Semi-automatic deburring machine

A deburring machine, semi-automatic technology, used in metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of unsuitable multi-variety and small batches, high skill requirements, high cost, and achieve high burr removal quality. , the overall structure is compact, the effect of occupying less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

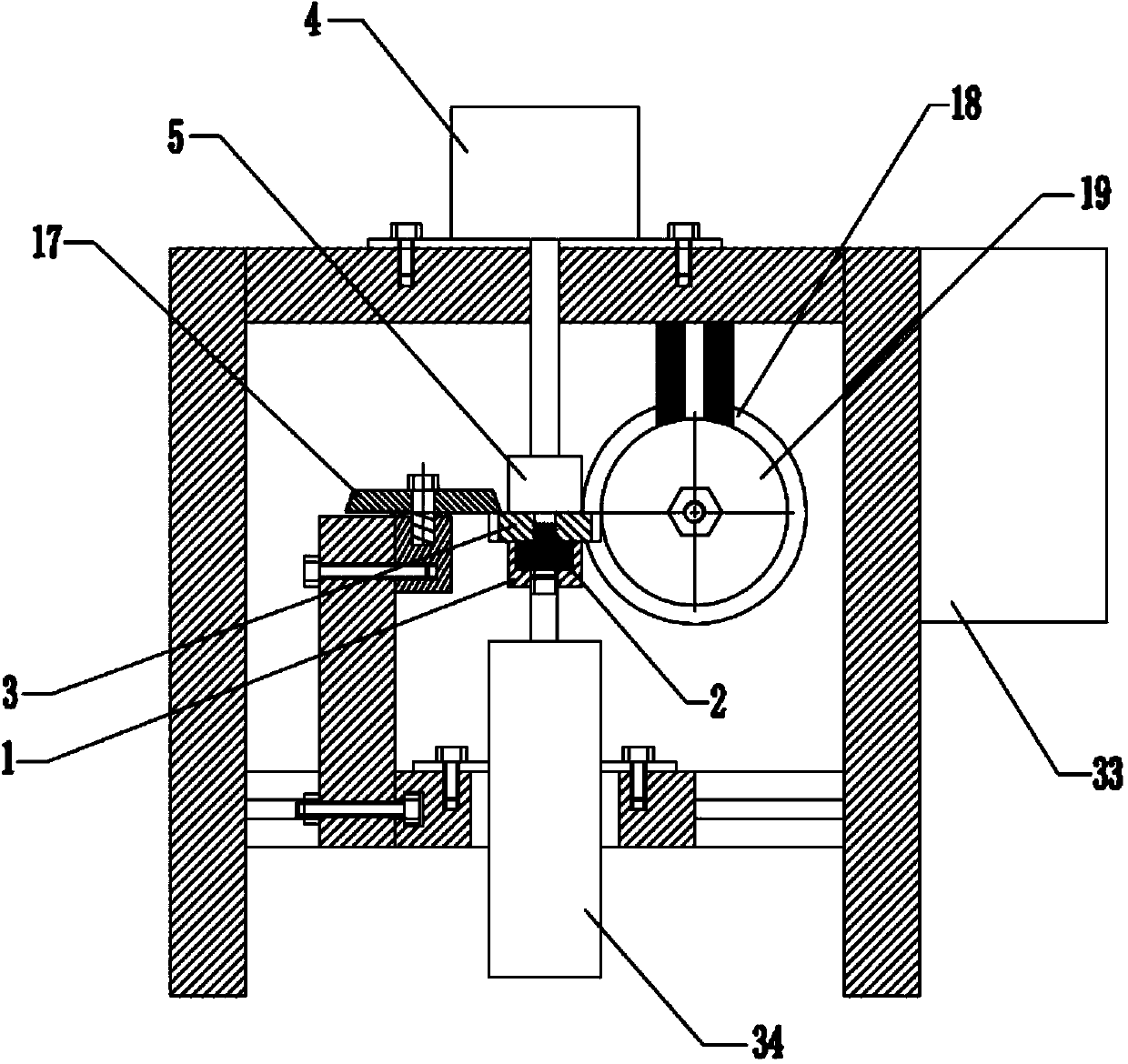

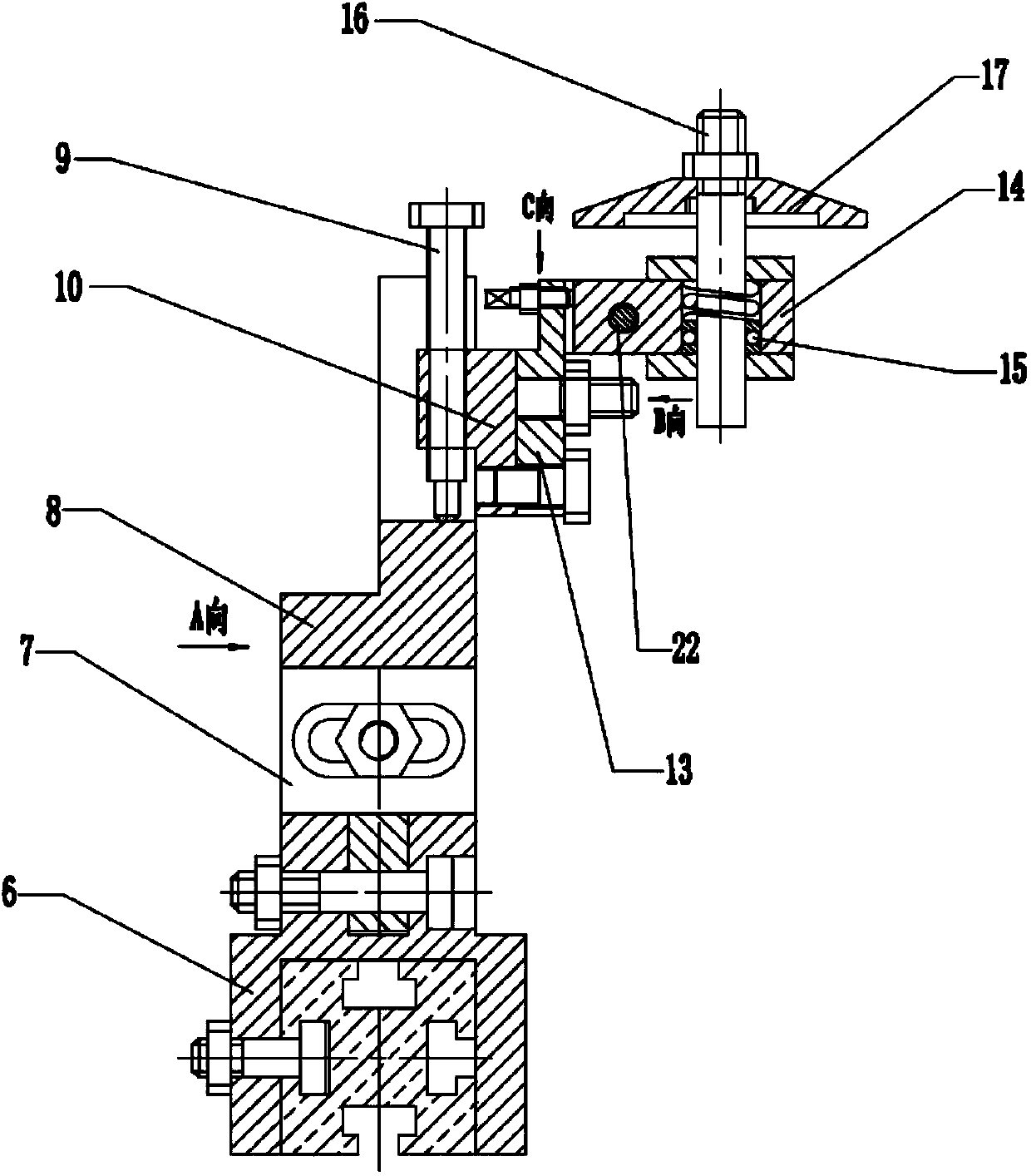

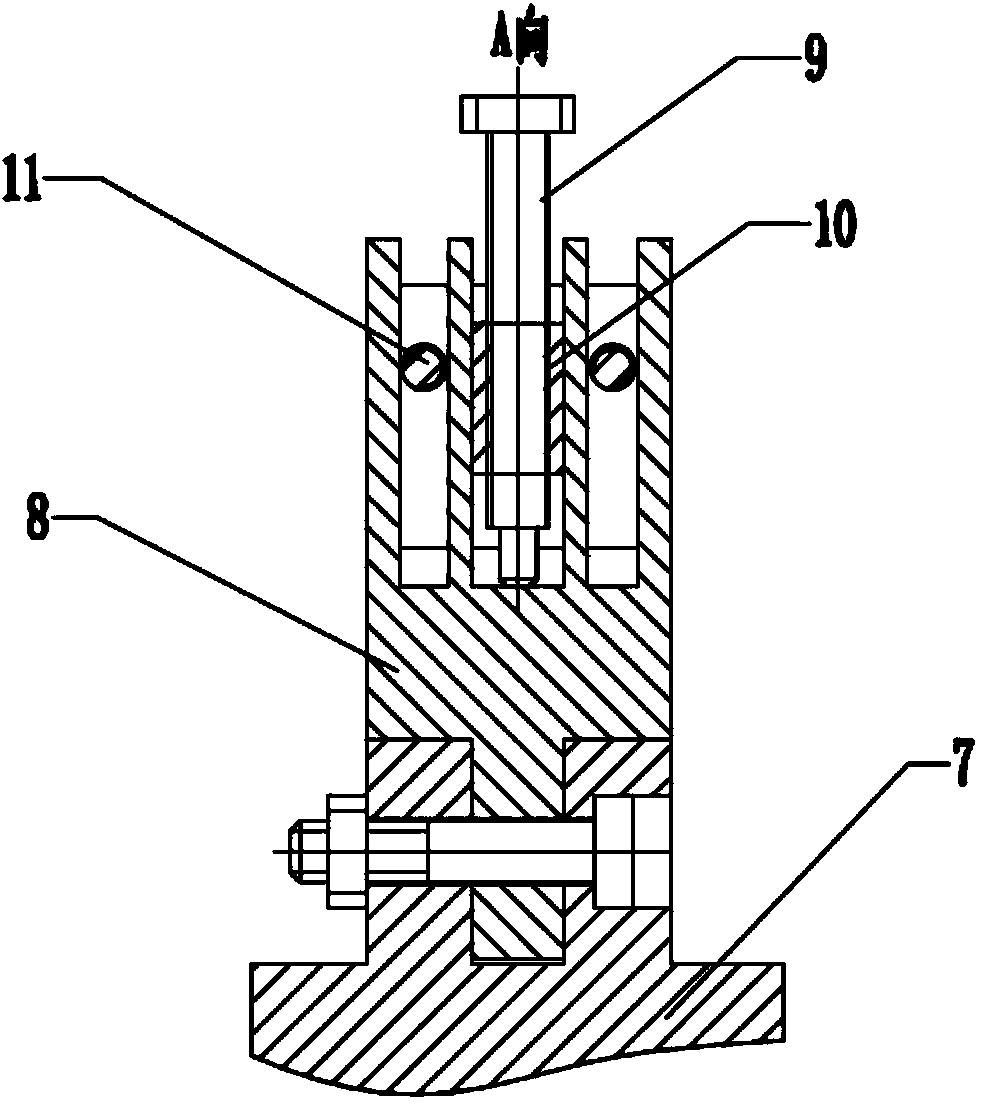

[0030] Embodiment: the semi-automatic deburring machine of the present embodiment comprises:

[0031] The gear lifting positioning device directly below the gear to be processed and the gear driving device directly above the gear;

[0032] A deburring knife and a deburring knife support and adjustment device for deburring the gear end face;

[0033] In specific settings, figure 1 As shown, the gear lifting positioning device includes: a connecting sleeve 1 that is threadedly connected with the cylinder piston rod, a gear mandrel 2 that is tightly matched with the step hole of the connecting sleeve, and the gear mandrel and the inner hole of the gear 3 are in clearance fit, and the gear can be in the Rotate horizontally on the gear mandrel.

[0034] The gear driving device includes a motor 4 arranged on the frame, and a friction wheel 5 arranged on the output shaft of the motor. The lower surface of the friction wheel contacts the upper surface of the gear to drive the gear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com