Patents

Literature

33results about How to "Improve removal quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

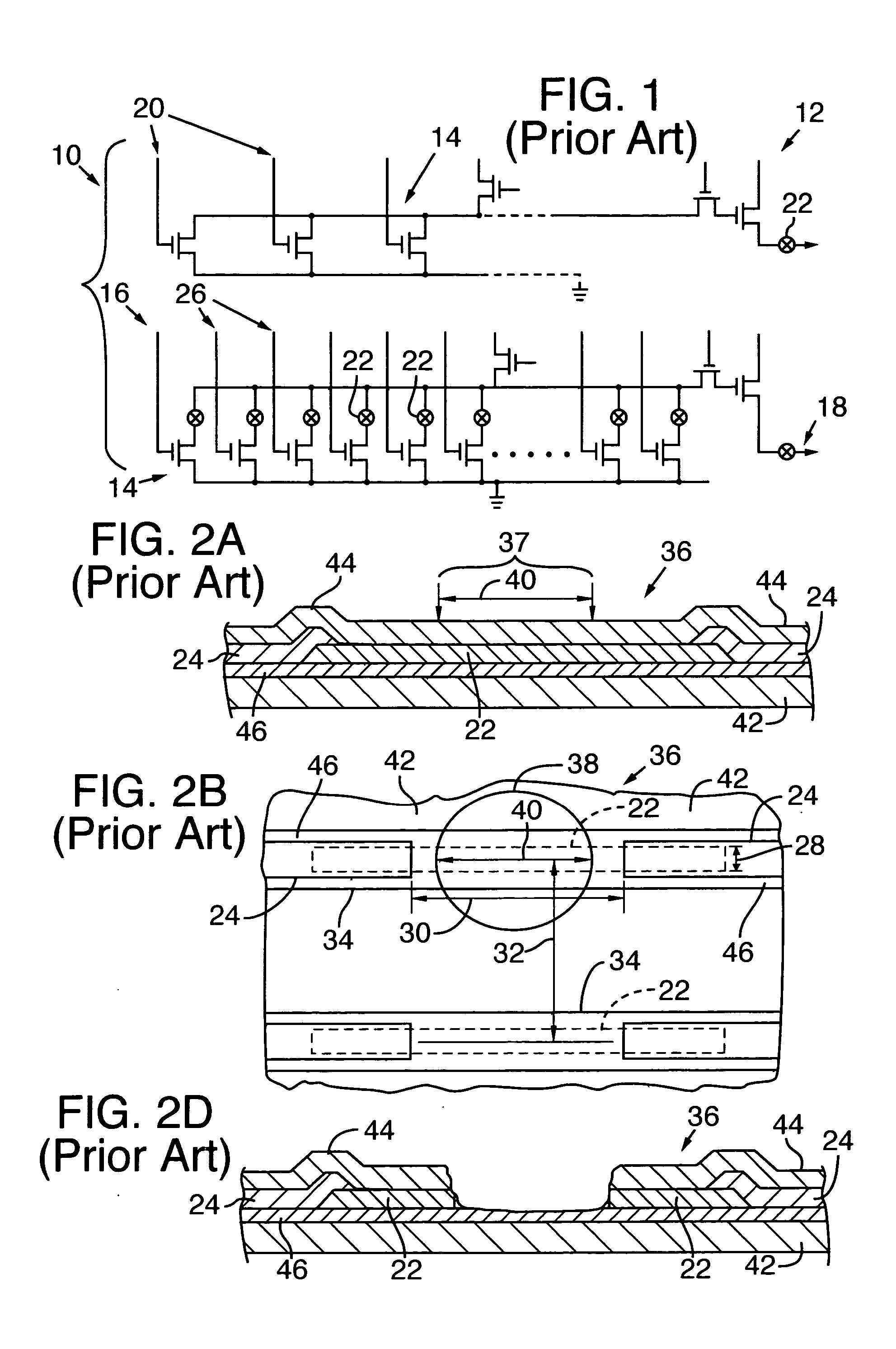

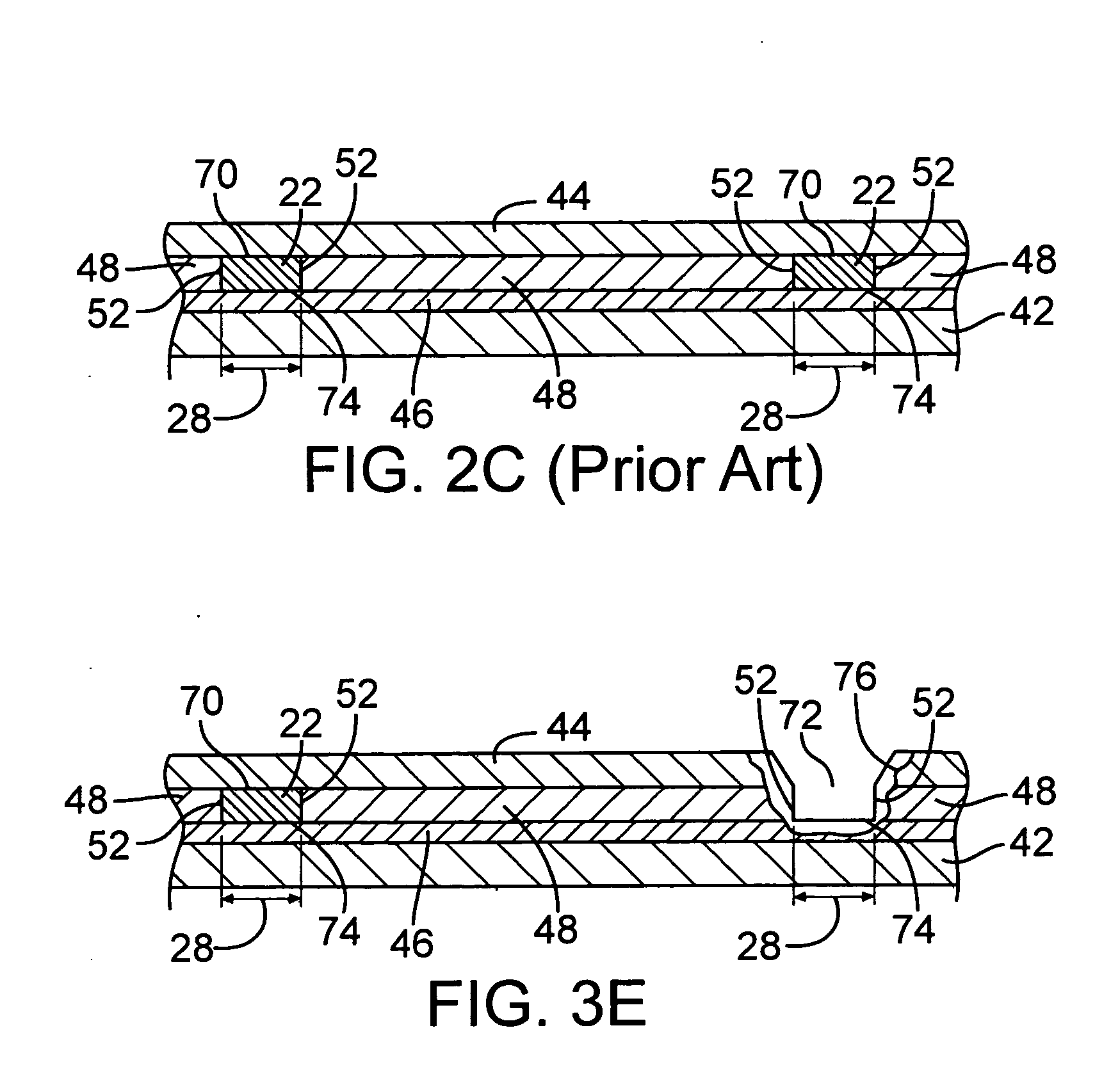

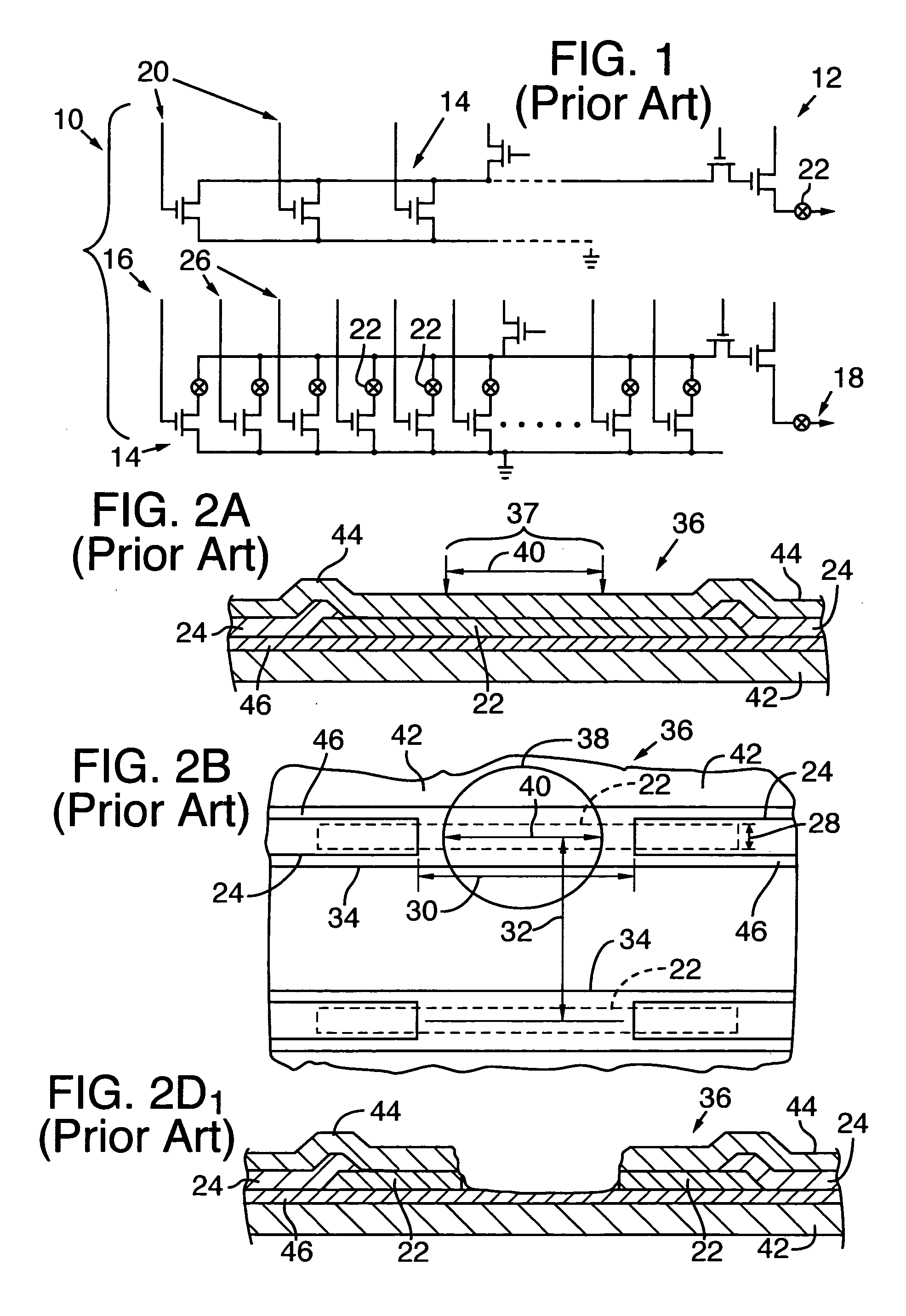

Methods of and laser systems for link processing using laser pulses with specially tailored power profiles

ActiveUS20050067388A1Improve removal qualityImprove processing qualityLaser detailsSemiconductor/solid-state device detailsPulse energyUltraviolet

Owner:ELECTRO SCI IND INC

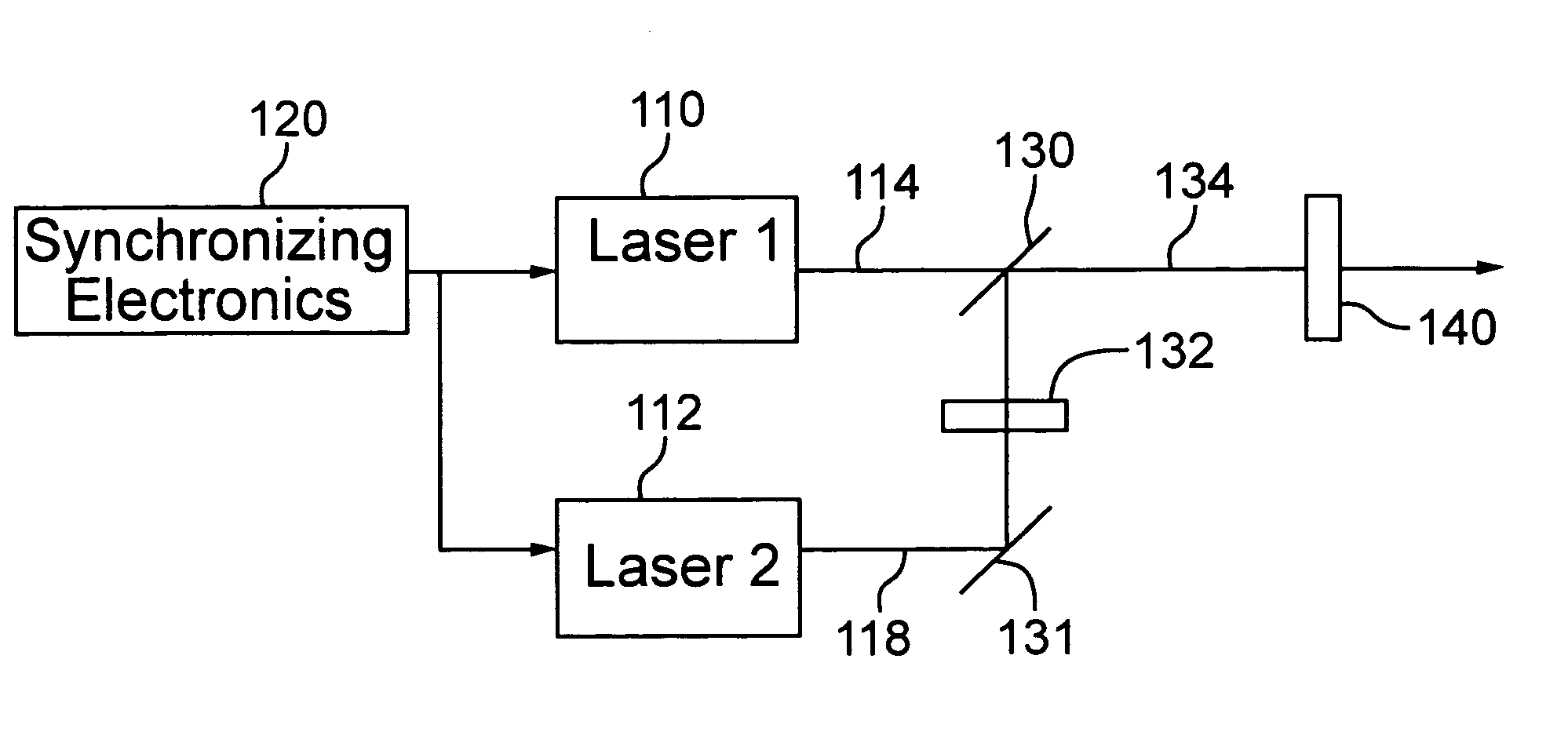

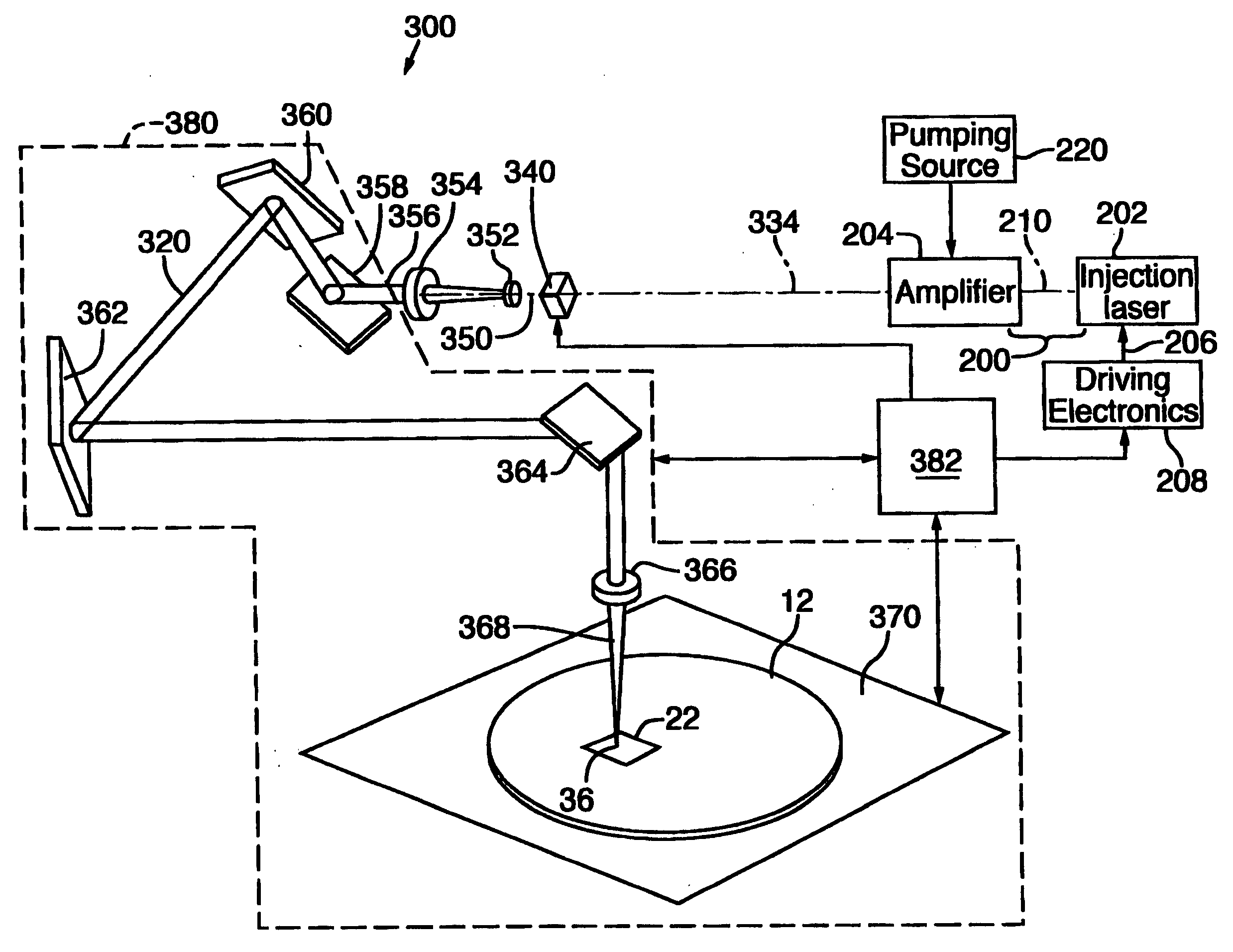

Generating sets of tailored laser pulses

ActiveUS20050041976A1Improve removal qualityComplicated processLaser detailsSemiconductor/solid-state device detailsAudio power amplifierMaster oscillator

In a master oscillator power amplifier, a driver (208) of a diode laser (202) is specially controlled to generate a set of two or more injection laser pulses that are injected into a power amplifier (204) operated in an unsaturated state to generate a set (50) of laser pulses (52) that replicate the temporal power profile of the injection laser pulses to remove a conductive link (22) and / or its overlying passivation layer (44) in a memory or other IC chip. Each set (50) includes at least one specially tailored pulse (52) and / or two or more pulses (50) having different temporal power profiles. The duration of the set (50) is short enough to be treated as a single “pulse” by conventional positioning systems (380) to perform on-the-fly link removal without stopping.

Owner:ELECTRO SCI IND INC

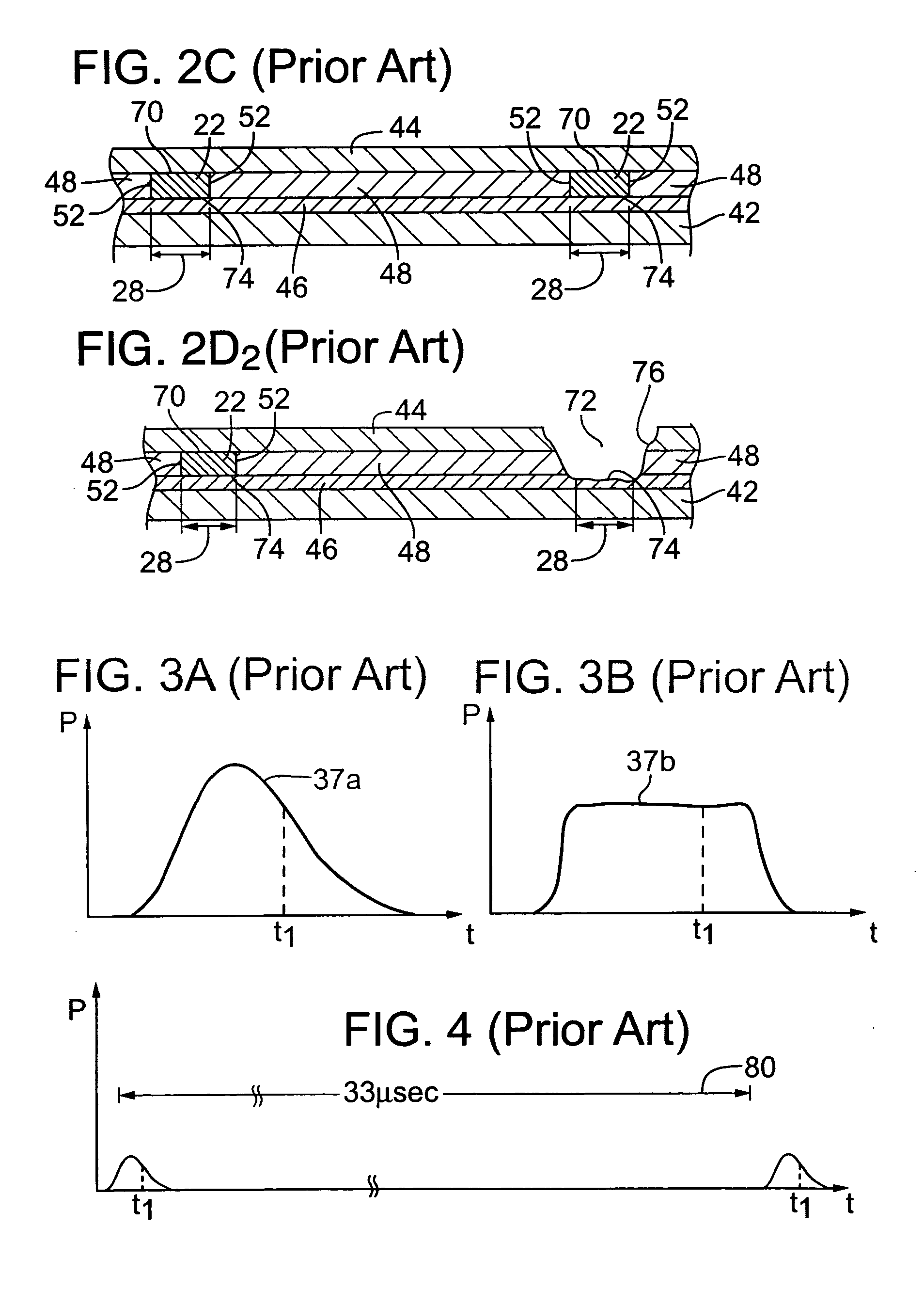

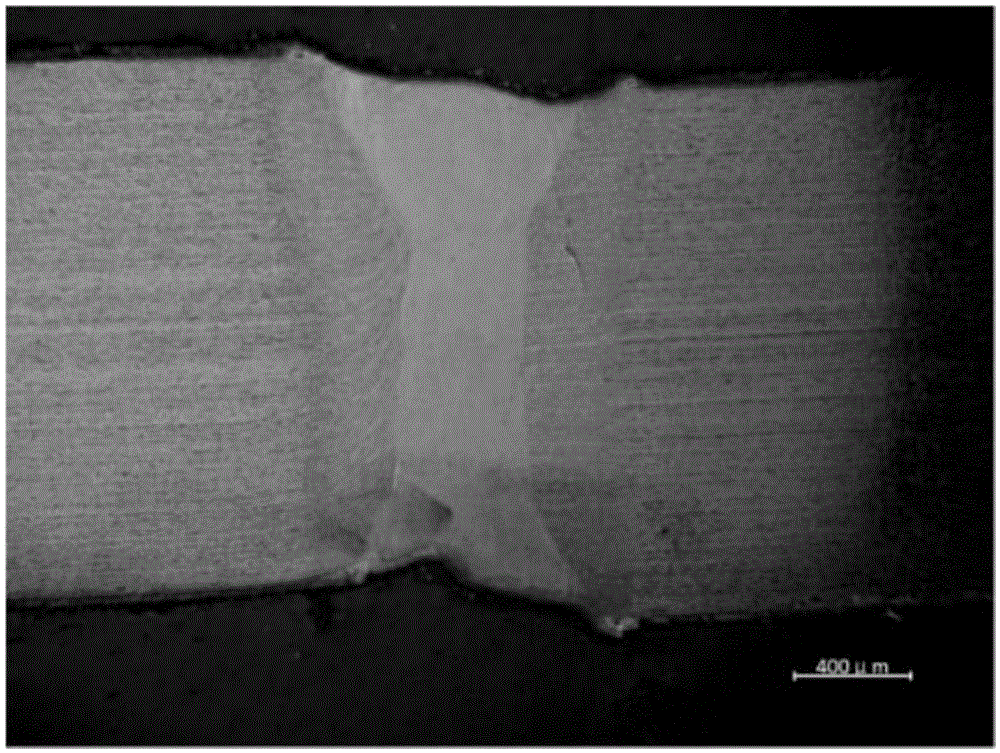

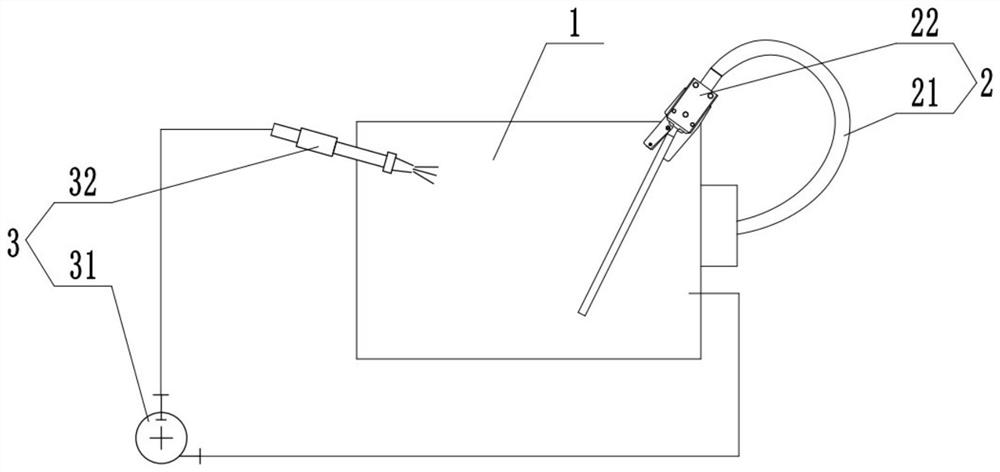

Method for removing coating of hot-rolled steel sheet by virtue of ultra-short pulse laser galvanometer

InactiveCN105598587AEasy to weldAchieve removalLaser beam welding apparatusUltra short pulseGalvanometer

The invention discloses a method for removing a coating of a hot-rolled steel sheet by virtue of an ultra-short pulse laser galvanometer. The method comprises the following steps: (1) cleaning the surface of a to-be-welded hot-rolled steel sheet with an Al-Si coating; (2) fixing the cleaned hot-rolled steel sheet to a frock clamp, and adjusting ultra-short pulse laser emitted by a laser to be vertical to the hot-rolled steel sheet; (3) turning on the laser to remove the Al-Si coating of the hot-rolled steel sheet according to technological parameters for removing the Al-Si coating by virtue of the ultra-short pulse laser galvanometer; and (4) turning off the laser, and taking down the hot-rolled steel sheet with the Al-Si coating, thereby finishing the process of removing the Al-Si coating of the hot-rolled steel sheet. By virtue of the method, a light splitting device does not need to be utilized; by virtue of a galvanometer scanning method, the energy density is relatively high, the removal efficiency is high, the size of the removed coating can be adjusted, and furthermore, the removing thickness of the coating can be controlled by controlling the laser power.

Owner:KUSN BAOJIN LASER TAILOR WELDED

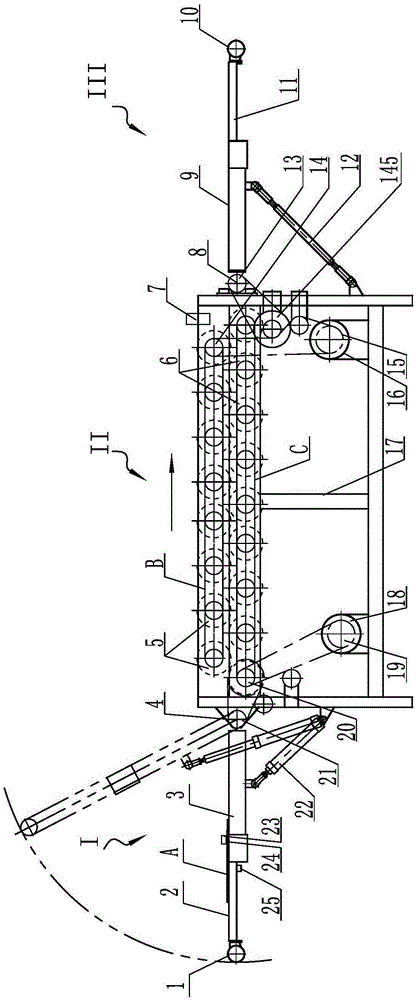

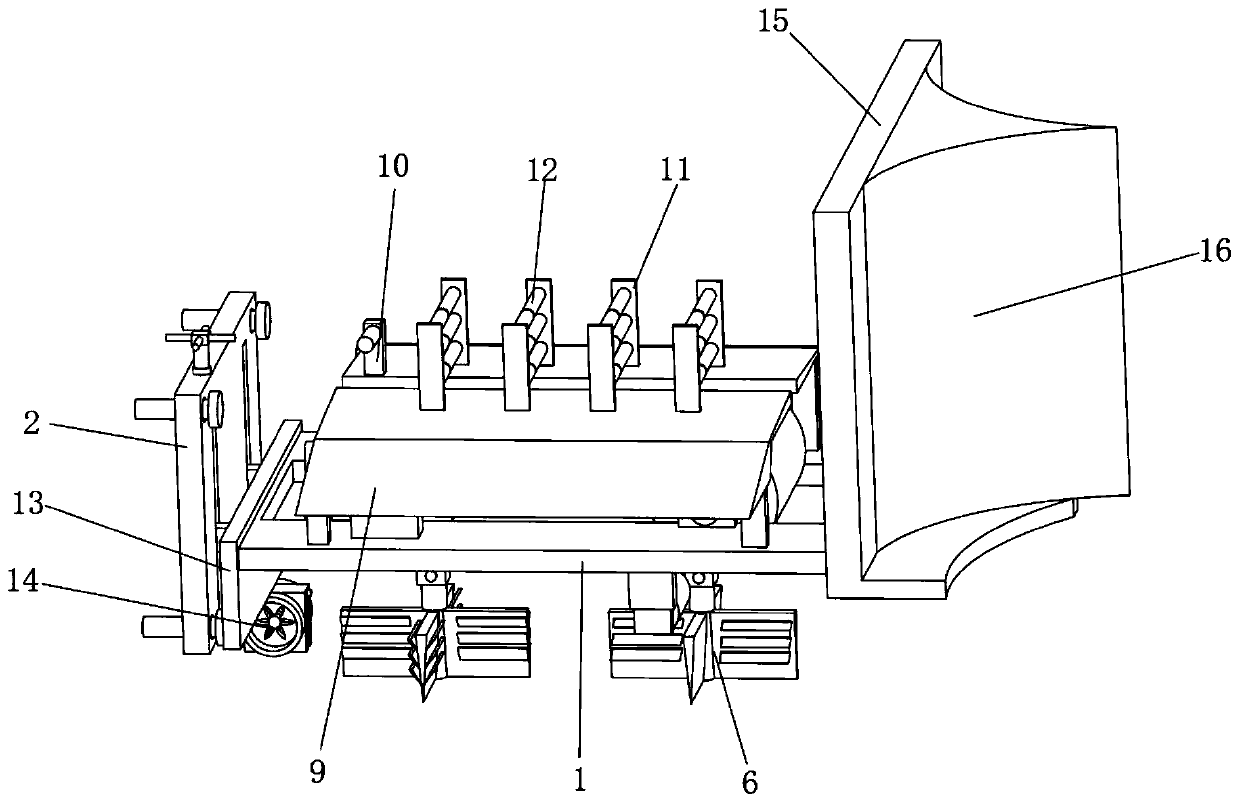

Paperboard waste cleaner

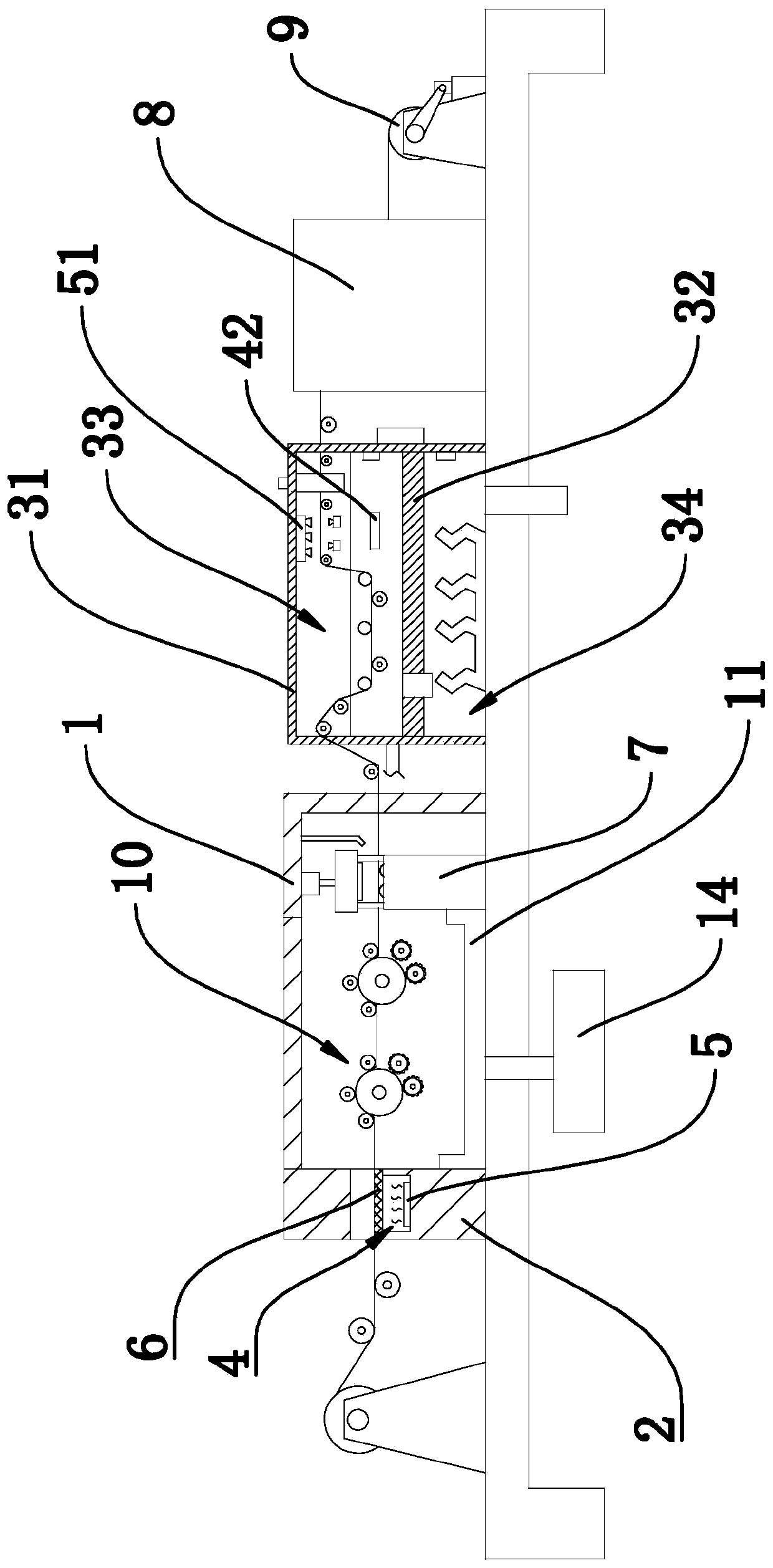

The invention discloses a paperboard waste cleaner which comprises a paperboard access device, a brush roller waste cleaning device and a paperboard sending device, wherein a gas-blowing waste cleaning device is arranged on the paperboard access device; the gas-blowing waste cleaning device comprises a blowing nozzle; the brush roller waste cleaning device comprises a plurality of horizontal upper brush rollers which are rotatably arranged and a plurality of horizontal lower brush rollers which are rotatably arranged; the upper brush rollers and the lower brush rollers are arranged in a staggered mode and are reverse in rotary direction; and a paper outlet end of the brush roller waste cleaning device is horizontally provided with a brush row. After entering the waste cleaner, the paperboards realize preliminary waste cleaning by virtue of the blowing nozzle; then, waste is ejected and dropped by virtue of the upper brush rollers and the lower brush rollers; and finally, un-scattered waste attached on the paperboards is finally brushed off by virtue of the brush row, and the waste is completely cleaned. The paperboard waste cleaner disclosed by the invention replaces manual operation, and realizes automatic waste cleaning, so that the paperboard waste is completely cleaned, the cleaning speed is high, the production efficiency is high and the product quality is guaranteed.

Owner:SHANDONG CENTURY MACHINERY

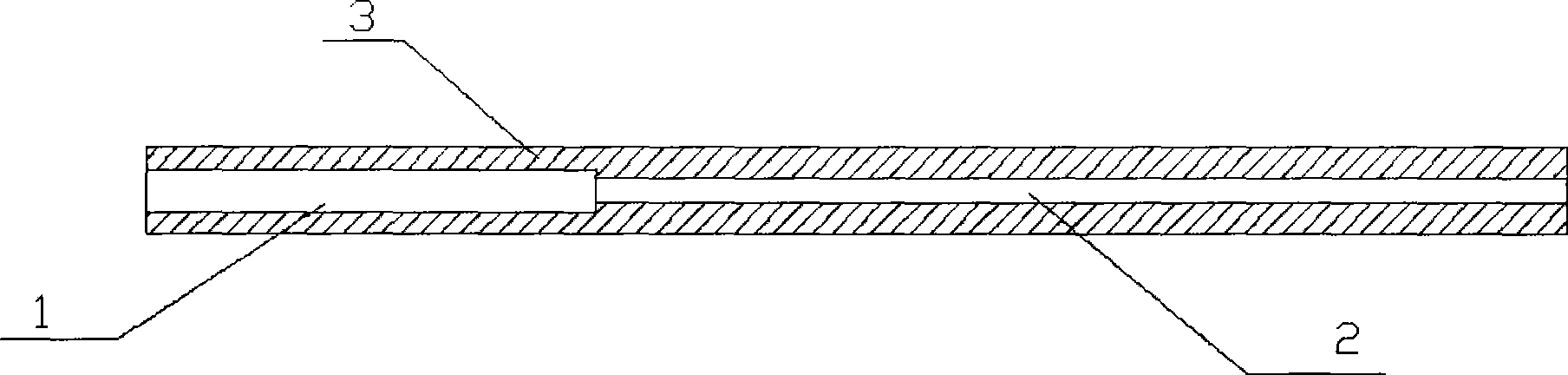

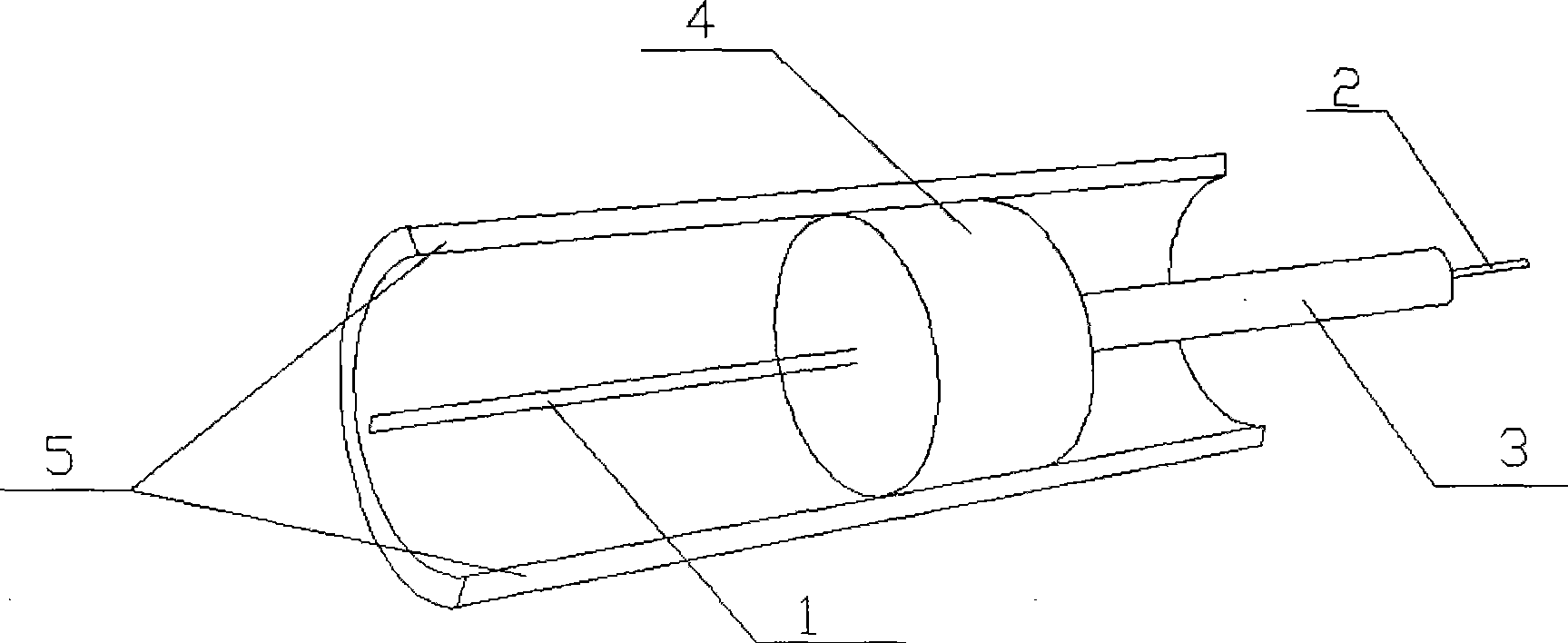

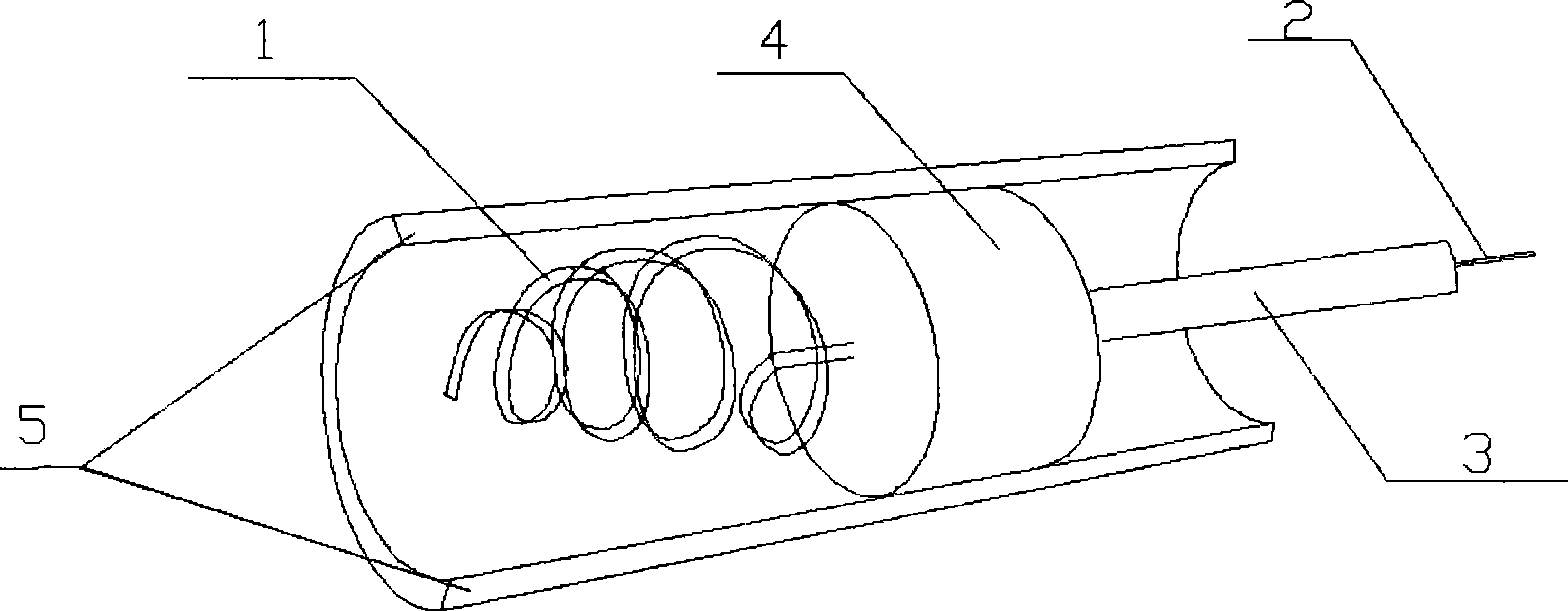

Novel thrombus cleaning device

A novel thrombus cleaning apparatus, the invention relates to a thrombus cleaning apparatus of surgical operation in order to solve the problem that the accurate and complicated surgical operation is difficult to perform in a narrow blood vessel cavity. The thrombus cleaning apparatus comprises a shape memory material minitype driver 1, a minitype connector 2 and a minitype vessel 3, the shape memory material minitype driver 1 and the minitype connector 2 are connected and mounted in the minitype vessel 3 together. The invention has simple design and manufacture, can satisfy the requirement that the accurate and complicated surgical operation can be performed in the narrow blood vessel cavity.

Owner:冷劲松

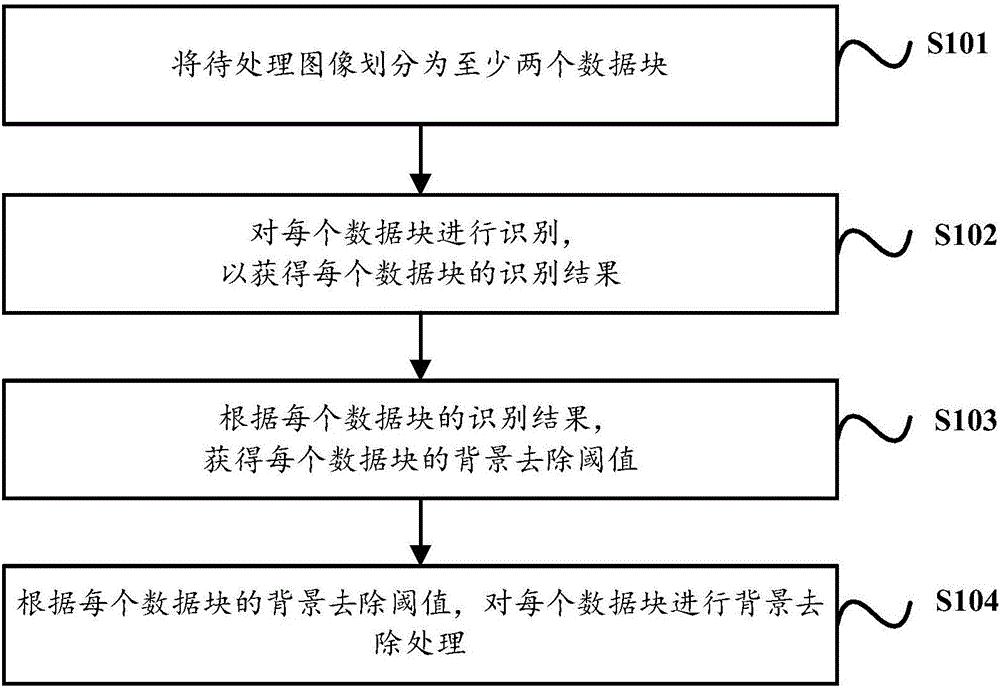

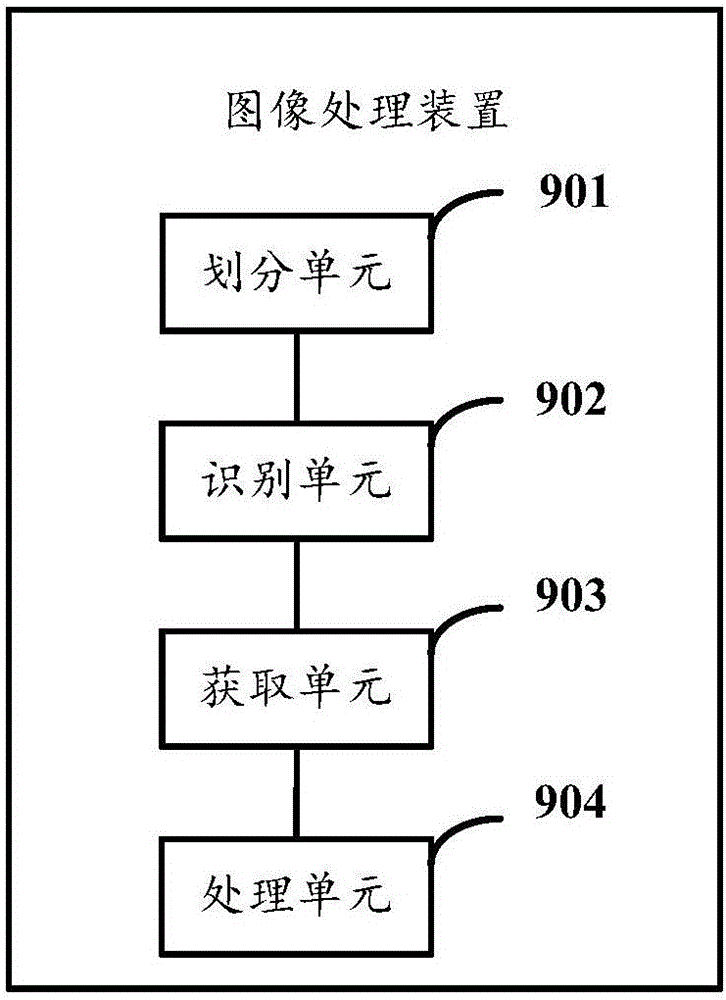

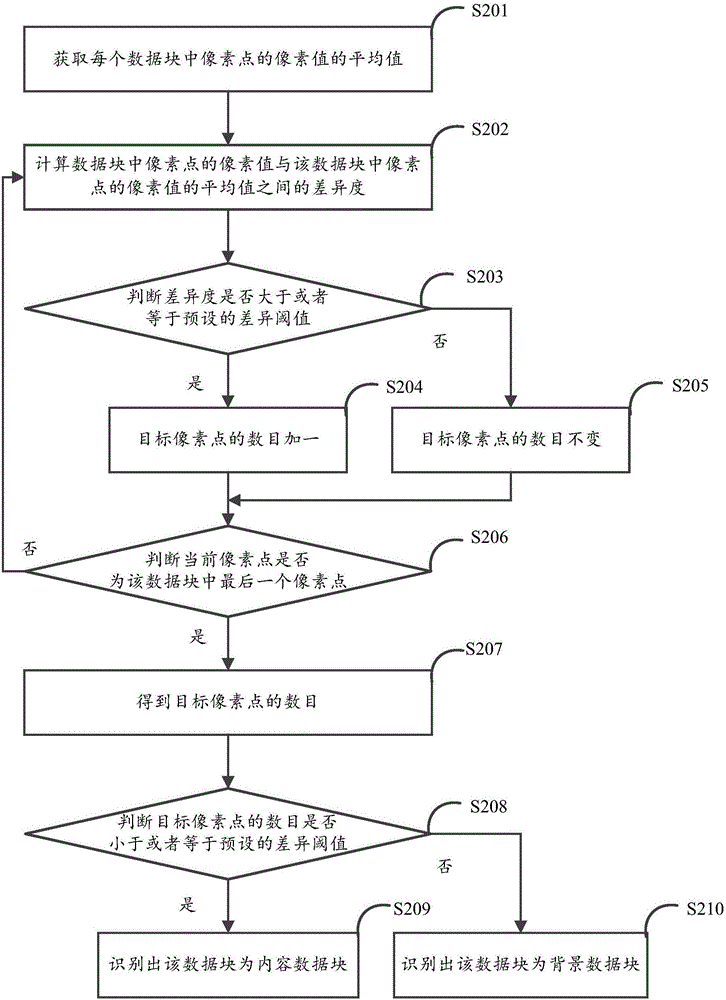

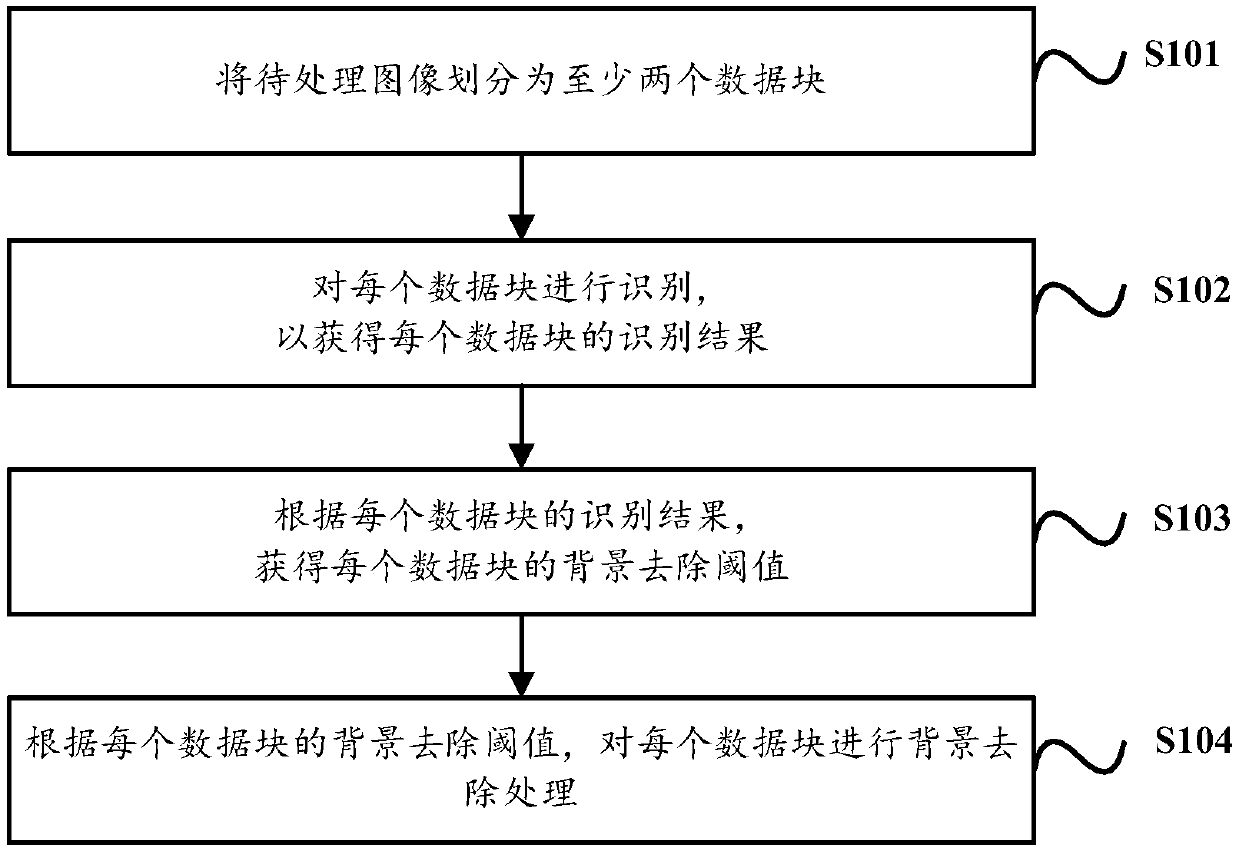

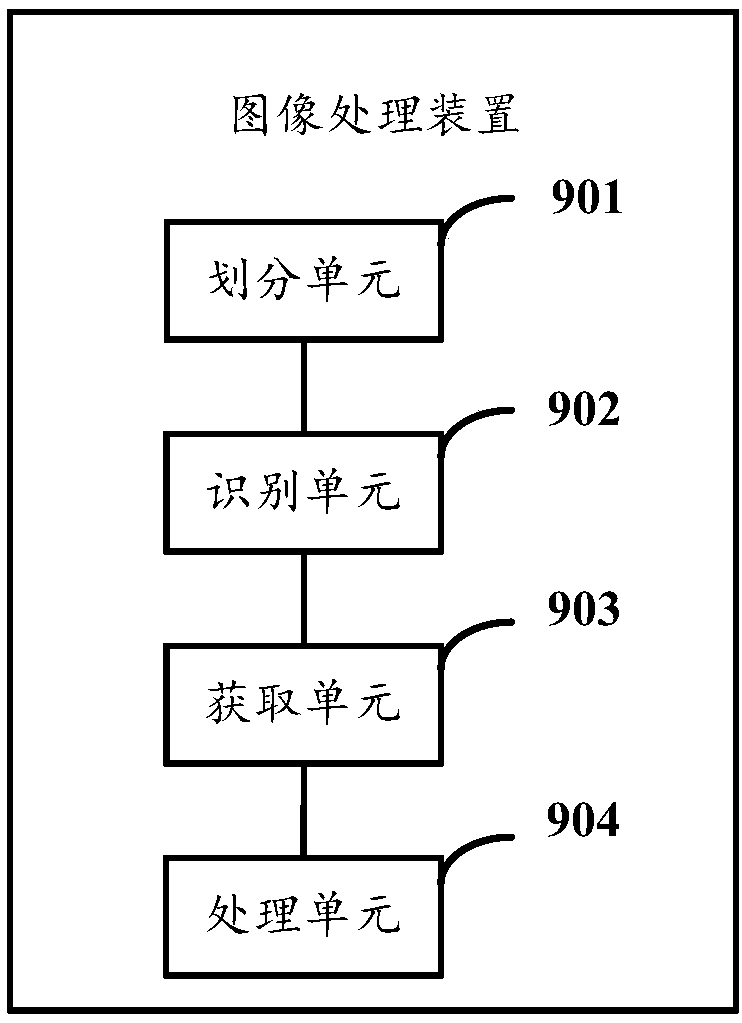

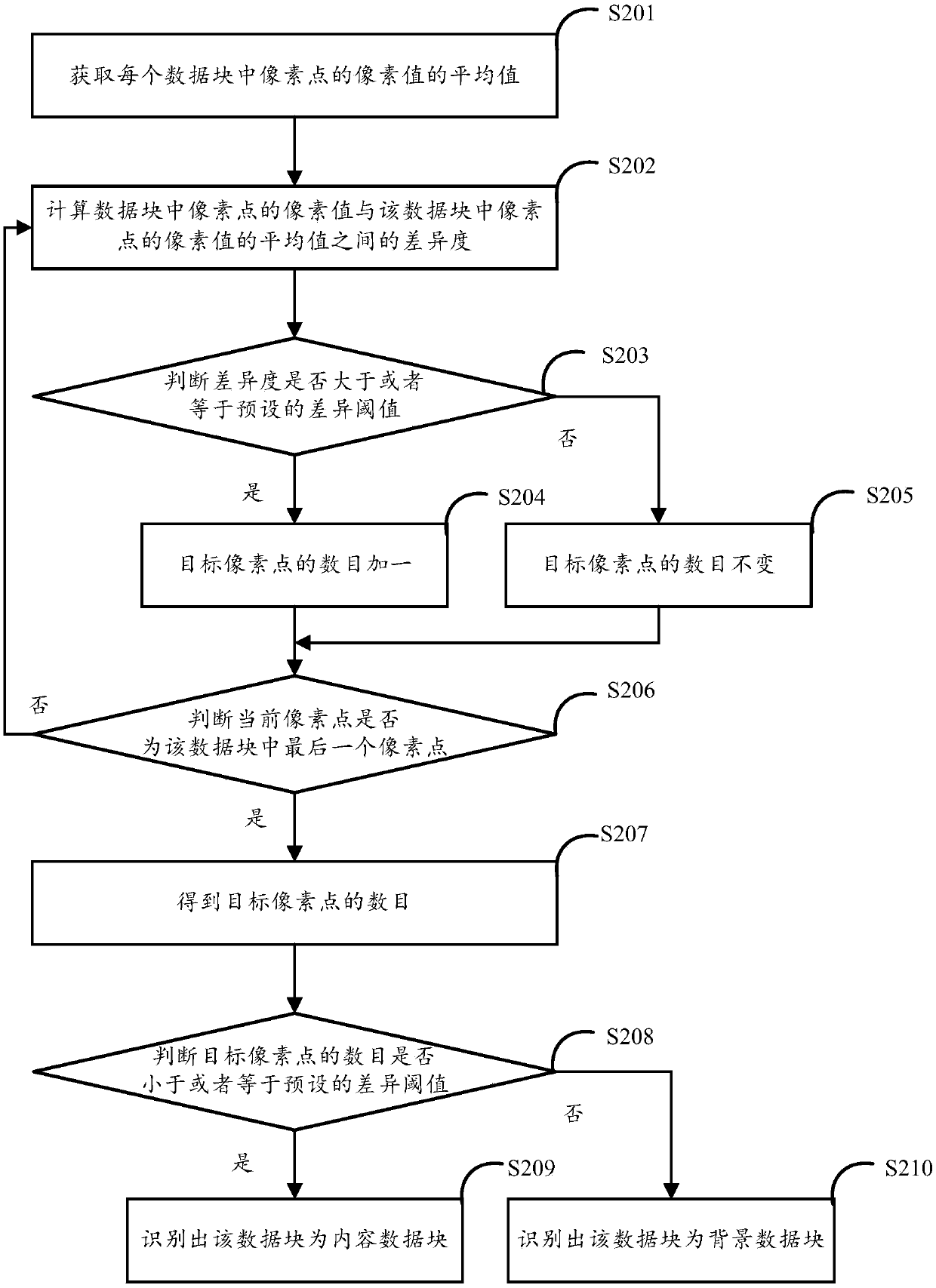

Image processing method and image processing device

ActiveCN106251358AImprove removal qualityImprove removal efficiencyImage enhancementImage analysisPattern recognitionImaging processing

Embodiments of the invention provide an image processing method and an image processing device. On one hand, a to-be-processed image is divided into at least two blocks; then, each data block is identified to get the identification result of each data block, wherein the identification result of each data block indicates whether each data block is a content data block or a background data block; a background removal threshold of each data block is obtained according to the identification result of each data block; and the background of each data block is removed according to the background removal threshold of each data block. Therefore, through the technical scheme provided by the embodiments of the invention, the problem of over-processing and partial loss of image content caused thereby due to unified background removal of a whole image in the prior art is solved.

Owner:ZHUHAI PANTUM ELECTRONICS

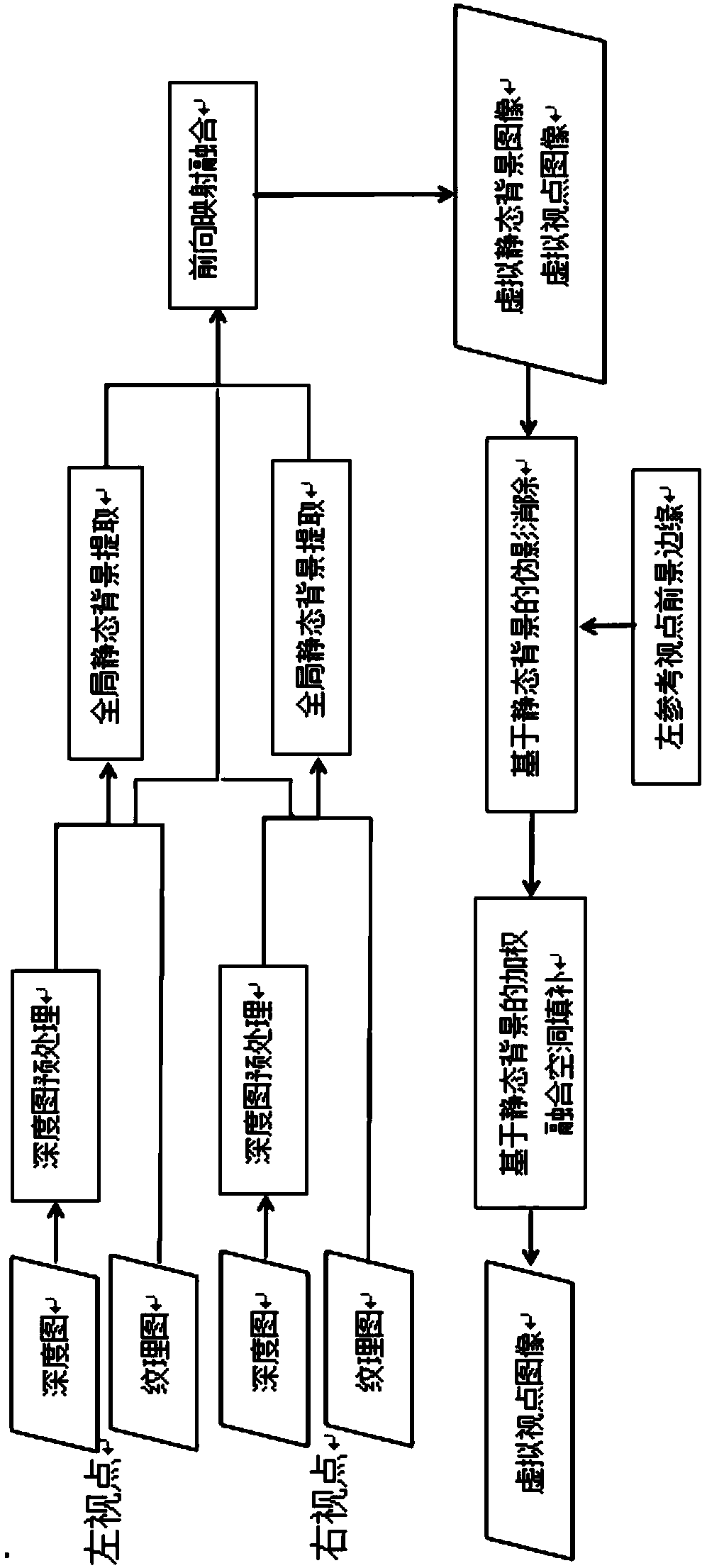

Virtual viewpoint synthesis method with spatiotemporal continuity

InactiveCN108833879AImprove drawing qualityMaintain time continuitySteroscopic systemsViewpointsSynthesis methods

The invention provides a virtual viewpoint synthesis method with spatiotemporal continuity. The method makes full use of correlation between adjacent frames in a reference viewpoint image sequence, aglobal static background map sequence of a scene is extracted from the reference viewpoint image sequence, and based on the global background map sequence, artifact elimination and hole filling are carried out on a virtual viewpoint image sequence synthesized by a left and a right reference viewpoint image sequence. Artifact and hole problems on a virtual viewpoint image can be well solved, the quality of a single frame of virtual viewpoint image is greatly improved, and the spatiotemporal continuity of the virtual viewpoint image is also well maintained.

Owner:SOUTHEAST UNIV

Vehicle-mounted snow shoveling device based on compression molding for railway track cleaning

InactiveCN111560908AImprove removal efficiencyReduce the amount of adhesionRailway cleaningCompression moldingSnow removal

The invention discloses a vehicle-mounted snow shoveling device based on compression molding for railway track cleaning. The device comprises a cleaning bearing plate and a vehicle-mounted mounting plate, wherein auxiliary inserting and embedding mechanisms are uniformly and fixedly connected to the middle position of the outer bottom end of a conveying belt, extrusion molding mechanisms are fixedly connected to the right side of the bottom of the cleaning bearing plate and located on the outer side of a communicating groove, guide inclined plates are fixedly connected to the top parts of supporting legs, a guide deflector rod is fixedly connected to the left side of the guide inclined plate on the back, side supporting frames are evenly and fixedly connected to the positions, which are close to the inner sides, of the top parts of the guide inclined plates, material shaking rubber rods are evenly and fixedly connected to the inner sides of the side supporting frames, and a wind powersnow removing mechanism is fixedly connected to the middle of the bottom of the supporting vertical plate. The invention relates to the technical field of railway track cleaning. According to the vehicle-mounted snow shoveling device based on compression molding for railway track cleaning, the removal efficiency of accumulated snow in a track is improved, the adhesion amount of the accumulated snow in the track after removal is reduced, and meanwhile, the accumulated snow shoveling area is reduced.

Owner:张有林

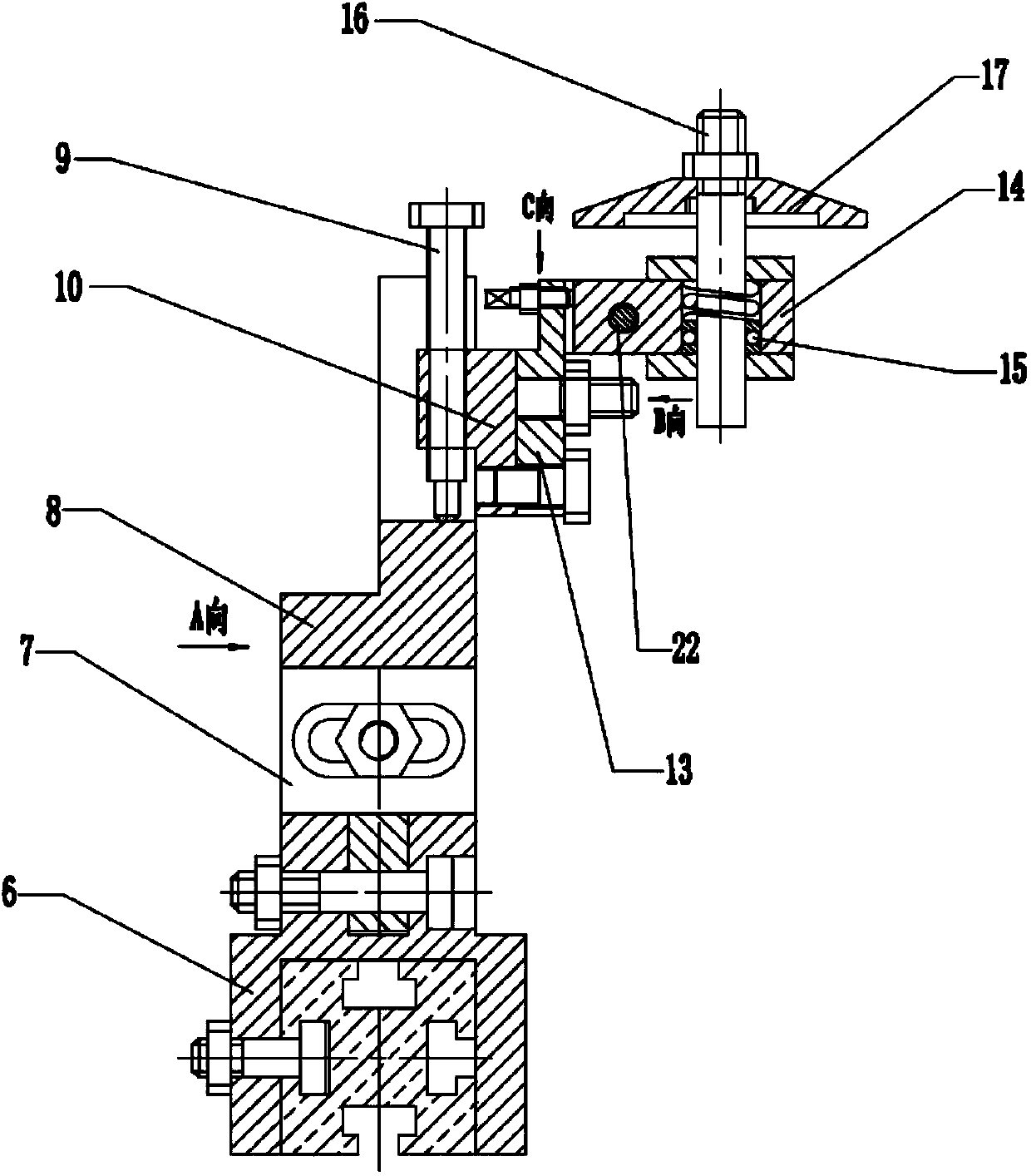

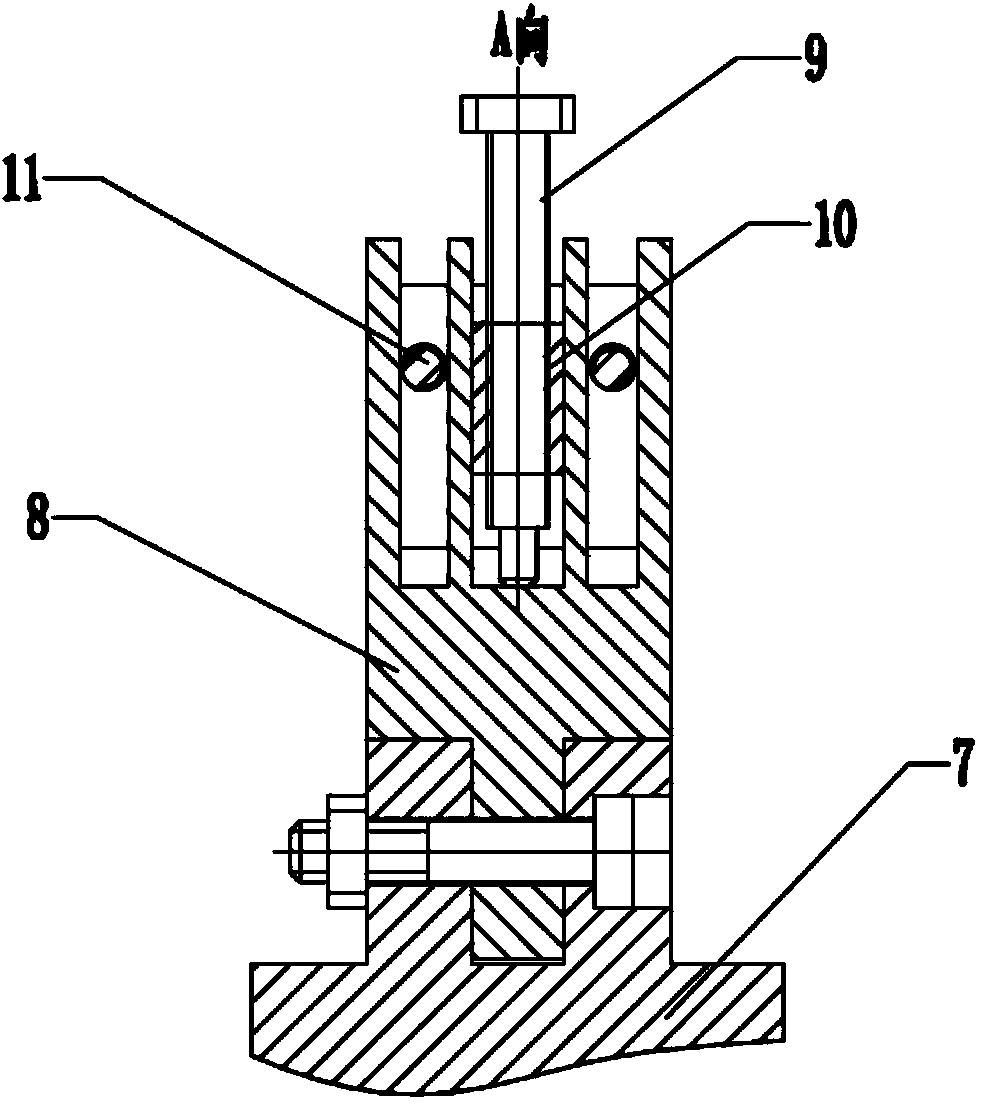

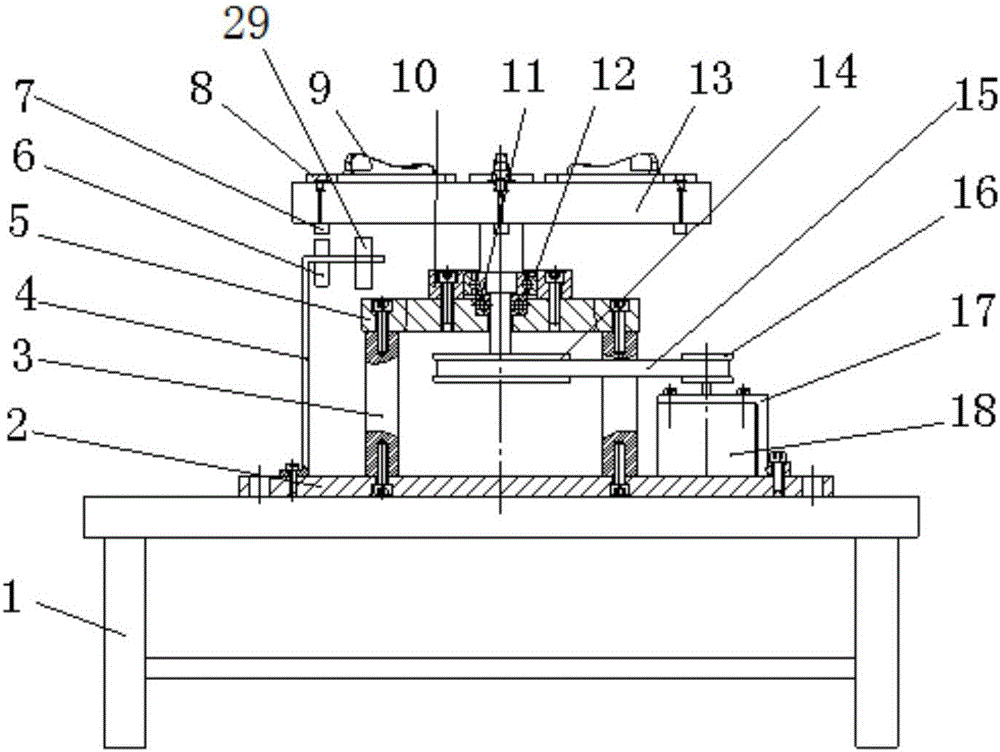

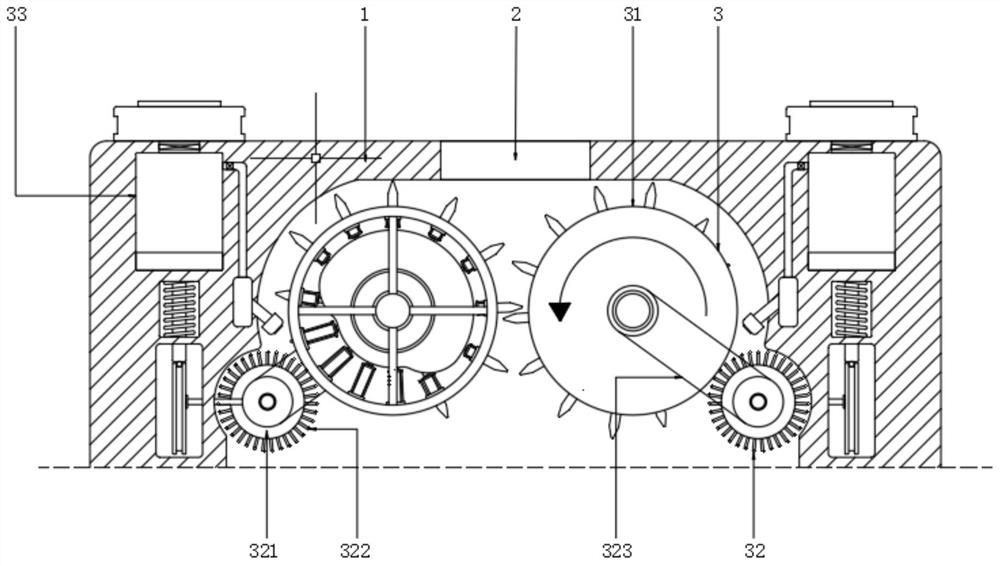

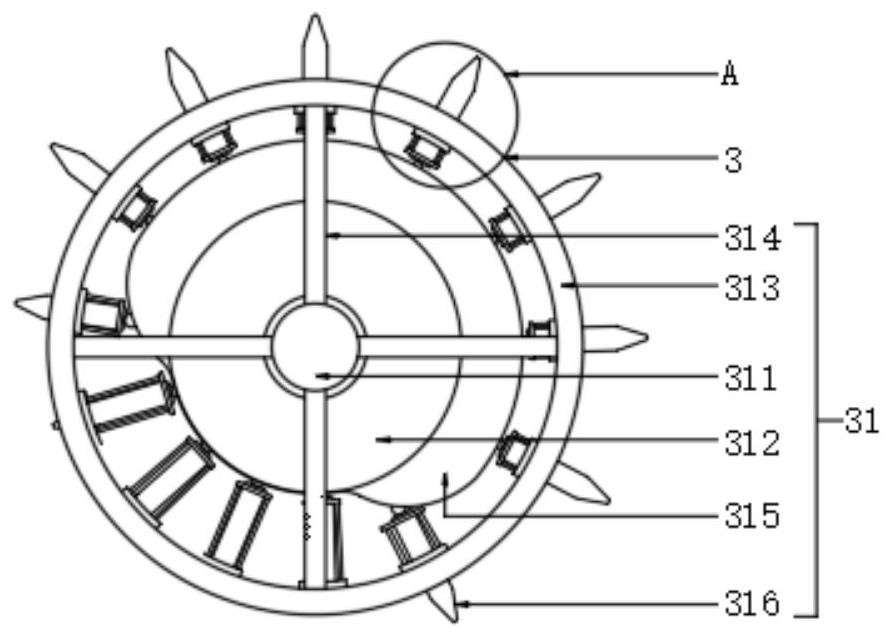

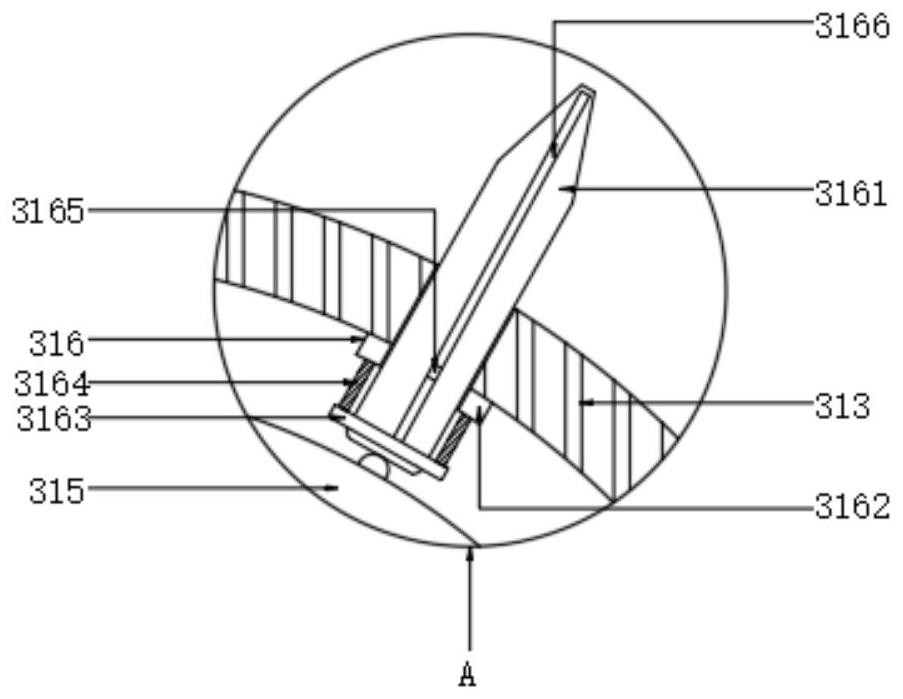

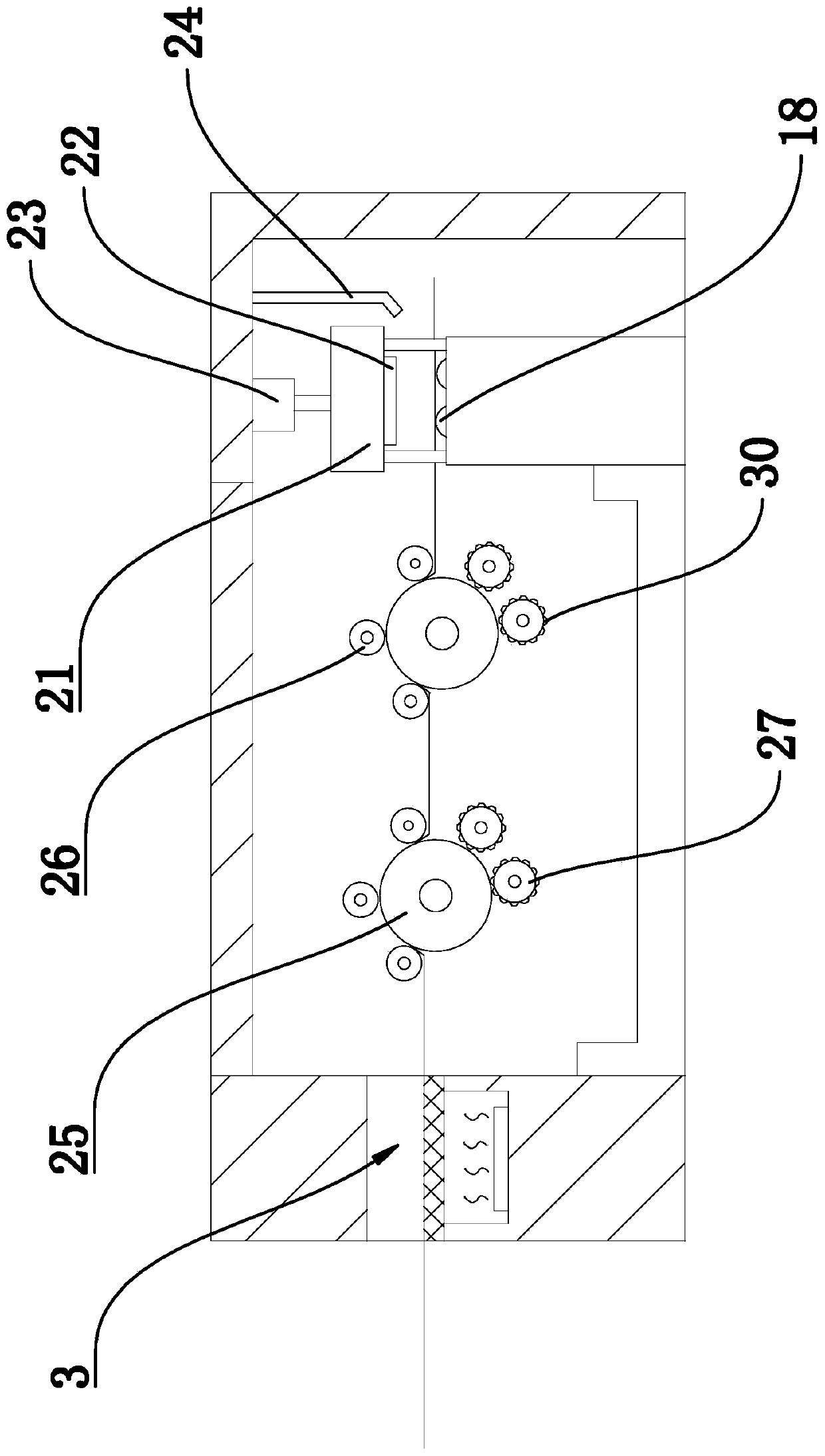

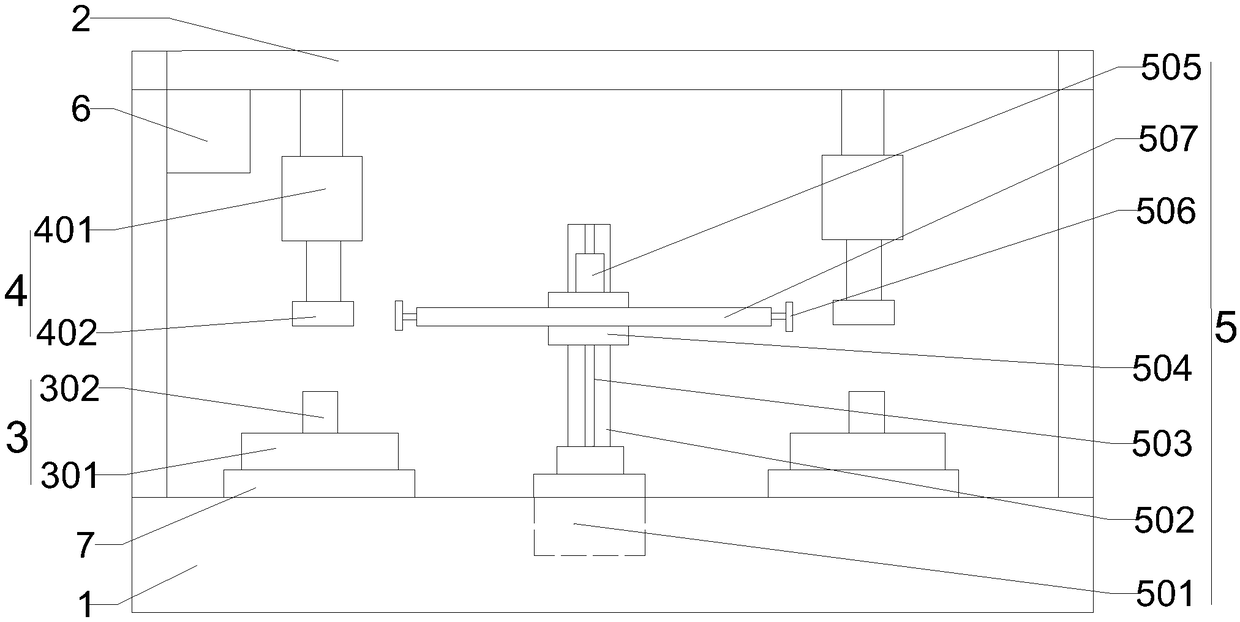

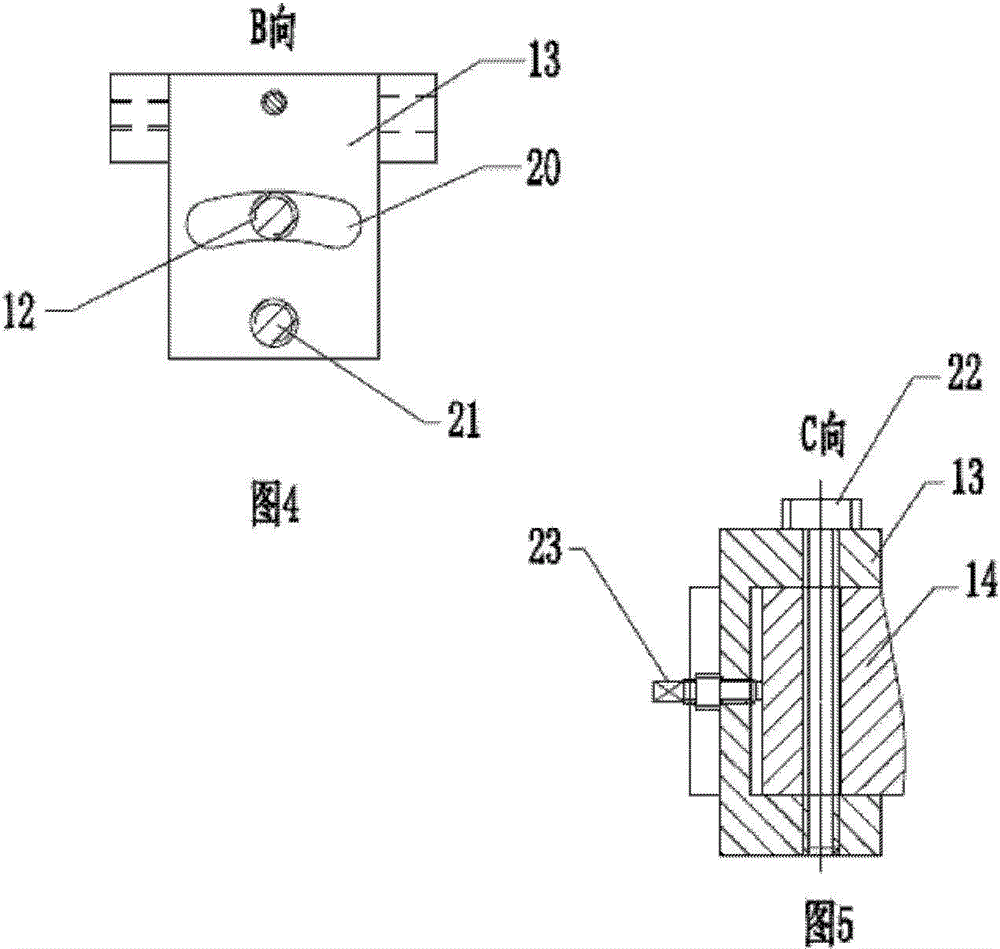

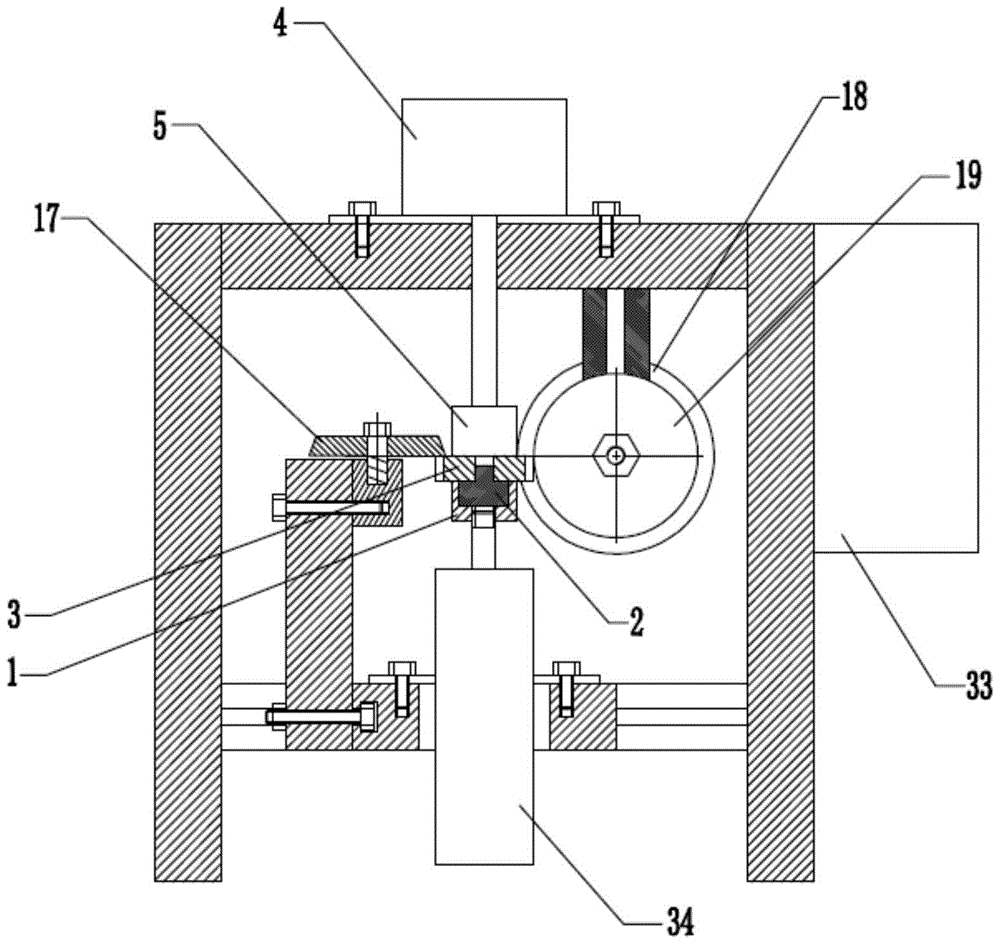

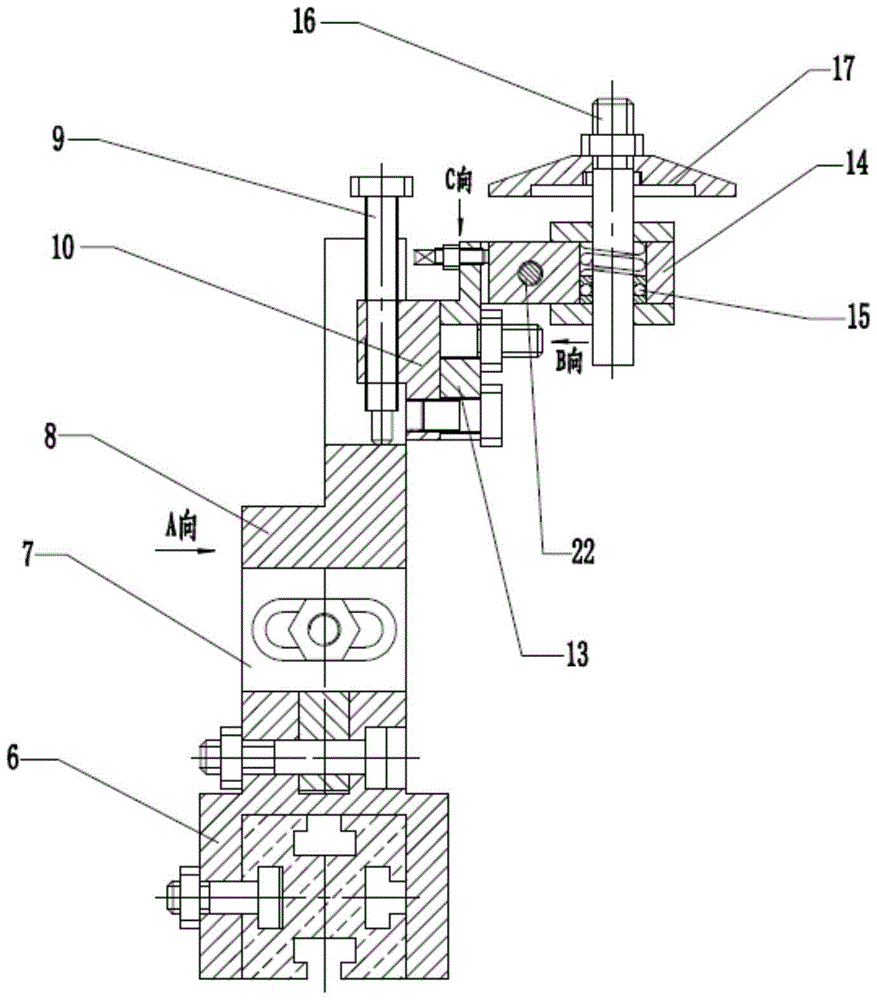

Semi-automatic deburring machine

ActiveCN104400133ACompact structureStable structureLarge fixed membersMaintainance and safety accessoriesGear driveSemi automatic

The invention discloses a semi-automatic deburring machine. The machine comprises a gear propping, raising and positioning device arranged right below a gear to be processed, a gear driving device arranged right above the gear, a deburring cutter for deburring of a gear end face, and a supporting and adjusting device for the deburring cutter, wherein guide rails in X, Y and Z directions of the supporting and adjusting device for the deburring cutter can adjust the deburring cutter forward and rearward, right and left and up and down; a deburring cutter rotating shaft and a deburring cutter fixing seat which are arranged above the guide rail in the X direction can adjust the swing and the pitch of the deburring cutter, so that different gears can be processed, and helical gears at different spiral angles can be deburred. Similarly, support components of a polishing wheel can perform three-dimensional and pitch adjustment on the polishing wheel. The semi-automatic deburring machine disclosed by the invention has a simple, efficient, safe and stable gear deburring processing method.

Owner:六安永达机械股份有限公司

Water removal hole machining process for producing connector die casting

The invention relates to the technical field of connector die casting, and discloses a water removal hole machining process for producing connector die casting, which comprises a lifting base, wherein a cutting mechanism is movably connected to the bottom of the lifting base, a supporting die table is movably connected to the bottom of the cutting mechanism, and a pressurizing rod is movably connected to the left side of the cutting mechanism; the bottom of a pressurizing rod is movably connected to a pressurizing block, the bottom of the pressurizing block is movably connected to a buffer spring, and the bottom of the buffer spring is movably connected to a piezoelectric switch; downward pressure is applied to the pressurizing block in the moving process of the lifting base, the pressure extrudes the piezoelectric switch to generate current, and an electrified coil is electrified to operate to generate magnetism, so that a clamping rotary rod is driven to move to firmly clamp the connector; and when the cutting mechanism operates to the bottommost part and starts to reset, the connector rotates at the moment to polish the cut water gap, so that the effects of automatically removing the water gap and improving the water gap removing quality are achieved.

Owner:深圳市宏泰丰盛科技有限公司

Home shoe cabinet

InactiveCN108294495AImprove removal qualitySimple structureWardrobesFurniture partsBiomedical engineering

The invention relates to a home shoe cabinet comprising a cabinet body, a bracket for placing shoes and a deodorizing device for removing odor in the cabinet body. The cabinet body comprises a first mounting portion and a second mounting portion. The bracket is mounted on the cabinet body through the first mounting portion, and the deodorizing device is mounted on the cabinet body through the second mounting portion. The bracket is provided with a deodorizing component for removing the odor in the shoes, the cabinet body is provided with an air outlet, and the cabinet body is provided with a fan for blowing air into the cabinet body. The home shoe cabinet has the advantages that by blowing air into the cabinet body through the fan disposed on the cabinet body, the odor in the cabinet bodycan flow under the action of the fan and is discharged out of the cabinet body through the air outlet, the odor in the cabinet body is removed through the deodorizing device disposed in the cabinet body, the odor removing quality can be further improved, the odor in the shoes is removed through the deodorizing component disposed on the bracket, and the air quality in the cabinet body is further improved.

Owner:杭州闪烁科技有限公司

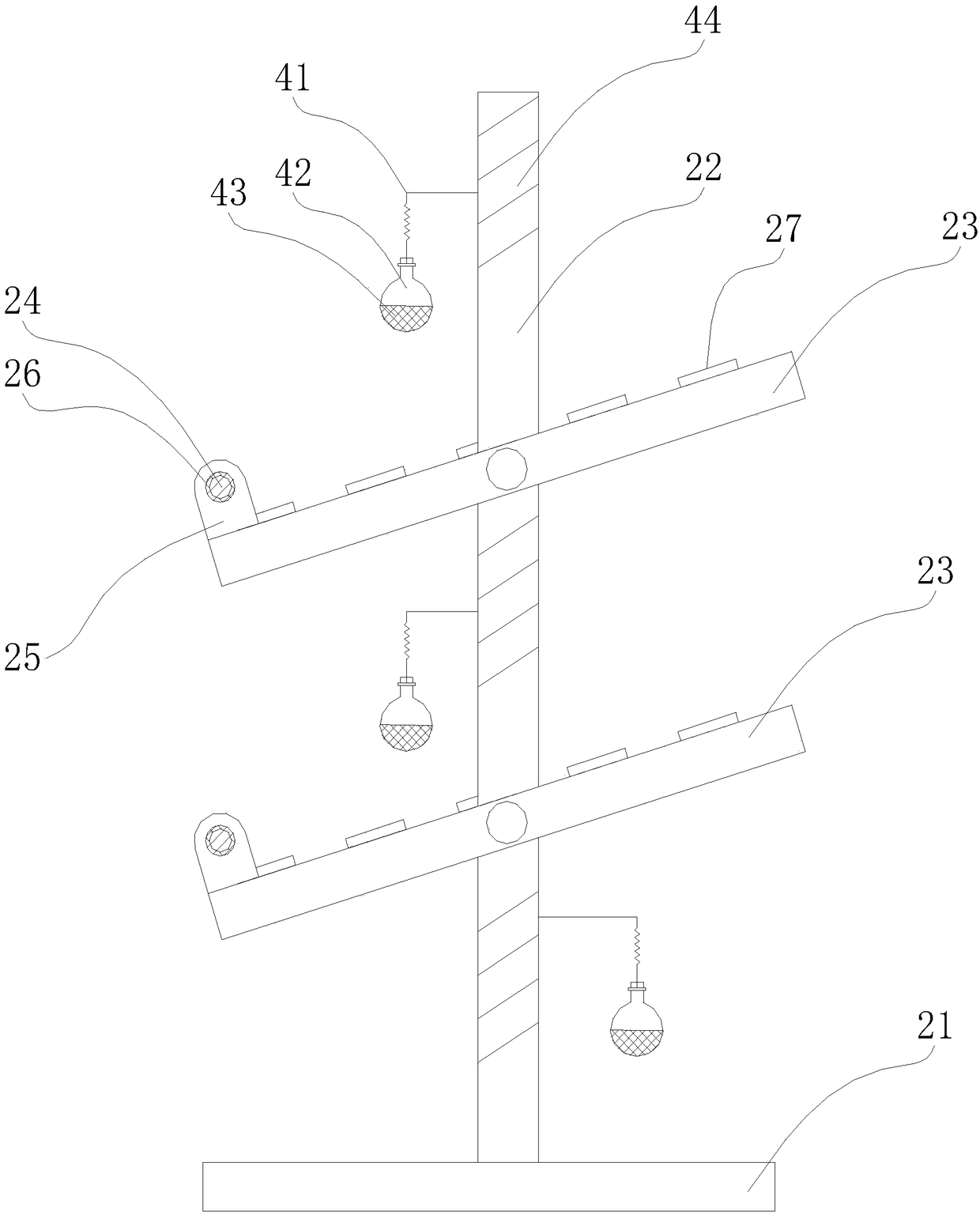

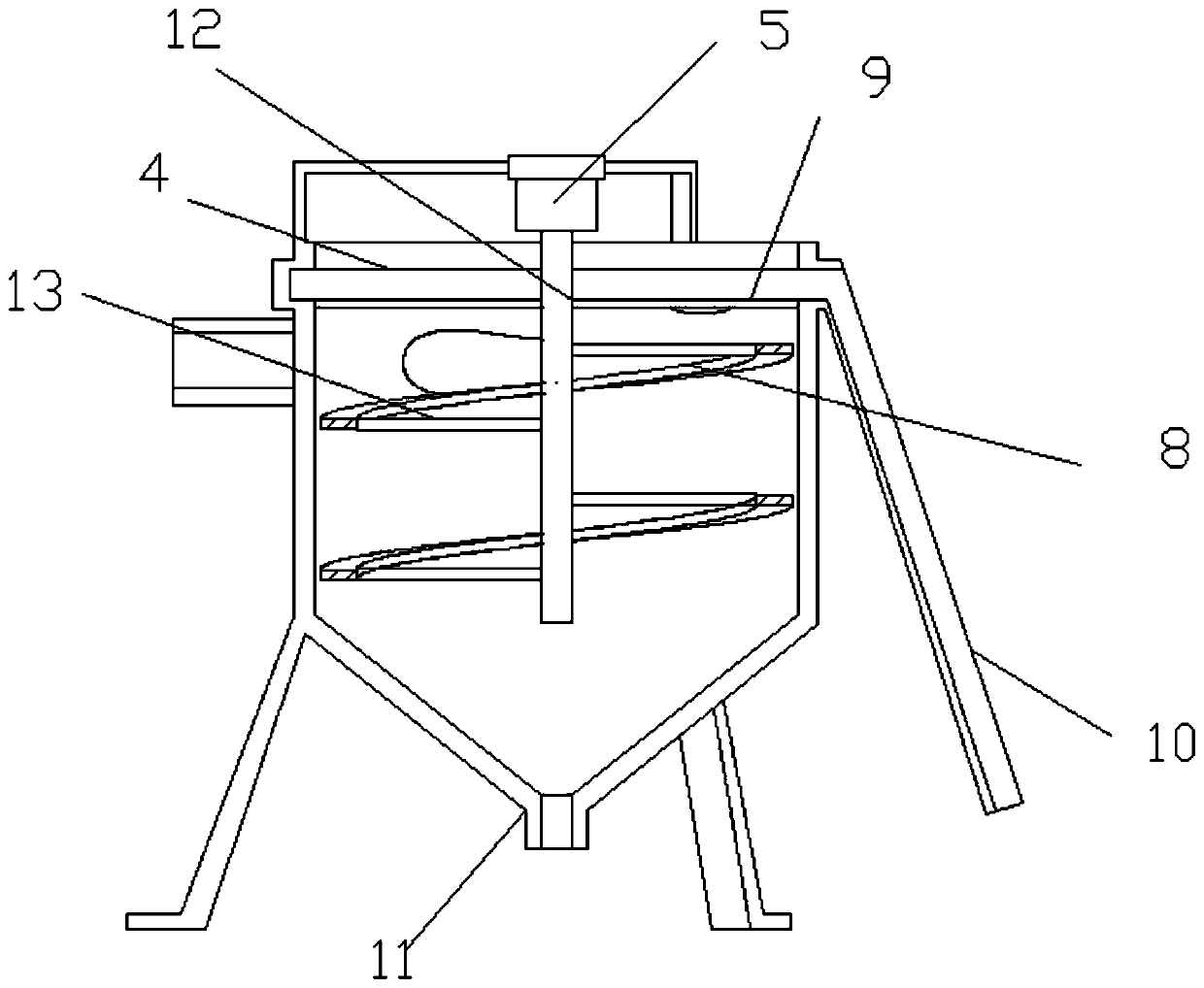

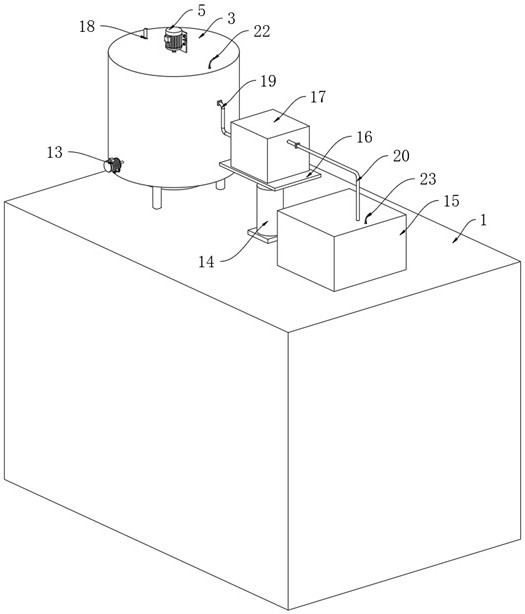

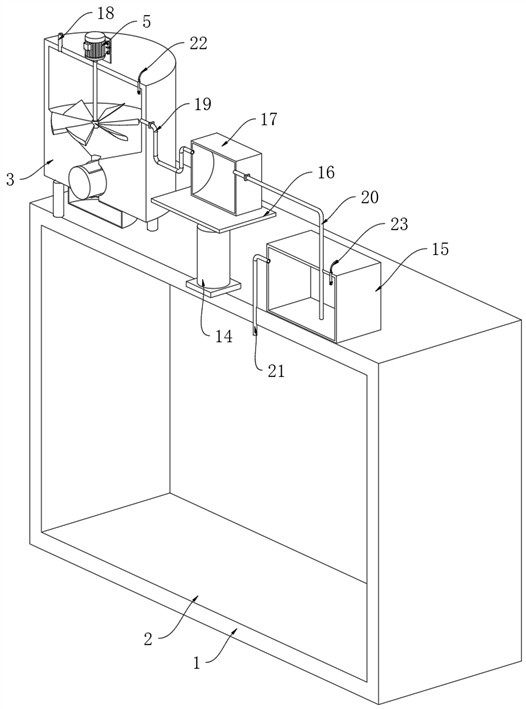

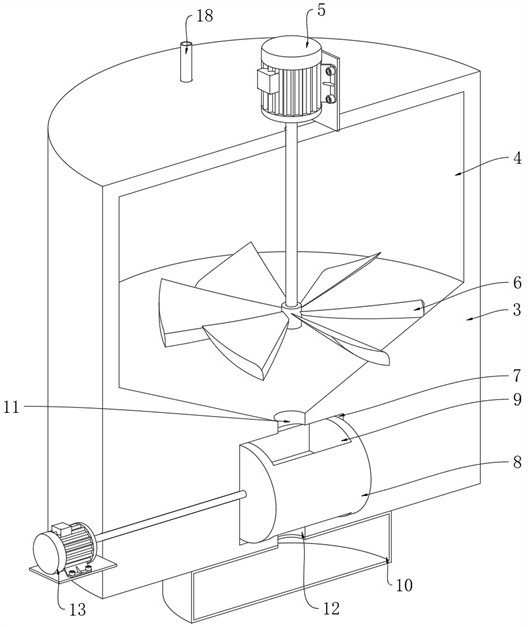

Pool floating sludge removal device for sewage treatment

InactiveCN111097209AEasy to disengageEasy to cleanSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationSludgeElectric machine

The invention relates to the technical field of sewage treatment, and particularly discloses a pool floating sludge removal device for sewage treatment. The device comprises a barrel and a motor, theside wall of the barrel is communicated with a water inlet pipe; a support frame is fixed at the top of the barrel; the middle position of the support frame is fixedly connected with a mounting seat;a motor is fixedly mounted at the bottom of the mounting seat; an output shaft of the motor is coaxially and fixedly connected with a rotating shaft; the rotating shaft is fixedly connected to the inner ends of the poking rod and the connecting rod, the outer end of the connecting rod is fixedly connected with a spiral scraper, the outer side of the spiral scraper makes contact with the inner sidewall of the barrel, a sludge discharging opening is formed in the bottom of the barrel, a collecting groove is formed in the inner side wall of the barrel, and the outer end of the poking rod is slidably nested in the collecting groove which communicates with a slag discharging groove. The floating sludge on the surface of the sewage is collected to the edge part of the barrel body by the pokingrod, and the sludge attached to the inner side wall of the barrel body is cleaned by the rotation of the spiral scraper. The device has the advantages of simple structure, convenience in cleaning, high removal quality and capability of realizing automatic cleaning.

Owner:陶李

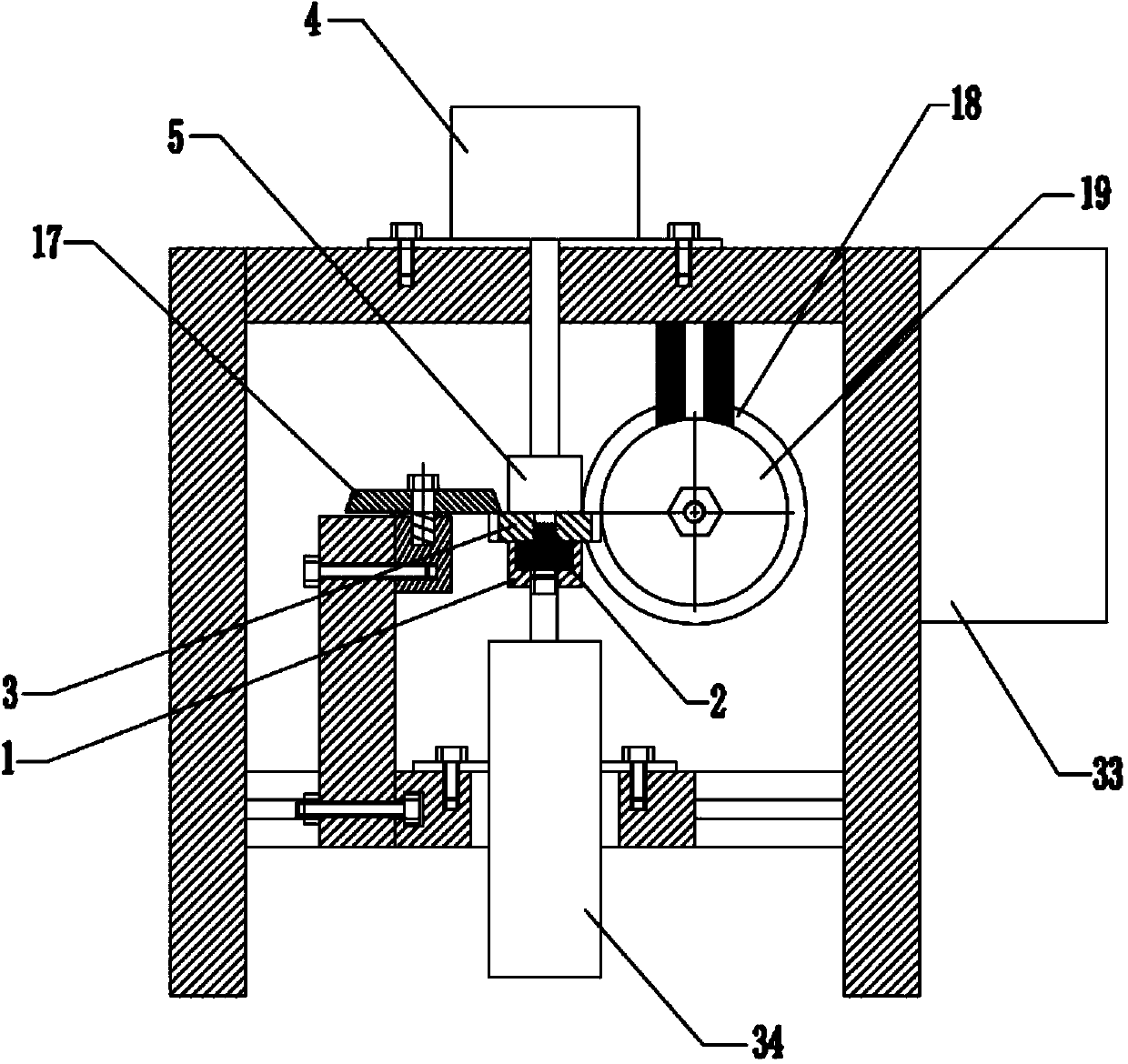

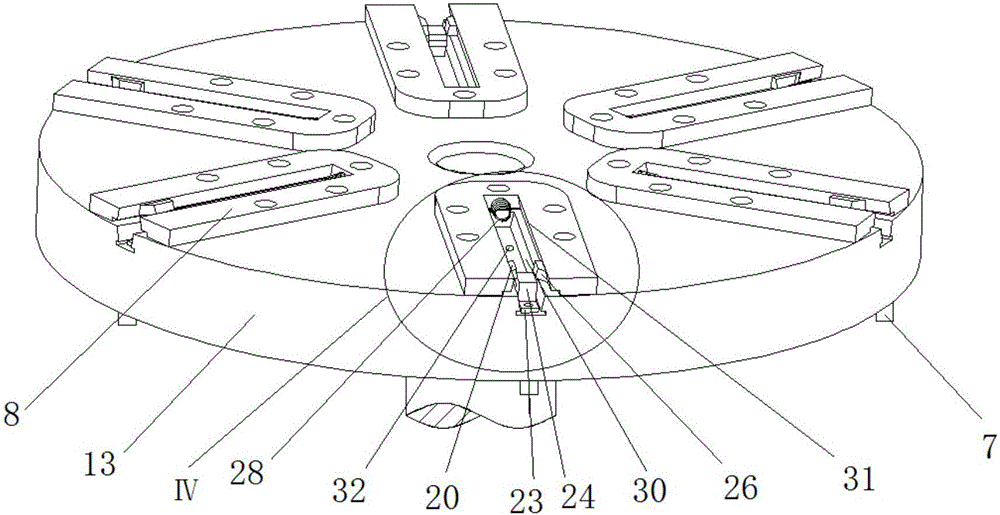

High-pressure copper finger touch fixture and clamping finger touch method thereof

InactiveCN106064316AHigh degree of automationRealize automatic flow operationPrecision positioning equipmentMeasurement/indication equipmentsEngineeringCopper

The invention discloses a high-pressure copper finger touch fixture. The high-pressure copper finger touch fixture comprises a base; the base is connected with a detecting mechanism and an indexing mechanism; and the indexing mechanism is connected with a finger touch clamping mechanism. The high-pressure copper finger touch fixture can realize three functions: (1) the finger touch clamping is realized by dint of the finger touch clamping mechanism; (2) the indexing function is realized by dint of the indexing mechanism; and (3) the detecting function is finished by dint of the detecting mechanism. The invention further discloses a finger touch clamping method; the finger touch clamping adopts forward and reverse clamping; the finger touch clamping method conveniently and quickly performs the finger touch clamping; and the method is high in finger touch burr removing efficiency and excellent in removing quality.

Owner:XIAN UNIV OF TECH

Railway-based overhead line system surface ice removing device

InactiveCN113422342APrevent secondary icingImprove removal efficiencyOverhead installationTrolley linesScrapStructural engineering

The invention belongs to the technical field of railway line deicing, and particularly relates to a railway-based overhead line system surface ice removing device which comprises a mounting base. A main supporting arm is movably mounted at the top of the mounting base, and a first electric push rod is movably mounted on the side face of the main supporting arm; the end, away from the main supporting arm, of the first electric push rod is movably connected with the mounting base, and the end, away from the mounting base, of the main supporting arm is movably provided with a switching connecting piece. Ice breaking and shoveling are conducted on the surface of an iced line through the ice breaking piece, residual ice scraps on the surface of the line can be cleaned through the bristles arranged on the inner side of the ice breaking piece, the situation of secondary icing is prevented, ice columns on the surface of the iced line are impacted and broken through the ice breaking elastic piece, and ice attached to the surface of a cable is shoveled away; while the efficiency of removing the ice on the surface of the overhead line system is greatly improved, the quality of removing the ice on the surface of the overhead line system is greatly improved, and the probability of secondary icing is effectively prevented.

Owner:杭州爱坦环保科技有限公司

An image processing method and device

ActiveCN106251358BImprove removal qualityImprove removal efficiencyImage analysisPattern recognitionPartial loss

Embodiments of the present invention provide an image processing method and apparatus. In one aspect, the embodiments of the present invention relate to dividing an image to be processed into at least two data blocks, and then identifying each data block to obtain the identification result of each data block, the identification result of each data block comprising the data block being a content data block or the data block being a background data block; obtaining a background removal threshold of each data block according to the identification result of each data block; and removing the background of each data block according to the background removal threshold of each data block. Therefore, the technical solution provided by the embodiments of the present invention can solve the problems in the prior art of over-processing and partial loss of image content caused thereby due to unified background removal of an entire image.

Owner:ZHUHAI PANTUM ELECTRONICS

Circuit board cleaning equipment and cleaning method

PendingCN113634547AImprove removal qualityShorten the soaking timeCleaning using liquidsProcess engineeringMechanical engineering

The invention discloses circuit board cleaning equipment and a cleaning method, and belongs to the field of printed circuits. The circuit board cleaning equipment comprises a cleaning container, a clamping assembly and a fluid power assembly, wherein the cleaning container contains a predetermined amount of cleaning solution; the clamping assembly is connected with the cleaning container; the fluid power assembly is communicated with the cleaning container, and applies a flowing force to the cleaning solution in the cleaning container, so that the cleaning solution flows according to a predetermined path; the clamping assembly fixes a circuit board, and places the circuit board in the cleaning solution of the cleaning container; and a cleaning area of the circuit board is positioned on the flowing path of the cleaning solution. When outer-layer rust in the cleaning area of the circuit board is removed and softened to a predetermined degree, the outer-layer rust is washed away by using the flowing speed of the cleaning solution, so that the cleaning solution reacts with inner-layer rust, the rust removing quality is improved, the circuit board dipping time is shortened, and the secondary damage to a circuit board protection layer is prevented.

Owner:南京屹正网络科技有限公司

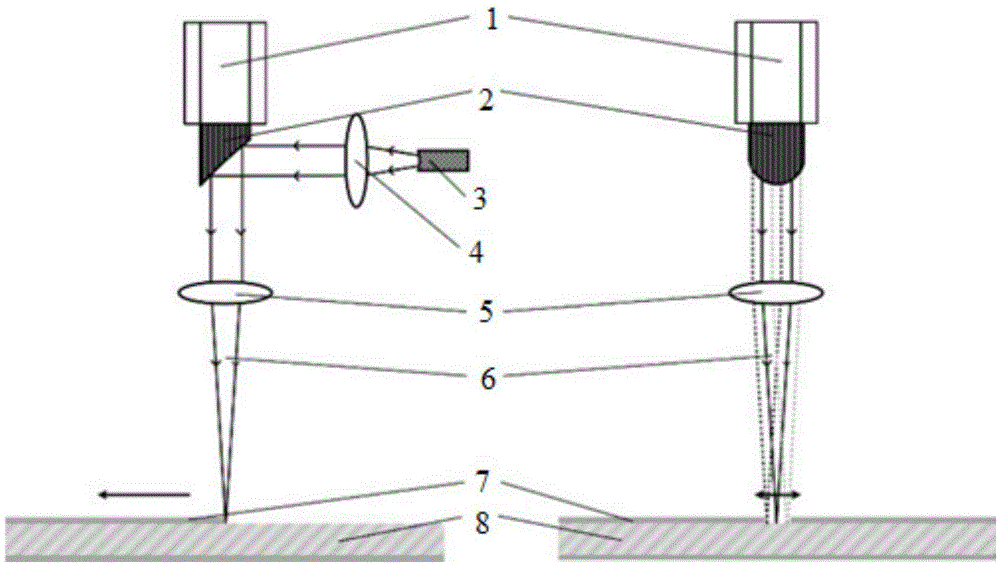

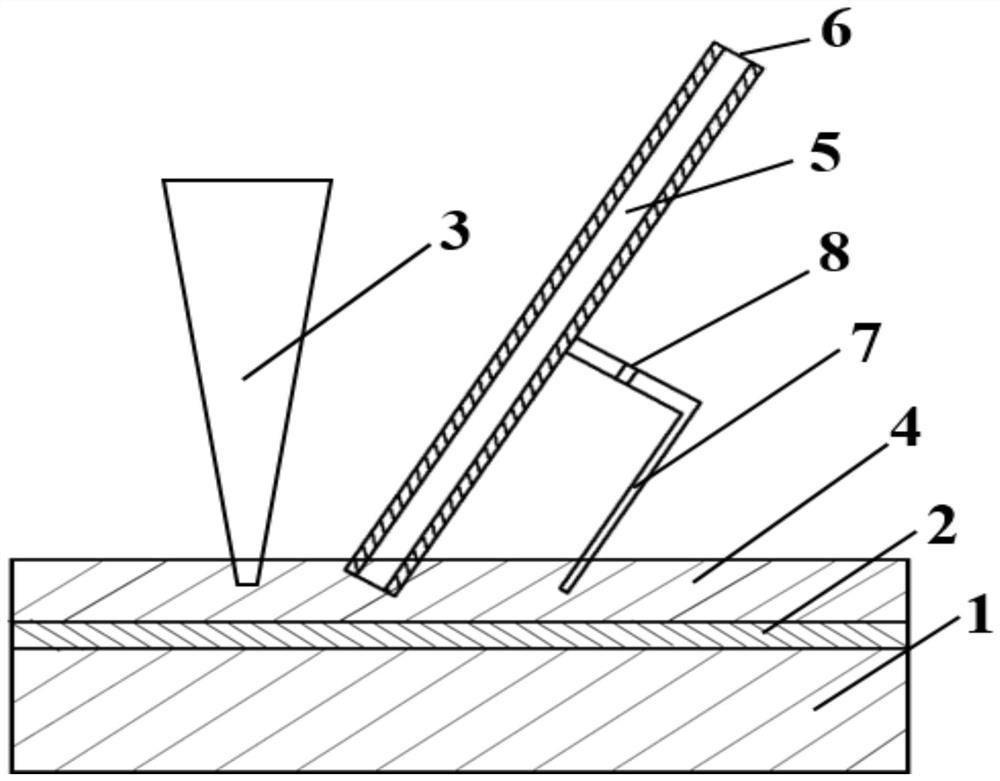

A gas-assisted laser processing method for removing stealth coatings on aircraft surfaces

The invention discloses a gas-assisted laser processing method for removing a stealth coating on the surface of an aircraft, which comprises the following steps: 1) fixing the aircraft surface sample to be treated with a stealth coating on the surface on a working platform, covered with One side of the coating is aimed at the laser cleaning head; 2) the gas-assisted protection device includes a main device and a tail device, and an inert gas is introduced from the protective gas inlet to form an inert gas protective layer on the surface area of the stealth coating; 3) adopt Pulse laser to remove the stealth coating; 4) Turn off the laser and the gas-assisted protection device, clean up the residual waste on the surface of the sample, and take out the sample; 5) If the stealth coating is not completely removed, repeat the above steps 1) to 4 ). The technology of the invention has the advantages of high precision, fast and high efficiency, no damage to the substrate, and can be used for large-area removal; the safety of the laser removal process is guaranteed through the gas-assisted protection device, and the removal quality of the stealth coating on the aircraft surface is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

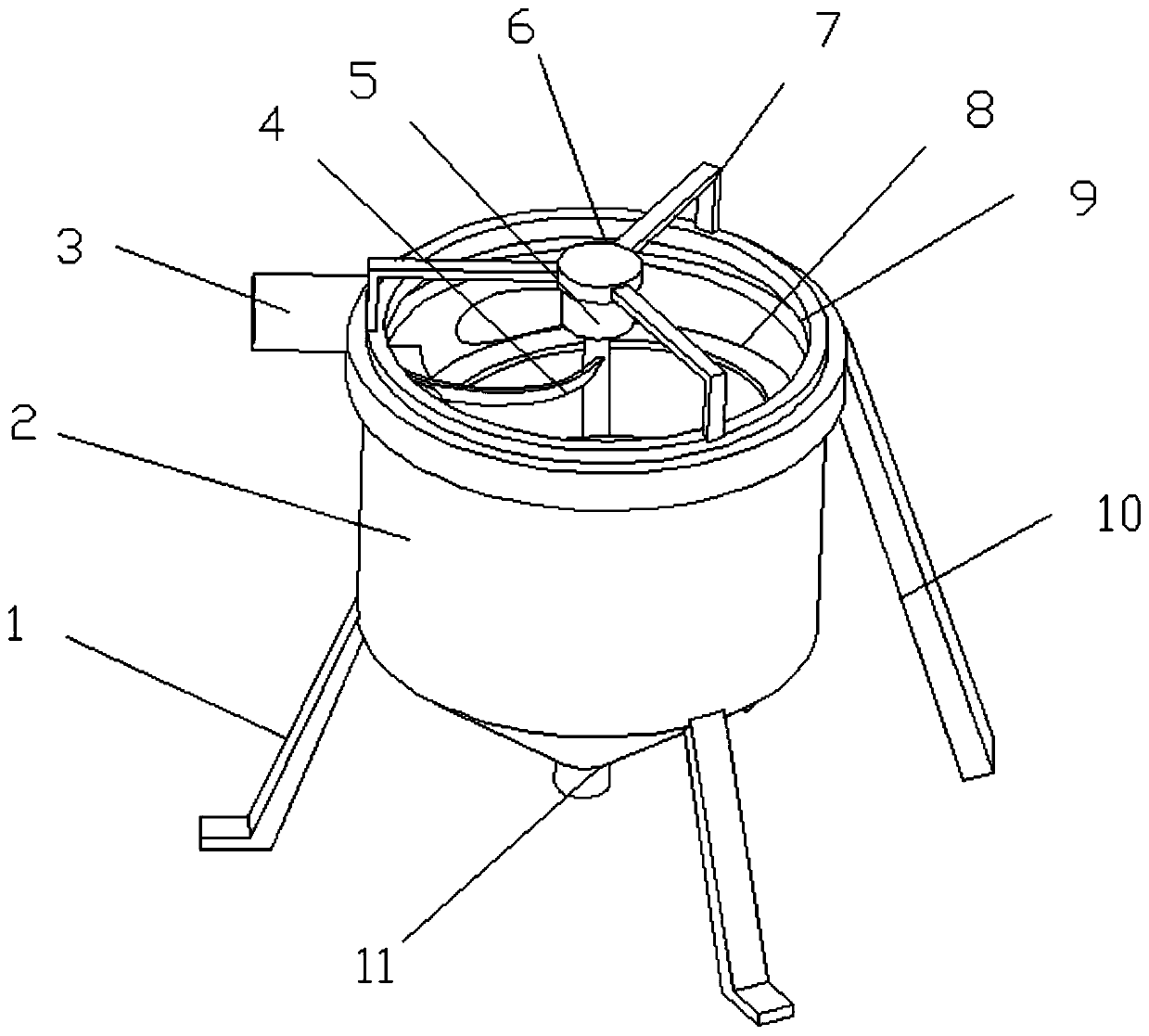

Handheld leather shoe skin dirt wiping device

ActiveCN108903886AChange the way the epidermis is wipedReduce intensityFootwear cleanersCouplingMicro motor

The invention relates to the technical field of leather shoe maintenance, and discloses a handheld leather shoe skin dirt wiping device. The wiping device comprises a barrel body; a transverse installing plate is fixedly connected between the inner walls of the left side and the right side of the barrel body; a storage battery is fixedly connected to the upper surface of the transverse installingplate; a micro motor is fixedly connected to the lower surface of the transverse installing plate through bolts; a switch button is arranged in the middle of the top of the barrel body; a limiting handle is fixedly connected to the left side of the barrel body through bolts; a fixed hollow circular ring is welded at the bottom of the barrel body; a rotary circular plate is movably connected to theinner side of the fixed hollow circular ring through movable roll balls; an output shaft of the micro motor is fixedly connected with a torque rotating shaft through a shaft coupler; one end, far away from the micro motor, of the torque rotating shaft is fixedly connected to the middle of the upper surface of the rotary circular plat; and a hollow threaded barrel is fixedly connected to the lowersurface of the rotary circular plate through a connecting plate. According to the handheld leather shoe skin dirt wiping device, the purpose of wiping dirt in gaps at the joints of leather shoe materials is achieved.

Owner:济宁高新文化创意园服务有限公司

Fixture for high-voltage copper contact finger and method for clamping contact finger

InactiveCN106064316BHigh degree of automationRealize automatic flow operationPrecision positioning equipmentMeasurement/indication equipmentsEngineeringCopper

The invention discloses a high-pressure copper finger touch fixture. The high-pressure copper finger touch fixture comprises a base; the base is connected with a detecting mechanism and an indexing mechanism; and the indexing mechanism is connected with a finger touch clamping mechanism. The high-pressure copper finger touch fixture can realize three functions: (1) the finger touch clamping is realized by dint of the finger touch clamping mechanism; (2) the indexing function is realized by dint of the indexing mechanism; and (3) the detecting function is finished by dint of the detecting mechanism. The invention further discloses a finger touch clamping method; the finger touch clamping adopts forward and reverse clamping; the finger touch clamping method conveniently and quickly performs the finger touch clamping; and the method is high in finger touch burr removing efficiency and excellent in removing quality.

Owner:XIAN UNIV OF TECH

Protection device for paper shredder capable of preventing residues on outer wall of paper shredding wheel

InactiveCN114178018AExtended service lifeWon't hurtCleaning using toolsCleaning using gasesBristlePaper dust

The invention discloses a paper shredder protection device capable of preventing residue on the outer wall of a paper shredding wheel in the technical field of paper shredders, and the paper shredder protection device comprises a paper shredder main body, the left and right sides of the top of the inner cavity of the paper shredder main body are symmetrically provided with residue-preventing paper shredding wheel protection mechanisms with the same structure; the anti-residue paper shredding wheel protection mechanism comprises paper shredding wheel pieces which are symmetrically and movably arranged on the left side and the right side of the top of an inner cavity of the paper shredder body, one end of each paper shredding wheel piece is connected with a clearing mechanism, and one end of each clearing mechanism is connected with a blowing piece. The anti-residue paper shredding wheel protection mechanism is arranged, when a paper shredding tooth piece moves to the outer wall of the driven roller from a transition arc-shaped convex part, under the action of a connecting spring, a tooth blade inwards enters a movable opening in the paper shredding roller, on one hand, paper shreds remaining on the tooth blade are pushed away from the tooth blade when the tooth blade moves, and on the other hand, the paper shredder is matched with a removing mechanism, so that the paper shredder is convenient to clean. And as the tooth blades at the positions are retracted inwards, the cleaning quality is higher, and the electrostatic eliminating bristles are prevented from being damaged due to the influence of the tooth blades.

Owner:宁波博采文具礼品有限公司

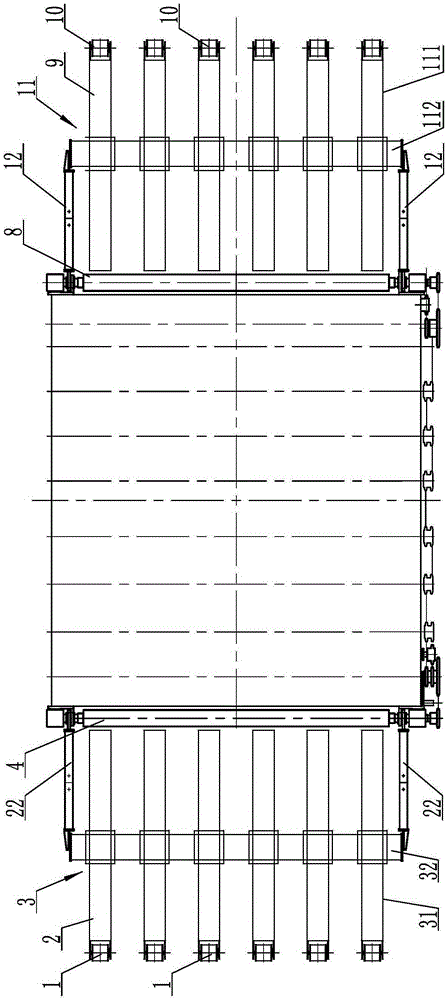

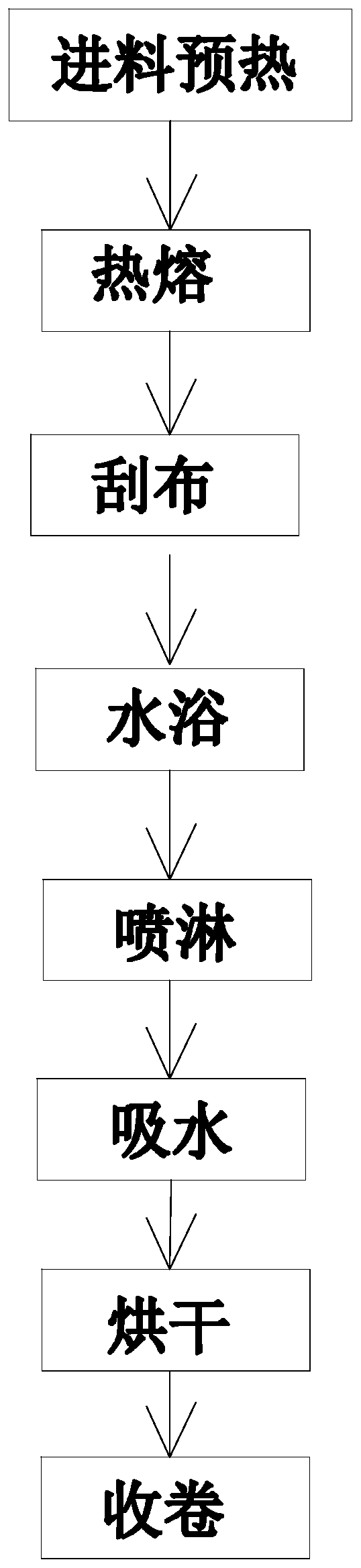

A kind of embroidery lining film removal process

The invention provides an embroidery lining film removing process. The embroidery lining film removing process comprises the following steps: A, feeding and preheating by coiling an embroidery cloth with a lining film on a feeding roller, conveying the embroidery cloth to a feeding table and preheating the embroidery cloth; B, hot melting by conveying the embroidery cloth to a hot melting assembly, enabling the embroidery cloth to pass between a pressing roller and a hot melting roller, pressing the embroidery cloth on the upper roller surface of the hot melting roller by the pressing roller, hot melting the lining film on the lower surface of the embroidery cloth and transferring the embroidery cloth to the hot melting roller; C, scraping the cloth by conveying the embroidery cloth to a cloth scraping table, wiping the embroidery cloth via a scraping roller on the cloth scraping table and removing the molten lining film carried by the embroidery cloth; D, carrying out water bath by conveying the embroidery cloth to a water bath tank, pressing the upper surface of the embroidery cloth via the pressing roller, enabling the embroidery cloth to be immersed in hot water and simultaneously rolling and brushing the lower surface of the embroidery cloth via a brushing roller; E, spraying by conveying the embroidery cloth to the water surface of the hot water for spraying the embroidery cloth; F, absorbing water by conveying the embroidery cloth to a water absorption assembly, and absorbing water on the embroidery cloth via a water absorption block I and / or a water absorption block II; G, drying; and H, coiling.

Owner:庆阳淑方香包刺绣有限公司

Ultra-hard insert product burr removing device using electric brush

PendingCN114650896AImprove production efficiencyShort preparation timePolishing machinesDirt cleaningForeign matterPunch press

The present invention relates to an apparatus for removing burrs of a superhard insert product using a brush, the apparatus for removing burrs of a molded article taken from a molding press apparatus and cleaning the surface thereof, the apparatus comprising: a burr removing part consisting of: a brush module held by a gripper, the brush module having a brush surface; removing burrs of the blade milling part of the forming object passing through the burr removing area and foreign matters adhered to the lower side surface part; an electric brush clamping device which is easy to mount and dismount the electric brush module; the upper surface cleaner is used for removing foreign matters on the upper surface part of the forming object together with the electric brush module; a cleaning module which suppresses the scattering of dust generated by the brush module and the upper cleaner and sucks the dust; the driving part is composed of the following components: a rotating part which rotates the electric brush module to clean the forming object; a moving part which moves the side brush to the inner side; the machine frame is in a cuboid shape and is composed of an upper portion provided with the burr removing portion and a lower inner side provided with the driving portion. Therefore, according to the device provided by the invention, the burrs of the superhard insert product taken from the forming punch press can be removed and cleaned by utilizing the two side electric brushes, the lower electric brush and the upper cleaner, so that the production benefit of the product is improved, the cleaned foreign matters are gathered at one place, the superhard alloy powder in the foreign matters is recovered, and the product quality is improved. And the production cost is reduced.

Owner:WINTECH AUTOMATION

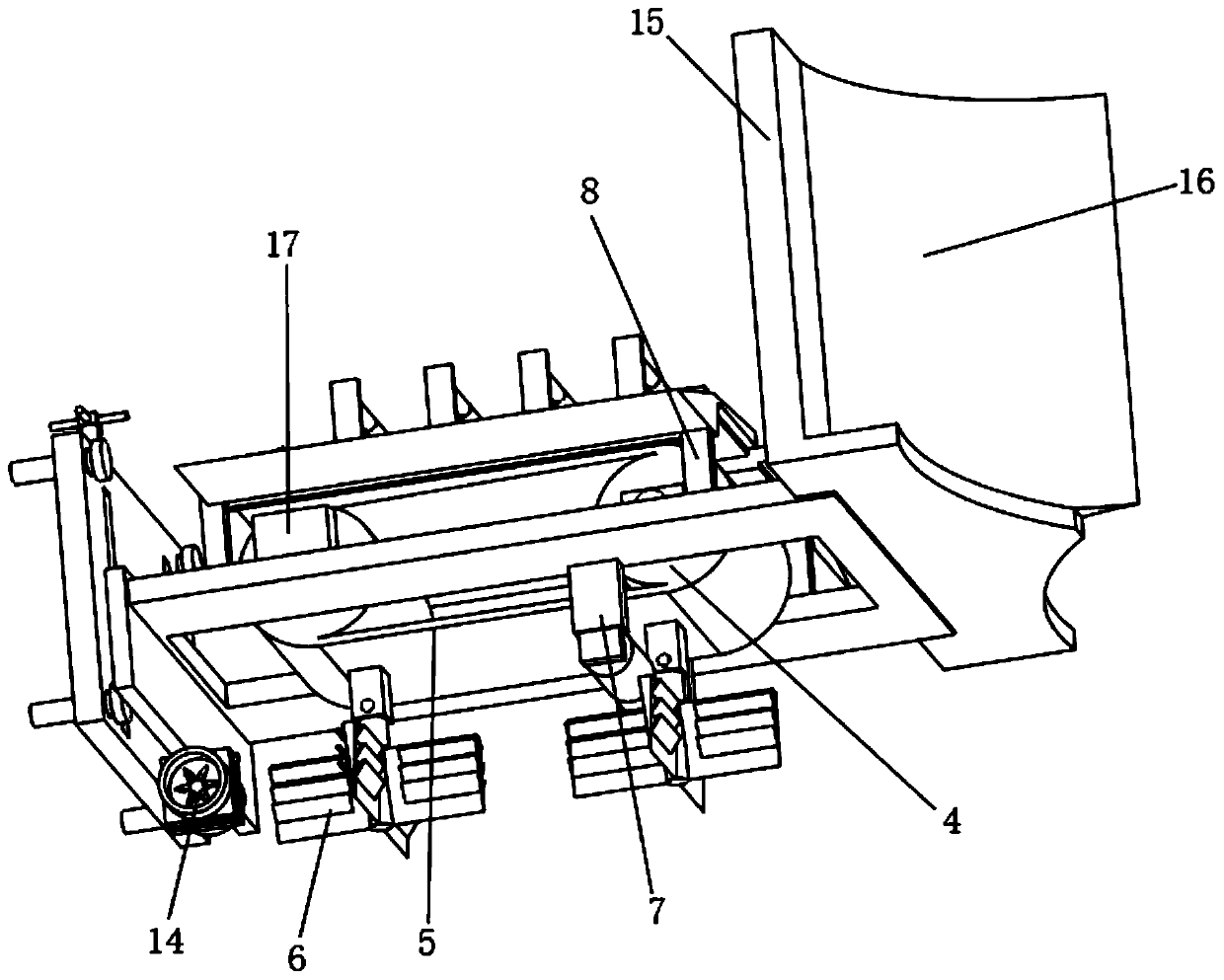

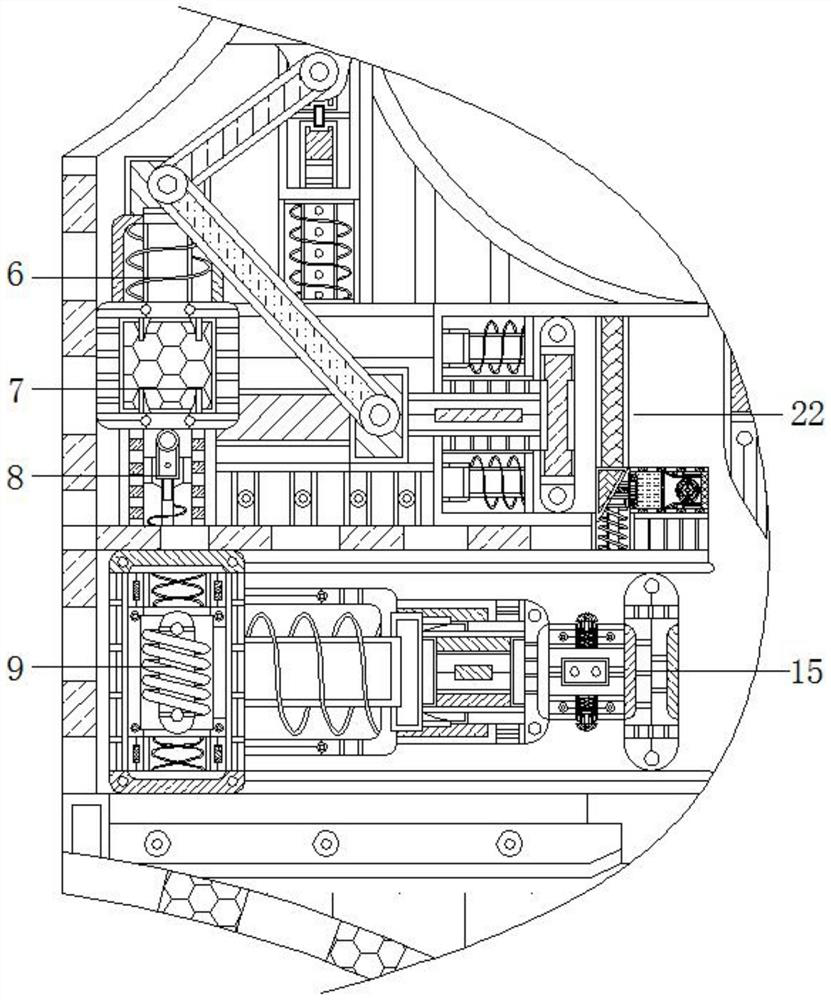

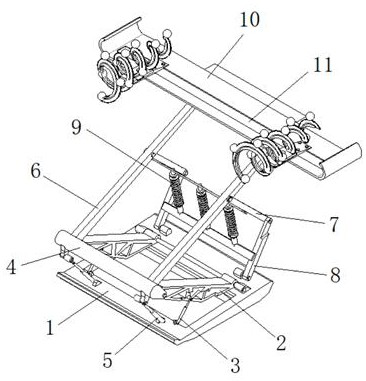

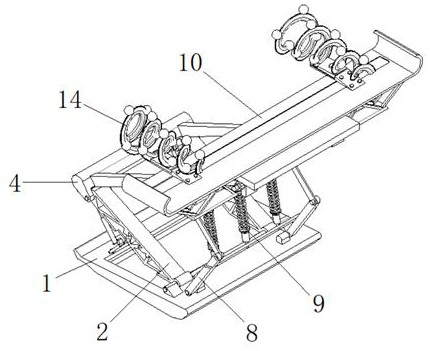

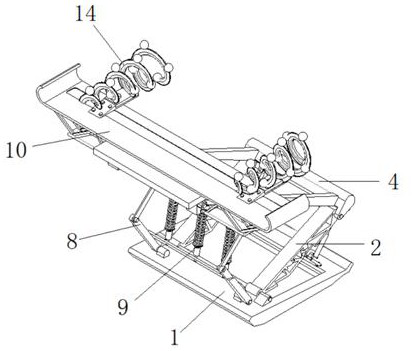

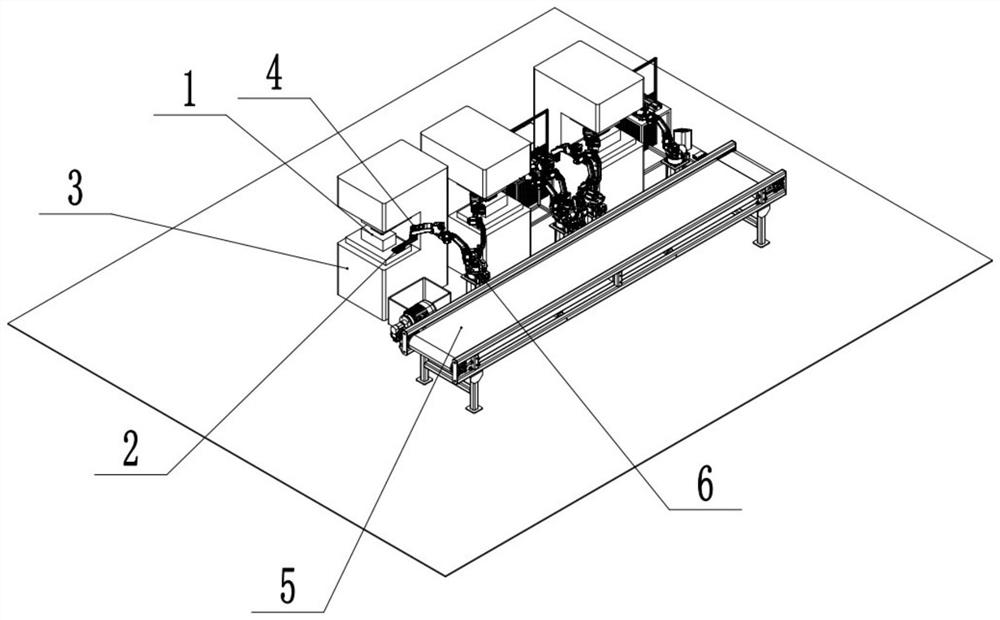

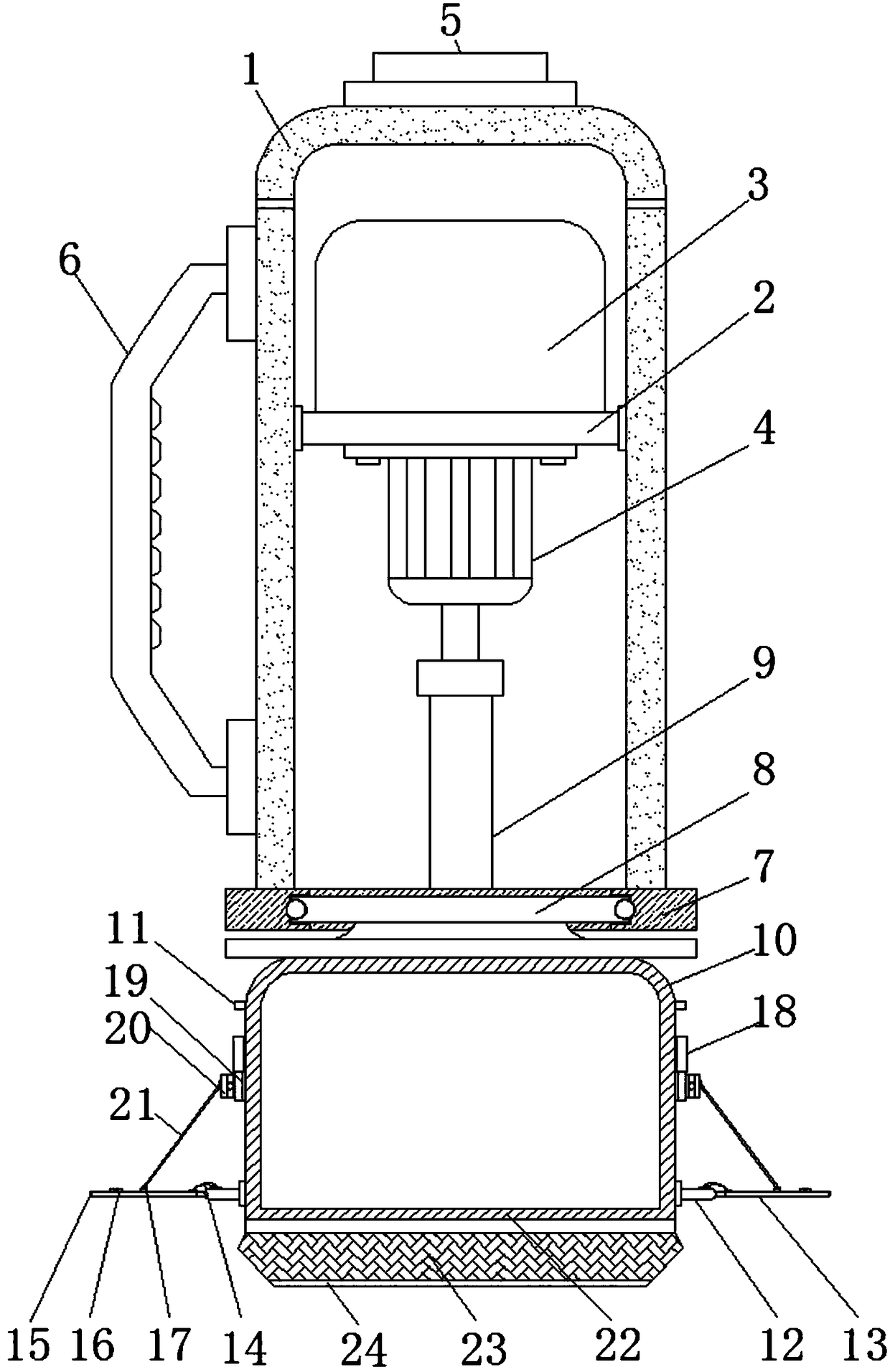

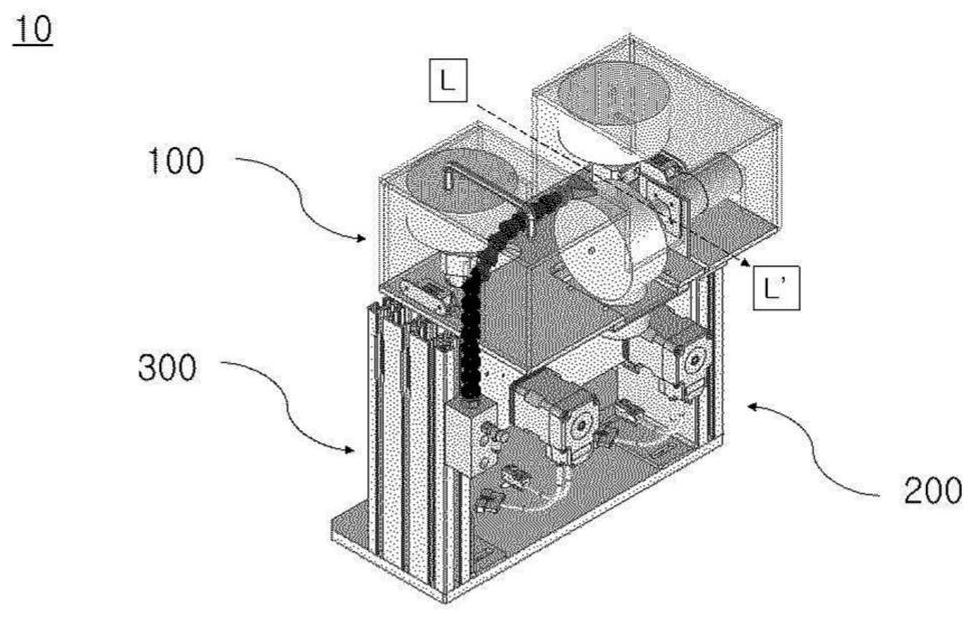

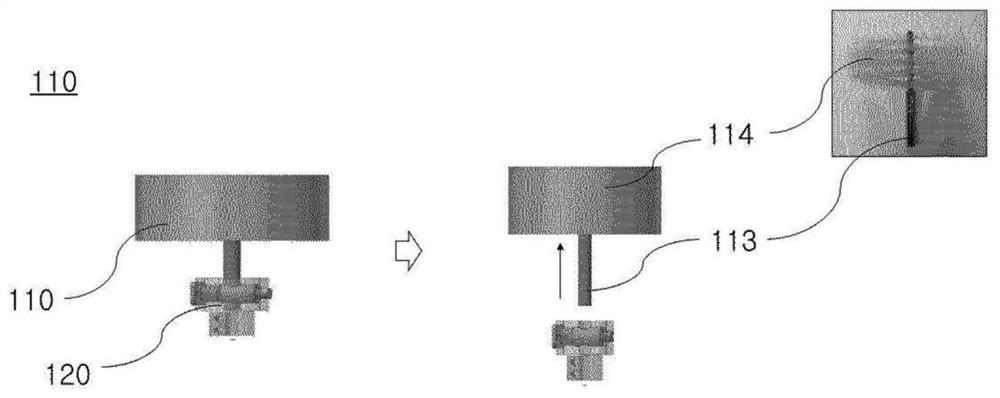

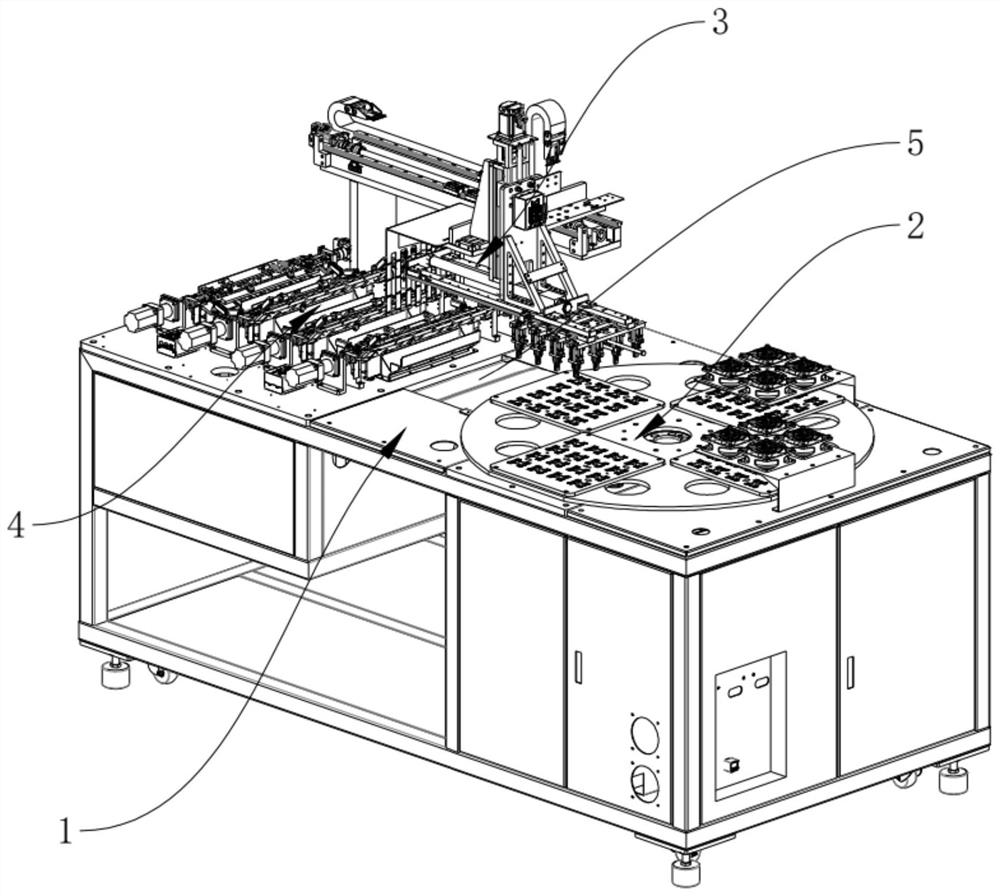

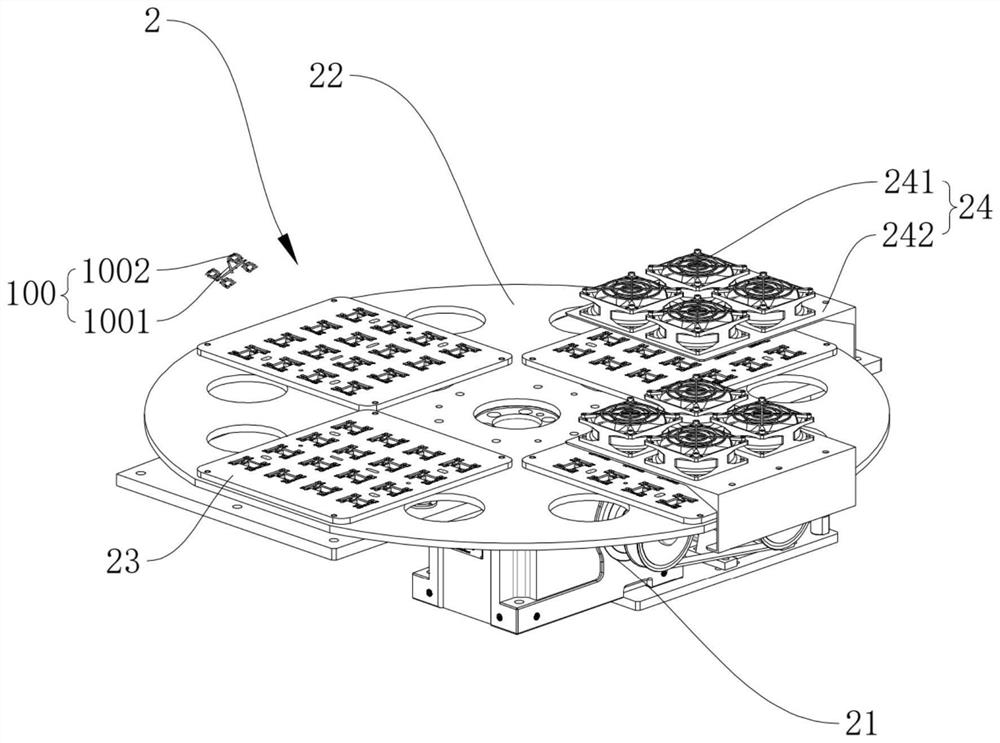

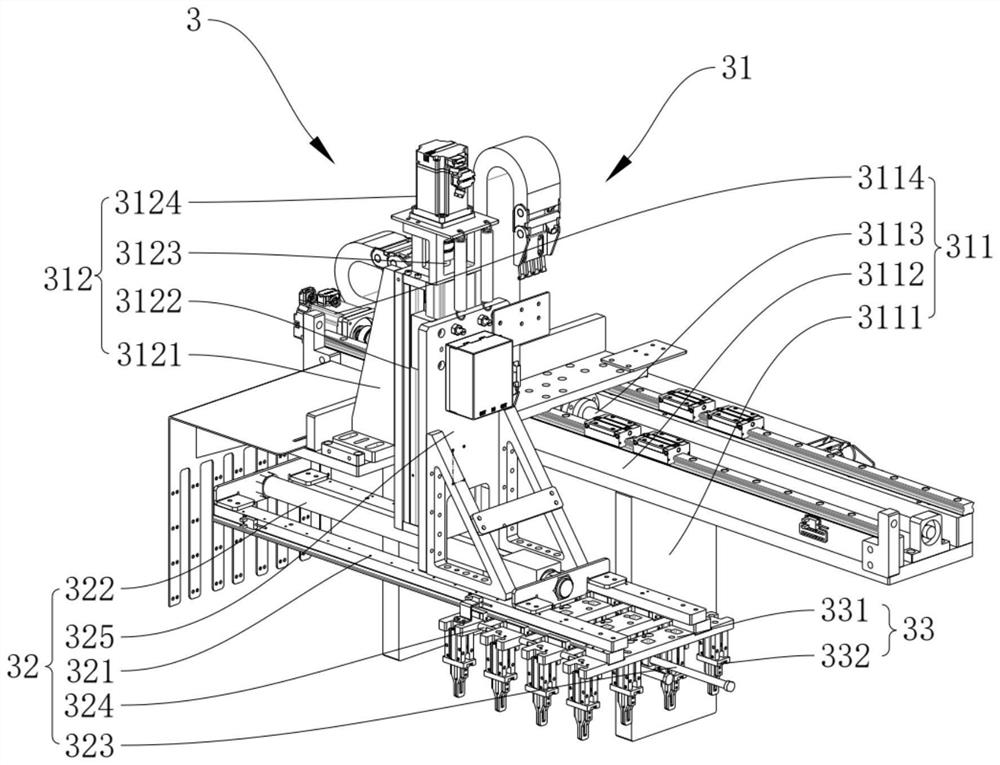

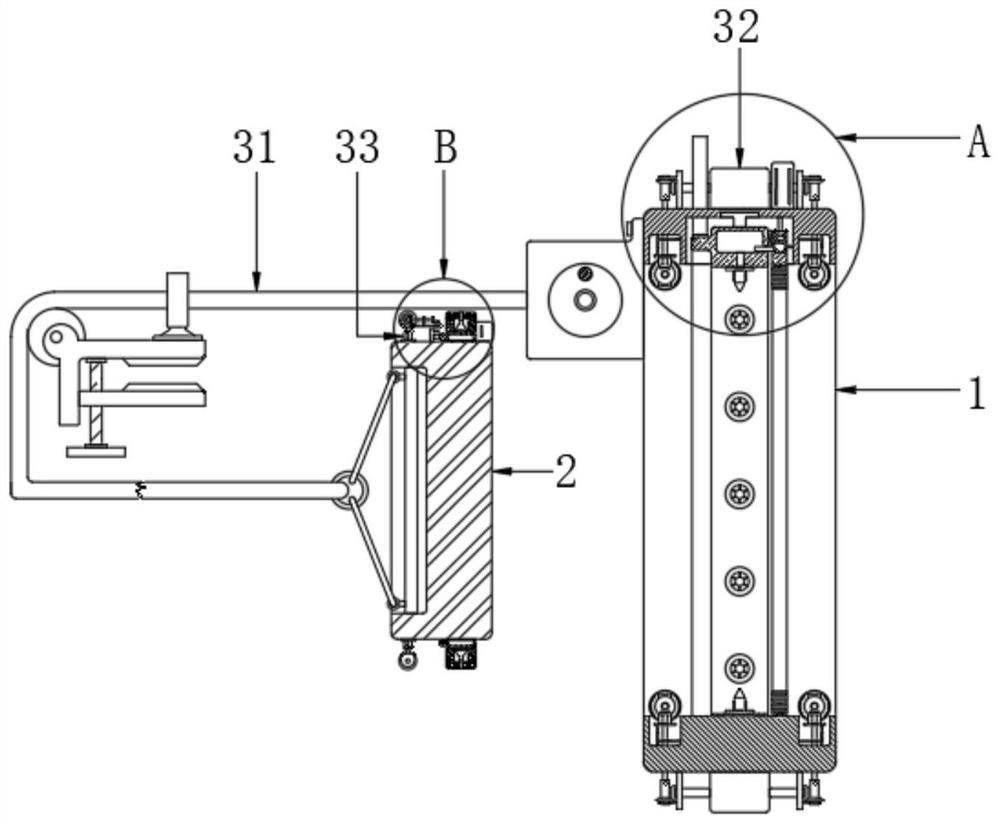

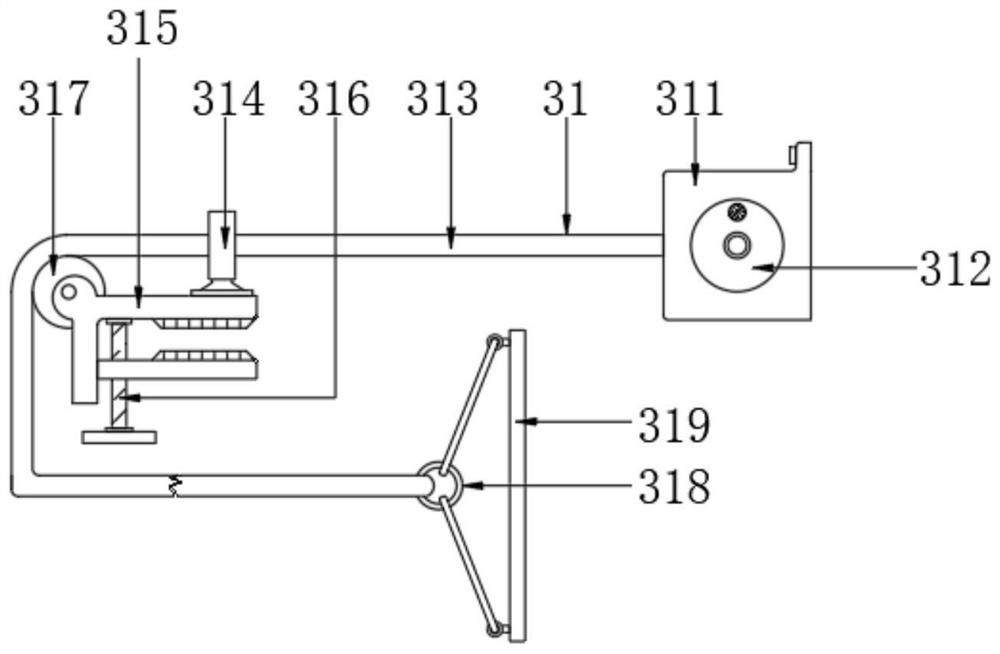

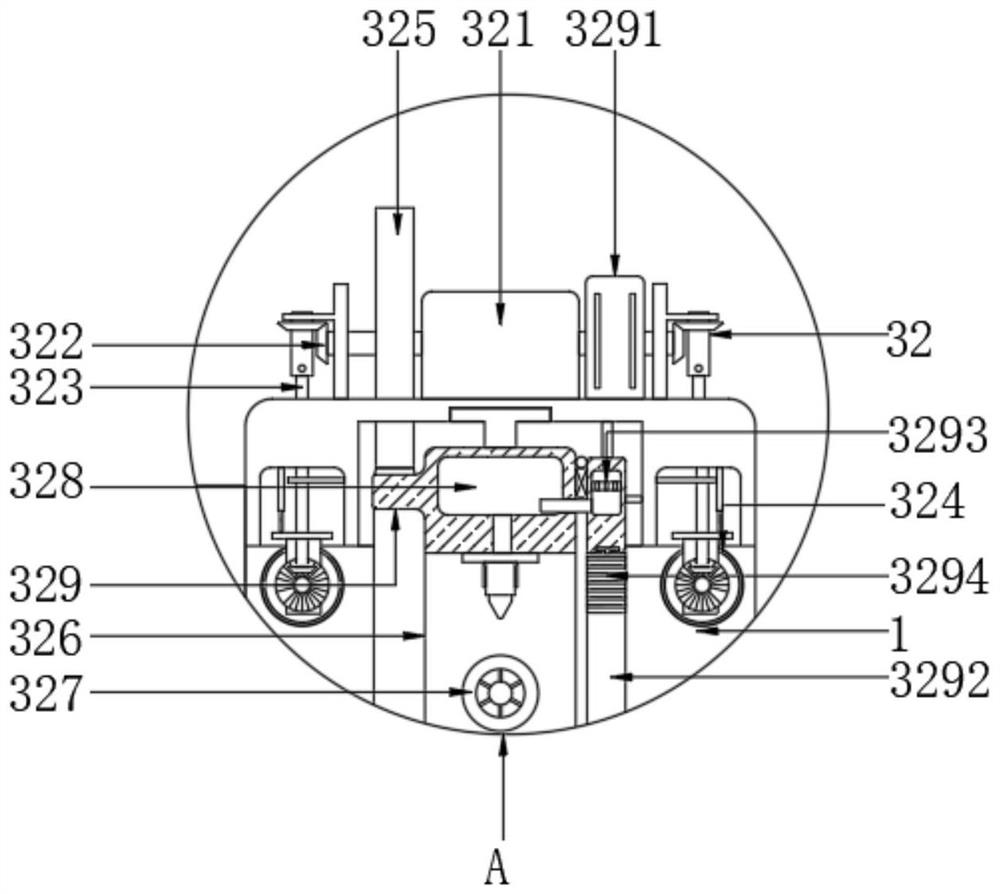

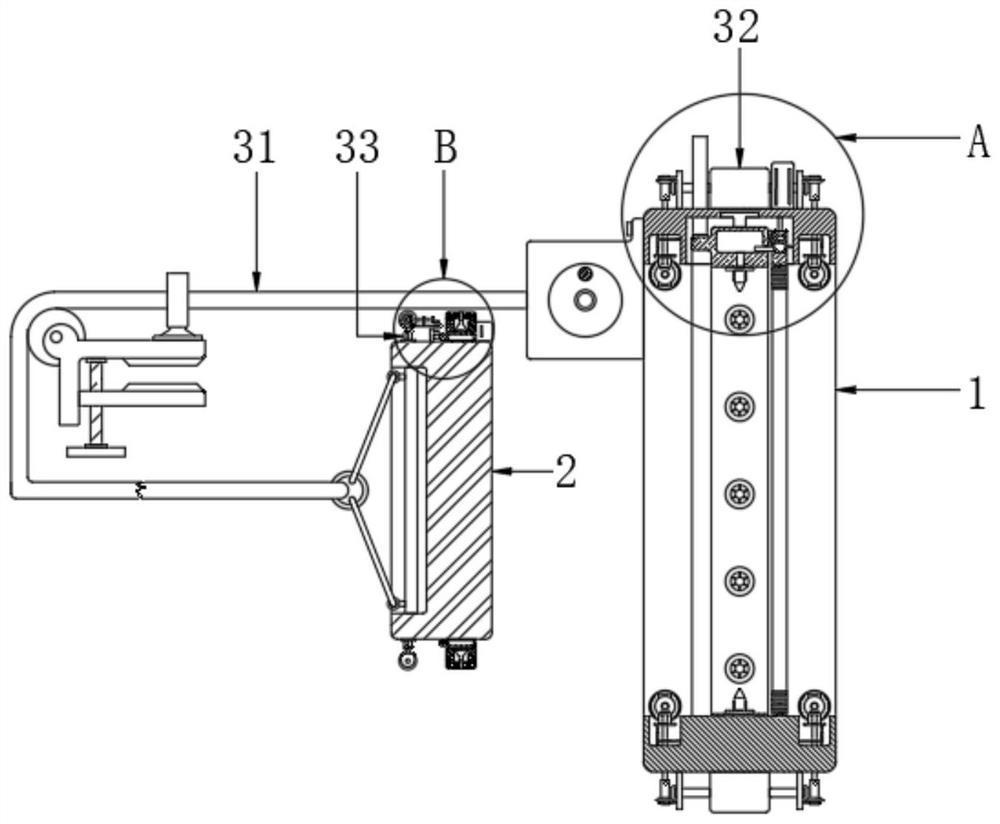

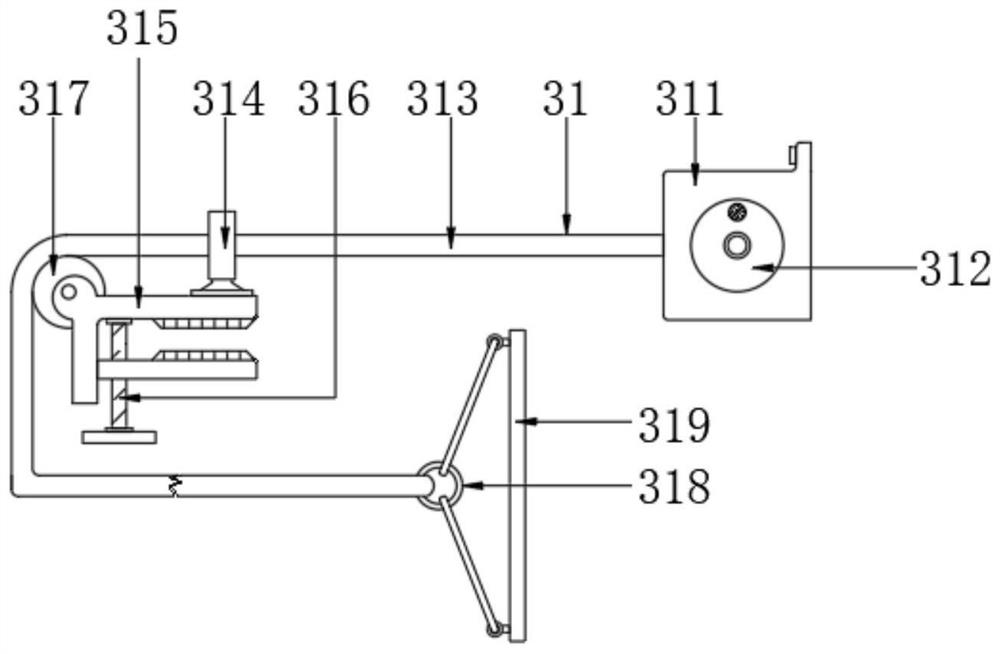

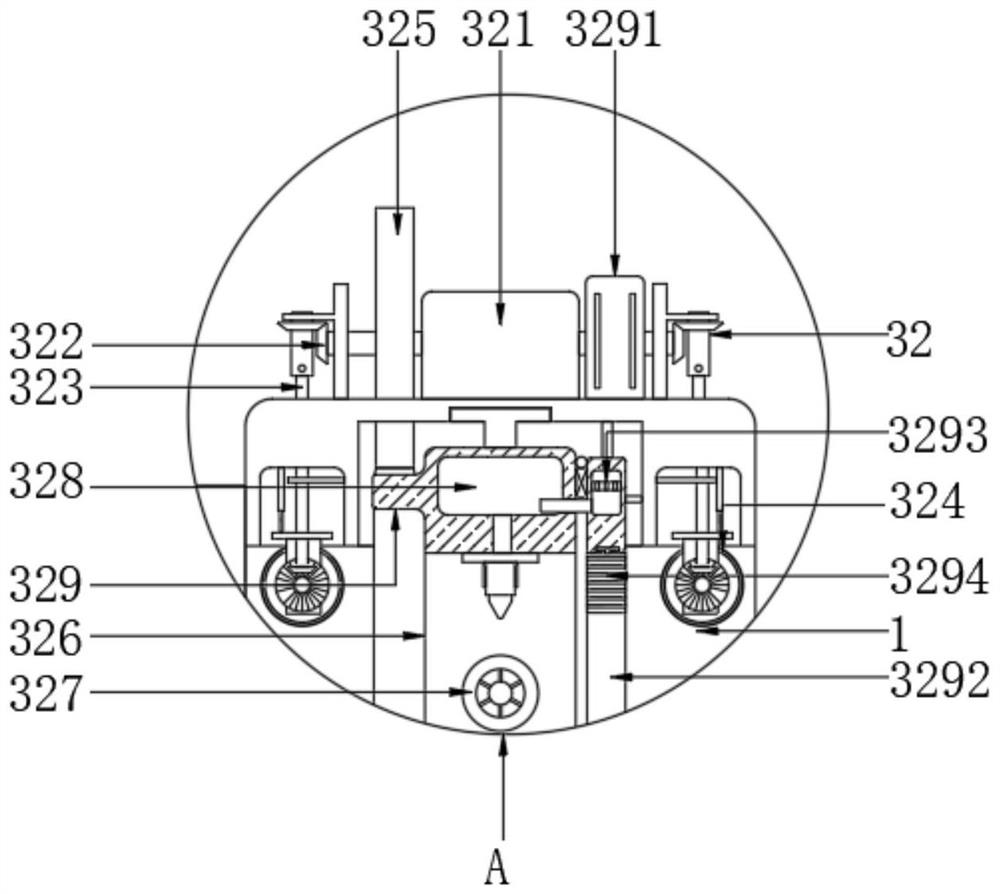

Injection molding part material root breaking equipment

ActiveCN113319936AGood removal effectImprove removal qualityPlastic recyclingMetal working apparatusEngineeringWorkbench

The invention relates to the technical field of injection molding part machining, and discloses injection molding part material root breaking equipment. The injection molding part material root breaking equipment is used for breaking a material root of an injection molding part and comprises a workbench, wherein a cooling feeding device, a material conveying device and a breaking device are arranged on the workbench, and the cooling feeding device is configured to bear the injection molding part subjected to injection molding and can also cool the injection molding part; the material conveying device is configured to grab the cooled material roots and convey the injection molding parts to the breaking device; the breaking device comprises two breaking assemblies which are symmetrically arranged at intervals, the two breaking assemblies are configured to clamp products on the two sides of the material roots correspondingly, and the breaking assemblies can drive the products to rotate relative to the material roots, so that the products can be separated from the material roots. According to the injection molding part material root breaking equipment, automatic separation of products and material roots of injection molding parts and integrated arrangement of cooling and breaking of the injection molding parts are achieved, so that the equipment cost is reduced, the production efficiency is improved, the material roots of the cooled injection molding parts are convenient to remove, and the material root removing quality is improved.

Owner:上海磐云科技有限公司

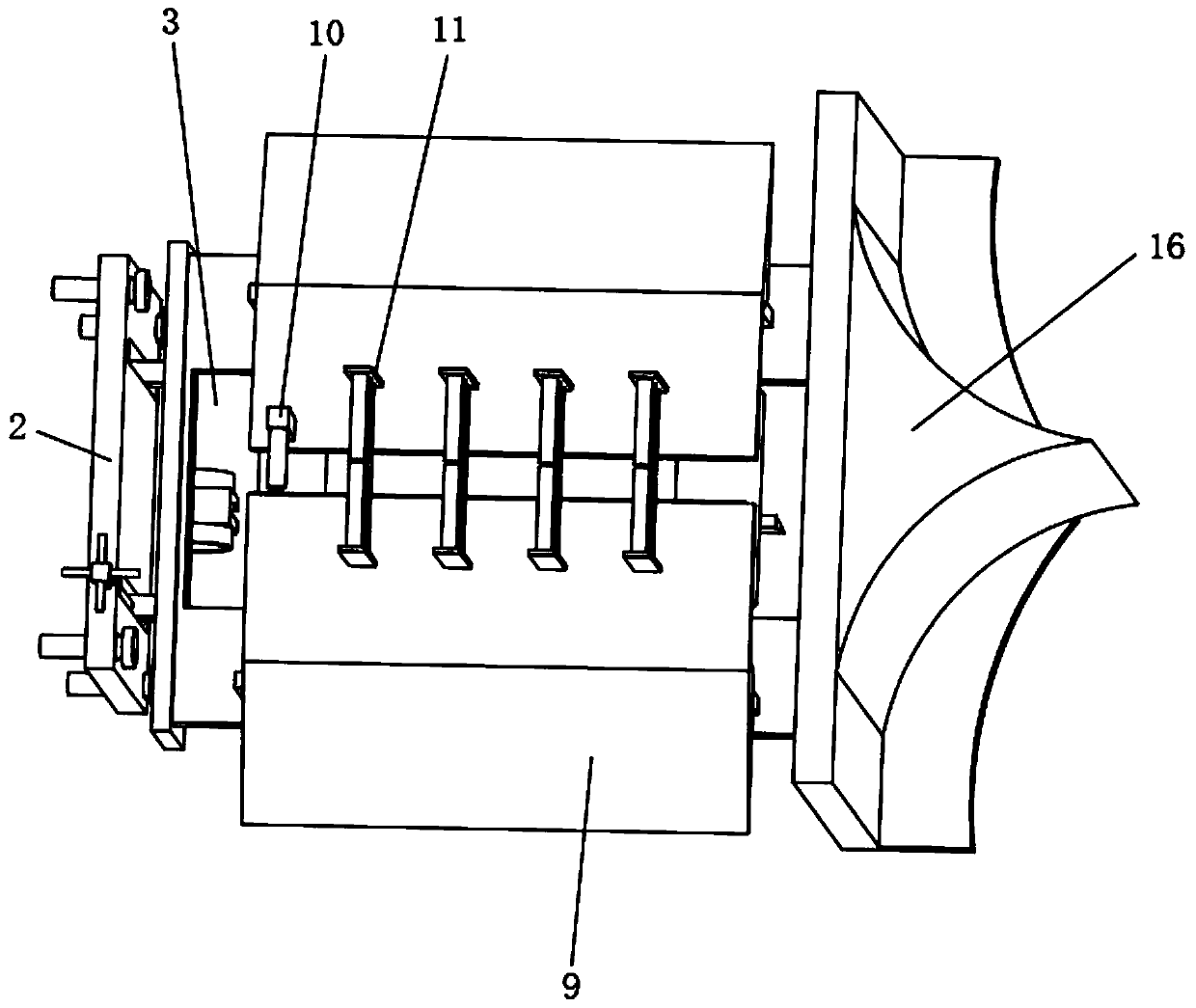

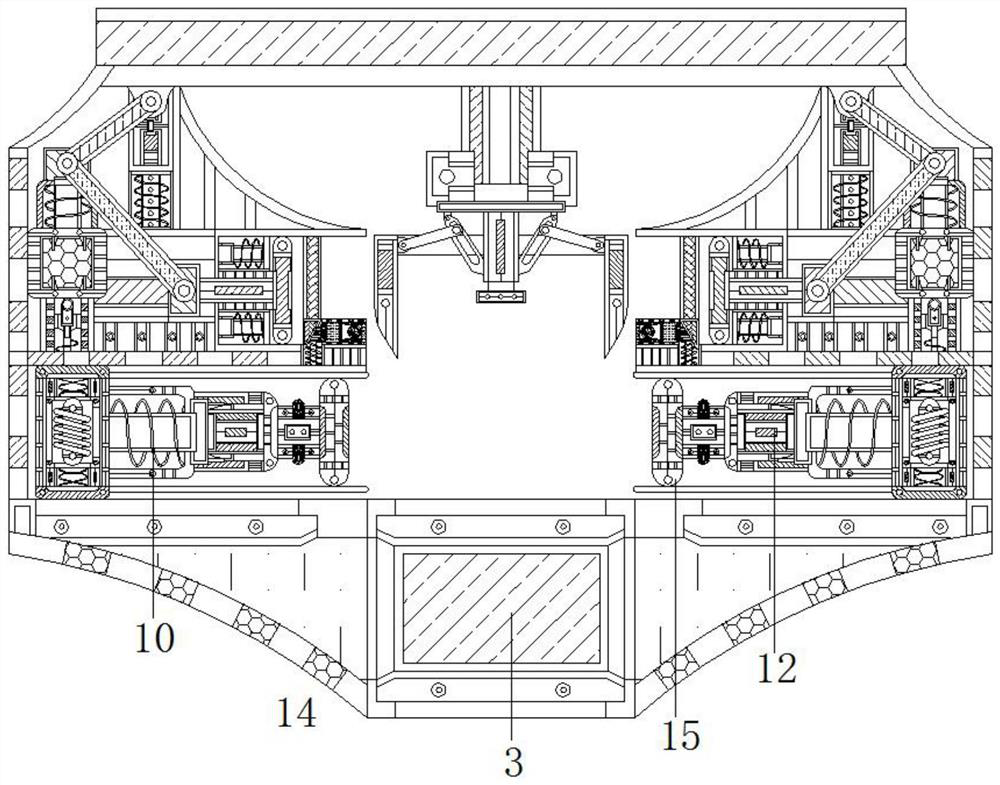

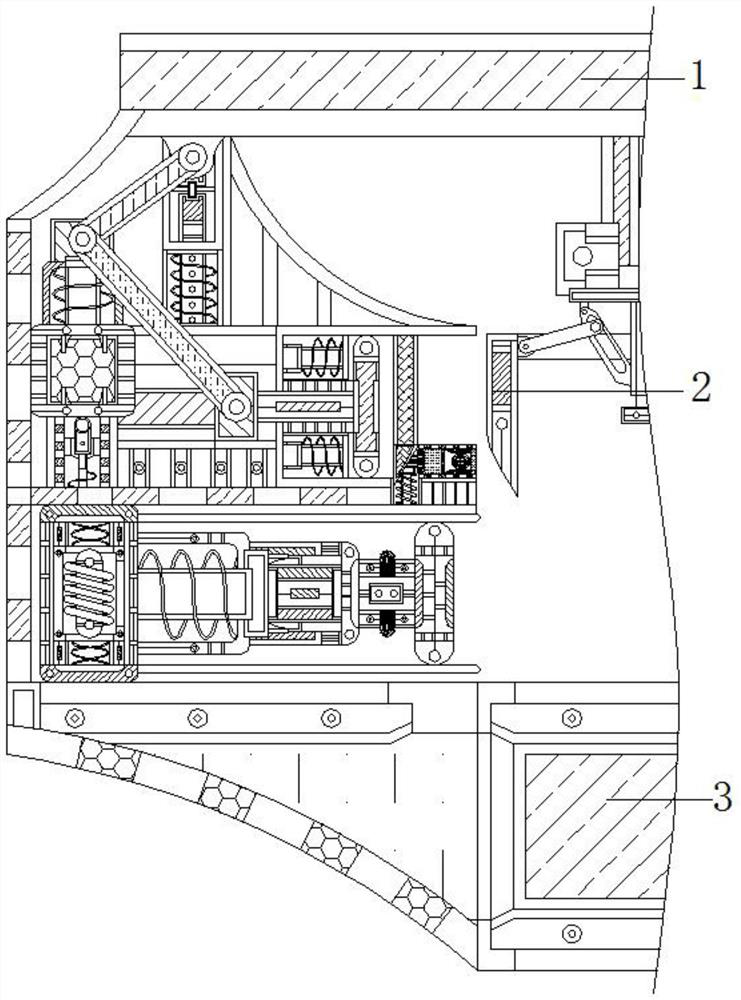

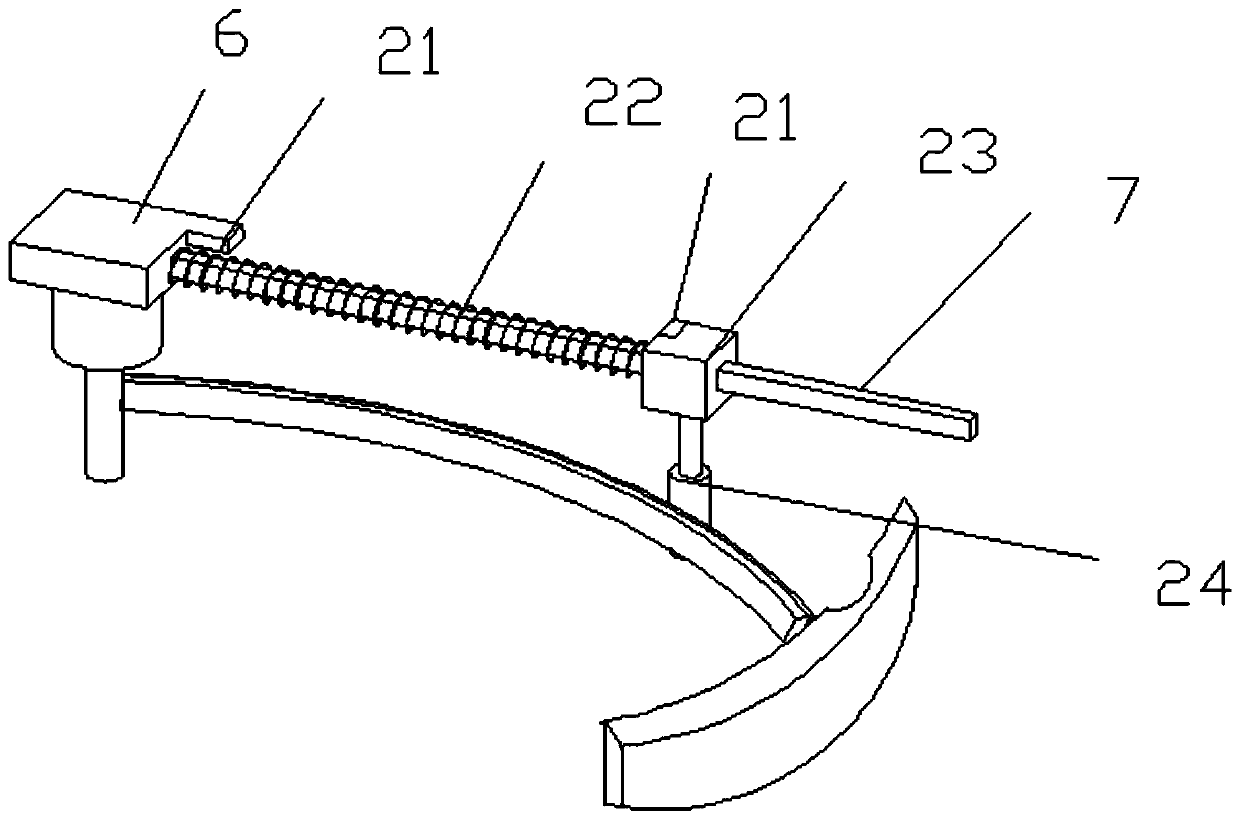

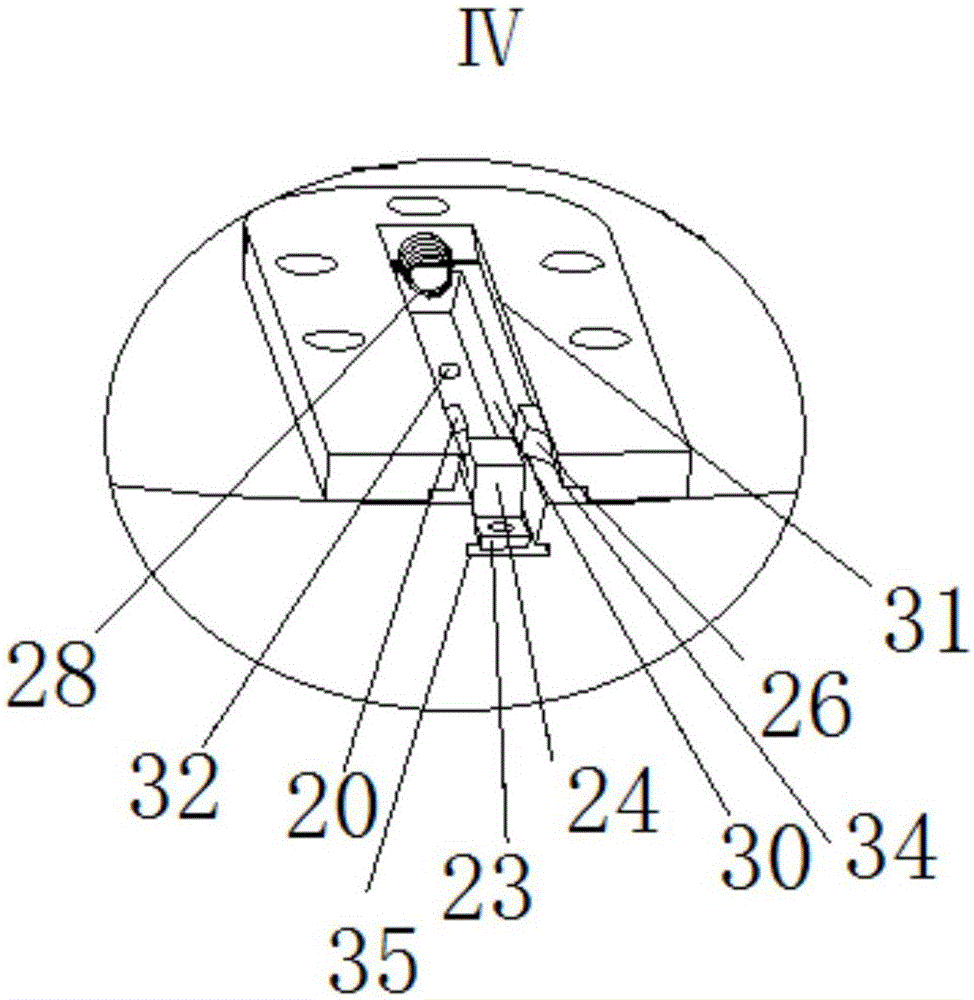

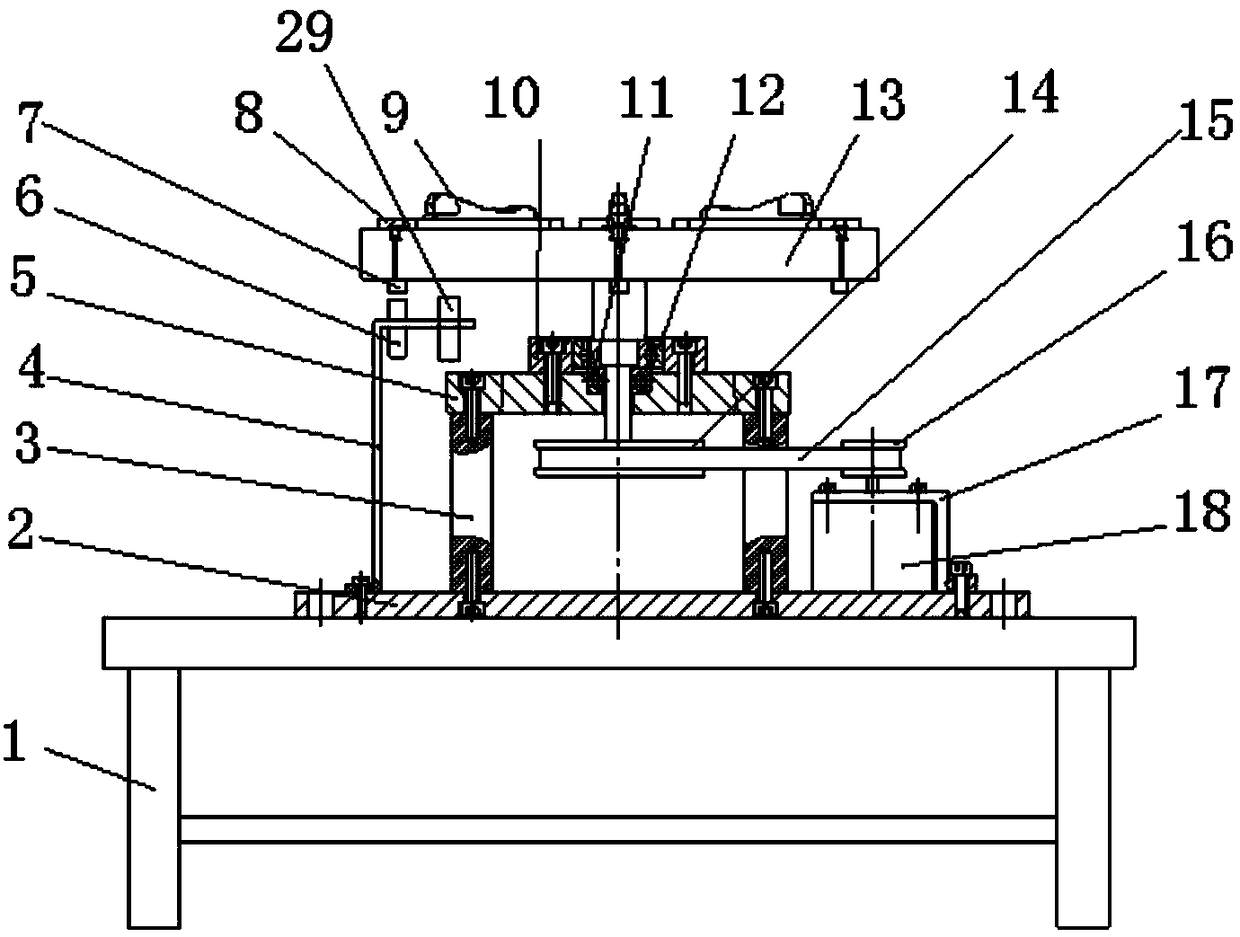

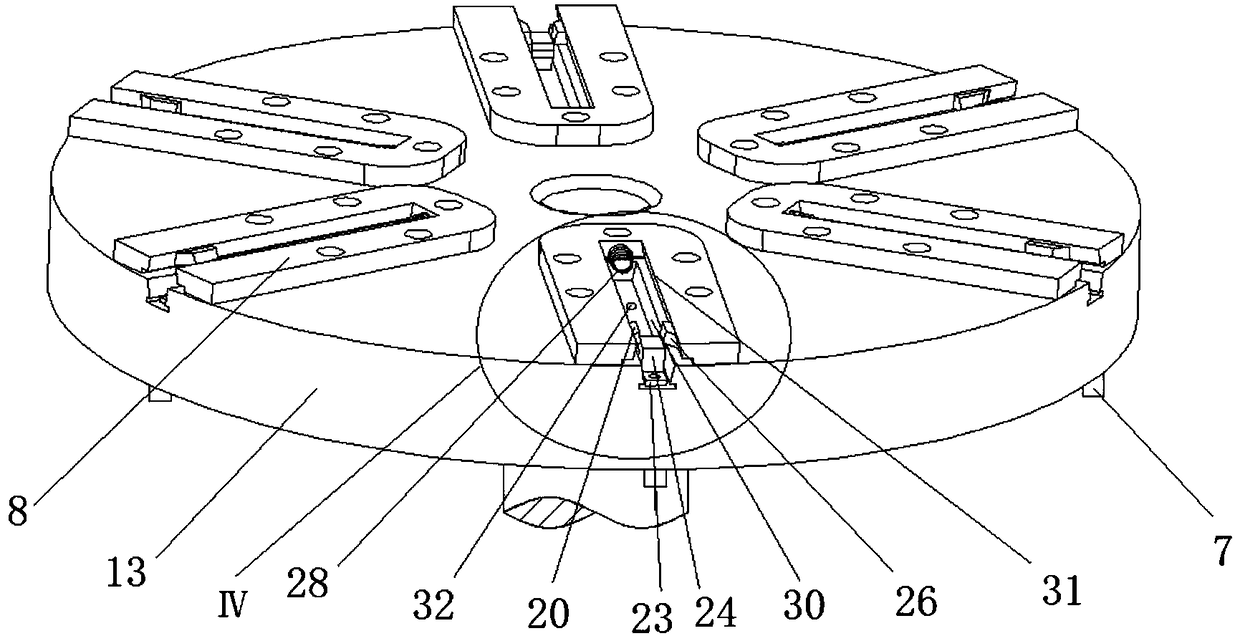

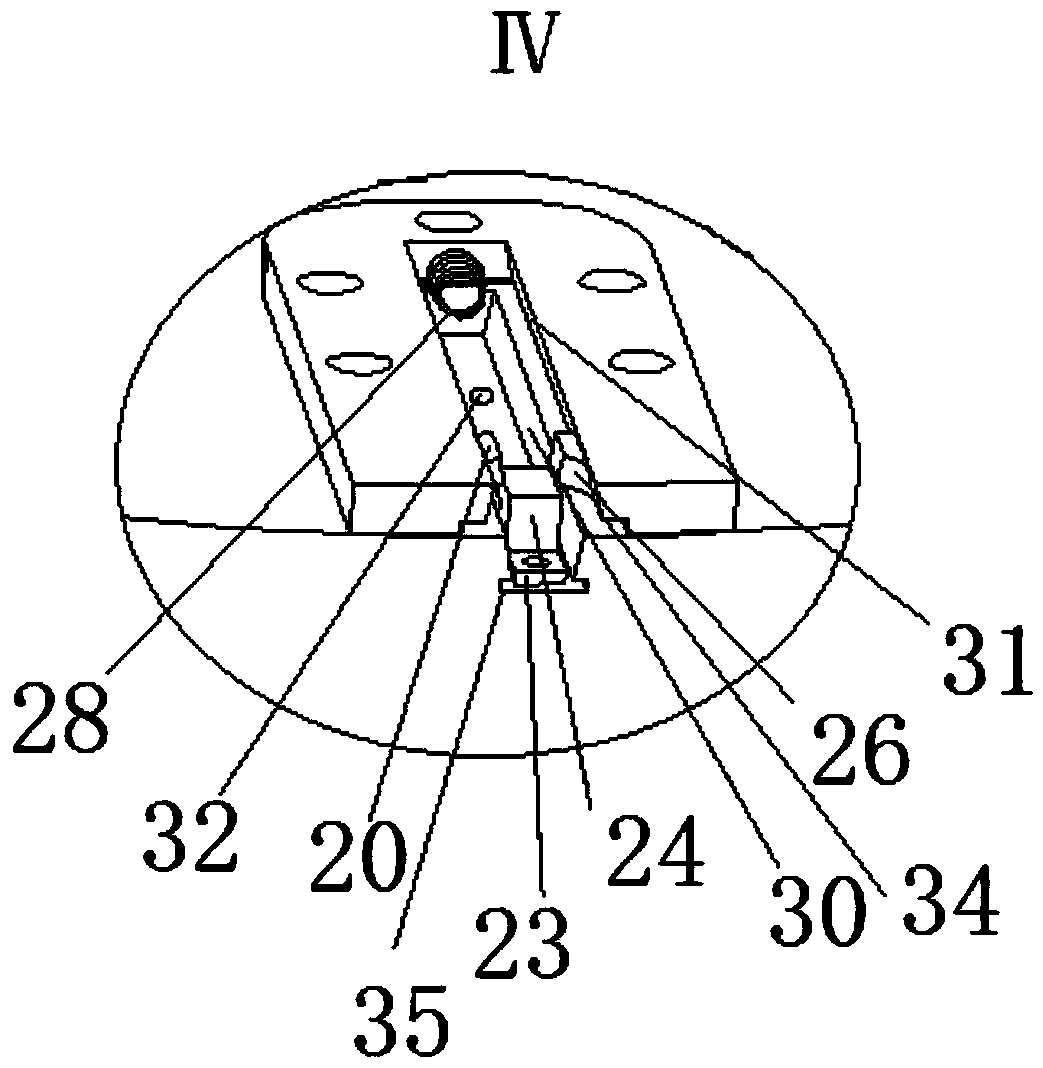

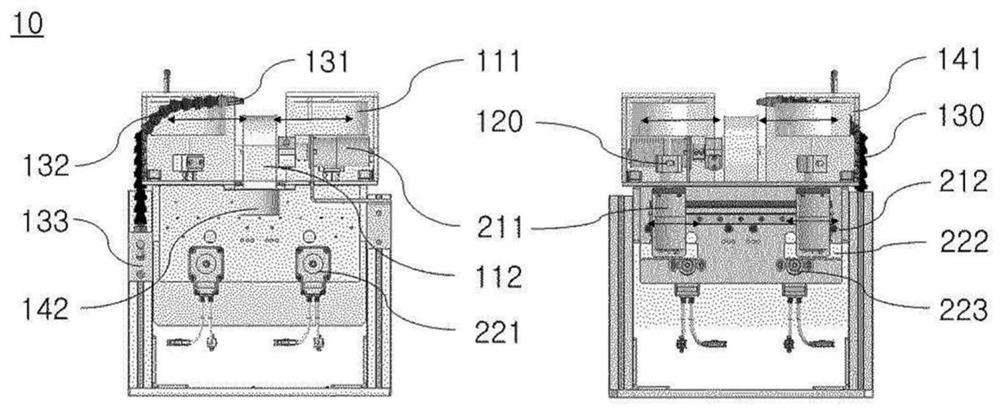

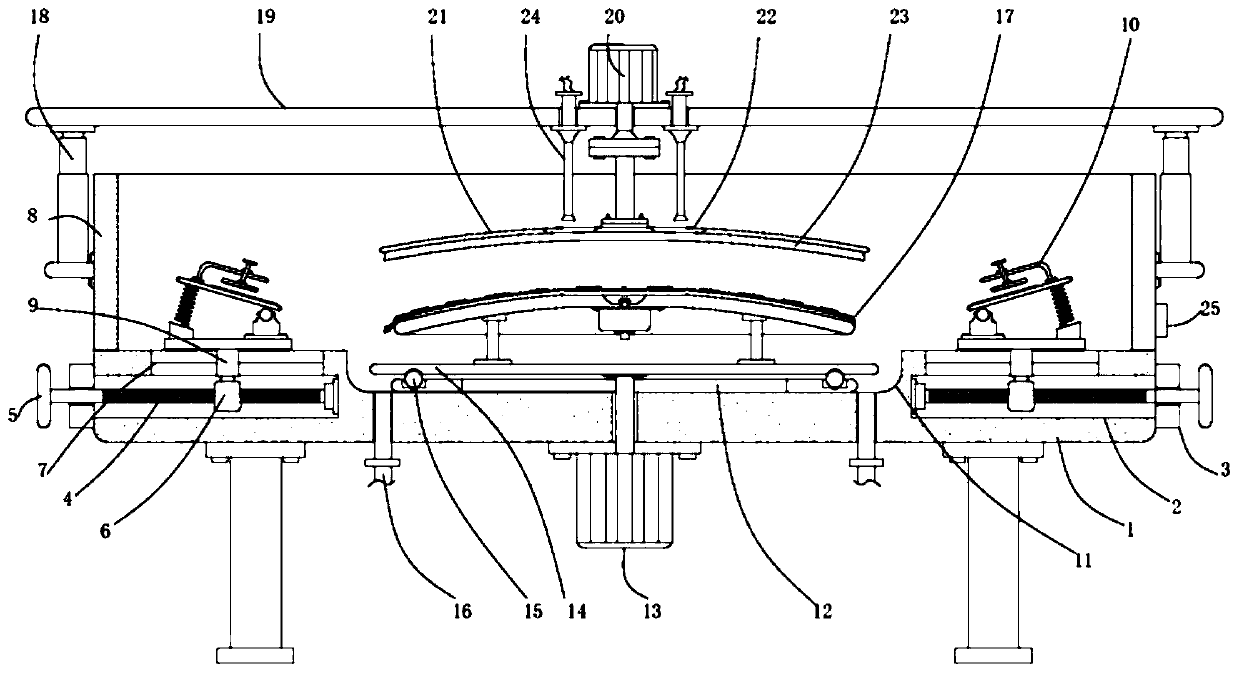

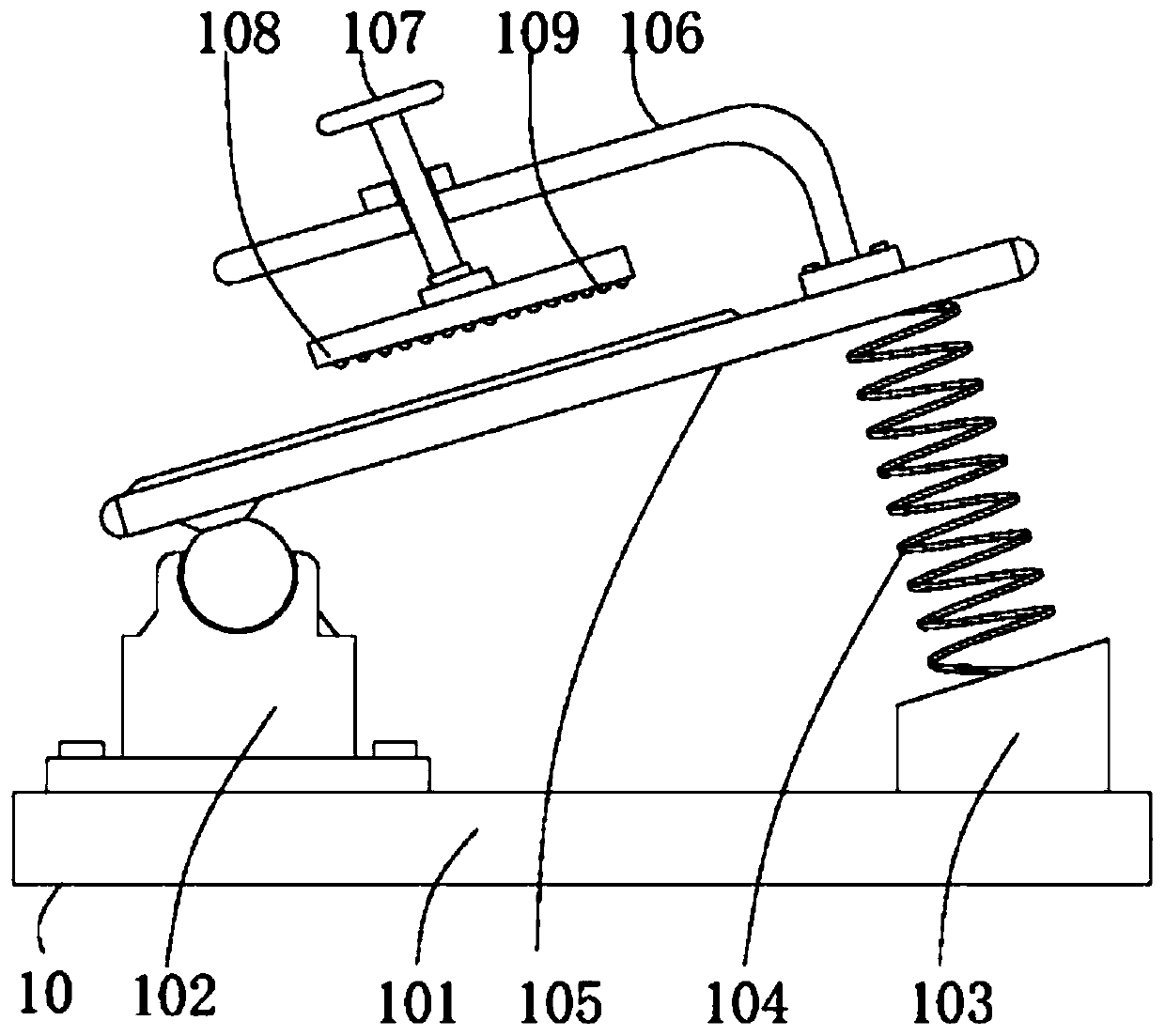

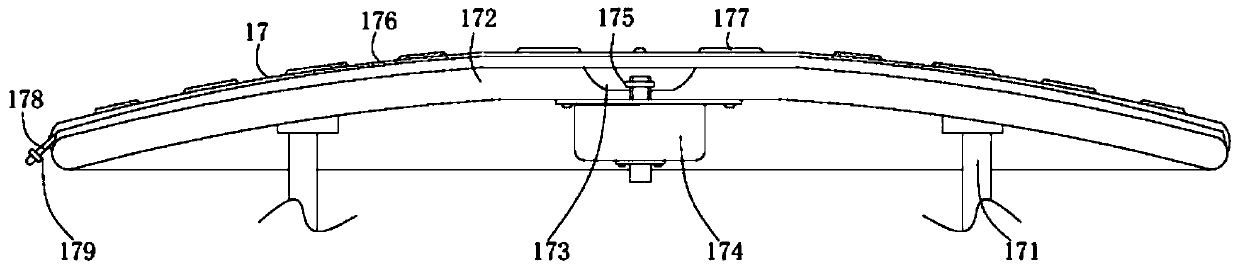

A deburring tool for double-station flywheel ring gear

ActiveCN107378673BImprove removal qualityHigh degree of automationEdge grinding machinesGrinding carriagesEngineeringFlywheel

The invention discloses a burr removing tool for a double-station flywheel ring gear. The burr removing tool comprises a base, an installation rack, rotating tables, flywheel fixing devices, flywheel auxiliary fixing devices, a burr removing device and a controller, wherein the two rotating tables are arranged at the upper end face of the base; the two flywheel fixing devices are arranged in the centers of the rotating tables; the burr removing device is rotatably arranged at the upper end face of the base, and is located on a central connecting line of the two rotating tables; the installation rack is arranged on the base; the two flywheel auxiliary fixing devices are arranged on the installation rack; the two flywheel auxiliary fixing devices are located right above the two flywheel auxiliary fixing devices; and the rotating tables, the burr removing device and the flywheel auxiliary fixing devices are connected with the controller. The burr removing tool for the double-station flywheel ring gear provided by the invention is high in automation degree, simple to operate, good in burr removing quality, and high in removal efficiency.

Owner:重庆五龙洪洋机械制造有限公司

An underground oil storage facility

ActiveCN113200506BImprove purityImprove removal qualityLarge containersLiquid transferring devicesCentrifugal forcePetroleum oil

The invention discloses an underground petroleum storage device, which comprises a foundation, and an oil storage depot for storing petroleum is opened in the foundation, and a centrifugal tank, an electric telescopic rod and an overflow box are respectively fixedly installed on the upper end surface of the foundation, and the electric telescopic The rod is located between the centrifuge tank and the overflow box, and a centrifuge chamber is coaxially opened in the centrifuge tank, and the bottom wall of the centrifuge room is conical, and the level of the bottom wall in the centrifuge room is above the overflow box, the centrifuge There is a centrifugal mechanism in the room, and a cylindrical horizontal groove is arranged in the centrifugal tank, and the horizontal groove is located directly below the centrifugal chamber, and a rotating roller is installed in the horizontal groove, and the peripheral wall of the rotating roller is symmetrically provided with Sink. The advantage is that the present invention uses centrifugal force to settle the residue in the oil by stirring and rotating the oil, and then uses the rotating roller and the sink to transfer the residue at the bottom wall of the centrifugal chamber to the slag storage box without shutting down .

Owner:南通市通州区袁灶燃气有限公司

A residual liquid removal device and method for hot-dip galvanized steel pipe

ActiveCN112760585BAchieve clearingReduce use costHot-dipping/immersion processesElectric machineBevel gear

The invention discloses a residual liquid removal device for hot-dip galvanized steel pipes in the technical field of hot-dip galvanized steel pipes, comprising an outer sleeve and an inner sleeve, the diameter of the outer sleeve is larger than that of the inner sleeve, and the The outer sleeve and the inner sleeve are equipped with a residual liquid removal assembly. After the device is installed in the present invention, the electric telescopic rod is driven to drive the rollers, so that the top and bottom rollers are respectively close to the top and bottom inner walls of the steel pipe, and then the double shaft is driven The motor, the double-axis motor drives the adjustable telescopic rod through the bevel gear set 1, and the adjustable telescopic rod drives the moving wheel through the bevel gear set 3, so that the outer sleeve moves to the right on the outer wall of the steel pipe, and the outer sleeve moves to the right. The inner sleeve is pulled by the pull rope to move to the left in the steel pipe to realize the synchronous removal of internal and external residual liquid. On the one hand, the use cost is greatly reduced, and the work efficiency is improved at the same time.

Owner:徐州瑞马智能技术有限公司

Residual liquid removing device and method for hot-dip galvanized steel pipe

ActiveCN112760585AAchieve clearingReduce use costHot-dipping/immersion processesElectric machineBevel gear

The invention discloses a residual liquid removing device for a hot-dip galvanized steel pipe in the technical field of hot-dip galvanized steel pipes. The residual liquid removing device comprises an outer sleeve and an inner sleeve, and the diameter of the outer sleeve is larger than that of the inner sleeve; and residual liquid removing assemblies are arranged in the outer sleeve and the inner sleeve. After the device is installed properly, rolling wheels are driven by electric telescopic rods, so that the top and bottom rolling wheels are tightly attached to the top and bottom inner walls of a steel pipe separately, and then a dual-axis motor is driven; an adjustable telescopic rod is driven by the dual-axis motor through a bevel gear set I, and a moving wheel is driven by the adjustable telescopic rod through a bevel gear set III; therefore, the outer sleeve is moved rightwards on the outer wall of the steel pipe; the outer sleeve is moved rightwards, and the inner sleeve is pulled by a pull rope to move leftwards in the steel pipe, so that residual liquid is synchronously removed inside and outside; and on one hand, the use cost is greatly reduced, and meanwhile the working efficiency is improved.

Owner:徐州瑞马智能技术有限公司

A hand-held leather shoe surface dirt wiping device

ActiveCN108903886BChange the way the epidermis is wipedReduce intensityFootwear cleanersElectric machineryHand held

The invention relates to the technical field of leather shoe maintenance, and discloses a handheld leather shoe skin dirt wiping device. The wiping device comprises a barrel body; a transverse installing plate is fixedly connected between the inner walls of the left side and the right side of the barrel body; a storage battery is fixedly connected to the upper surface of the transverse installingplate; a micro motor is fixedly connected to the lower surface of the transverse installing plate through bolts; a switch button is arranged in the middle of the top of the barrel body; a limiting handle is fixedly connected to the left side of the barrel body through bolts; a fixed hollow circular ring is welded at the bottom of the barrel body; a rotary circular plate is movably connected to theinner side of the fixed hollow circular ring through movable roll balls; an output shaft of the micro motor is fixedly connected with a torque rotating shaft through a shaft coupler; one end, far away from the micro motor, of the torque rotating shaft is fixedly connected to the middle of the upper surface of the rotary circular plat; and a hollow threaded barrel is fixedly connected to the lowersurface of the rotary circular plate through a connecting plate. According to the handheld leather shoe skin dirt wiping device, the purpose of wiping dirt in gaps at the joints of leather shoe materials is achieved.

Owner:济宁高新文化创意园服务有限公司

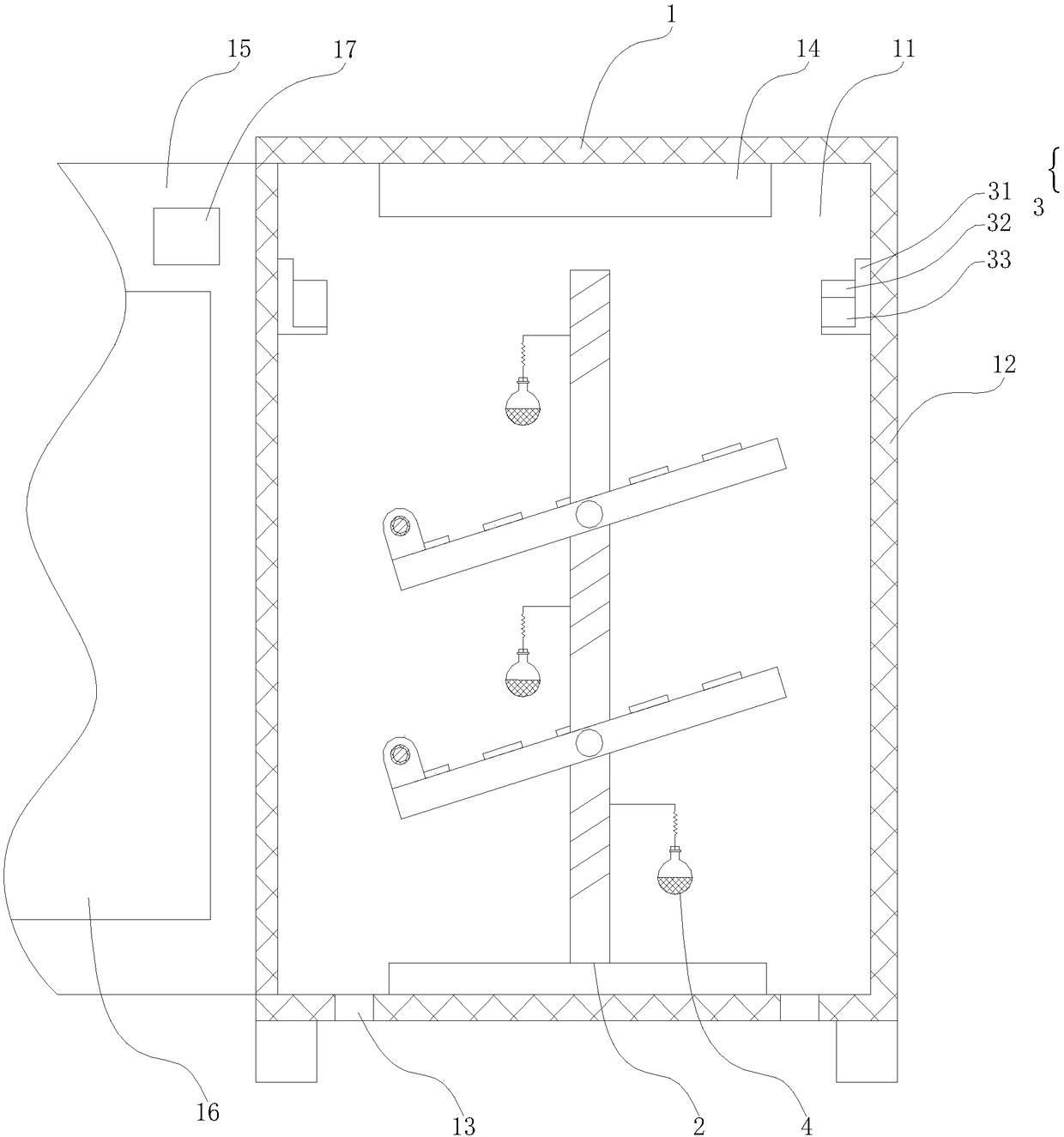

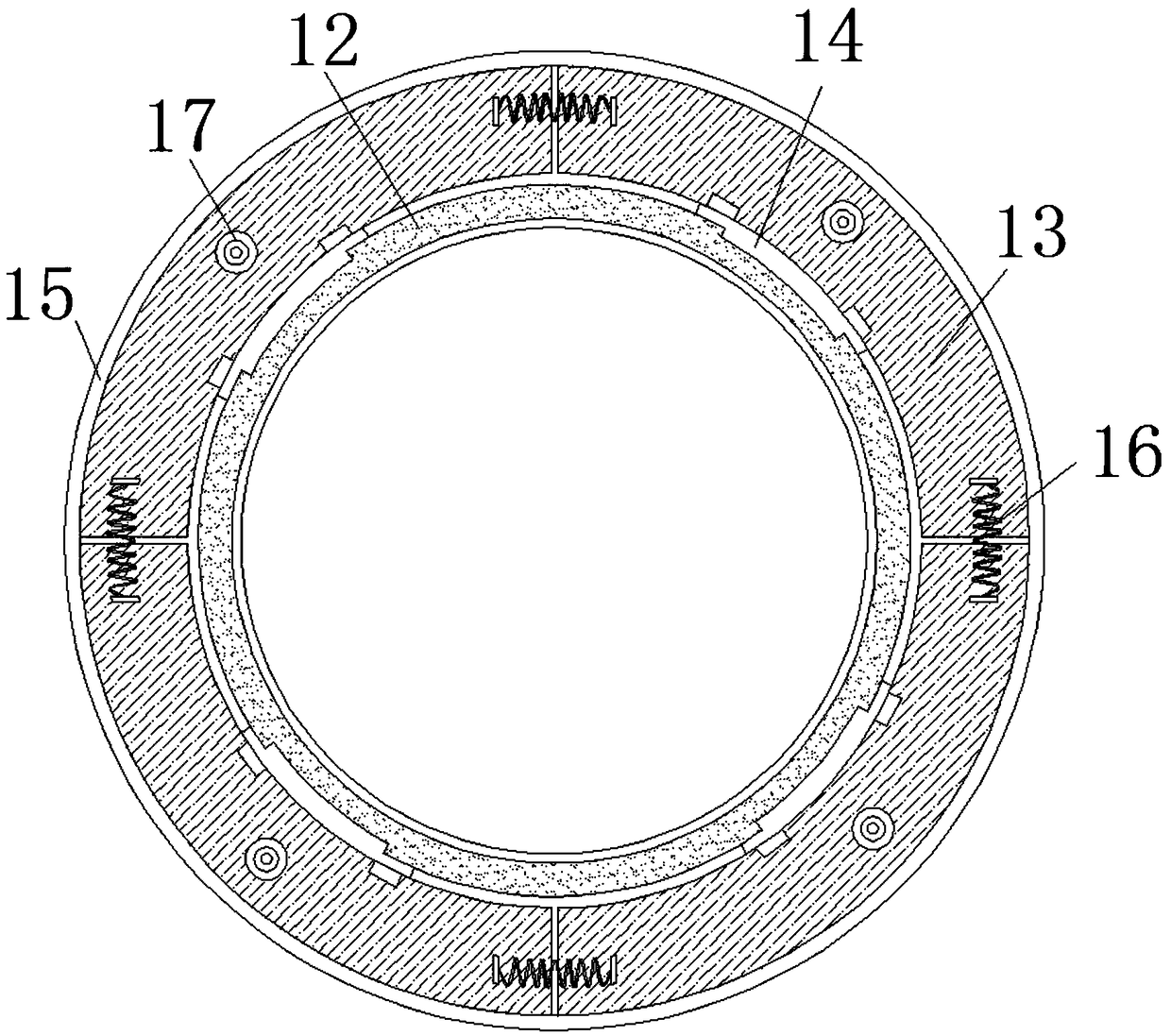

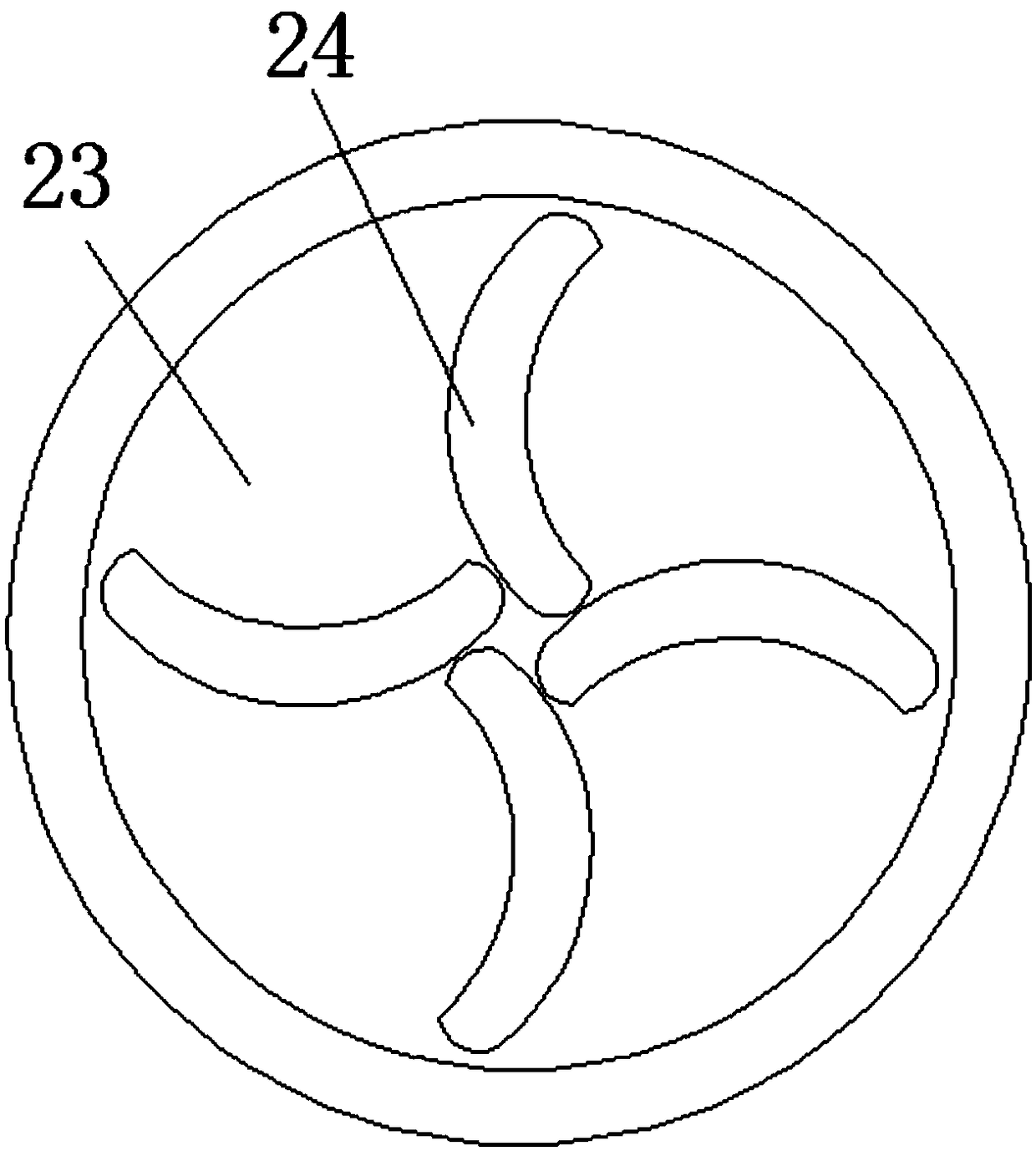

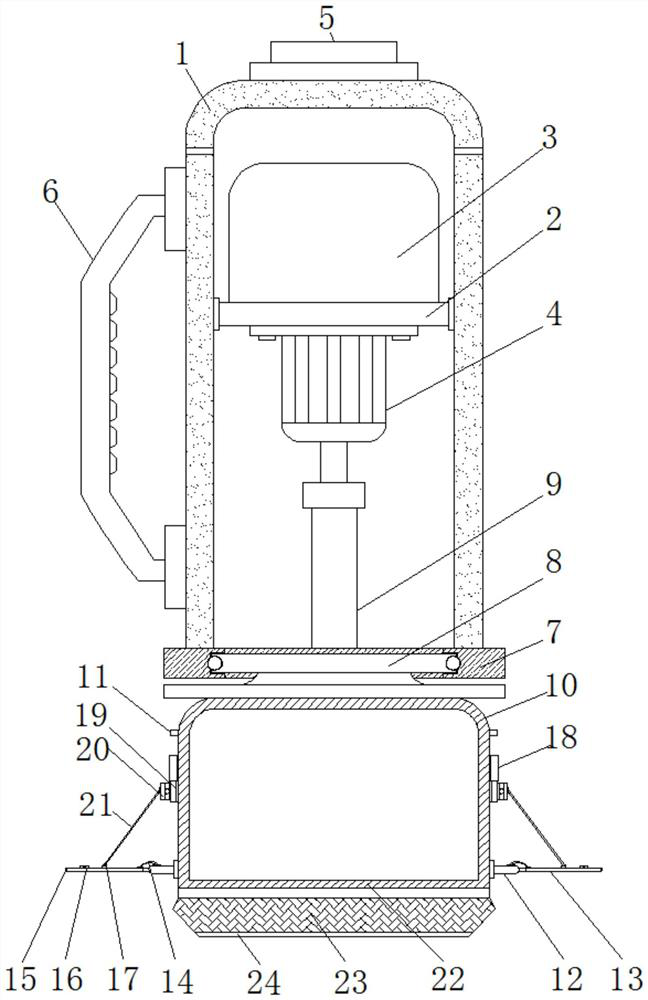

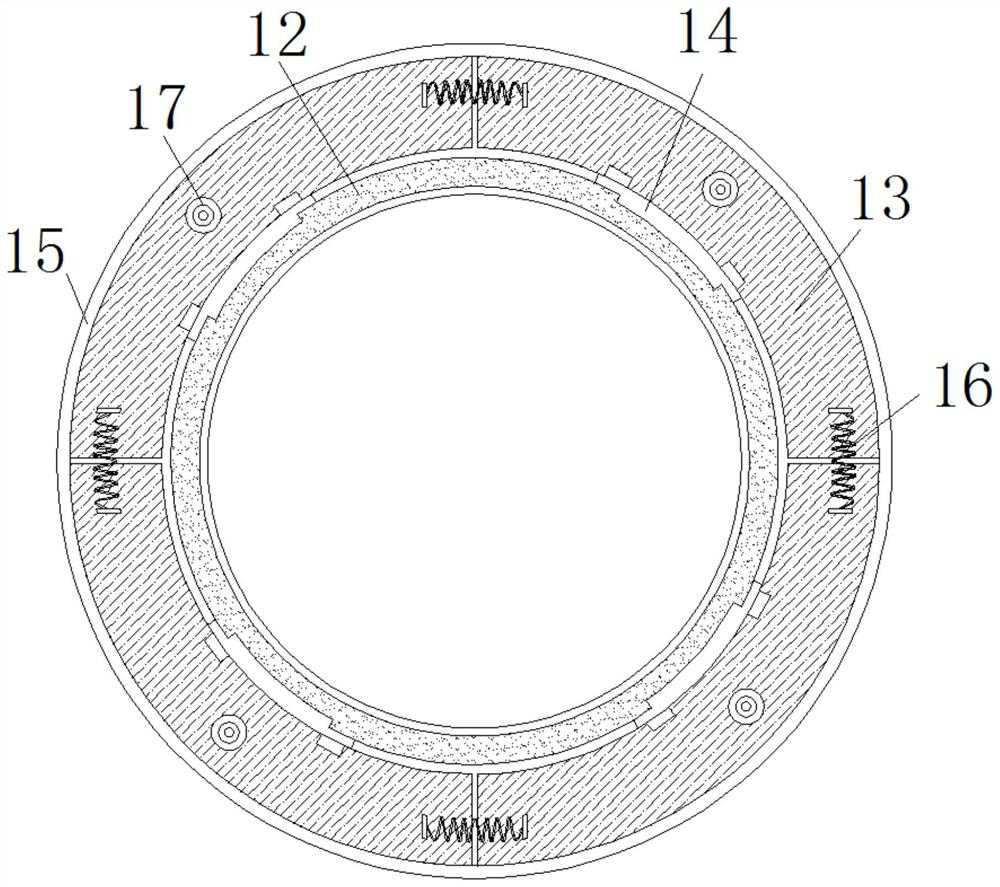

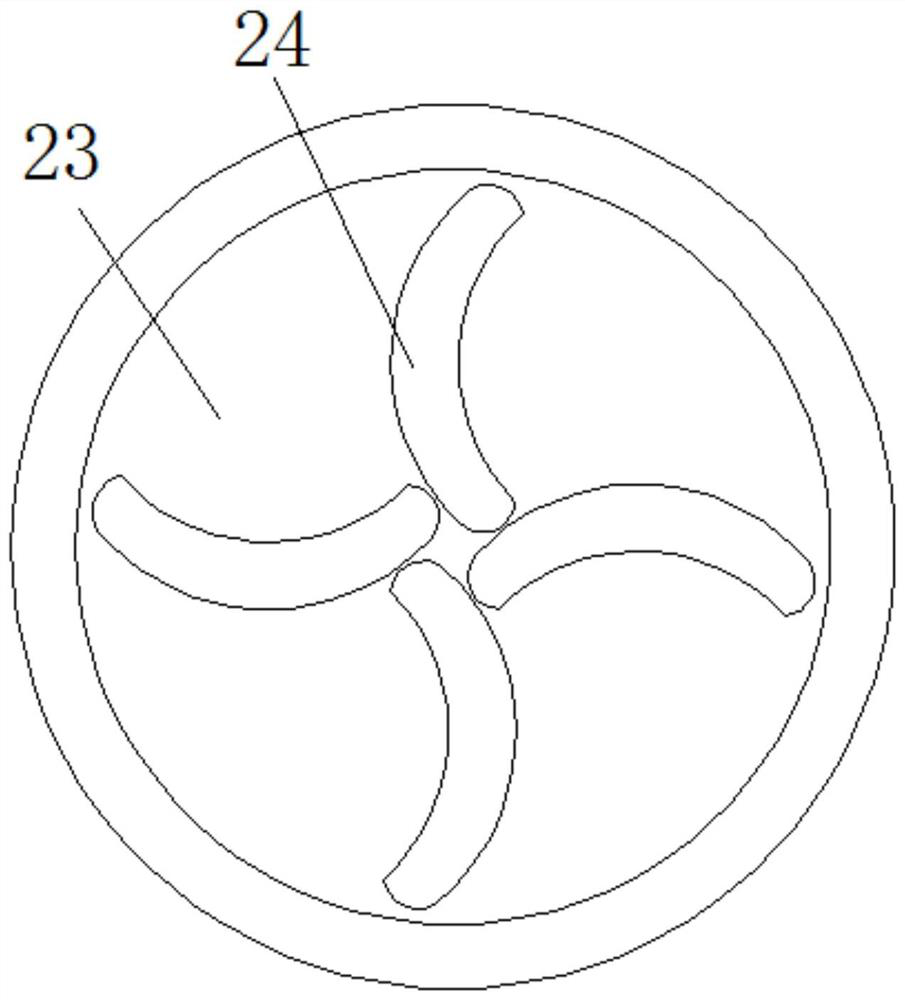

Flushing equipment and flushing method for circular mahjong mat

ActiveCN111067464AAvoid damageImprove removal qualityHousehold cleanersStructural engineeringMechanical engineering

The invention relates to the technical field of circular mahjong mats. The invention further discloses washing equipment and a washing method for a circular mahjong mat. The washing equipment comprises an operating platform, radial through grooves are formed in the front surface, the back surface, the left side surface and the right side surface of the operating platform, ports of the radial through grooves in the front surface, the back surface, the left side surface and the right side surface of the operating platform are fixedly connected with positioning bearings through bolts, radial screw rods are arranged on the inner sides of the four radial through grooves, the tail ends of the four radial screw rods are movably connected to the inner side walls of the radial through grooves through bearing bases, the other ends of the four radial screw rods penetrate through the inner sides of the corresponding positioning bearings and extend to the outer side of the operating platform, and star-shaped handles are fixedly connected to the ends, on the outer side of the operating platform, of the four radial screw rods. According to the flushing equipment for the circular mahjong mat, gapsamong bamboo blocks of the mat are better separated, so that the gaps among the bamboo blocks of the mat are increased, and the dirt removing quality among the bamboo blocks of the circular mahjong mat is effectively improved.

Owner:嘉兴科禾能源科技有限公司

Semi-automatic deburring machine

ActiveCN104400133BCompact structureStable structureLarge fixed membersMaintainance and safety accessoriesGear driveSemi automatic

Owner:六安永达机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com