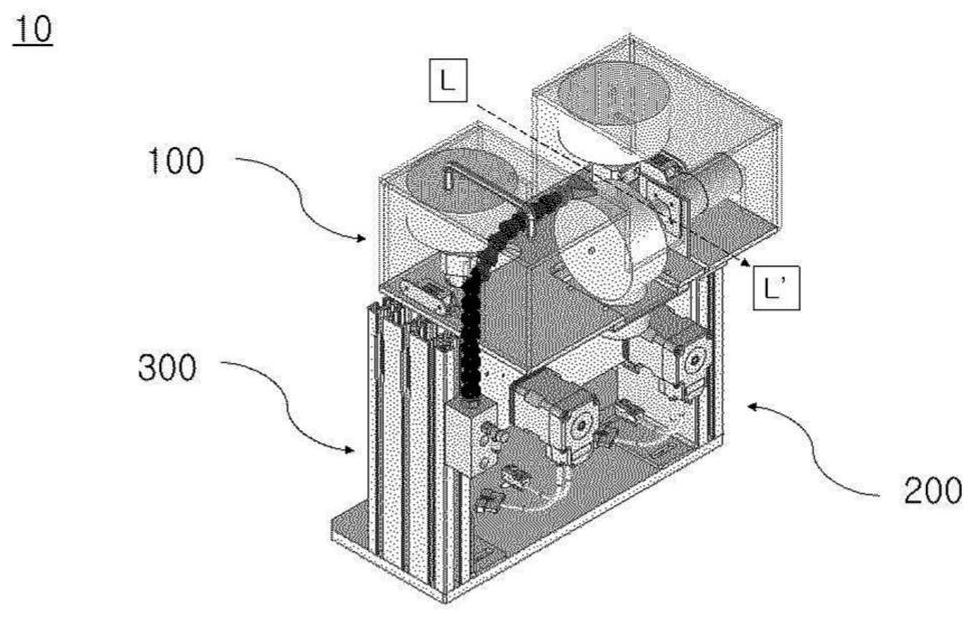

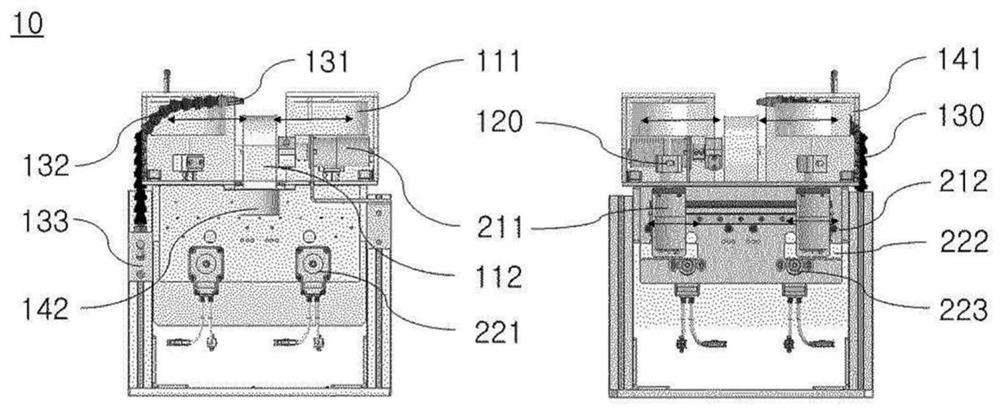

Ultra-hard insert product burr removing device using electric brush

A burr removal and electric brush technology, which is used in the cleaning method of tools, grinding/polishing safety device, and smoke removal, etc., can solve the problems of low work efficiency, difficult quality management, and residual foreign matter in the edges and corners of electric brushes. The effect of short preparation time, improved burr removal quality, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

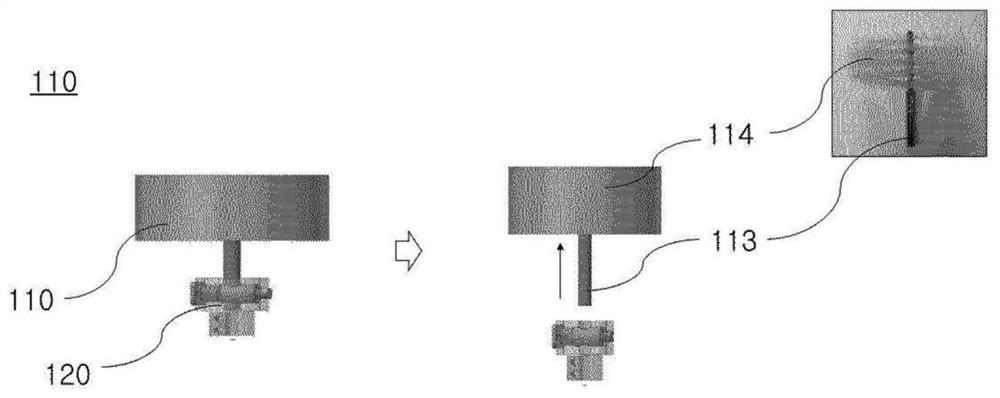

[0070] The present invention is capable of various modifications and has various embodiments, and below, the invention is described in detail with reference to the accompanying drawings to illustrate specific embodiments.

[0071] However, the present invention is not limited to a specific embodiment, and it should be understood that all changes, equivalents, and substitutes included in the technical idea and technical scope of the present invention are included.

[0072] The terms or words used in the present invention are only used to describe specific embodiments, and are not intended to limit the present invention. It should be based on the concept of properly defined terms, the principle of describing my invention in the best way, and interpreting the meaning and concept in accordance with the technical idea of the present invention.

[0073] In the terms used in the present invention, "molded product" refers to the "superhard insert product" in the state taken out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com