Injection molding piece clamping device

A clamping device, injection molding technology, applied in clamps, machine tools suitable for grinding workpiece edges, grinders, etc. energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

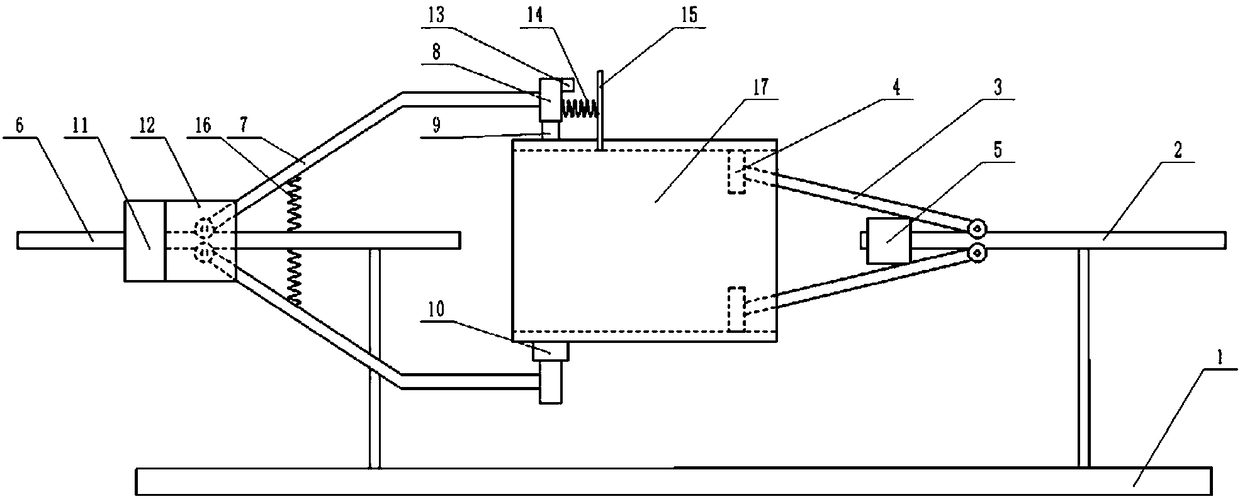

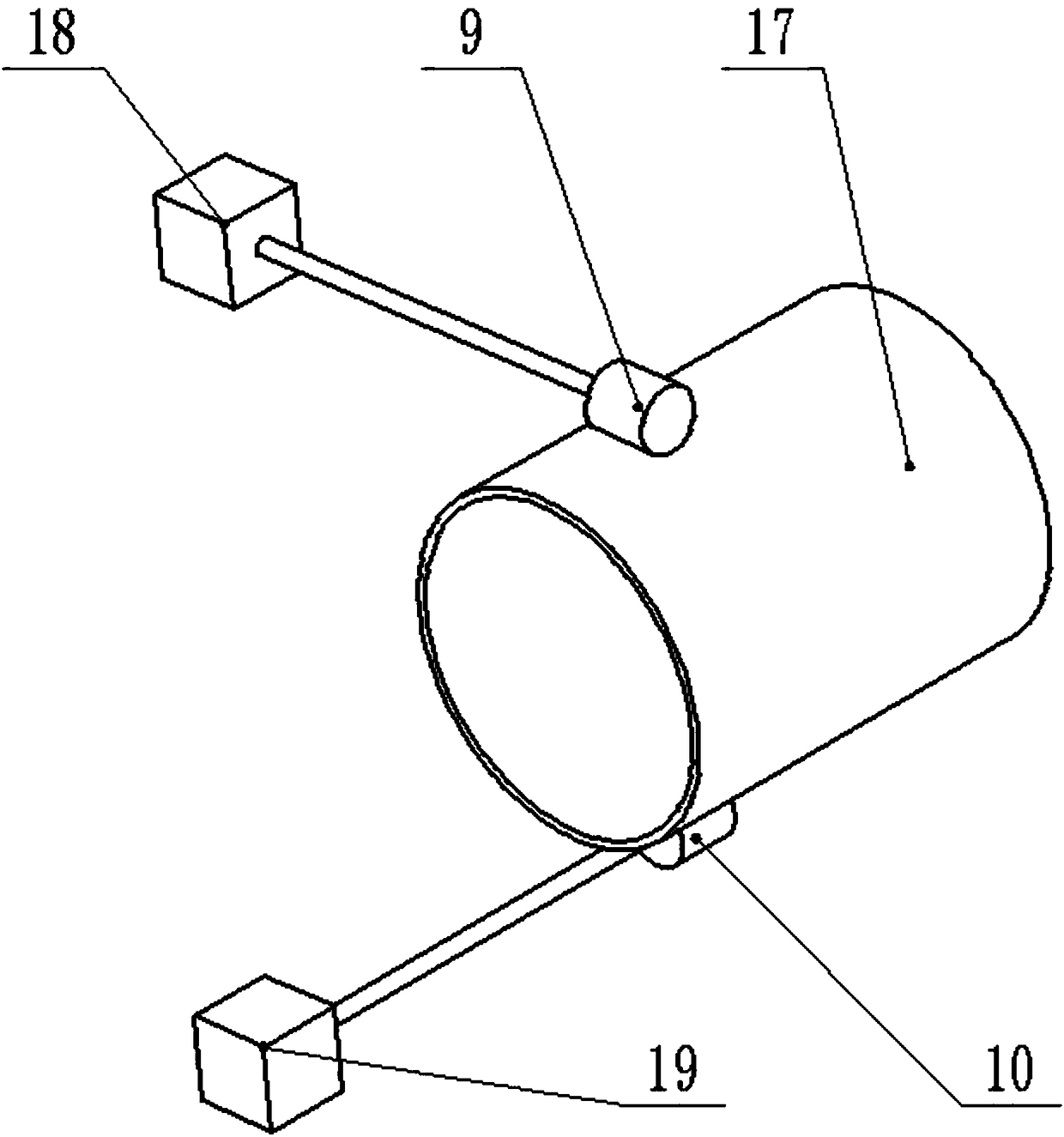

[0015] The reference signs in the drawings of the description include: frame 1, first pole 2, first bracket 3, first clamping block 4, first threaded sleeve 5, second pole 6, second bracket 7, second Two clamping blocks 8, first roller 9, second roller 10, second threaded sleeve 11, pressing piece 12, conductive block 13, insulating spring 14, electric heating blade 15, ordinary spring 16, injection molded part 17, first motor 18. The second motor 19.

[0016] Such as figure 1 , figure 2 As shown, the clamping device for injection molded parts in this embodiment includes a frame 1, a first strut 2 is provided on the right side of the frame 1, and two first brackets are respectively hinged on the upper side and the lower side of the first strut 2 3. The left end of each first bracket 3 is provided with a first clamping block 4, and the end of the first clamping block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com