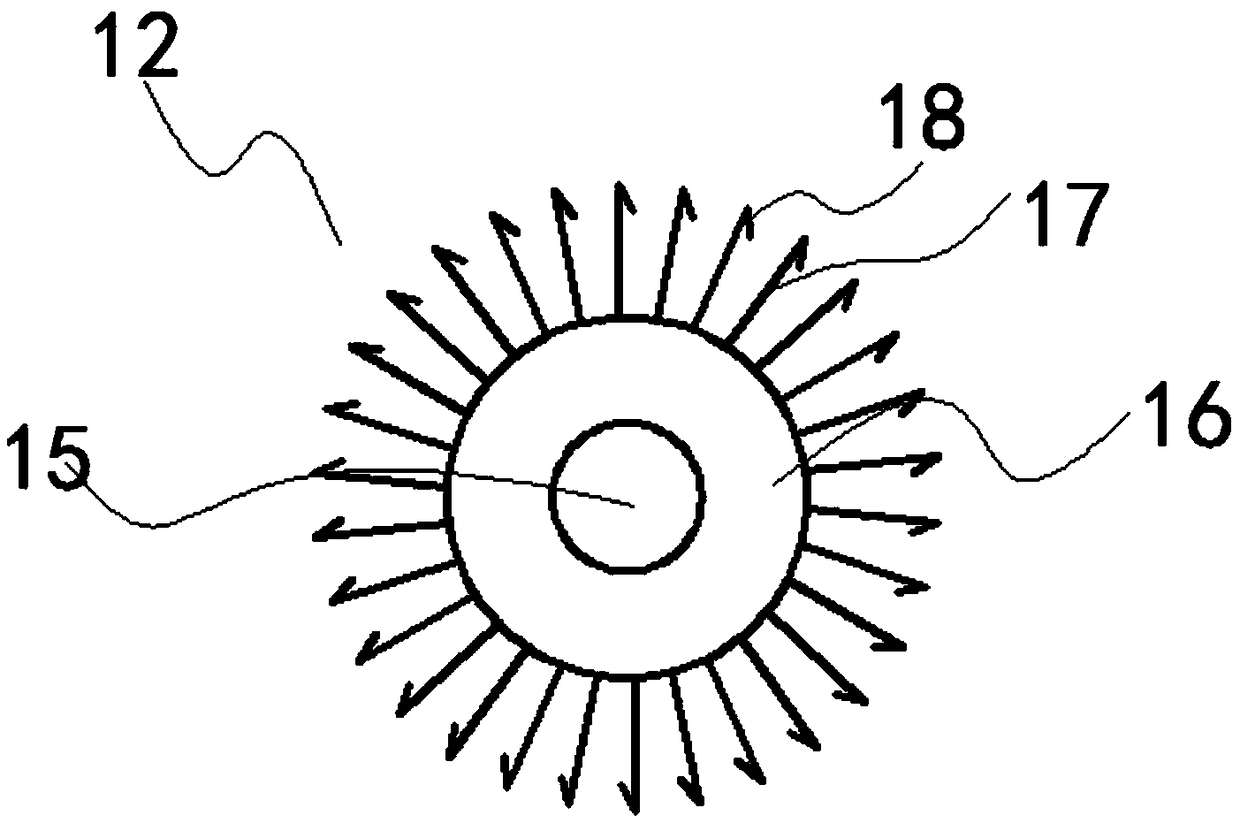

Method and device for removing high voltage transmission line foreign matter by means of laser electrification

InactiveCN104377590ALive clear implementationWork without power outageApparatus for overhead lines/cablesForeign matterLaser light

The invention discloses a method and device for removing high voltage transmission line foreign matter by means of laser electrification. The method and device are used for removing kites, plastic films, balloons, banner advertisements and other foreign matter which threatening high voltage transmission line operation safety. According to the method and device, laser light is used as working media, a pan-tilt is used as a rotating device, foreign matter object searching, recognition and collimation are achieved through image information, laser automatic focusing is achieved through distance information, and electrification removing of foreign matter is achieved by radiating focused high energy laser on the foreign matter object. Remote, non-contact and electrification removing of the foreign matter is achieved, the foreign matter removing speed is high, all the work is completed on the ground, and a worker does not need to carry out hazardous operation such as climbing a telegraph pole and being online and gets away from a high voltage electric field. The device has the image information collection and processing function, can check the foreign matter removing effect in real time, and has the good visualization experience, and laser light can avoid a high voltage transmission line when emitted and will not damage the cable.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

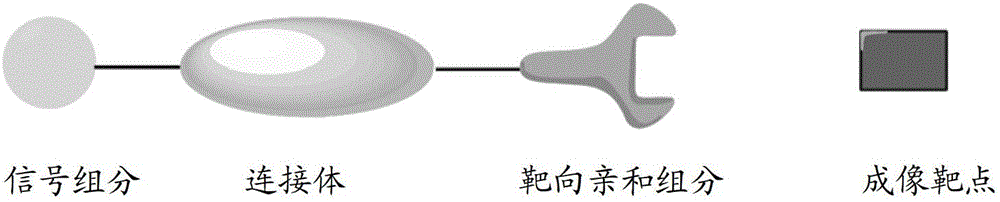

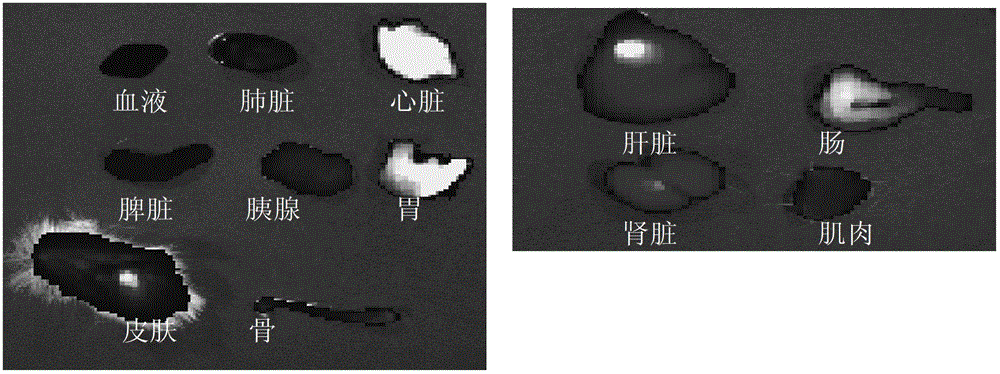

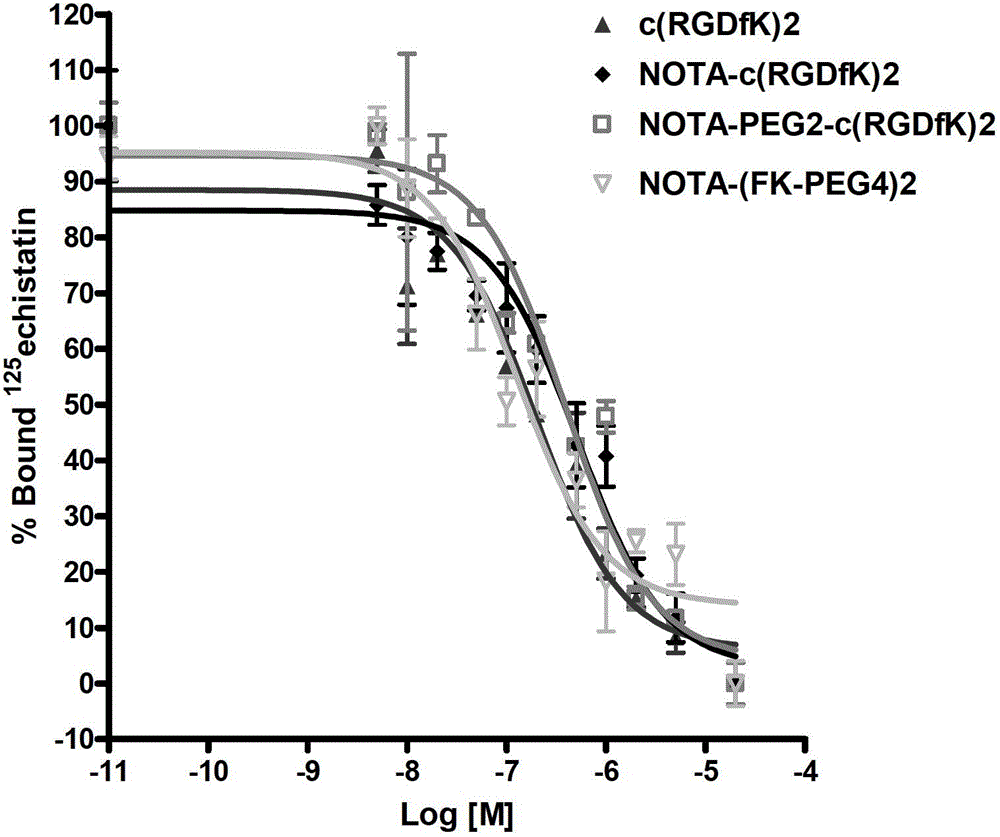

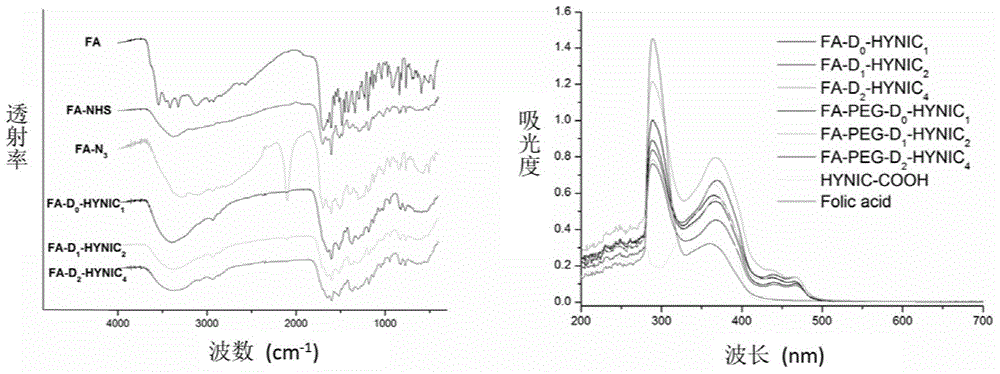

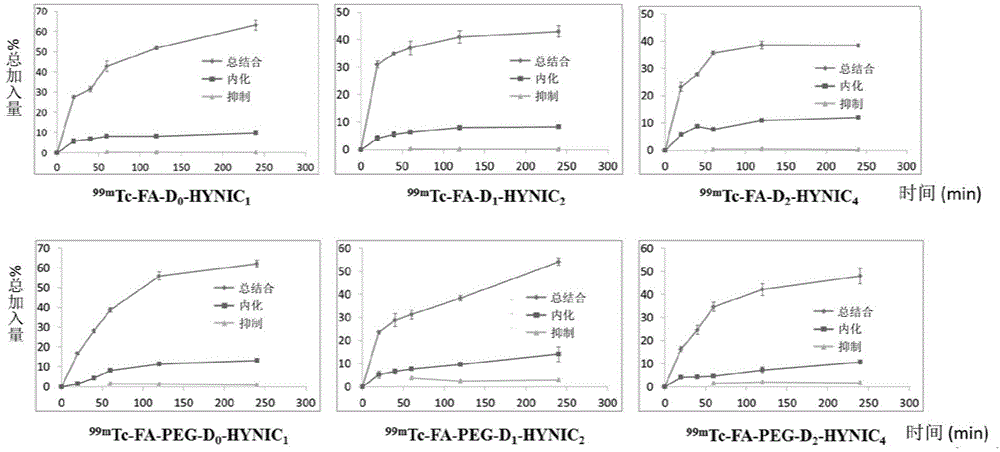

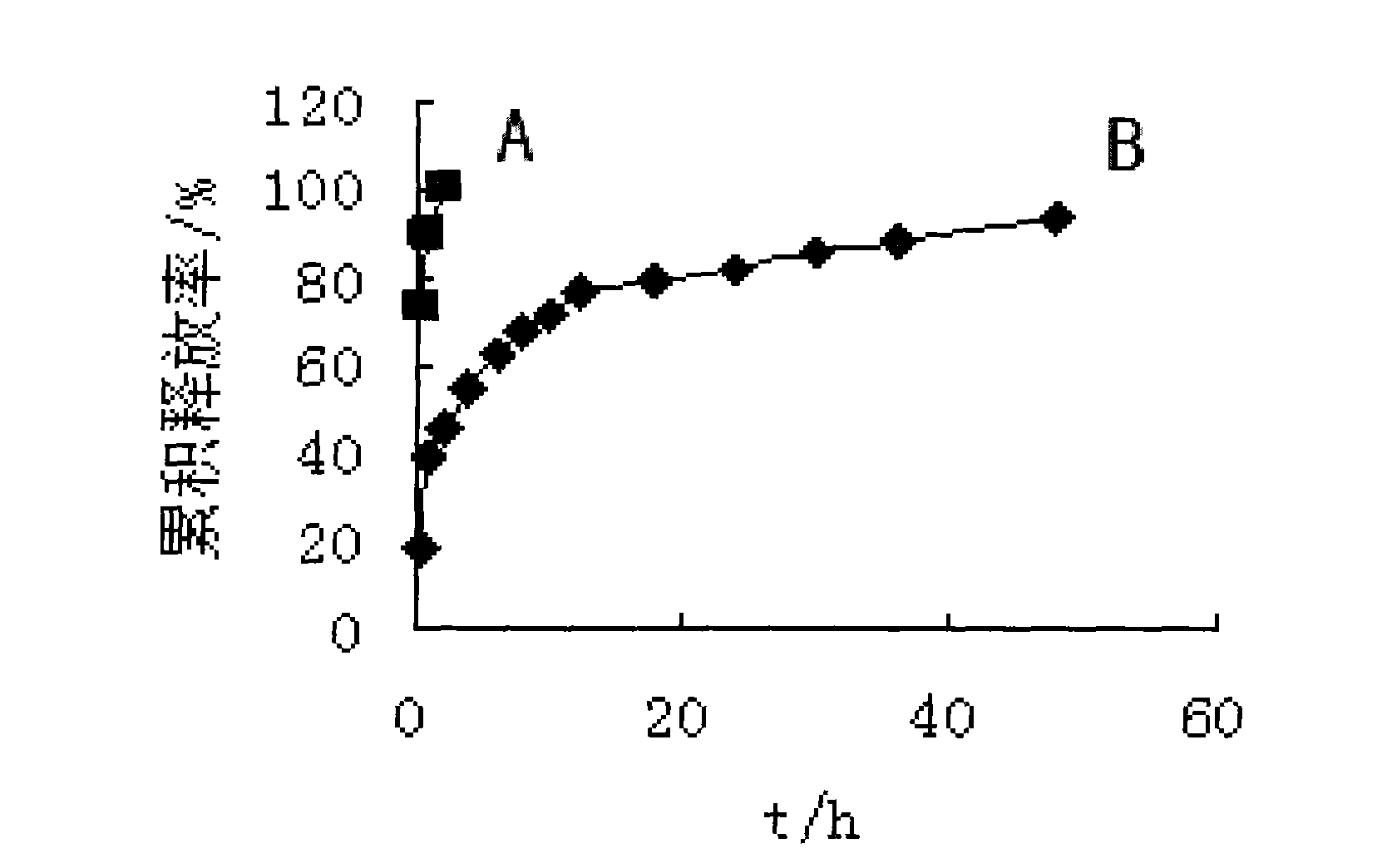

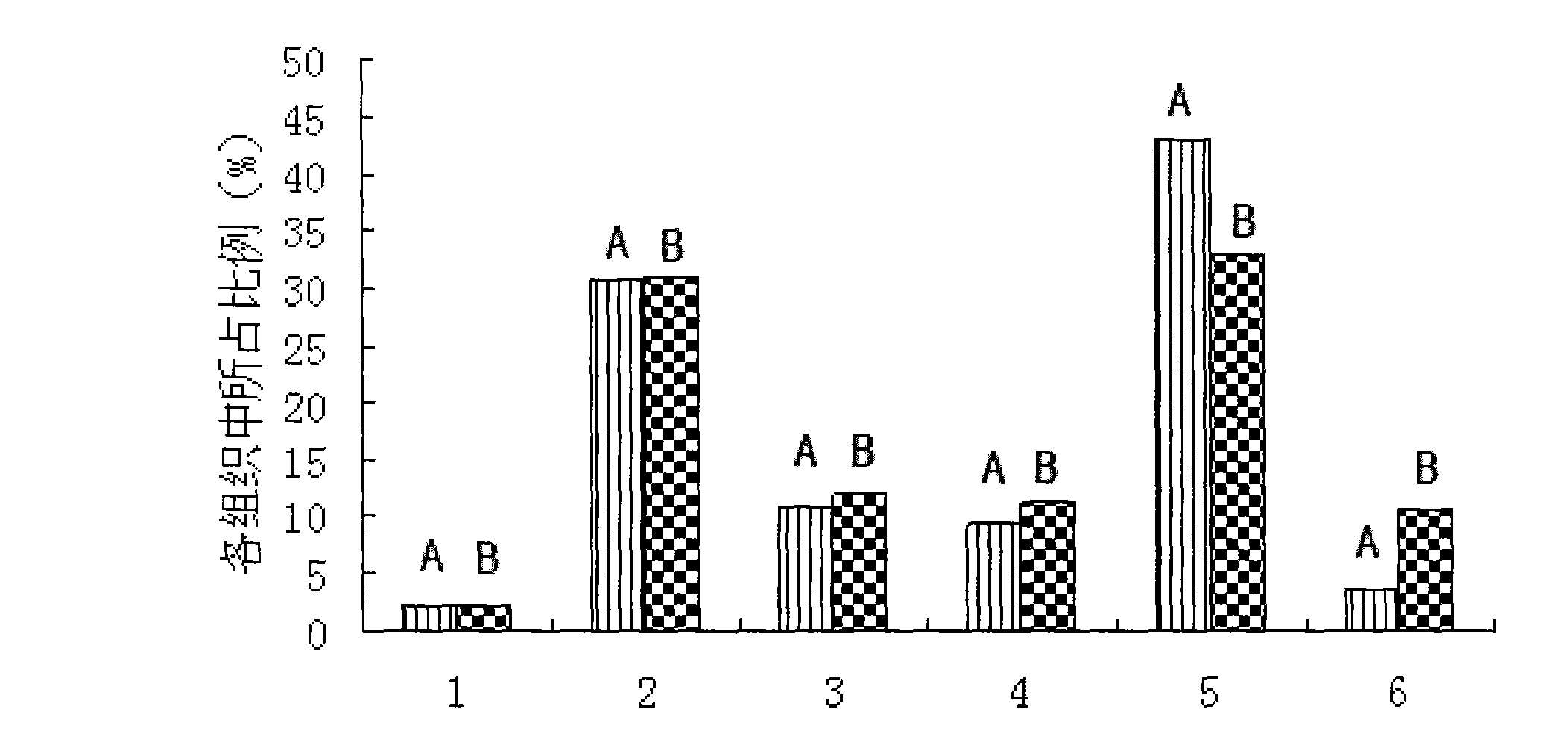

Targeting molecular imaging probe and living molecular imaging method

InactiveCN102743770AGuaranteed accuracyTarget-specificGeneral/multifunctional contrast agentsRadioactive preparation carriersMolecular imagingDistribution characteristic

Owner:申宝忠

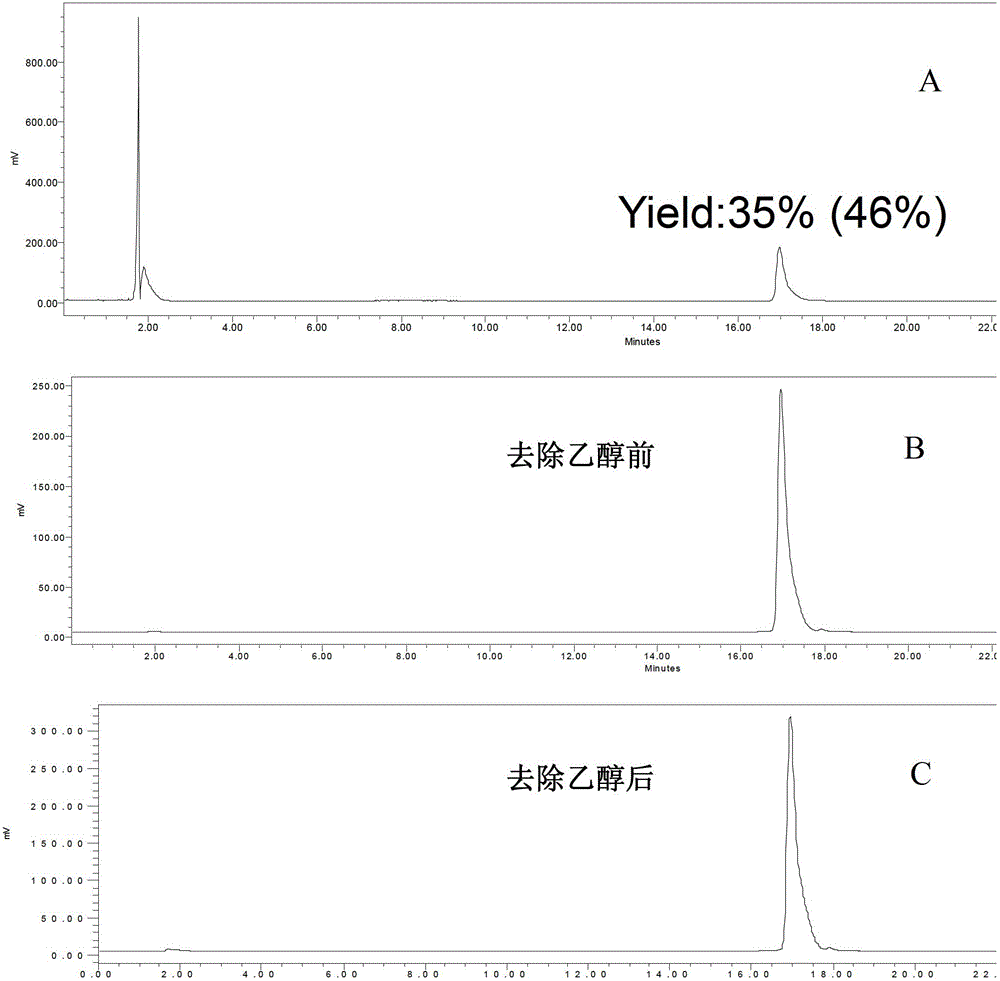

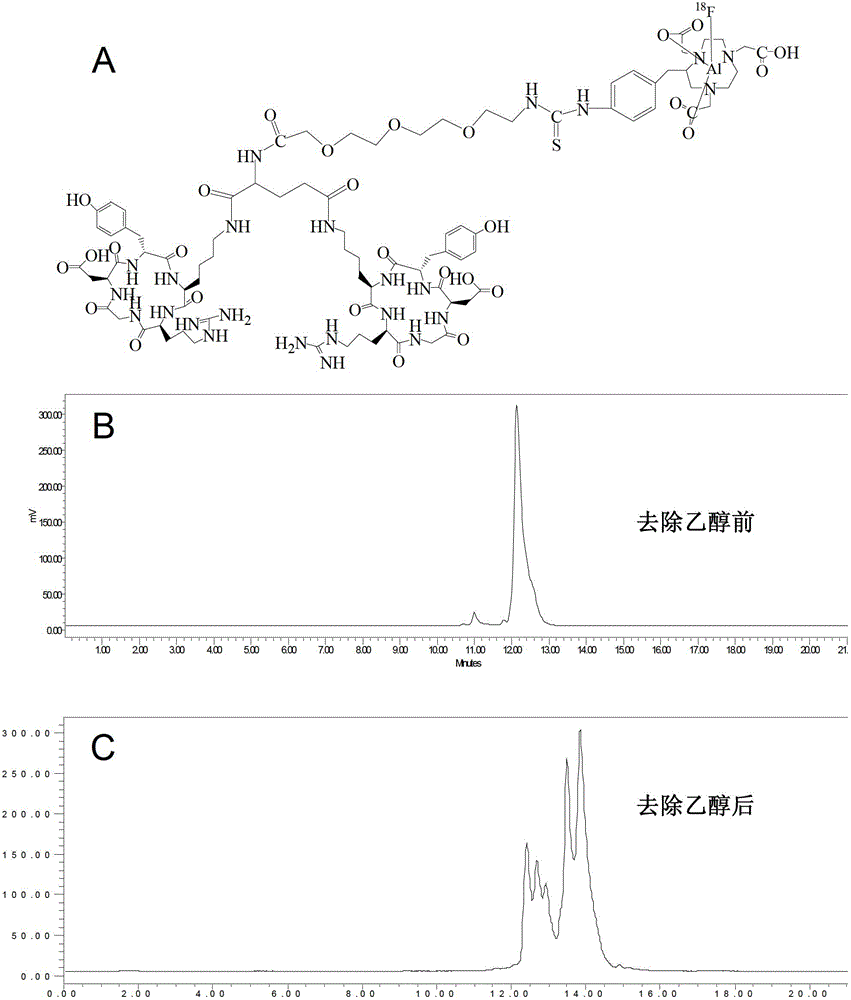

Radioactive label polypeptide coordination complex and preparation method and application thereof

ActiveCN102911256APromote commercial applicationSimple radiolabeling methodRadioactive preparation carriersPeptide preparation methodsCoordination geometryRadioactive Label

The invention provides an RGD polypeptide coordination complex of a radioactive nuclide label. According to the structure of the coordination complex, the radioactive nuclide is selected from 64Cu, 68Ga, 111In, 62Cu, 67Cu, 67Ga, 86Y, 89Zr or 18F; the ligand is a ligand compound containing an RGD structure, which is shown in a formula (I). The coordination complex has stronger ligand stability and high target / non-target ratio, and the appetency of the ligand with integrin AlphavBeta3 is stronger. The invention further provides a preparation method of the coordination complex, and an application of the coordination complex in preparing tumor developers.

Owner:NANTONG SHIMEIKANG PHARMA CHEM

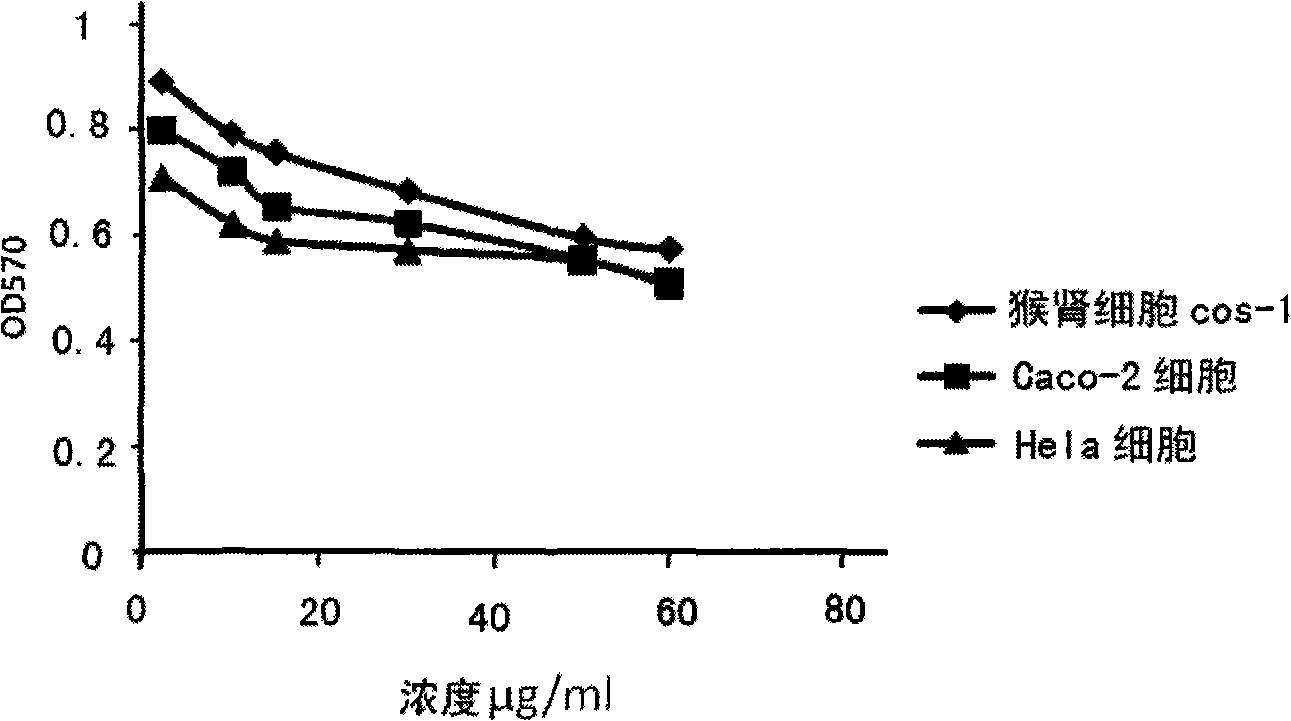

Tumor cell actively targeted drug delivery system, preparation method and application thereof

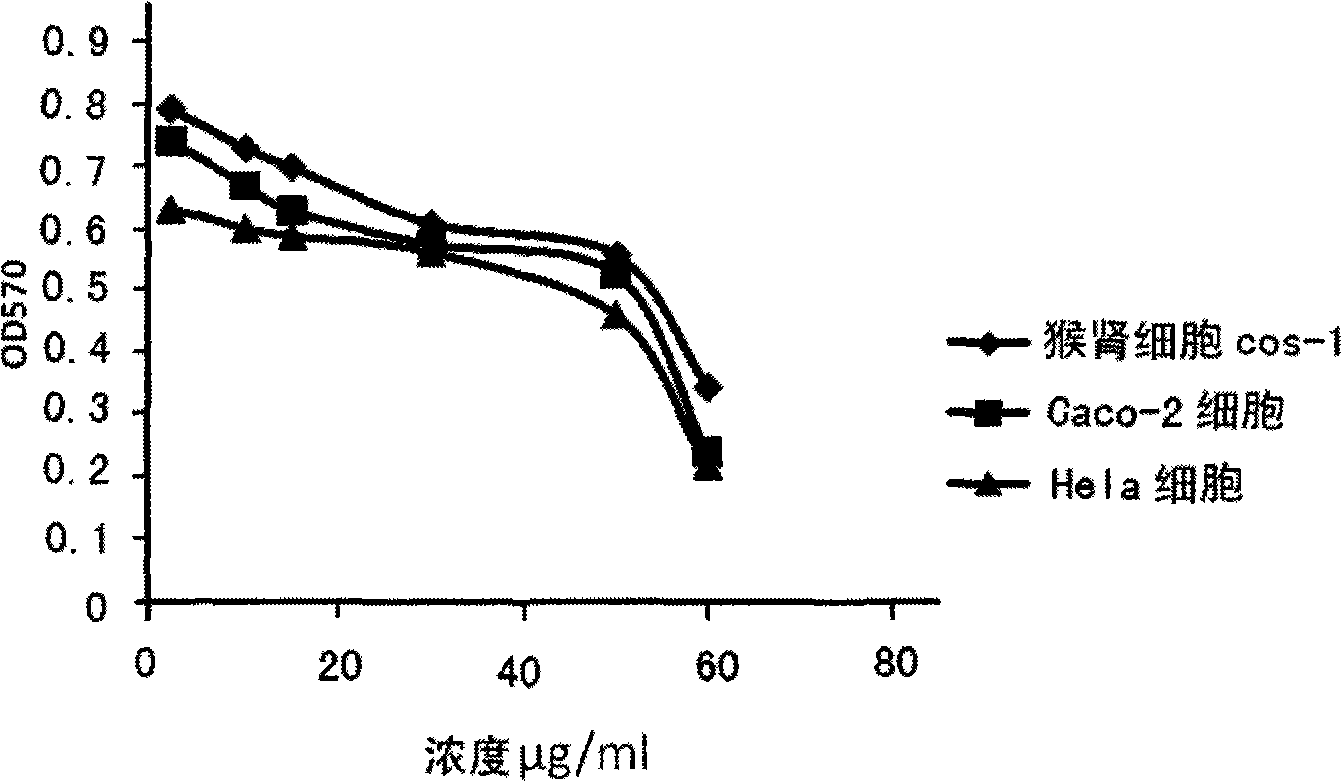

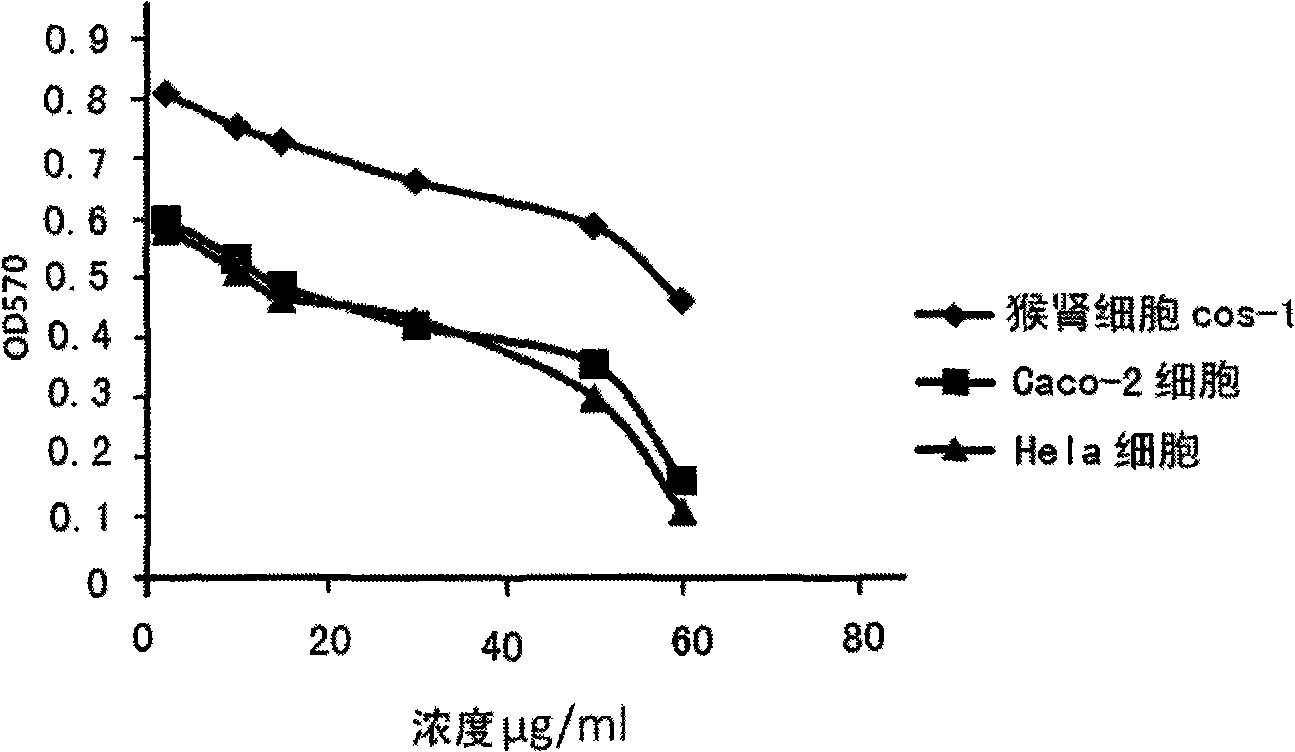

InactiveCN101537185AInaccessibleBiodegradableOrganic active ingredientsSolution deliveryTumor chemotherapyBovine serum albumin

The invention discloses a tumor cell actively targeted drug delivery system. The drug delivery system comprises the following component contents (by weight): 100-200 parts of bovine serum albumin, 200-400 parts of folic acid, 0.05-0.10 part of 25% glutaral pentanedial, 0.005-0.01 part of alcohol, 5-15 parts of anhydrous dimethyl sulphoxide, 80-100 parts of dicyclohexylcarbodiimide, 70-80 parts of N-hydroxysuccinimide, 0.4-0.6 part of tri-ethylamine, 100-200 parts of anhydrous acetone, 100-200 parts of ether, and 50-100 parts of polybutylene succinate. The drug delivery system comprises preparation steps of activated folate ester, folic acid-bovine serum albumin and colloid suspension. The drug delivery system has low toxicity to normal tissues while killing tumor cells with high-expression of folate receptors; and the folic acid has low immunogenicity, convenient modification and simple storage. The drug delivery system has the advantages of needing short time to reach targets and clearing blood quickly; has obvious advantages in tumor chemotherapy. The invention further discloses a preparation method and application of the tumor cell actively targeted drug delivery system.

Owner:WUHAN UNIV OF TECH

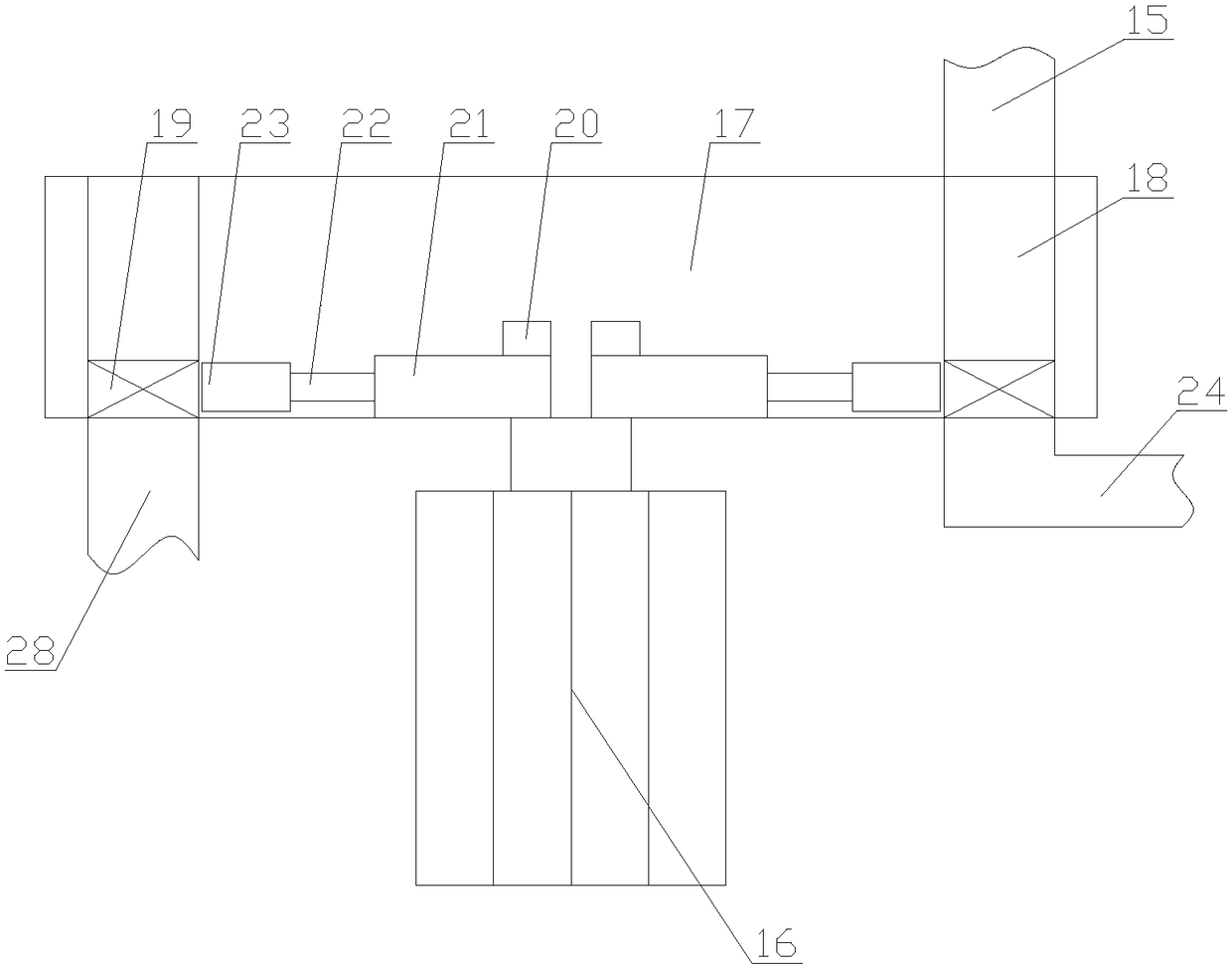

Intelligent pipeline corridor maintenance device with water removing and dredging functions

InactiveCN108086386AImprove drainage capacityClear fastMechanical machines/dredgersSewer systemsSludgeAir pump

The invention relates to an intelligent pipeline corridor maintenance device with water removing and dredging functions. The intelligent pipeline corridor maintenance device comprises a shell, a supporting block, a water pumping mechanism, a mud storage box, two dredging mechanisms and four wheels, the water pumping mechanism comprises a water suction unit, a sewage box and a filtering unit, the water suction unit comprises a first motor, a turntable, a swing rod, a moving rod, a lifting block, a limit rod, a water suction cover, a water suction pipe, a water pump and a water outlet pipe, andthe dredging mechanisms comprise second air pumps, second cylinders, second pistons and scraping plates. The intelligent pipeline corridor maintenance device is provided with the dredging mechanisms,so that sludge on the ground of a pipeline corridor can be cleaned, sludge in a drainage ditch can be cleaned, the drainage ditch is not plugged by the sludge, and the drainage capacity of the intelligent pipeline corridor is enhanced. Besides, the device is provided with the water pumping mechanism, the intelligent pipeline corridor maintenance device can remove water accumulated in the drainageditch of the pipeline corridor and can also remove water accumulated on the ground of the pipeline corridor, and rusting of pipelines and devices in the intelligent pipeline corridor is avoided.

Owner:NANJING AITASI INTELLIGENT TECH CO LTD

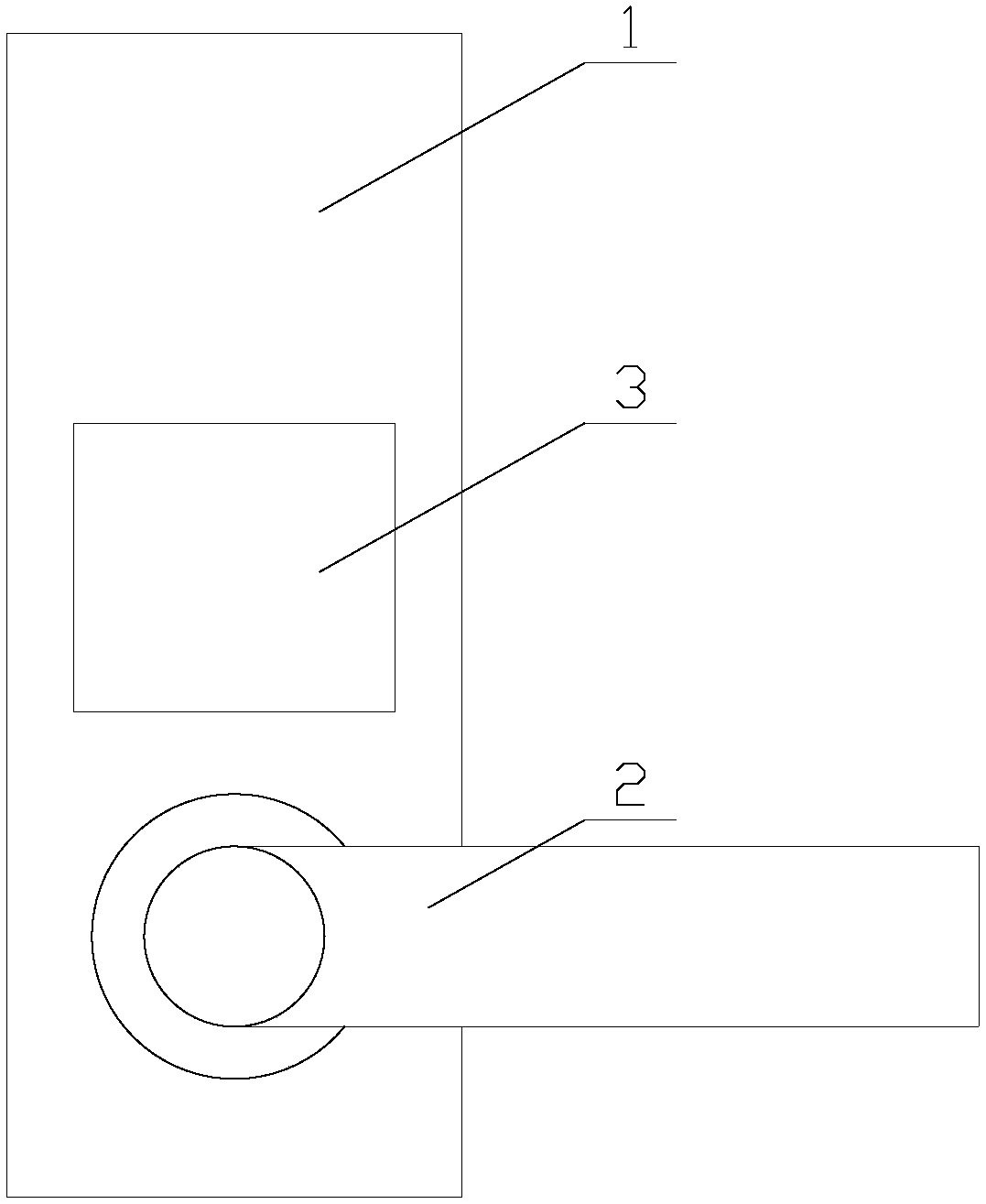

Intelligent induction lock with dehumidification and dedusting functions

ActiveCN108166846AAffect sensing performanceSensing performance is fast and efficientCleaning using toolsElectric permutation locksEngineeringElectronic component

The invention relates to an intelligent induction lock with dehumidification and dedusting functions. The intelligent induction lock comprises a main body and a handle. The main body is internally provided with a groove, a lifting groove, a dehumidification mechanism and a dedusting mechanism. An induction head is arranged in the groove, and the dedusting mechanism comprises a lifting unit, a baffle and a cleaning block. The dehumidification mechanism comprises an air extraction unit, a dehumidification pipe and an air exhaust pipe, and the air extraction unit comprises a motor, a rotary disc,a positioning pin, a limiting rod, a swing rod, a strip-shaped hole, a shipper rod, a pushing block, an air extraction pipe and a check valve. According to the intelligent induction lock with the dehumidification and dedusting functions, dust accumulated on the induction head can be cleaned up through the dedusting mechanism to prevent the situation that the dust affects the induction property ofthe intelligent induction lock so that the intelligent induction lock can quickly and effectively sense an induction card; and not only that, air in the groove can be dehumidified by the intelligentinduction lock through the dehumidification mechanism, damage to electronic components in the intelligent induction lock is prevented, the induction property of the induction head is ensured, and theworking efficiency of the intelligent induction lock is improved.

Owner:四川兴事发门窗有限责任公司

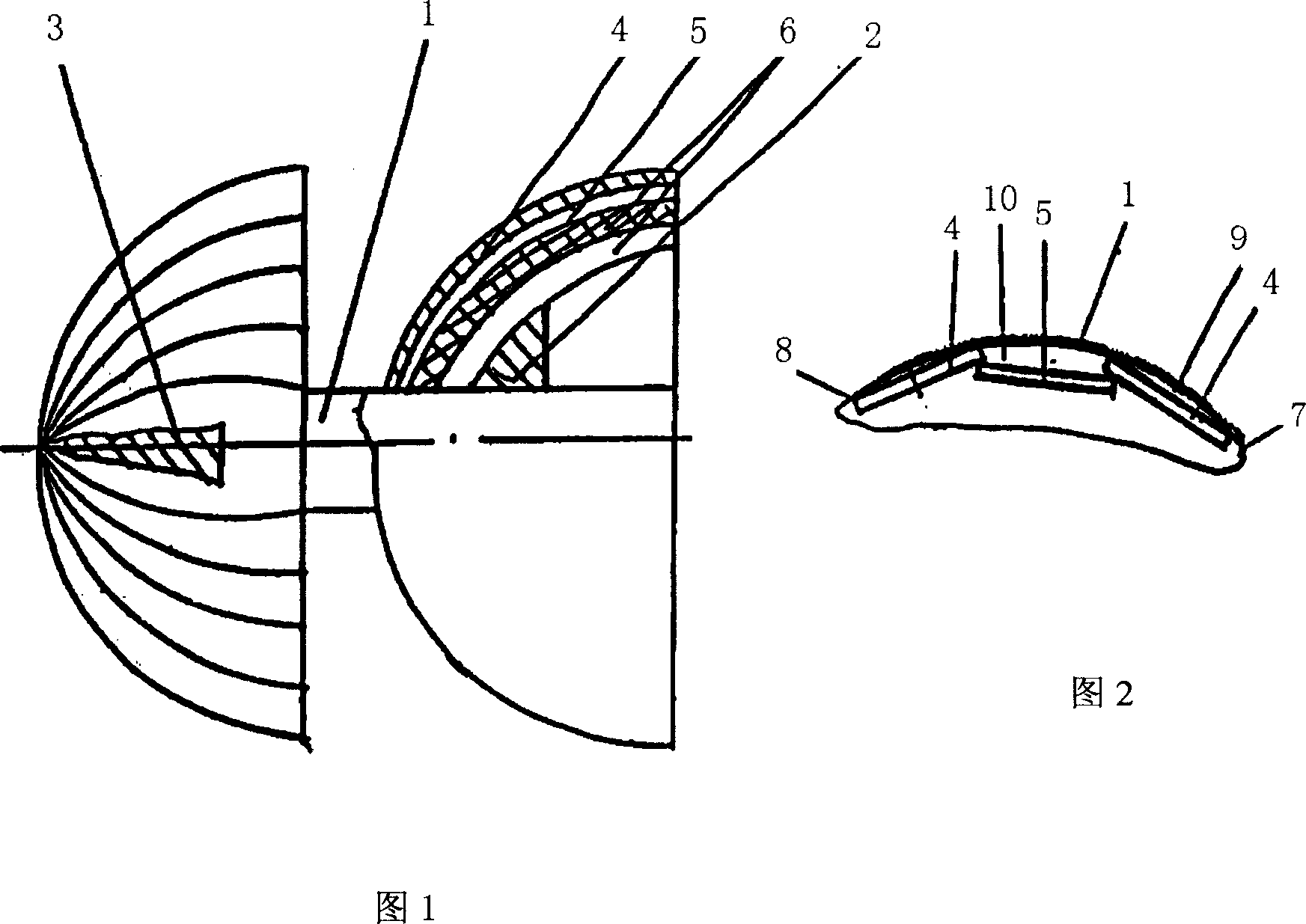

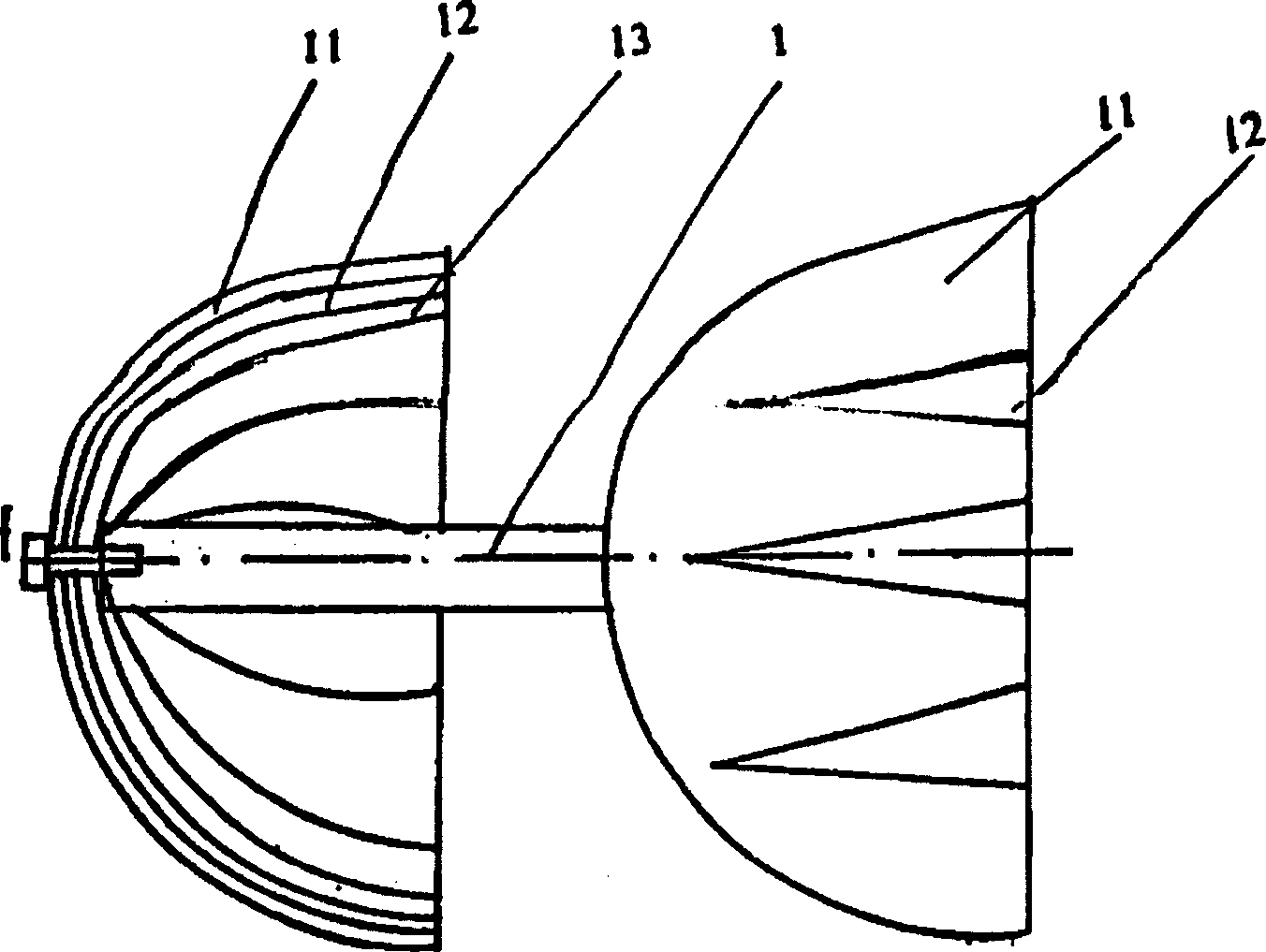

Pipeline cleaning method and device

A method for cleaning pipeline features that a bowl-shaped cleaning part is driven by liquid stream to move in a pipeline, its edge can generate the liquid jet, and its vibration can squeeze the dirt and generate holes in fluid, so removing the dirt from the inner surface of pipeline. Its apparatus is composed of an axle with axle sleeve and the elastic sheets and elastic soft sheets, which are installed to said axle.

Owner:大连玛斯特科技发展有限公司

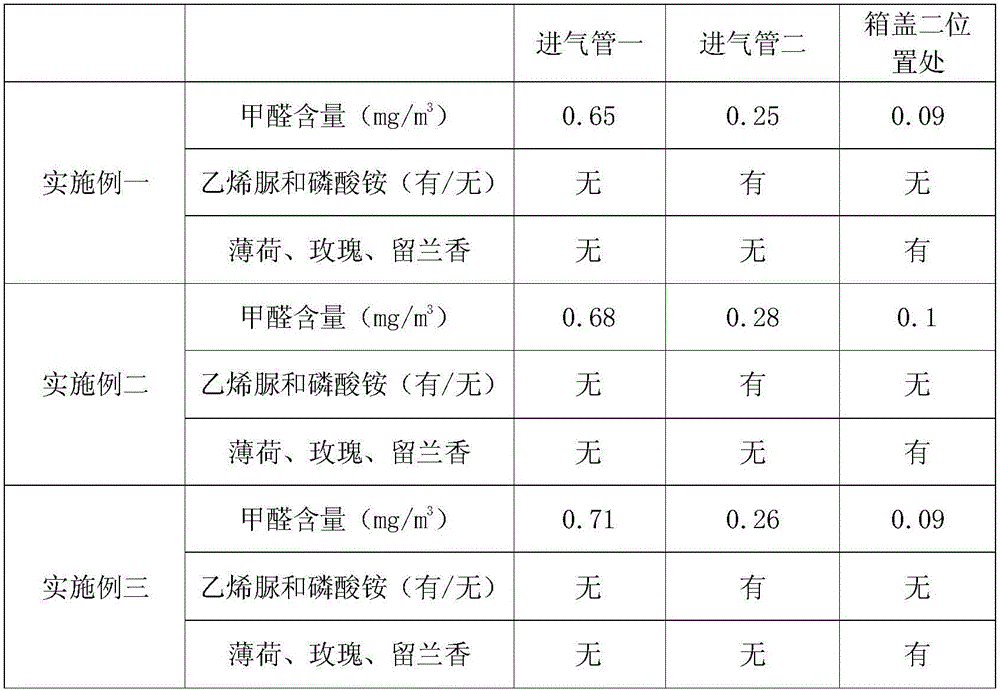

Formaldehyde scavenging agent and formaldehyde scavenging method thereof

InactiveCN105771627AImprove comfortFast removalDispersed particle separationDeodrantsAir cycleSodium Bentonite

The invention discloses a formaldehyde scavenging agent and a formaldehyde scavenging method thereof. The formaldehyde scavenging agent comprises a plant component A, an essential oil component B and an adsorption component C, wherein the plant component A is prepared from, by weight, 3-8 parts of Chlorophytum comosum (Thunb.) Baker, 3-9 parts of Epipremnum aureum, 3-7 parts of Hedera nepalensis var. Sinensis (Tobl.) Rehd, 2-6 parts of aloe, 1-7 parts of Agave americana L., 2-5 parts of Sansevieria trifasciata Prain and 1-8 parts of Commelina communis; the essential oil component B is prepared from, by weight, 10-20 parts of ethanol, 5-15 parts of distilled water, 3-5 parts of peppermint oil, 1-2 parts of rose essential oil and 2-3 parts of spearmint oil; the adsorption component C is prepared from, by weight, 1-3 parts of attapulgite and 3-5 parts of bentonite by means of uniform mixing. In the formaldehyde scavenging method, a formaldehyde scavenging device is used for scavenging formaldehyde circularly. The formaldehyde scavenging agent and the formaldehyde scavenging method have the advantages of good formaldehyde scavenging effect and capabilities of improving air quality after formaldehyde scavenging and accelerating formaldehyde scavenging.

Owner:ANHUI ZHONGHONG TECH DEV CO LTD

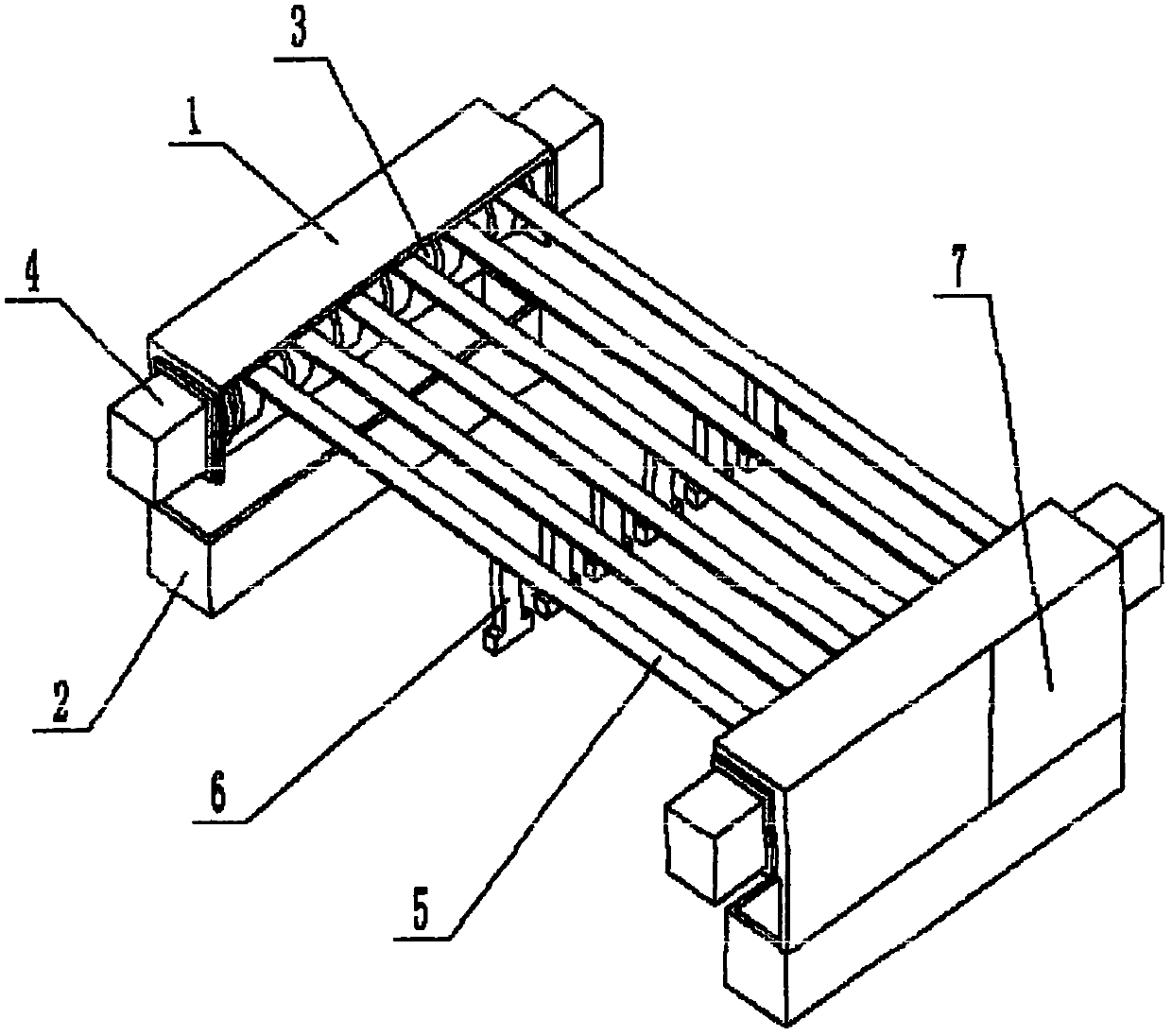

Paperboard waste cleaner

The invention discloses a paperboard waste cleaner which comprises a paperboard access device, a brush roller waste cleaning device and a paperboard sending device, wherein a gas-blowing waste cleaning device is arranged on the paperboard access device; the gas-blowing waste cleaning device comprises a blowing nozzle; the brush roller waste cleaning device comprises a plurality of horizontal upper brush rollers which are rotatably arranged and a plurality of horizontal lower brush rollers which are rotatably arranged; the upper brush rollers and the lower brush rollers are arranged in a staggered mode and are reverse in rotary direction; and a paper outlet end of the brush roller waste cleaning device is horizontally provided with a brush row. After entering the waste cleaner, the paperboards realize preliminary waste cleaning by virtue of the blowing nozzle; then, waste is ejected and dropped by virtue of the upper brush rollers and the lower brush rollers; and finally, un-scattered waste attached on the paperboards is finally brushed off by virtue of the brush row, and the waste is completely cleaned. The paperboard waste cleaner disclosed by the invention replaces manual operation, and realizes automatic waste cleaning, so that the paperboard waste is completely cleaned, the cleaning speed is high, the production efficiency is high and the product quality is guaranteed.

Owner:SHANDONG CENTURY MACHINERY

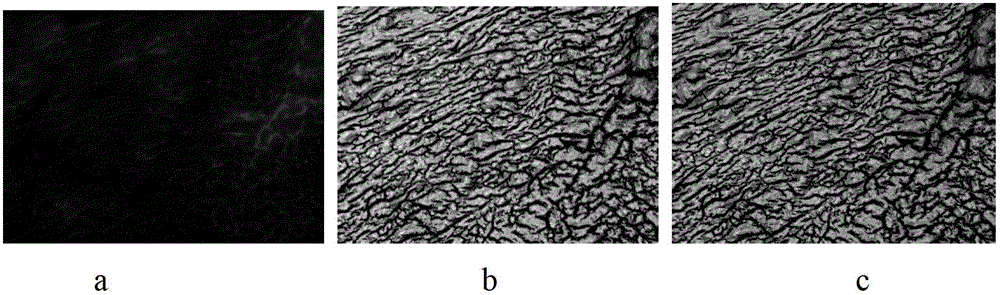

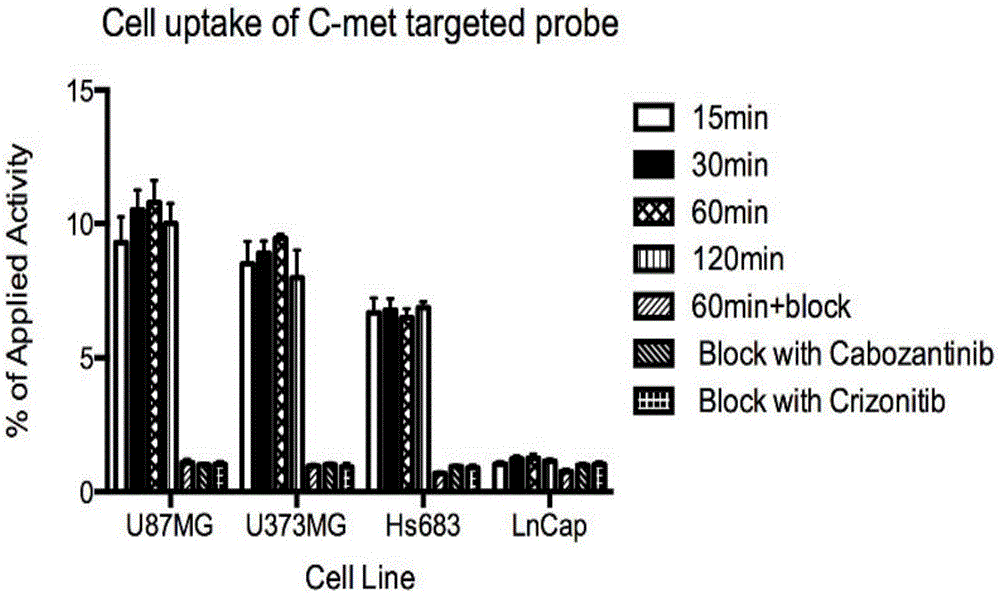

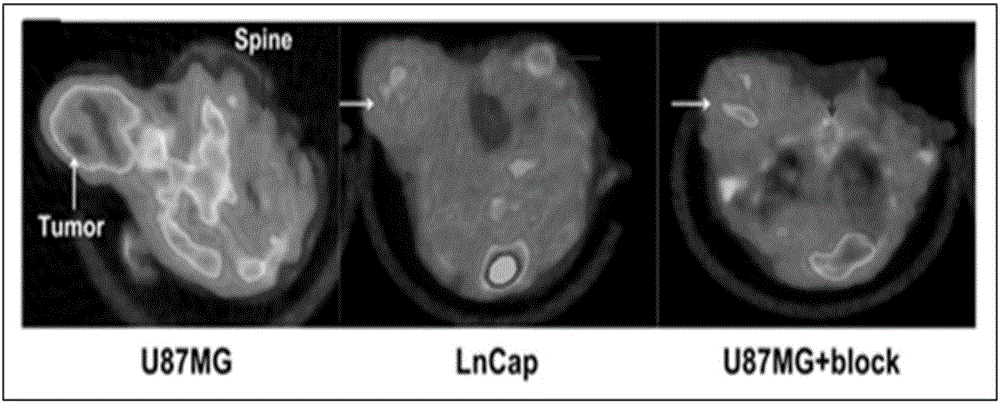

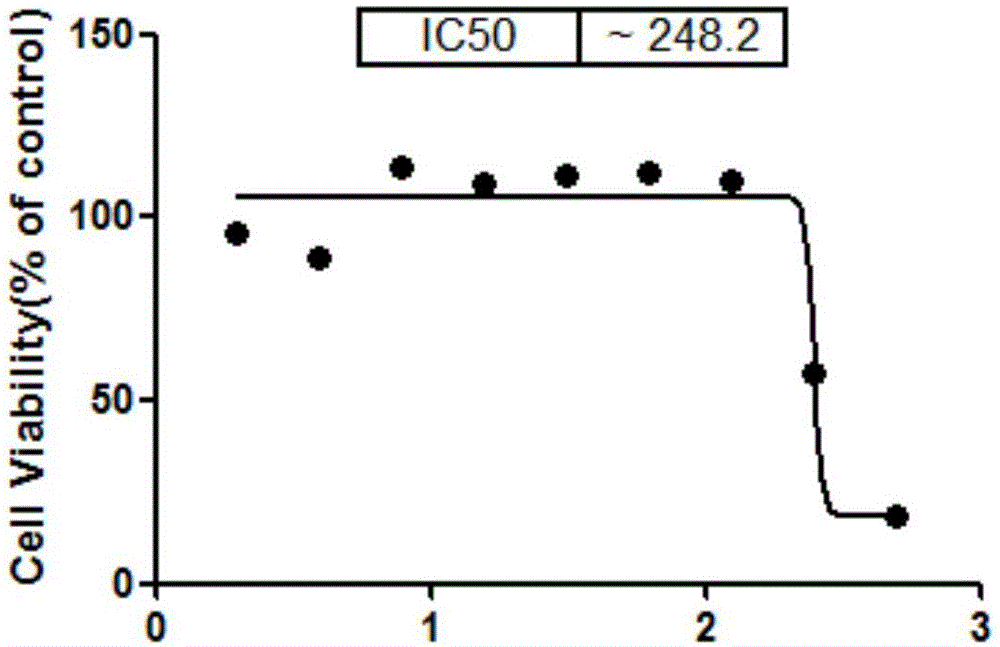

Radioactive C-MET-targeted affinity micromolecular compound and application thereof

ActiveCN106008339AGood pharmacokinetic profileGood biological distribution characteristicsIsotope introduction to heterocyclic compoundsRadioactive preparation carriersNuclear medicineLung cancer

The invention especially relates to a radioactive C-MET-targeted affinity micromolecular compound and application thereof, belonging to the field of medical diagnosis and treatment. According to the invention, in-vivo tracking and imaging of diseases like tumors is realized through radiolabeling of a C-MET receptor antagonist. The radioactive C-MET-targeted affinity micromolecular compound can be used for monitoring the characteristics of biochemical changes of a hepatocyte growth factor receptor, visually displays the distribution and quantity of C-MET and is applicable to specific detection of a plurality of cancers including glioma, lung cancer, prostatic cancer, breast cancer, esophagus cancer, stomach cancer, liver cancer, pancreas cancer, ovarian cancer, rectal cancer and cervical cancer. The radioactive C-MET-targeted affinity micromolecular compound also has certain anticancer activity and has wide clinical application prospect.

Owner:上海准视生物科技有限公司

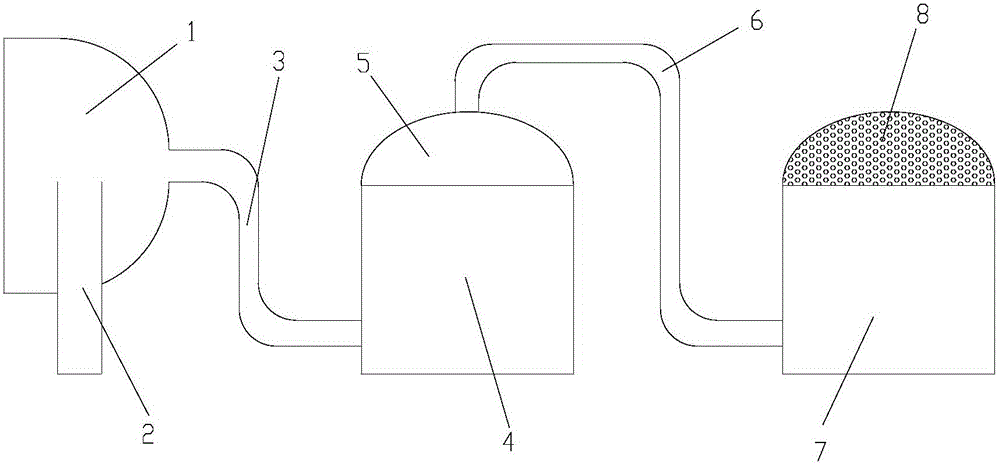

Fast desulfuration and dust removal device with multiple cavities

InactiveCN104307311AIncrease the degree of uniform sprayingFull and fast clearanceCombination devicesEngineeringWater pipe

The invention relates to the technical filed of desulfuration and dust removal equipment and in particular relates to a fast desulfuration and dust removal device with multiple cavities. The fast desulfuration and dust removal device with the multiple cavities comprises a first reaction box, wherein the reaction box is divided into five layers from top to bottom, namely a first cavity, a second cavity, a third cavity, a fourth cavity and a fifth cavity; the third cavity is uniformly divided into four filtering chambers A; the left side surface of the third cavity is provided with a rotation motor which is connected with a stirring shaft; the stirring shaft is arranged in the third cavity and is arranged in the four filtering chambers in a penetrating manner; a horizontal water pipe is arranged at the upper part in the third cavity; four rotation atomizers are arranged on the horizontal water pipe, are correspondingly arranged at the upper part of the four filtering chambers A and are respectively connected with a micro servo motor; the left end of the horizontal water pipe is a closed end. The fast desulfuration and dust removal device has the advantages that the structure is simple, the operation is convenient, the small space of the multiple cavities is cleaned simultaneously, the smoke inlet amount is controllable, the removing speed is quicken, the working efficiency is improved and the like.

Owner:广州市协通玻璃钢厂

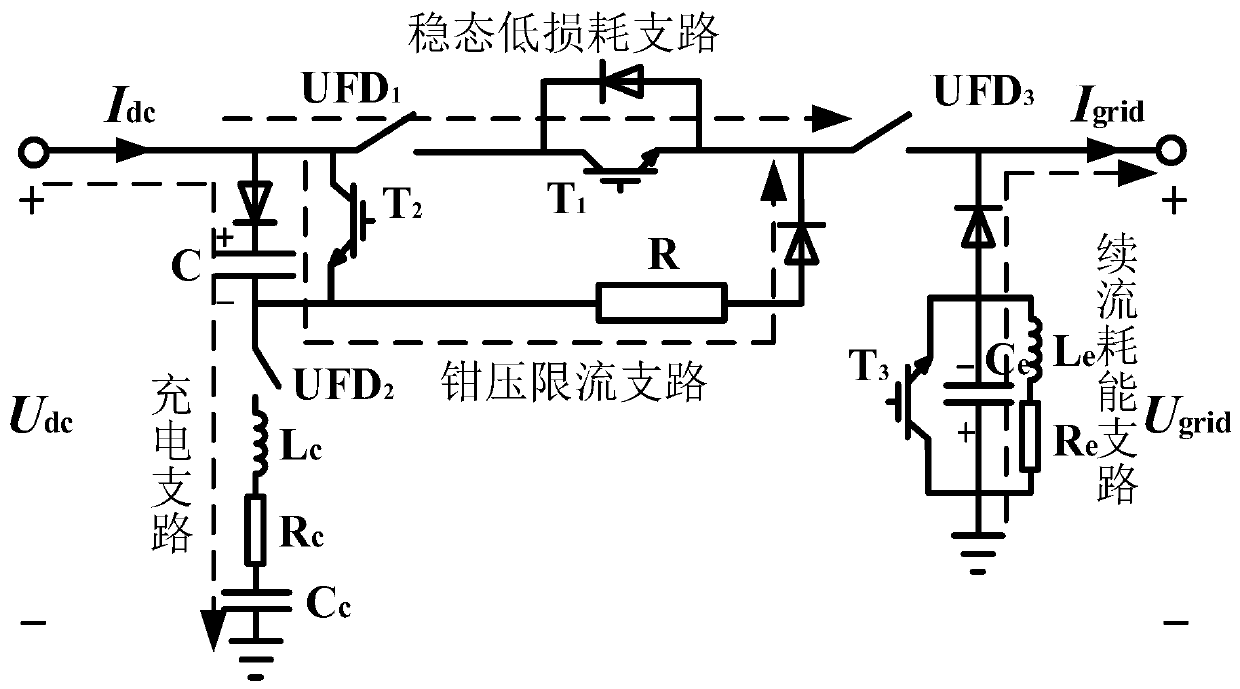

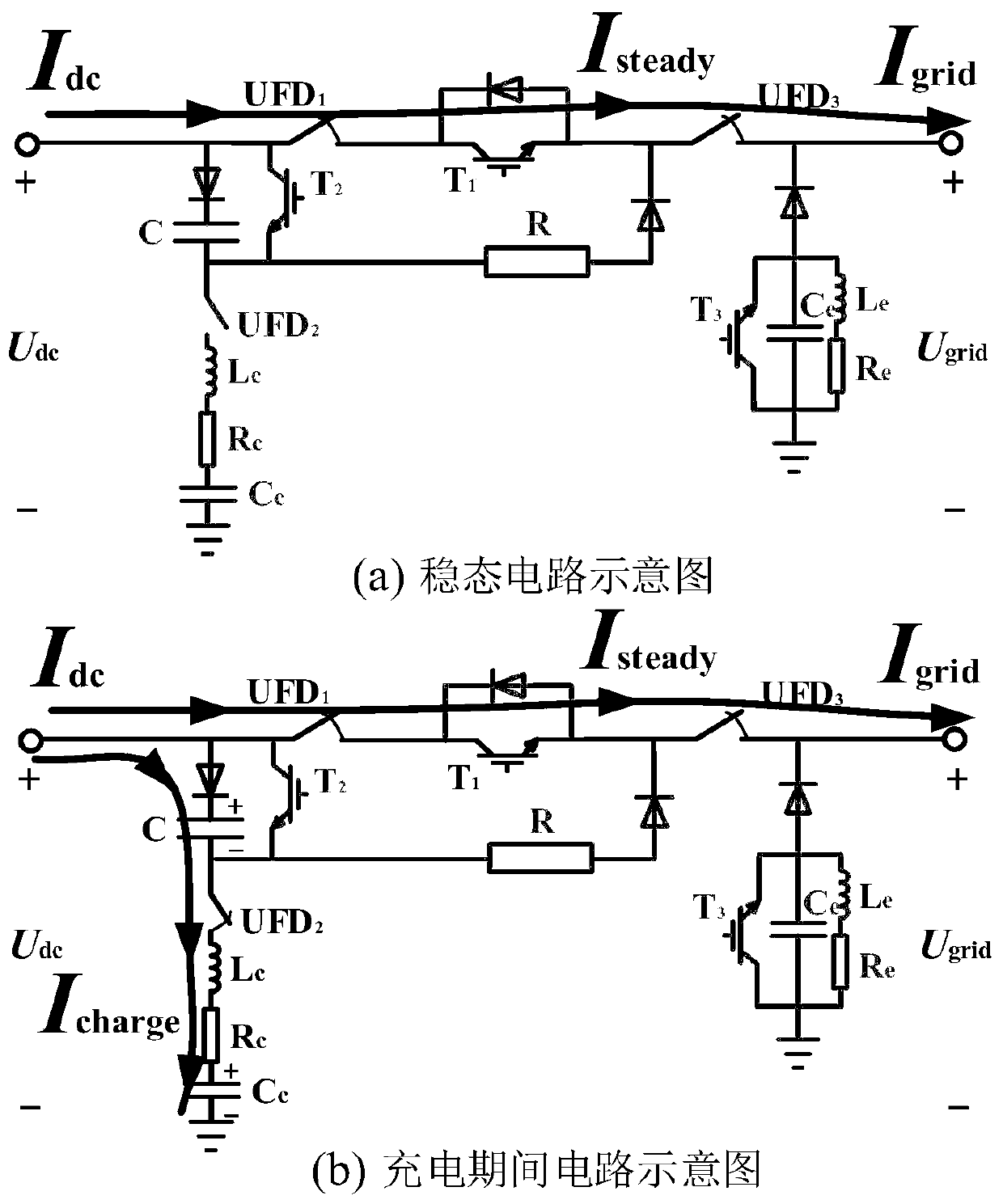

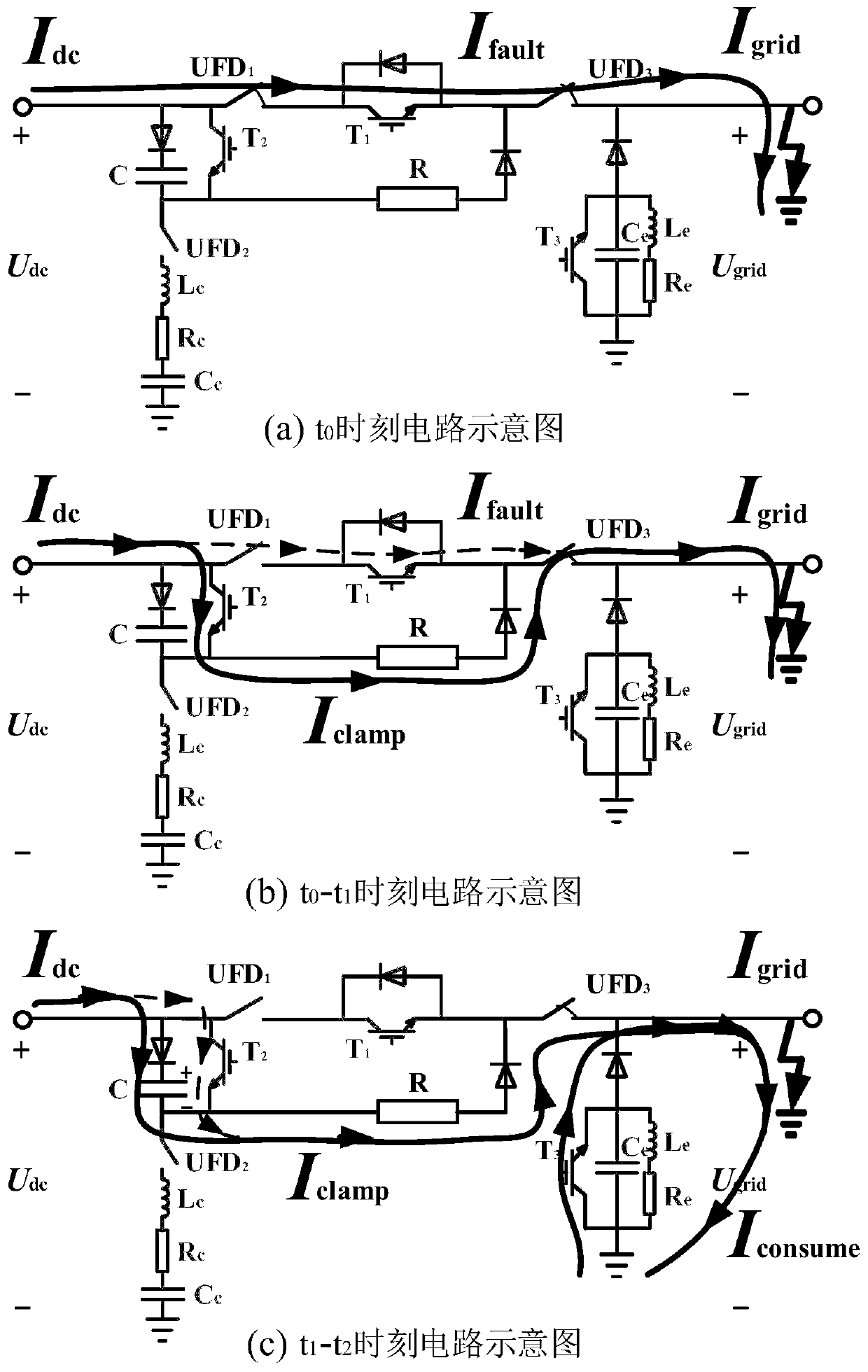

Voltage-reduction clamping type direct-current circuit breaker suitable for direct-current power grid

InactiveCN109888743AFast Fault Isolation OperationIncrease speedEmergency protective circuit arrangementsElectric power transfer ac networkElectrical resistance and conductanceCurrent limiting

The invention relates to a voltage-reduction clamping type direct-current circuit breaker suitable for a direct-current power grid, and belongs to the technical field of multi-end direct-current and direct-current power grids. A topology can be divided into four branches, comprising a voltage clamping and current limiting branch circuit, a charging branch circuit, a steady-state low-loss branch circuit and a follow-current energy consumption branch circuit; and a capacitor, an isolation switch, a resistor, an inductor and other devices are required to be used. According to the voltage-reduction clamping type direct-current circuit breaker, a pre-charging capacitor is connected to a fault loop, and by virtue of the clamping voltage generated by the charging process and the current increaselimiting effect, a grid side circuit voltage is reduced to be zero, so that a direct current fault is eliminated.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

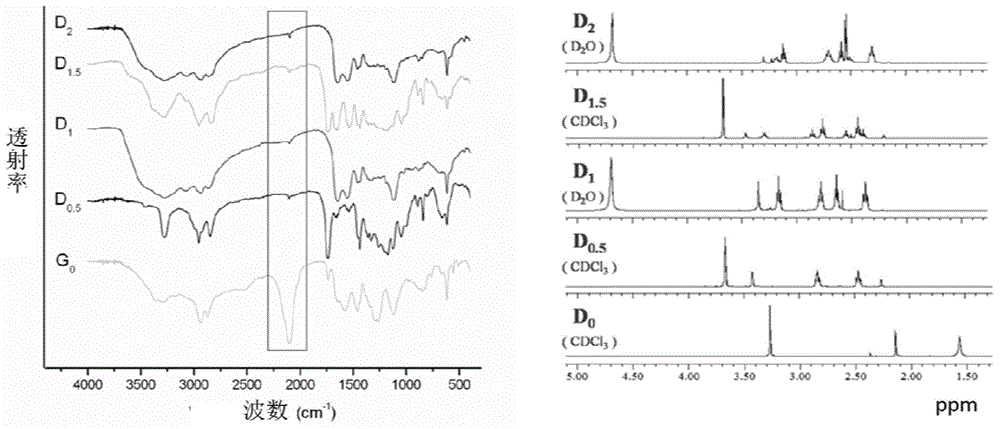

Targeted probe for nuclide labeling and preparation method and application of targeted probe

ActiveCN104830316AStrong marking abilityShort marking timeOrganic chemistryRadioactive preparation carriersDiseaseTherapeutic effect

The invention discloses a targeted probe for nuclide labeling and a preparation method and an application of the targeted probe. A general structural formula of a complex is as shown in the specification, wherein R' is a nuclide chelating group; R is a targeted group; Dn is a molecular skeleton which is formed by repeated michael addition reaction and amidation reaction employing propargylamine as an initial reactant, the peripheral group is amino, n represents different algebras, and the numerical value of n is an integer greater than or equal to 0; and m is equal to 2n. A polymer in the targeted probe for nuclide labeling is beneficial to improvement of the specific activity; a high-quality developing result can be obtained by instrument scanning; the targeted probe can play a role in effectively monitoring tumors or inflammatory diseases; meanwhile, carrying of relatively many nuclides on a molecule is facilitated by the formed polymer; the nuclide concentration of focus location is improved; and the targeted probe plays a relatively good treatment role.

Owner:XIAMEN UNIV

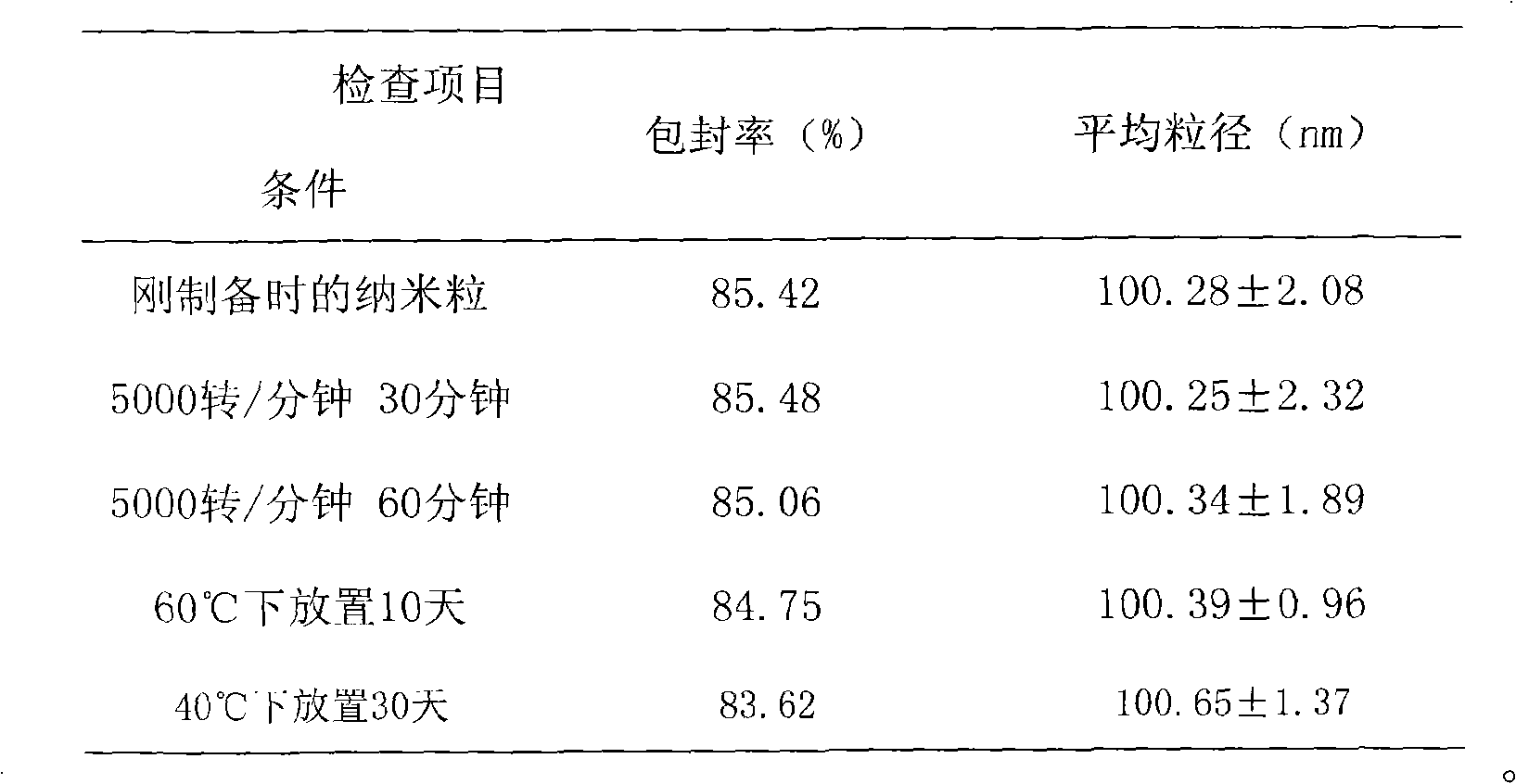

Deproteinated calf blood ingredient brain targeting nanosphere and preparation method thereof

The invention discloses a deproteinated calf blood ingredient brain targeting nanosphere preparation method, specifically comprising: according to the parts by weight, dissolving 5-30 parts of stabilizing agent in distilled water, then dissolving 5-30 parts of pluronic F-68 in distilled water, mixing the two obtained solution, shaking well, adding 50-100 parts of deproteinated calf blood extractive injection, shaking well, after constant volume, adjusting the PH value to 1-4, slowly adding 5-30 parts of polybutylcyanoacrylate while stirring; stirring for 1-6h, adjusting PH value to 6-8, stirring for 1-6h to obtain the colloid solution of deproteinated calf blood ingredient nanosphere, filtering, freeze drying; dissolving the freezedrying powder of deproteinated calf blood ingredient nanosphere, adding 5-30 parts of tween 80 and stirring for 0.5-3h to obtain deproteinated calf blood ingredient brain targeting nanophere. The invention has the advantages of simple preparation method, low cost, easy storage, short time to reach the brain, rapid blood clearance rate and the like.

Owner:WUHAN UNIV OF TECH

Metal scavenger composition and method for producing the same

The invention discloses a metal-removing agent combination for removing pure tin, tin-lead or tin-copper alloy on printed circuit boards and a production method for the metal-removing agent combination, which comprises by weight the following components: iron nitrate 15.9-16.3%, urea 0.3-0.4%, benzotriazole 0.3-0.4%, methyl benzotriazole 0.2-0.3%, hydrochloric acid 1.5-1.7%, nitric acid 33-36%, and the remainder water. The method for producing the removing agent combination comprises such procedures as (1) adding in sequence according to proportion the raw materials nitric acid, iron nitrate, hydrochloric acid, urea, benzotriazole, methyl benzotriazole and water in a production tank; (2) agitating till the raw materials solve completely, and inspecting. The metal-removing agent combination is a standalone fluid, can erode rapidly any foreign matters on a copper surface while maintaining a very low eroding rate to the copper, contains no fluoride and will not erode the base material, has a high removing speed, low environmental pollution, and is of a wide applicability and operation convenience.

Owner:珠海顺泽科技股份有限公司

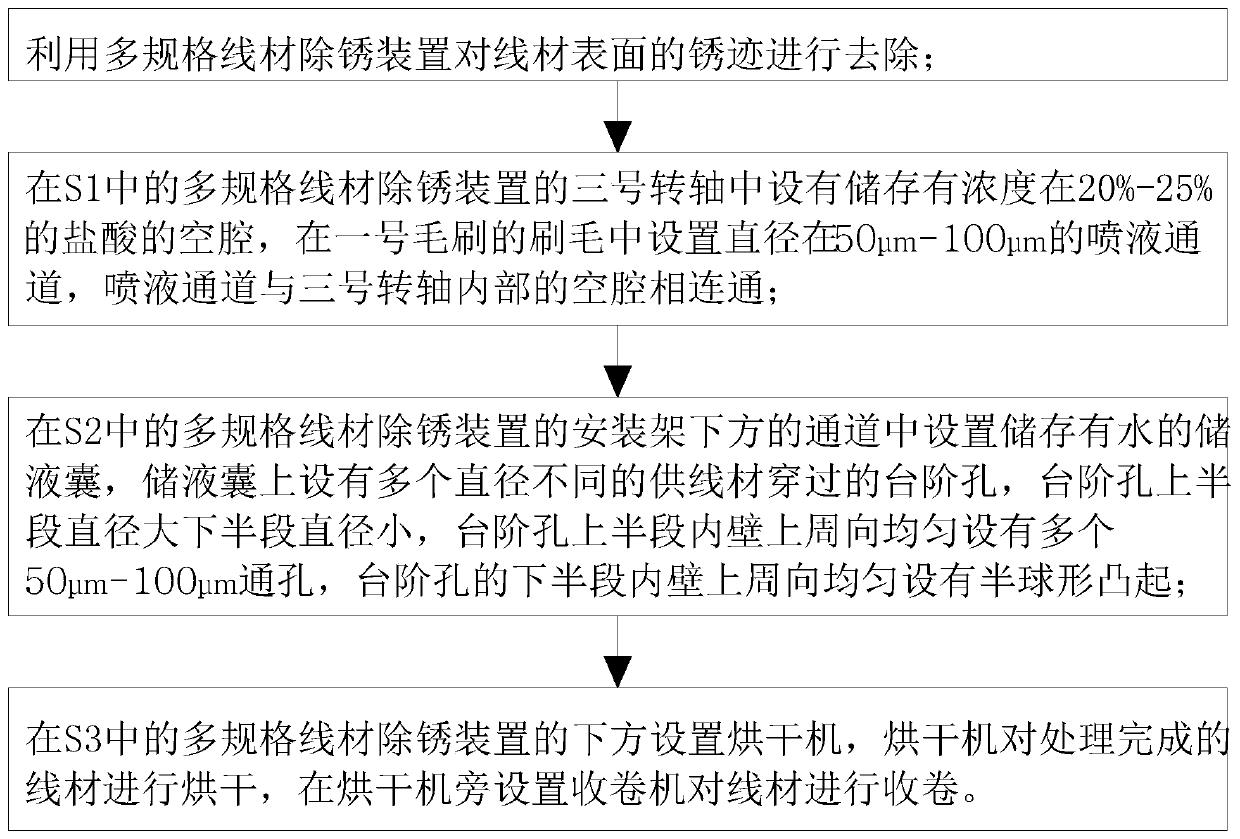

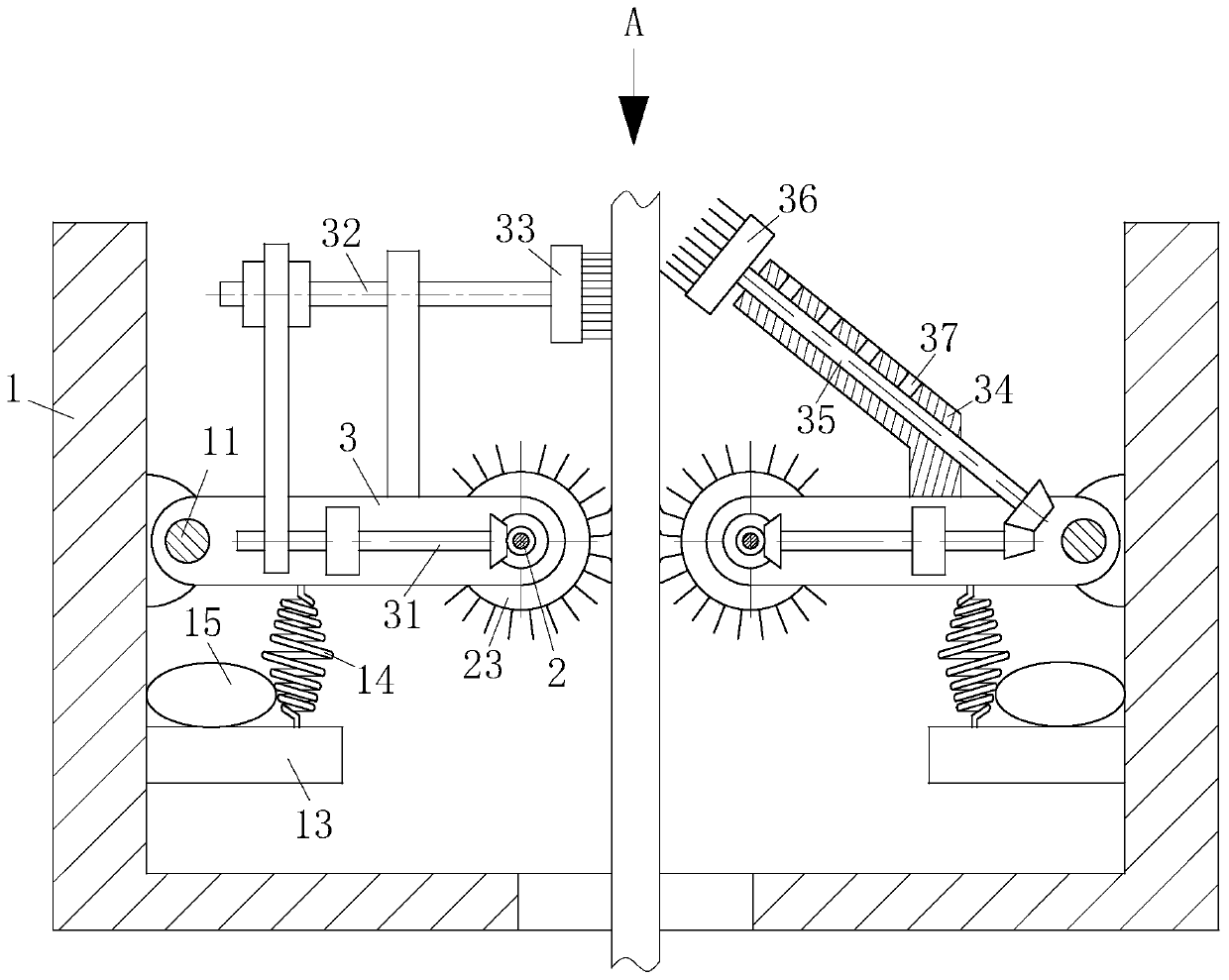

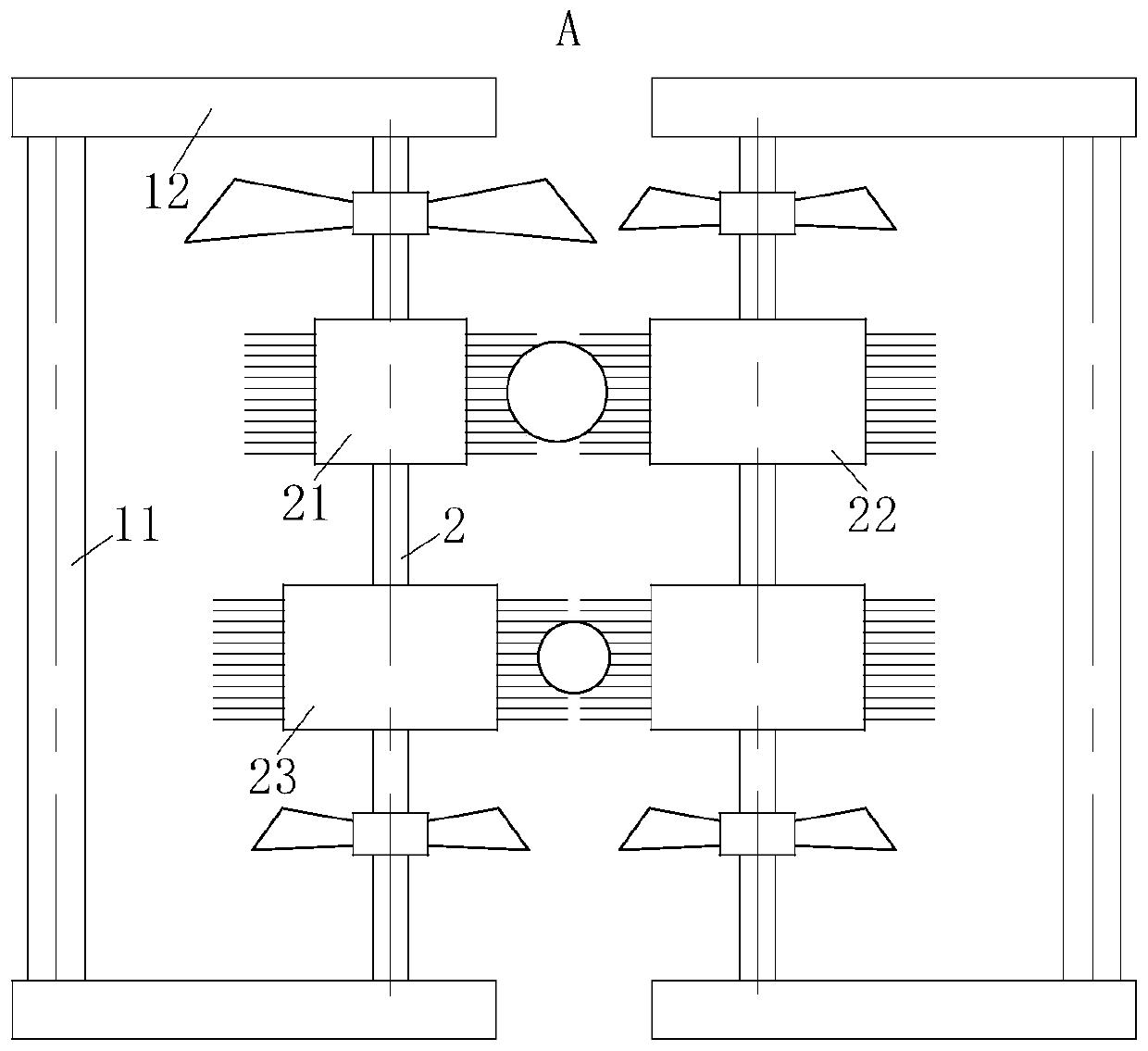

Wire rod rust removal process

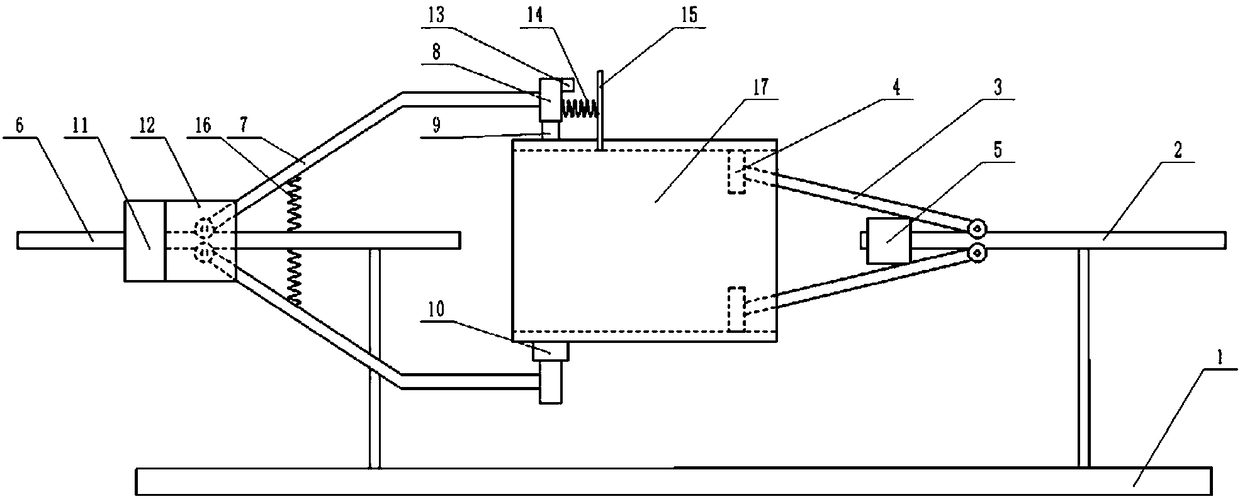

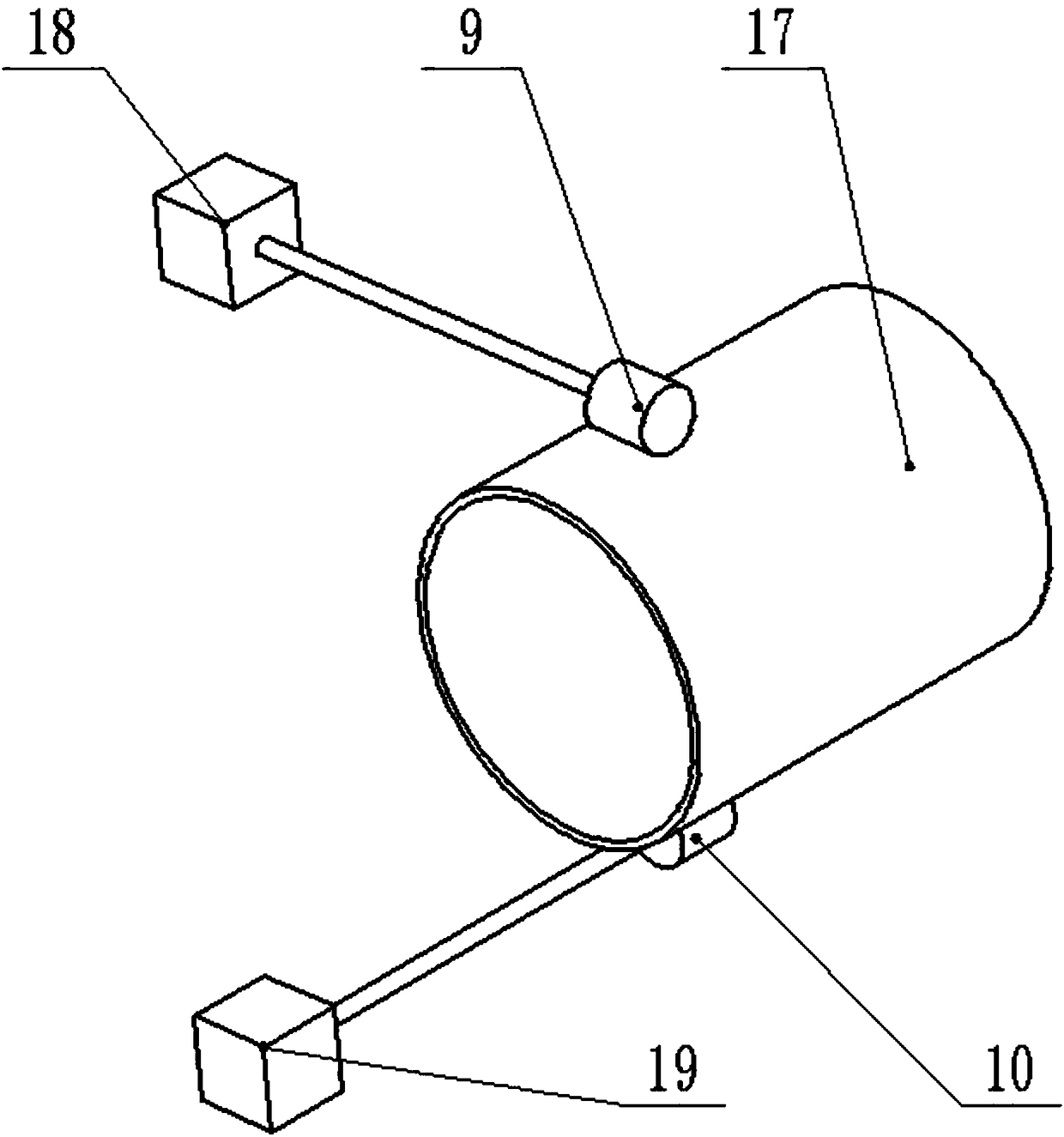

ActiveCN109848246AFast rust removalRemove cleanCleaning using toolsCleaning using gasesWater storageWinding machine

Owner:德清林缘金属制品有限公司

Cleaning device for floor surface

ActiveCN108784555AReduce slippageEasy to removeCarpet cleanersFloor cleanersSpokeLiquid storage tank

The invention discloses a cleaning device for the floor surface. The cleaning device comprises a car body, a cover body, an air injection assembly, a liquid spraying assembly and a brush assembly, wherein the car body comprises a chassis and a wheel. The wheel comprises a center shaft and spokes, the spokes are of a bent rod-shaped structure, the first ends of the spokes are fixed to the center shaft, the second ends are radiated outwards, a suction cup is fixed to the second of each spoke, a screw hole is formed in the center of the chassis, and a screw is matched with the screw hole; the upper end of the cover body is fixed to the screw, an opening in the lower end of the cover body is close to the floor surface, and a containing space is formed inside the cover body; the air injection assembly comprises an air pump and an air tap, the air tap is arranged inside the containing space, one end of the air tap is inclined downwards to point the floor, and the air pump is communicated with the air tap; the liquid spraying assembly comprises a hydraulic pump and a nozzle, the nozzle is arranged inside the containing space, one end of the nozzle is inclined downwards to point the floor,the hydraulic pump is communicated with the nozzle, and a liquid storage tank arranged on the chassis is communicated with the hydraulic pump; the air tap and the nozzle are arranged in a spaced mode; the brush assembly is arranged between the air tap and the nozzle.

Owner:嘉兴巨腾信息科技有限公司

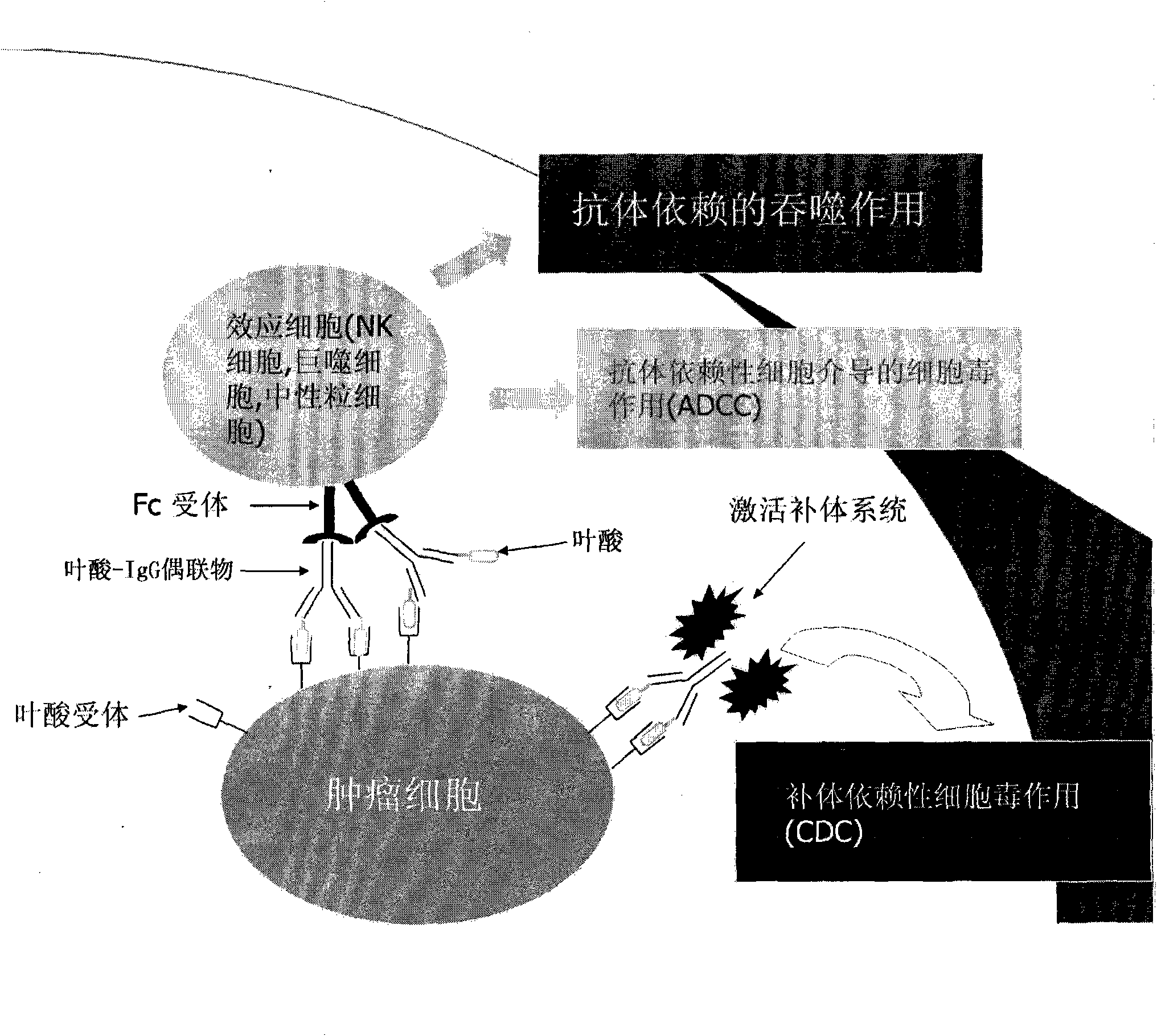

Folate-IgG conjugate as well as preparation method and application thereof

ActiveCN101985471AShort time to targetShort target timeOrganic active ingredientsDigestive systemImmunologic disordersDisease

The invention provides a folate-IgG conjugate as well as a preparation method and application thereof. The folate-IgG conjugate is composed of folate and human souce IgG or recombinant IgG or the Fc section of IgG. The method for preparing the folate-IgG conjugate comprises the following steps: leading 0.1 to 30mol of the folate to react with 0.1 to 40mol of dicyclohexylcarbodiimide and 0.1 to 30mol of hydroxysuccinimide eater in dimethylsulfoxide (DMSO) at room temperature; centrifuging to extract precipitate; leading the precipitate to react with 0.01 to 2.0 times of the human source IgG or the recombinant IgG or the Fc section of the IgG at room temperature for 2 to 5 hours; and filtering the reactant through a molecular screen, and collecting the product, namely the folate-IgG conjugate. The folate-IgG conjugate can be used as a medicament for treating cancer and a medicament for treating autoimmune diseases. The folate-IgG conjugate can be specifically combined to cancer cells and macrophages activated in a patient body with the autoimmune diseases, but cannot be combined to normal cells, so that the problem of damaging the normal cells by the cancer treatment medicament and autoimmune disease medicament in the prior art can be solved.

Owner:ZHEJIANG JIANFENG HANSHENG BIOSCI

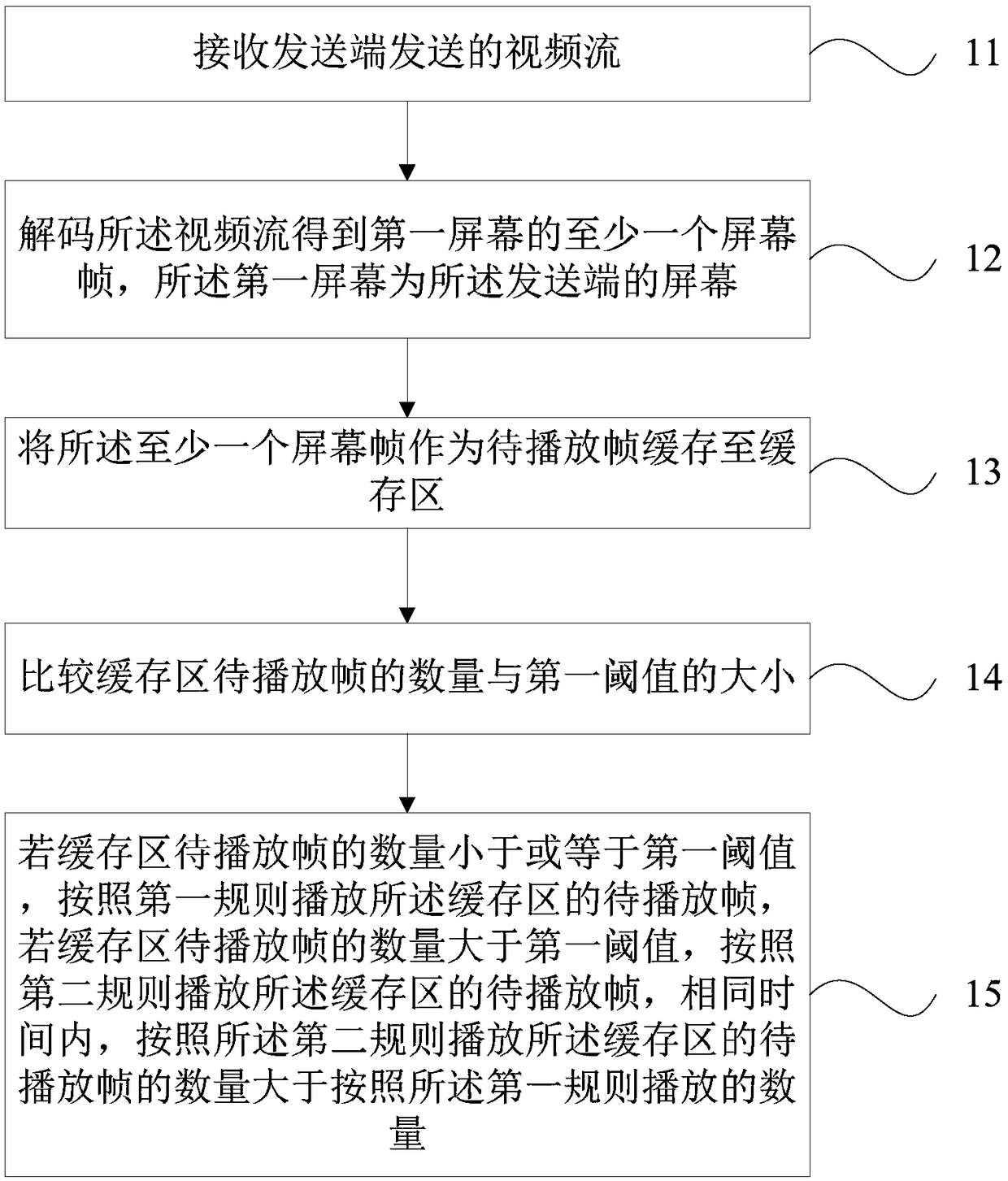

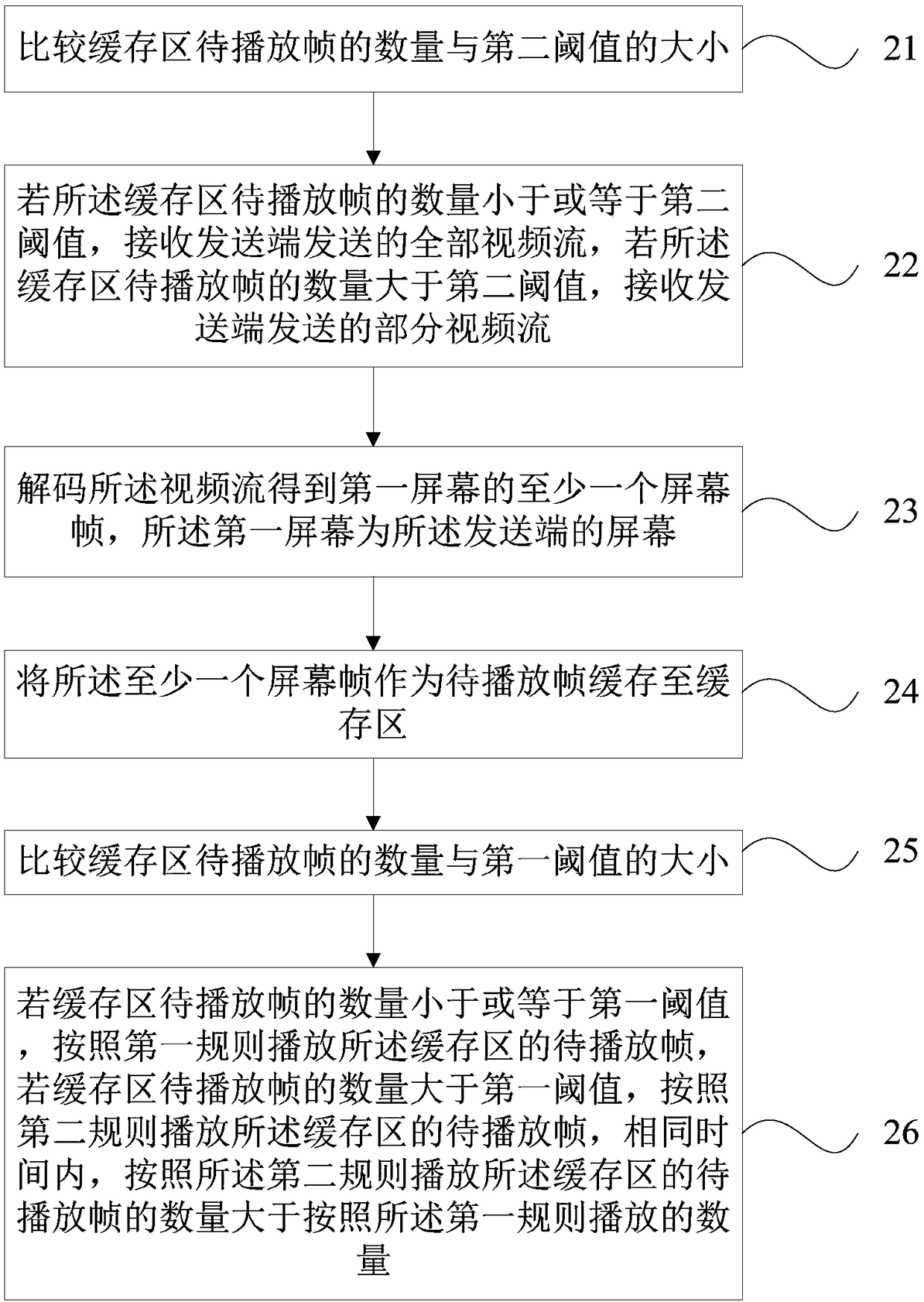

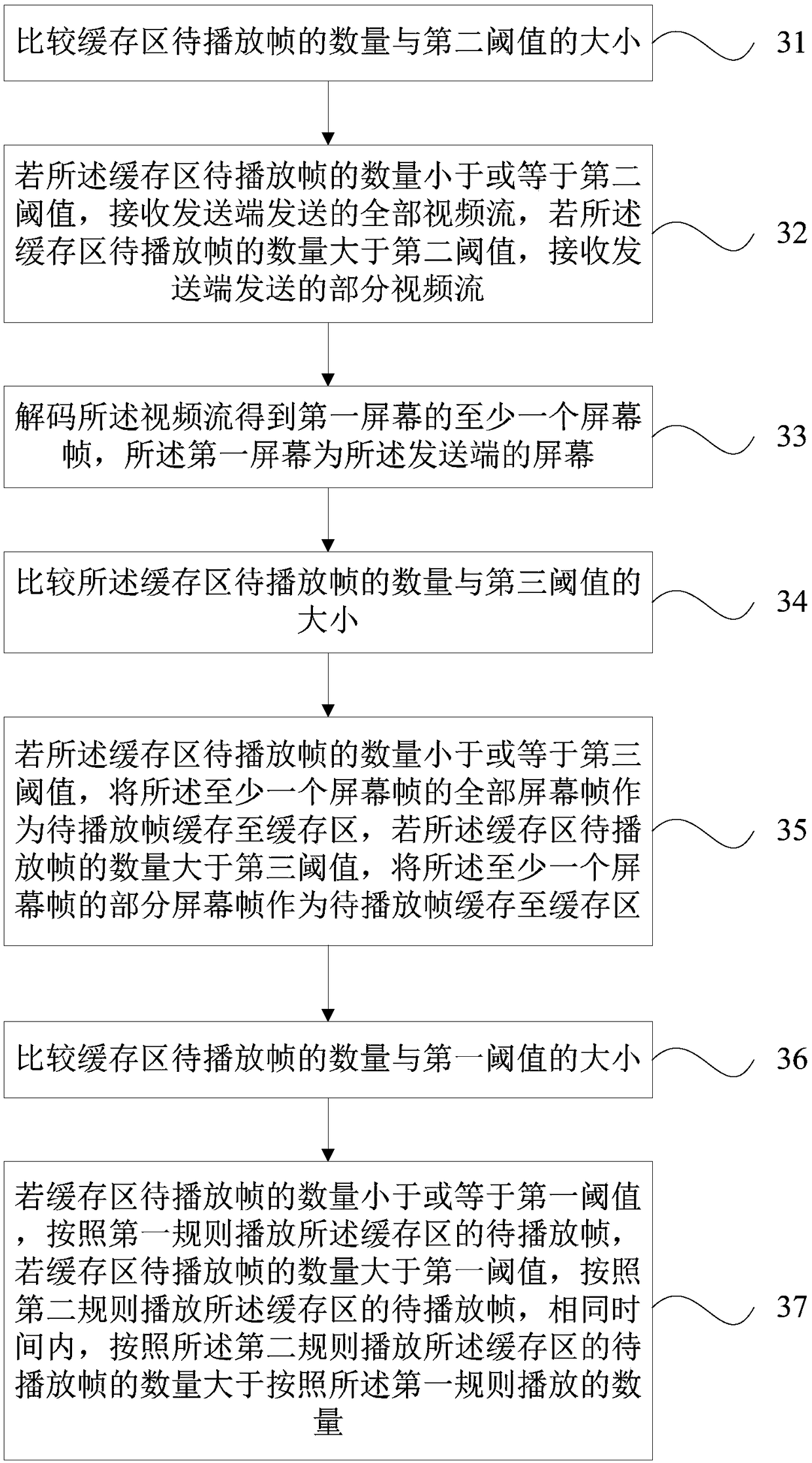

Wireless screen transmission method and device

InactiveCN109144445AClear fastAvoid accumulationTelevision system detailsColor television detailsTransmission technologyTime difference

The invention is applicable to the technical field of screen transmission, and a method and apparatus for wireless screen transmission are provided. The method includes steps: receiving a video streamsent by the sending end, decoding the video stream to obtain at least one screen frame of the first screen, at least one screen frame being buffered to a buffer area as a frame to be play, comparingthe number of frames to be played in the buffer area with the size of the first threshold value, if the number of frames to be played in the buffer area is less than or equal to the first threshold value, playing a frame to be played in the buffer area according to the first rule, otherwise, the frame to be played in the buffer area is played according to the second rule, within the same time, thenumber of frames to be played in the playback buffer area according to the second rule is larger than the number of frames to be played in the playback buffer area according to the first rule. The invention accelerates the clearance speed of the frame to be played in the buffer area of the receiving end, avoids the accumulation of a large number of frames to be played in the buffer area of the receiving end, thereby shortening the playback time difference between the receiving end and the sending end, and solves the problems that the receiving end and the sending end are not synchronous and the playback delay is long in the prior art wireless screen transmission technology.

Owner:深圳市创易联合科技有限公司

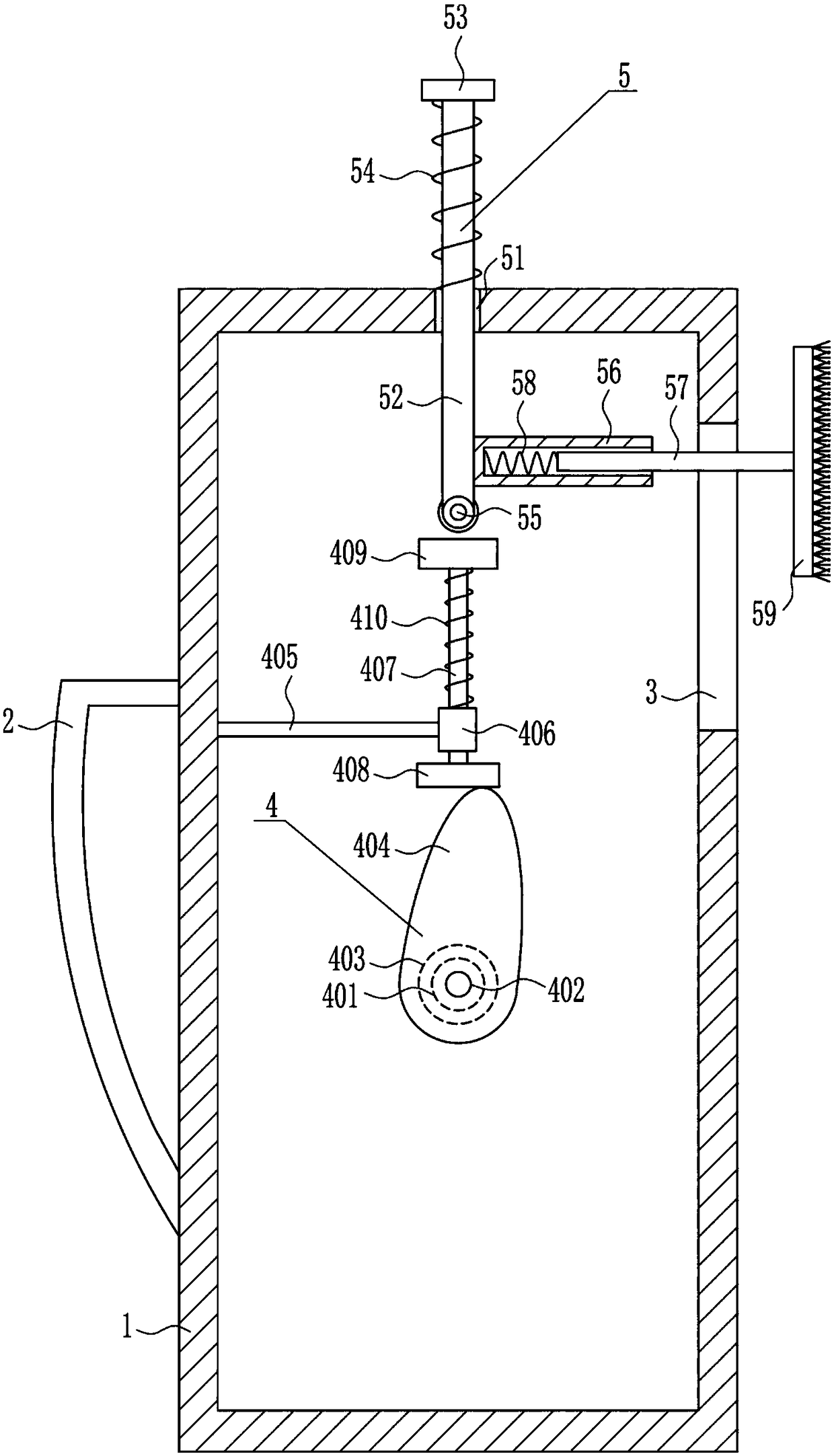

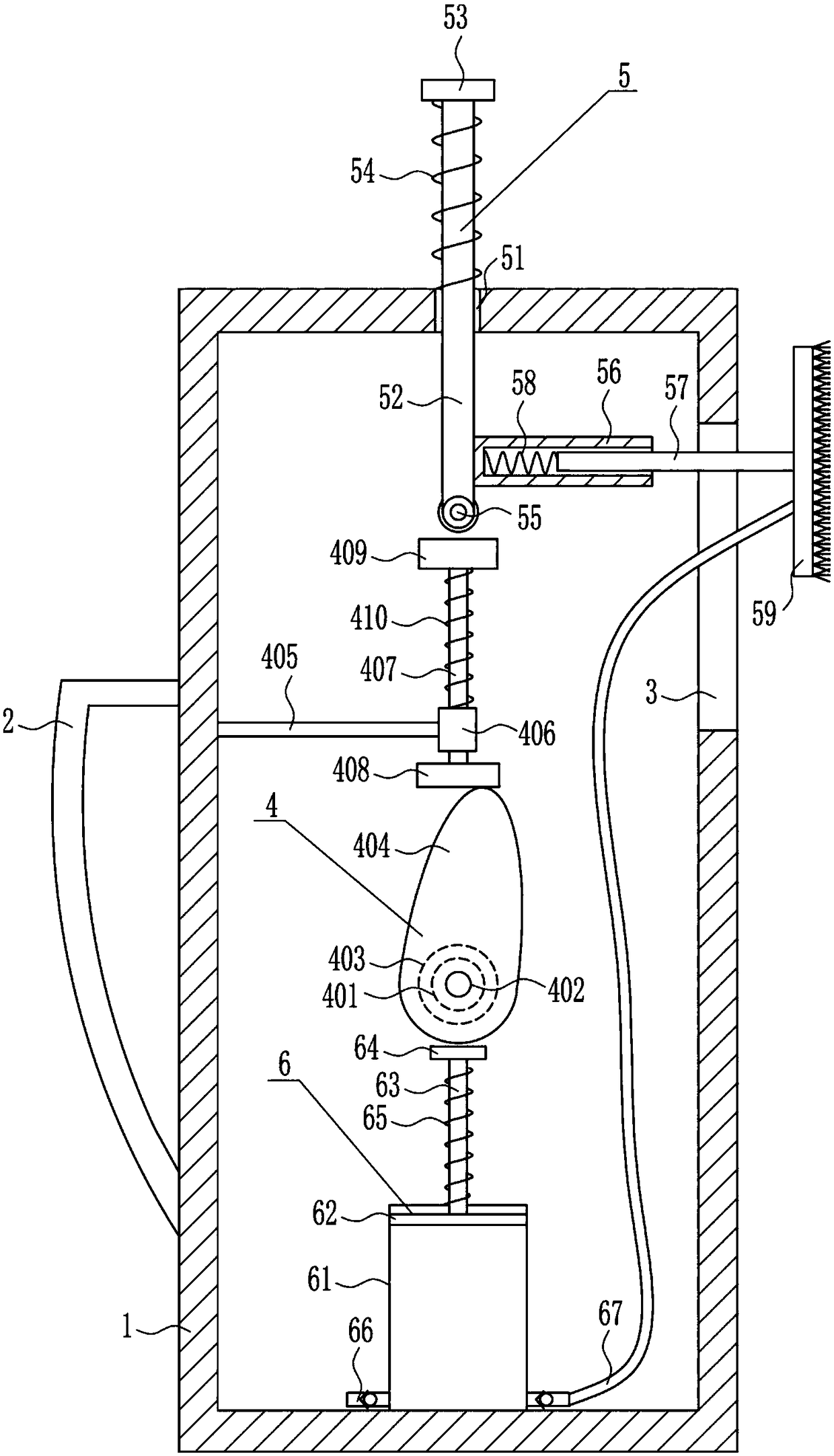

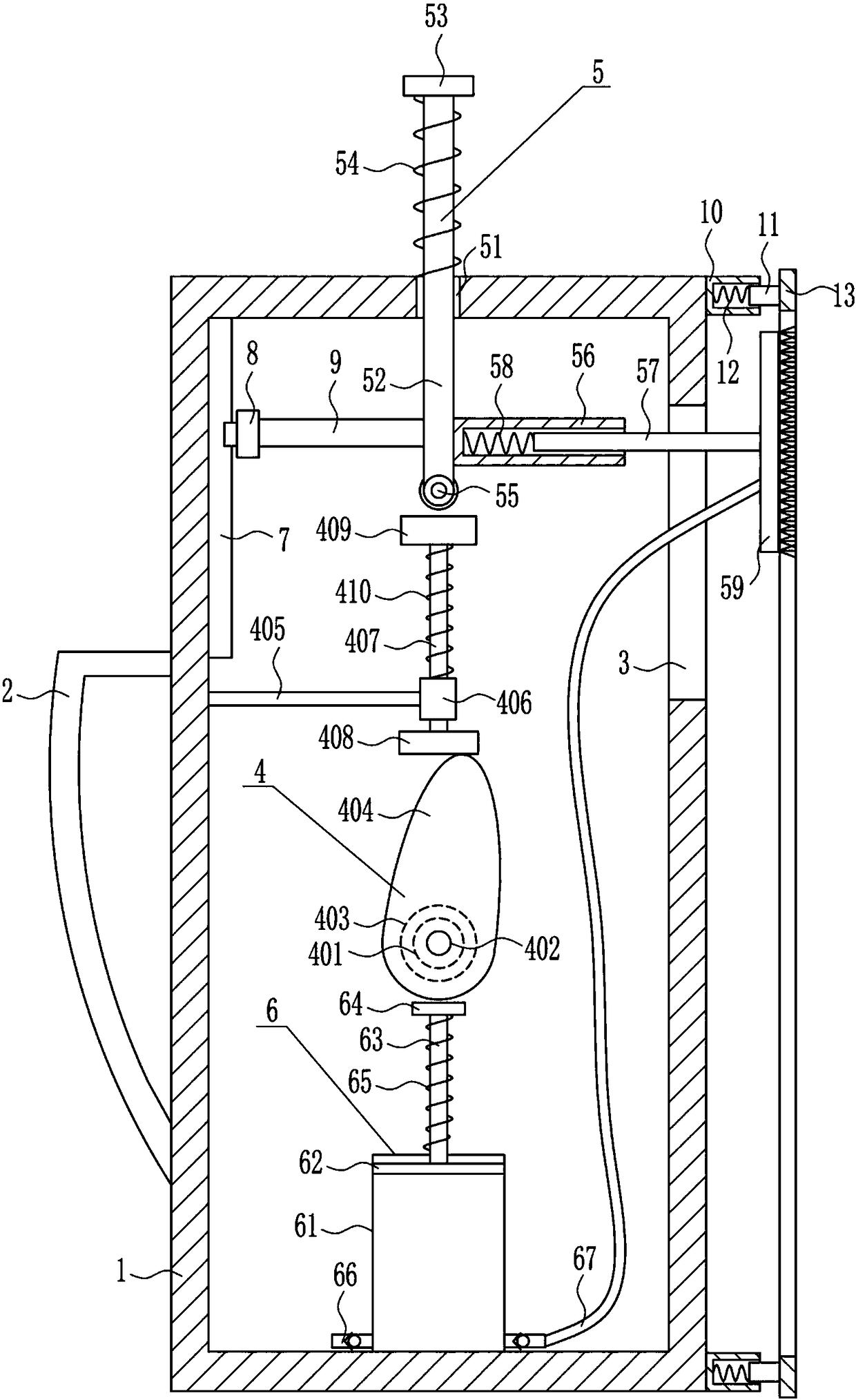

Solar water heater solar energy tube dust removal device

InactiveCN108458501AGood dust removalImprove dust removal effectSolar heating energySolar heat collectors safetySolar waterEngineering

The invention relates to a dust removal device, in particular to a solar water heater solar energy tube dust removal device which is provided for achieving the technical effects that the cleaning speed is high, and cleaning is sufficient and complete. In order to achieve the technical effects, The solar water heater solar energy tube dust removal device provided by the invention comprises a box and the like. A handle is mounted in the middle portion of the left side of the box. The upper portion of the right side of the box is provided with an opening. A driving device is arranged in the middle portion of the interior of the box. A dust removal device is arranged on the upper portion of the interior of the box. A dust removal component of the dust removal device is located on the upper portion of the right side of the exterior of the box. The solar water heater solar energy tube dust removal device drives the dust removal device to remove dust from solar energy tubes through the driving device, thereby achieving the effects of being high in cleaning speed and capable of sufficiently and completely removing the dust.

Owner:刘飞云

Injection molding piece clamping device

ActiveCN108297000AEasy to holdHigh safety and energy savingEdge grinding machinesClampsEngineeringInjection molding machine

The invention belongs to the technical field of clamping devices, and particularly discloses an injection molding piece clamping device. The injection molding piece clamping device comprises a rack, an inner ring clamping mechanism, an outer ring clamping mechanism and a flash removal mechanism; the inner ring clamping mechanism comprises a first strut, a first support is arranged on the first strut and is provided with a first clamping block, and a first threaded sleeve is arranged on the first strut; the outer ring clamping mechanism comprises a second strut, a second support is hinged to the second strut, a second clamping block is arranged on the second support, a second threaded sleeve is arranged on the second strut, and a compression sheet is arranged on the second threaded sleeve;and the flash removal mechanism comprises a first motor, a first roller, an electric conduction block, an insulation spring and an electric heating blade, the first roller is arranged on the second clamping block, the first motor is arranged on the rack, the output end of the first motor is connected with the first roller, and the insulation spring is connected with the second clamping block and the electric heating blade. The injection molding piece clamping device aims at solving the problems that pipe-shaped injection molding pieces are difficult to clamp, and injection molding pieces withdifferent diameters need to use different clamps.

Owner:重庆雷钜电子科技有限公司

Loading gate with force eliminating and silt removing functions for hydraulic engineering

The invention relates to a loading gate with force eliminating and silt removing functions for hydraulic engineering. The loading gate comprises a beam, a gate flap, a limiting column and two supporting columns, wherein a driving mechanism is arranged in the beam; a scraping mechanism is arranged in the gate flap; a plurality of buffer gears are arranged between the gate flap and the supporting columns; the scraping mechanism comprises a first motor, a worm and two moving units; a clearing mechanism comprises a swing plate, a groove, a fixed shaft and a movable trough; the buffer gears comprise first chutes and third chutes. According to the loading gate with force eliminating and silt removing functions for hydraulic engineering, silts and wastes stacked in the limiting groove at the bottom of the loading gate can be removed by the scraping mechanism and the clearing mechanism, and the condition that the loading gate cannot be normally closed due to the silts and wastes is avoided. Moreover, due to the buffer gears, impact force of underflow to the gate flap can be reduced by the loading gate, and the condition that the gate flap deforms due to non-uniform stress at each position,so that the sealing performance of the loading gate is prevented from being reduced.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

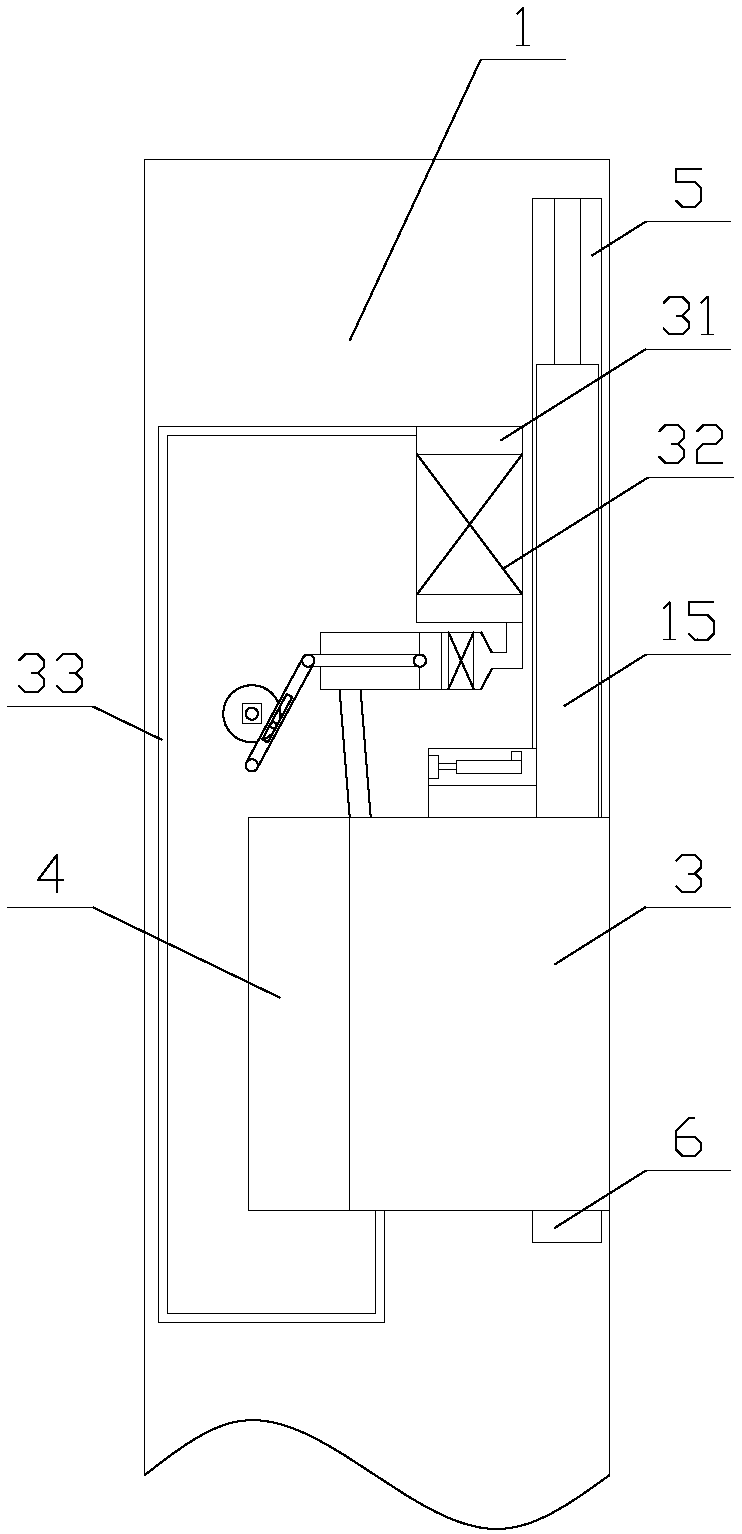

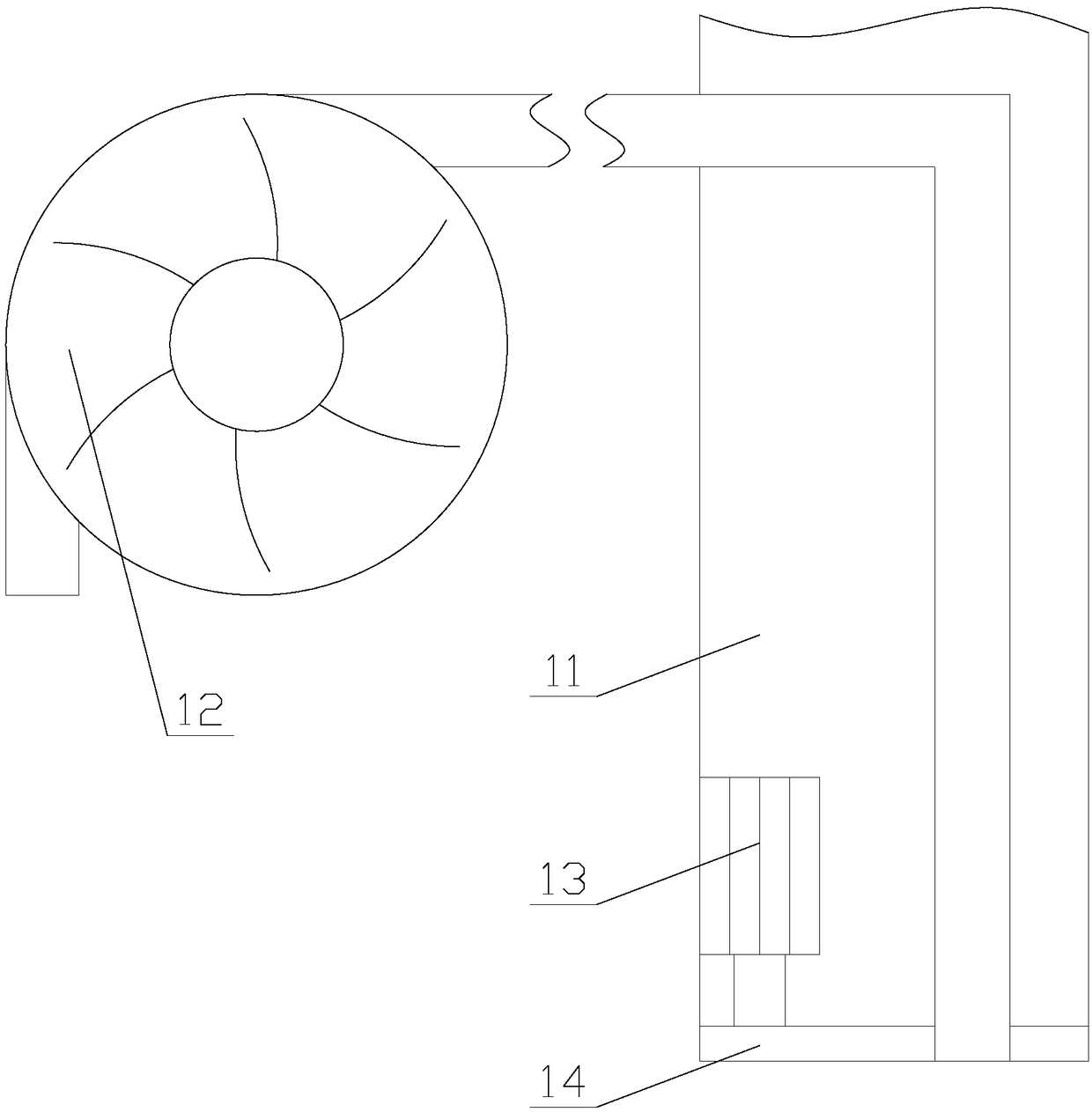

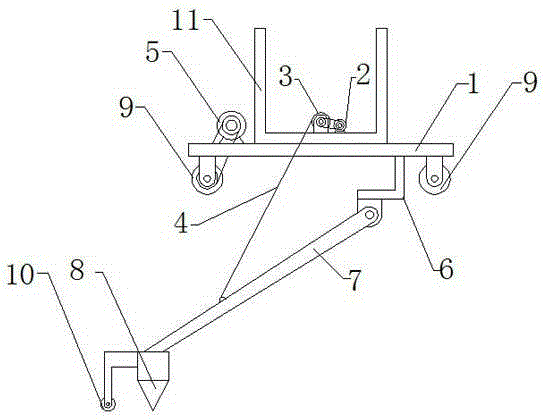

Device for quickly lifting and clearing crucible of vacuum furnace

InactiveCN106017087AReduce lossAccurate and fast cleaningCharge treatment typeTrolley cranesCrucibleEngineering

The invention discloses a device for quickly lifting and clearing a crucible of a vacuum furnace. The device for lifting and clearing the crucible of the vacuum furnace comprises a furnace body. A furnace door is arranged on the left side of the furnace body, and can horizontally move on a furnace door guide rail; the crucible is connected with the furnace door, and can horizontally move along with the furnace door; a lifting machine horizontally runs on a crane rail; limiting stoppers are arranged on two ends of the crane rail; a motor is arranged on a crucible clearing device, so that the positive and negative turning of a crucible rack can be controlled; and a dust collection device comprises a gas-collecting hood, an induced draft fan, a ventilating pipe and a purifier. The device for lifting and clearing the crucible of the vacuum furnace provided by the invention has the advantages that after alloy smelting is finished, the lifting machine can be accurately and quickly utilized for lifting the crucible and putting the crucible into the crucible clearing device, waste heat of the crucible is utilized for quickly clearing alloy adhered to a wall of the crucible, and the dust collection device can be used for purifying waste gas produced during the crucible purifying and clearing process, so that the efficiency is high, the clearing speed is quick, the energy loss is saved, and the economy and the environment protection in use are realized.

Owner:江苏立美航材科技有限公司

Automatic cleaning device of machine tool worktable

InactiveCN107775433AImprove securityClear fastMaintainance and safety accessoriesEngineeringConductor Coil

The invention relates to an automatic cleaning device for a machine tool workbench. It is mainly designed to solve the problem that the chute of the existing machine tool table is difficult to clean. It includes installation frame, iron chip collection tank, winding roller, motor, transmission belt, brush head and operation panel. The T-shaped brush head is clamped in the chute of the machine tool console, and the iron chip collection tank is fixedly connected to the bottom of the installation frame. The two ends of the rotating shaft of the winding roller are movably connected with the mounting frame, and the ends of the rotating shaft of the winding roller are connected with the output shaft of the motor, and the motor is installed at the front and rear ends of the mounting frame. There are two mounting frames, two iron scrap collecting tanks and two winding rollers, the brush head is connected to the lower surface of the transmission belt, and the two ends of the transmission belt are wound on the two winding rollers. The operation panel is arranged on the outer wall of the installation frame. The installation frame is connected with the chip collecting tank by screws, and the chip collecting tank is located under the winding roller. The advantage is that the removal speed is fast and the efficiency is high.

Owner:朱丽辉

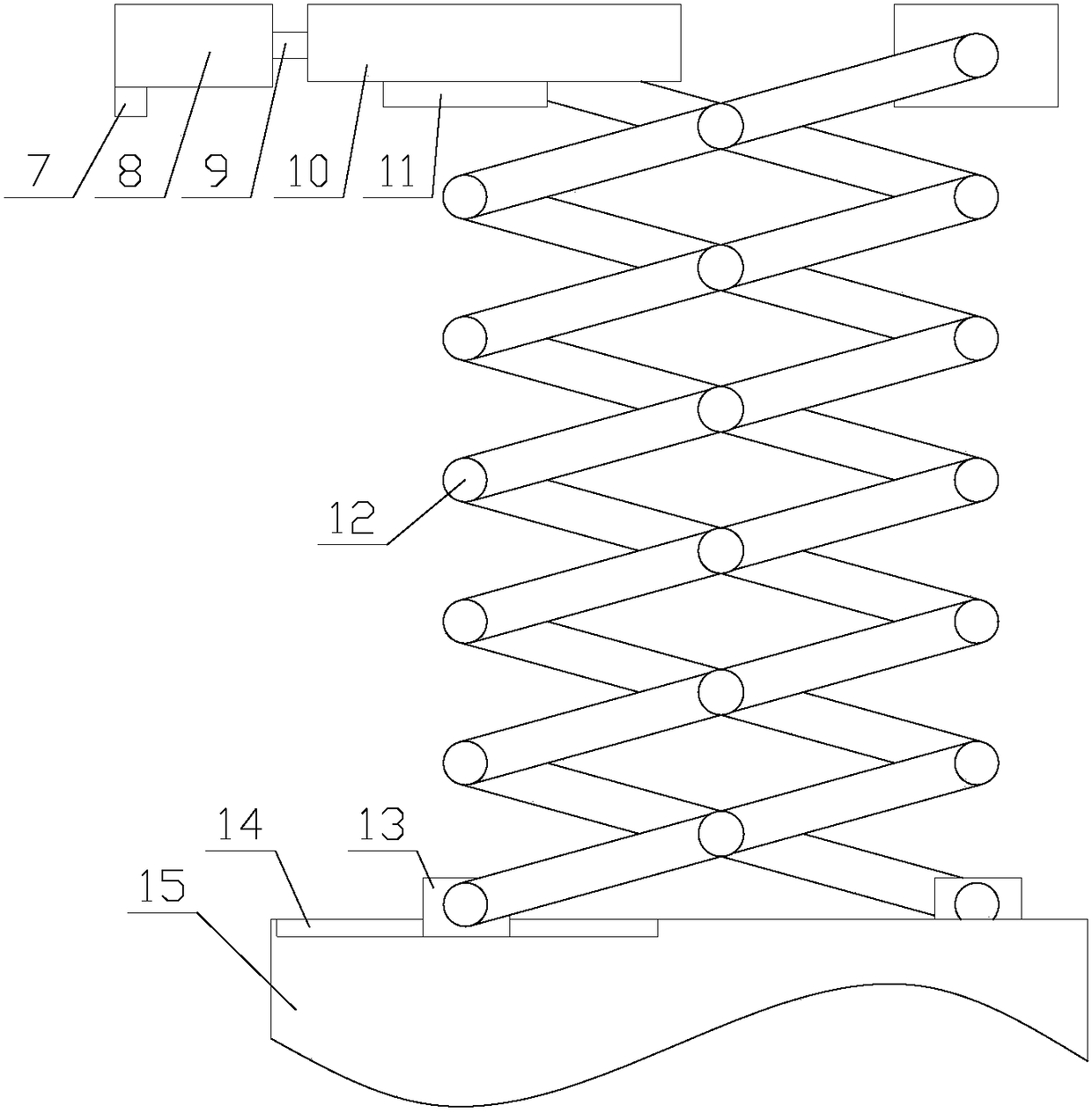

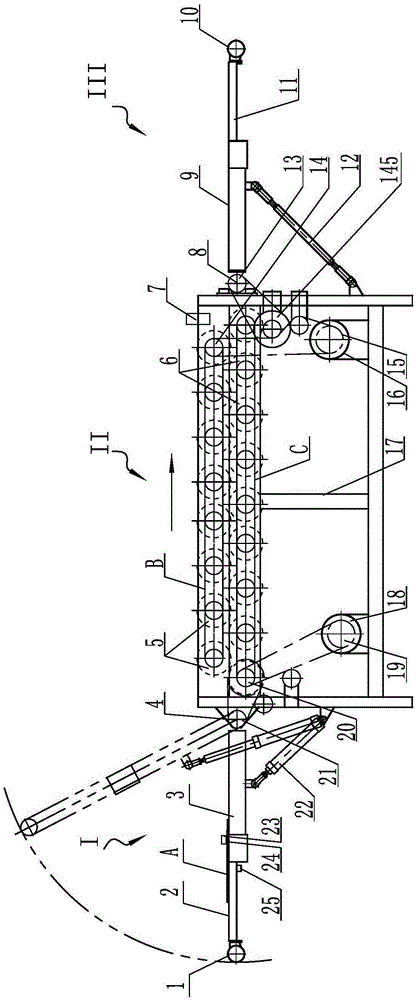

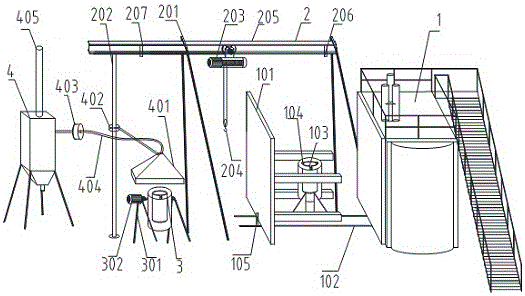

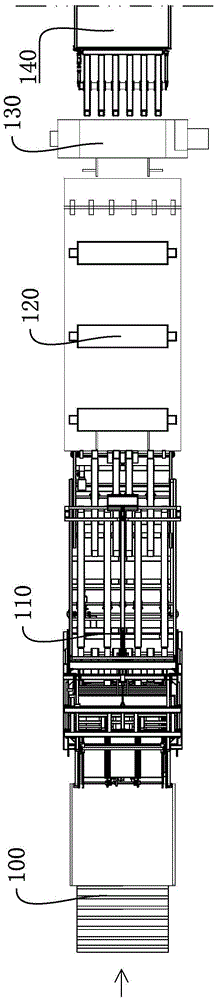

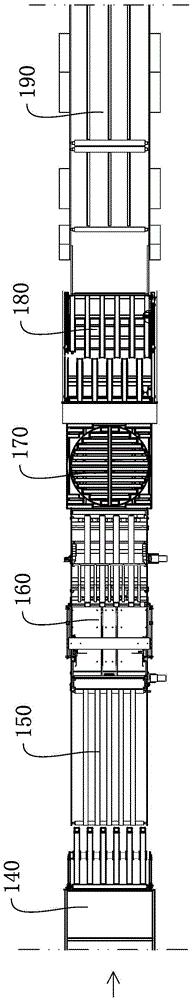

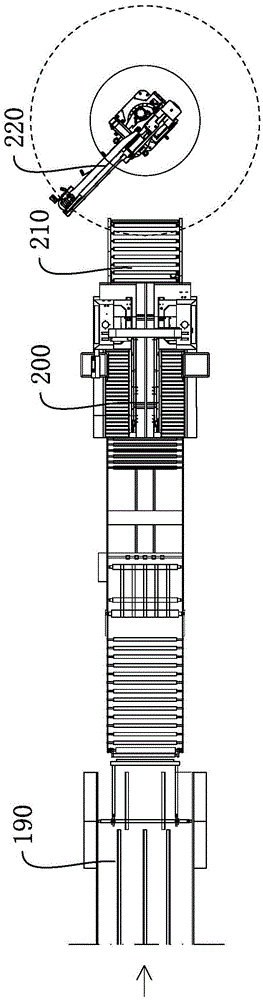

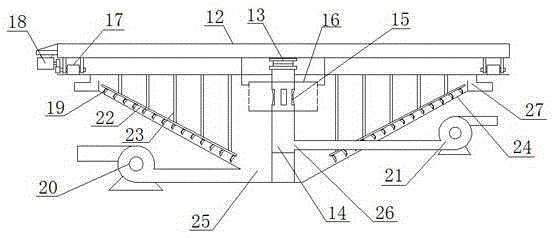

Ink-printing corrugated carton linkage production method and production line

InactiveCN105538778ARealize continuous productionImprove efficiencyPaper-makingBox making operationsProduction lineCardboard

The invention discloses an ink-printing corrugated carton linkage production method. The ink-printing corrugated carton linkage production method comprises the following steps, sequentially completed on a production line, of conducting die cutting and shaping on corrugated boards on a column to column die cutting machine, conducting debris removing on the corrugated boards subjected to die cutting and shaping on a board debris removing machine, face turning, rotating, carton pasting and packing, conducting front-and-back gauging and left-and-right gauging on packed cartons on a gauging mechanism and stacking and film wrapping. The invention further discloses a linkage production line embodying the ink-printing corrugated carton linkage production method. The linkage production line comprises the column to column die cutting machine, the board debris removing machine, a board turning machine, a board rotating machine, a board feeding machine, a carton pasting machine, a packing machine, a locating and gauging mechanism, a robot stacking machine and a wrapping machine which are sequentially arranged. Communication and speed synchronization of all single-machine devices of the production line is controlled by a central electric control system. By means of the ink-printing corrugated carton linkage production method and production line, the production efficiency of ink-printing corrugated cartons is improved, and the production cost is reduced.

Owner:边继庆

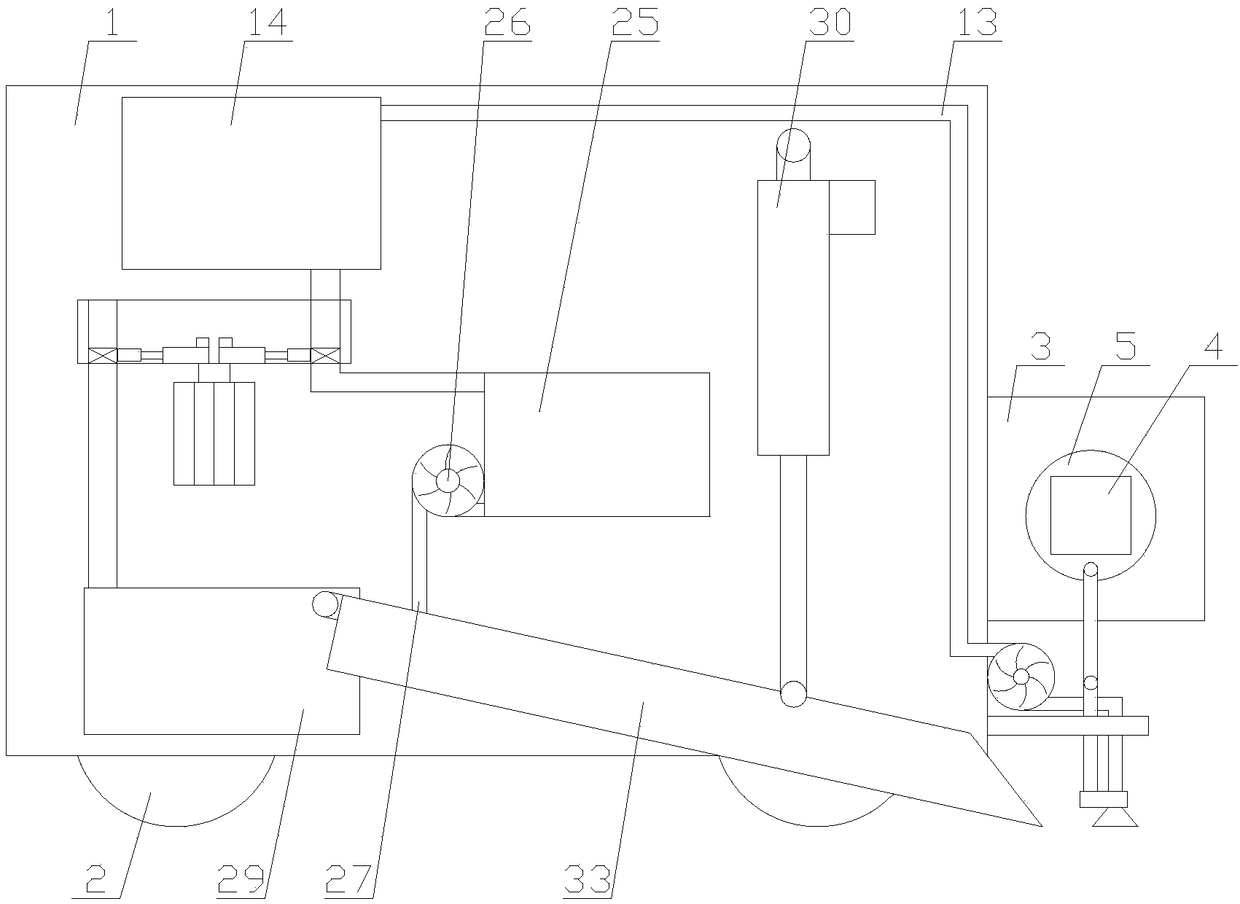

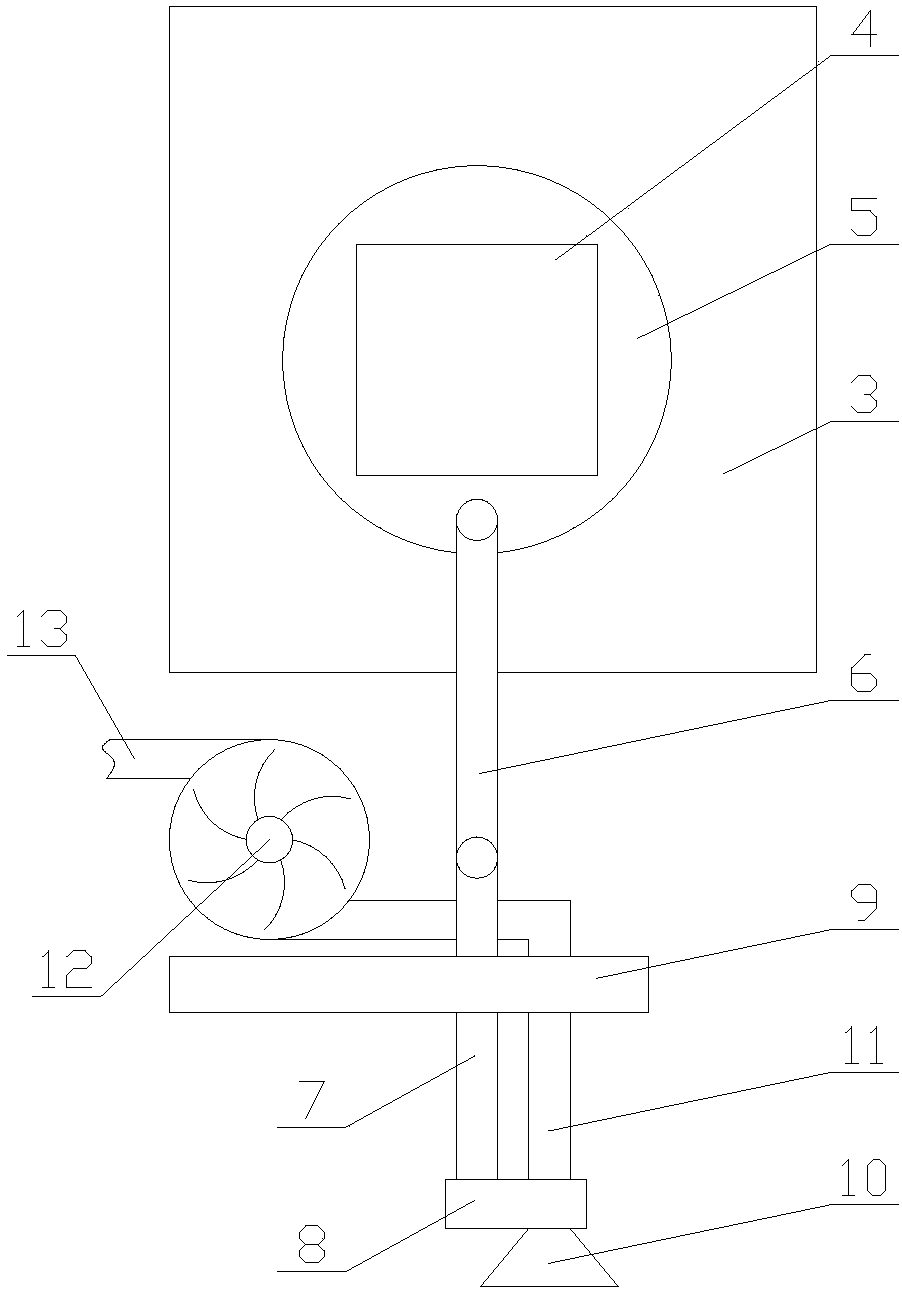

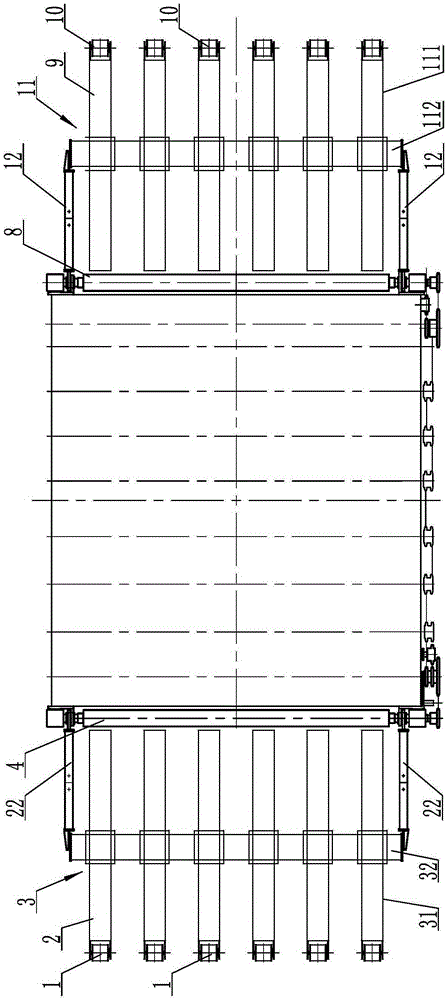

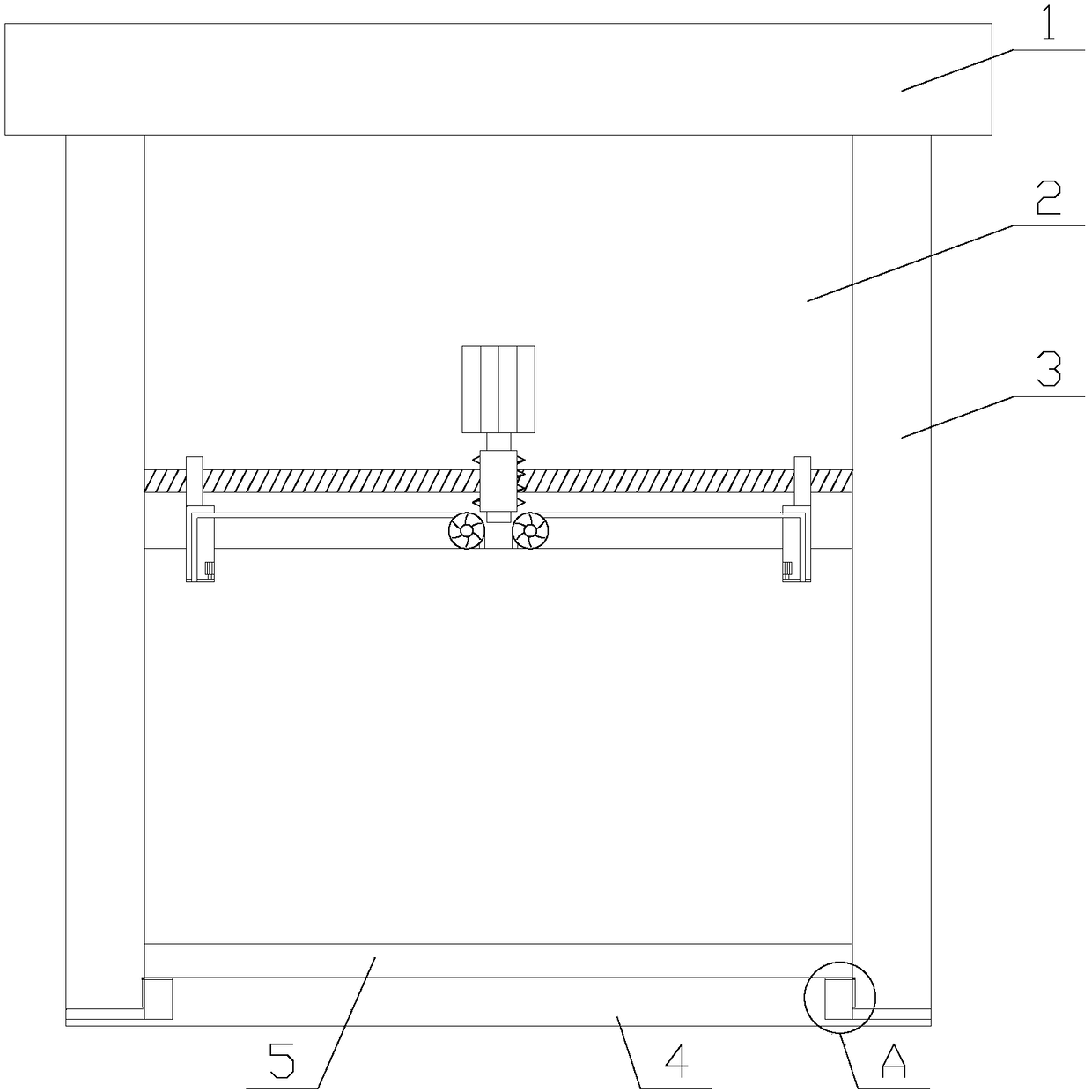

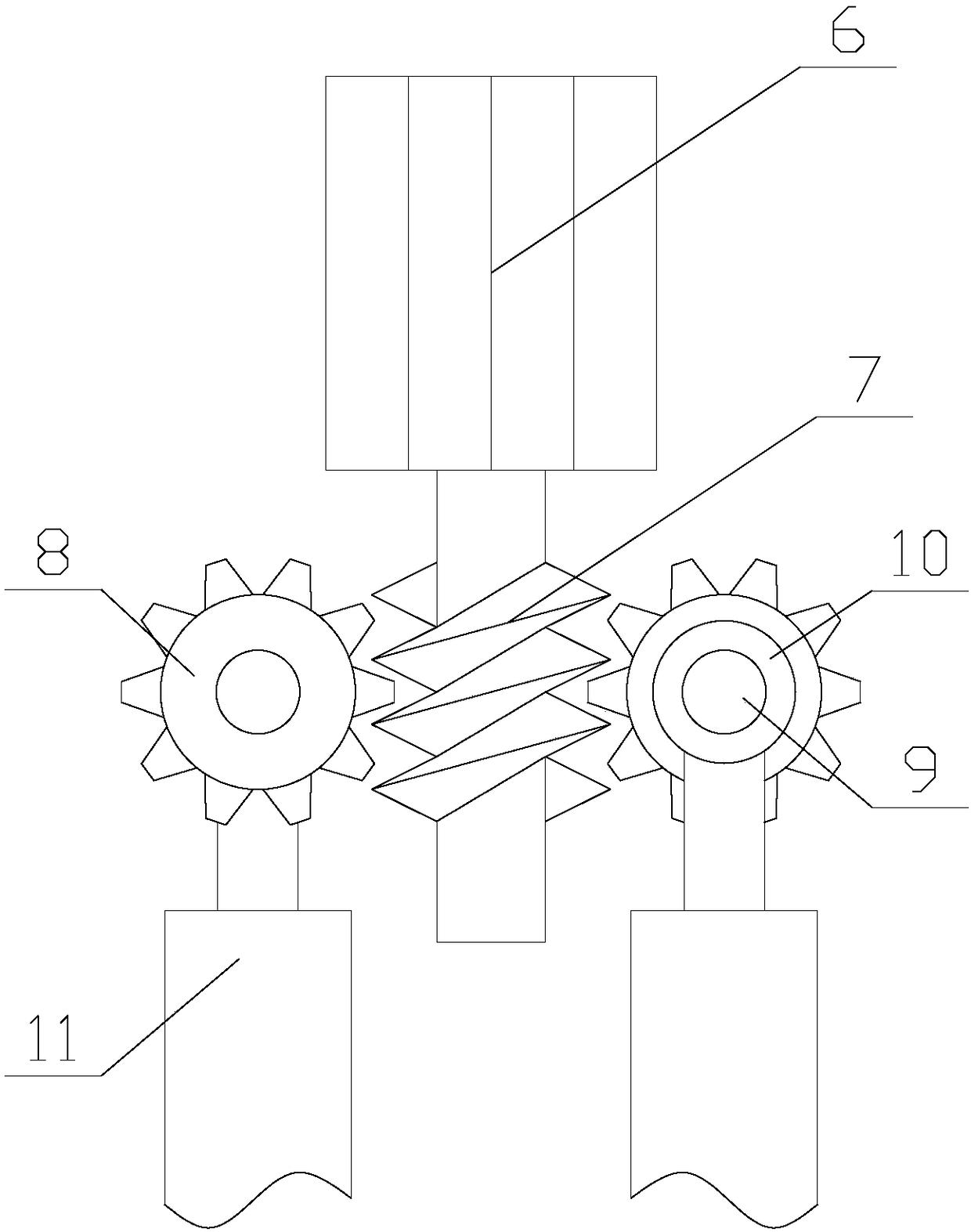

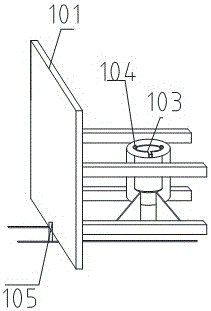

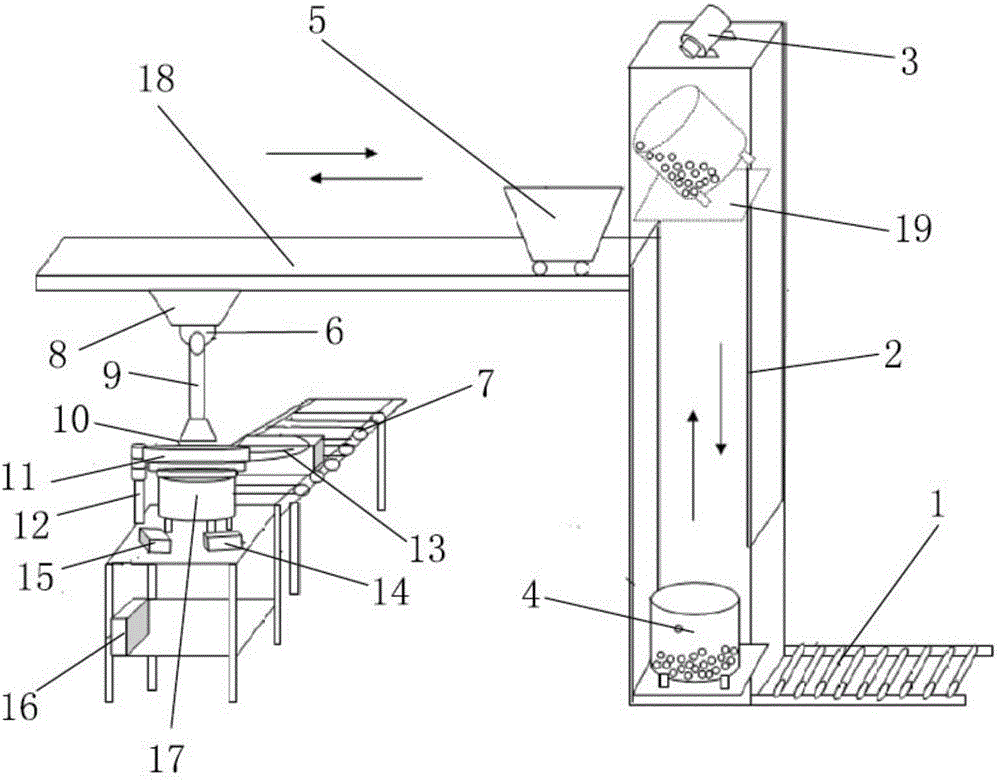

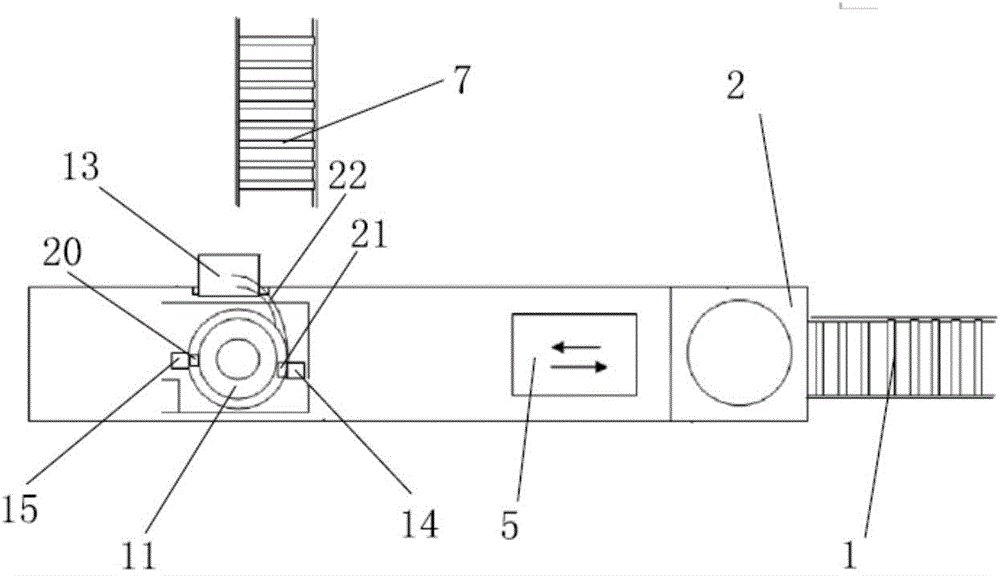

Full-automatic nut inspection machine

The invention relates to a full-automatic nut inspection machine. A roller conveying belt (1) is transversely mounted at the lower part of one side of a loading machine (2), and a material feeding rail (18) is transversely mounted at the upper part of the other side of the loading machine (2); a transferring table (19) capable of moving up and down is mounted in the loading machine (2); a material feeding trolley (5) capable of moving back and forth is mounted on the material feeding rail (18); a plurality of groups of inspection assemblies (17) are mounted below the material feeding rail (18) side by side. The full-automatic nut inspection machine has the characteristics of simple structure, low manufacturing cost, great increase of disqualified product clearing speed, lower labor cost, lower labor intensity of workers and the like.

Owner:宁波长华布施螺子有限公司

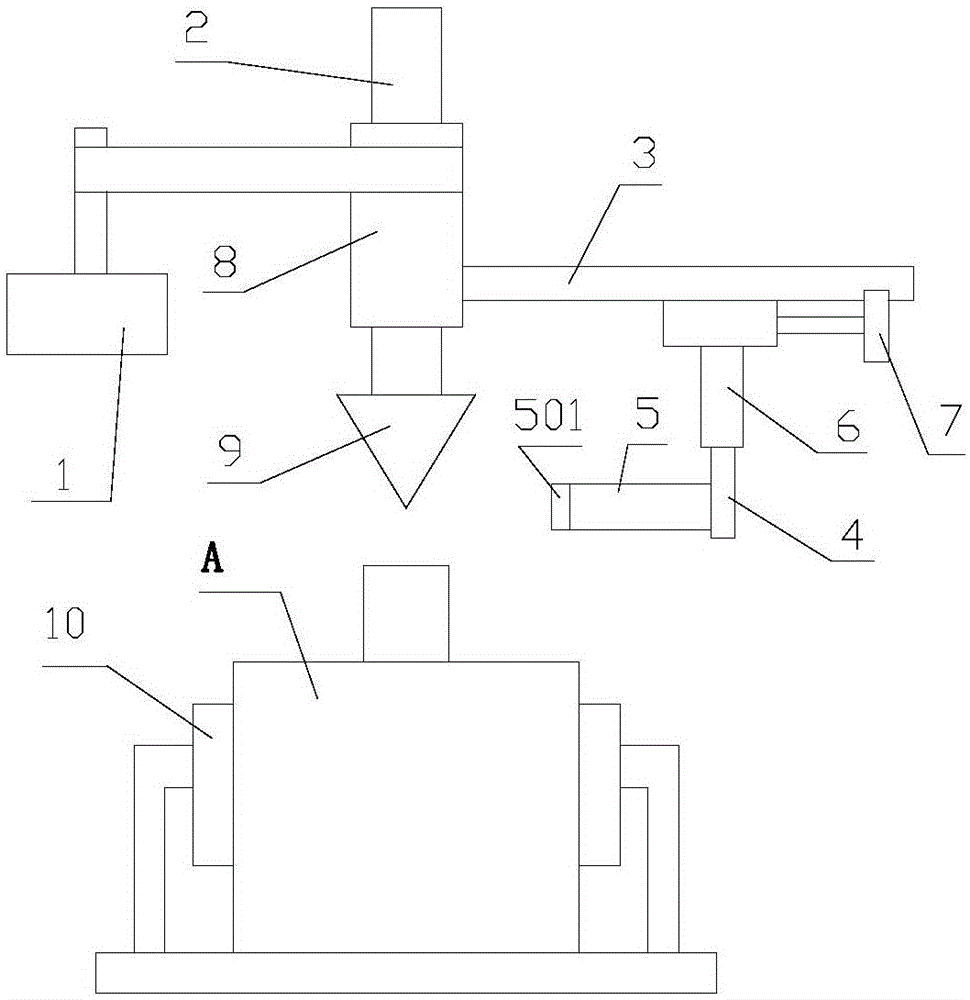

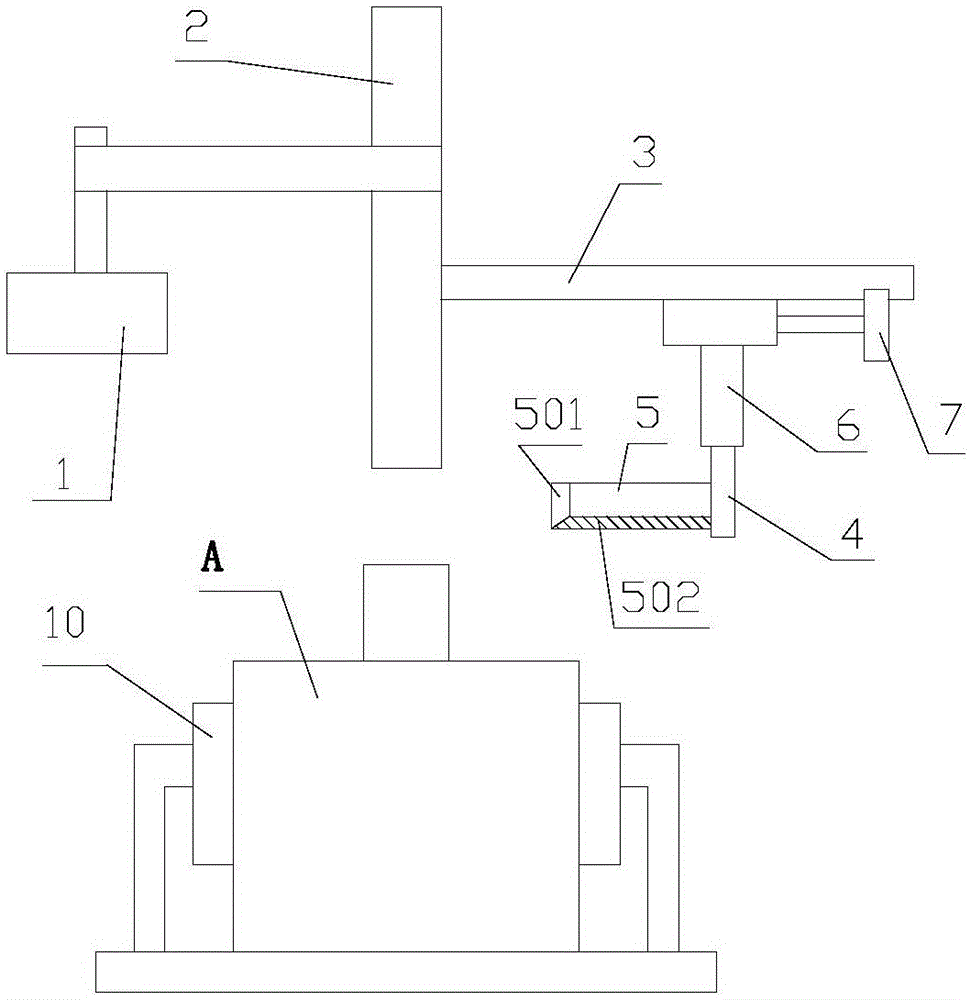

Device for removing oddments on mouth of packaging bottle

The invention discloses a device for removing oddments on the mouth of a packaging bottle. The device for removing the oddments on the mouth of the packaging bottle comprises a clamp used for clamping the packaging bottle and a removing mechanism used for removing the oddments on the mouth of the packaging bottle. The removing mechanism comprises a driving unit, a supporting rod, a cross rod, a connecting rod and a blade. The center line of the clamp coincides with the axis of the supporting rod. One end of the cross rod is connected with the supporting rod. The other end of the cross rod is connected with the connecting rod. The driving unit drives the cross rod to revolve with the axial direction of the supporting rod as the center. One end of the connecting rod is connected with the cross rod. The other end of the connecting rod is connected with the blade. The extension direction of the blade is perpendicular to the axial direction of the supporting rod or obliquely intersects with the axial direction of the supporting rod. By the adoption of the device, the oddments and burrs on the packaging bottle can be completely removed, the removing speed is high, and the effect is good.

Owner:芜湖友信激光模具有限公司

Oil-degrading composite bacterium and microbial inoculum applied to high salt environment

ActiveCN103232960AClear fastHigh activityBacteriaWater contaminantsSeawaterOrnithinimicrobium kibberense

The invention discloses an oil-degrading composite bacterium and microbial inoculum applied to a high salt environment. The composite bacterium is composed of a bacterium W25 and a bacterium W33, wherein the bacterium W25 is named Ornithinimicrobium kibberense of which the microbial collection number is CGMCC No.6844; the bacterium W33 is named Gordonia alkanivorans of which the microbial collection number is CGMCC No.6845; and the oil-degrading composite bacterium has the capacity for degrading oil in a high salt environment. The experiment proves that the composite bacterium and microbial inoculum disclosed by the invention have high speed for clearing oil pollution in a high salt environment; the composite bacterium and microbial inoculum disclosed by the invention have wide adaptability to salinity of the oil pollution environment, and can be applied to the high salt environment with the maximum salinity of 8% NaCl; and the composite bacterium and microbial inoculum disclosed by the invention can be used for quickly and effectively treating oil pollution salinized soil, oil pollution seawater, oil pollution wastewater and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +2

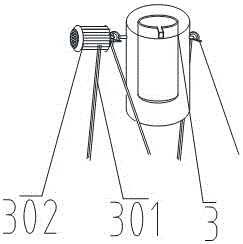

Sludge settling and removal system after sewage treatment

InactiveCN106693456AClear fastEasy to settleSettling tanks feed/dischargeSedimentation settling tanksEngineeringSludge settling

The invention discloses a sludge settling and removal system after sewage treatment. The sludge settling and removal system is characterized in that walking wheels are respectively arranged at the bottom parts of both ends of a transverse beam; a walking driving motor is fixedly arranged on the transverse beam and is in transmission connection with the walking wheels; a lifting rotary shaft is movably arranged on the transverse beam, a lifting driving motor is fixedly arranged on the transverse beam and is in transmission connection with the lifting rotary shaft, the upper end of a large frame is movably arranged on the transverse beam through a bracket, a sludge scraping shovel is fixedly arranged at the lower end of the large frame, one end of a lifting rope is wound on the lifting rotary shaft, and the other end of the lifting rope is fixedly arranged on the large frame; rollers are respectively arranged at both sides of the large frame, and the motor is fixedly arranged on the large frame and is in transmission connection with the rollers. The sludge settling and removal system has the advantages that the structural design is reasonable, the sludge removal speed is high, the time is saved, the labor intensity is decreased, the normal and smooth implementing of the sewage treatment is guaranteed, and the sewage treatment effect is good.

Owner:HUBEI JINHANJIANG REFINED COTTON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com