Method for removing coating of hot-rolled steel sheet by virtue of ultra-short pulse laser galvanometer

A technology of ultra-short pulse laser and hot-rolled steel plate, which is applied in the field of material processing, can solve the problems of limited coating removal width, cumbersome operation, and low removal efficiency, and achieve digital automation, smooth surface, and high removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

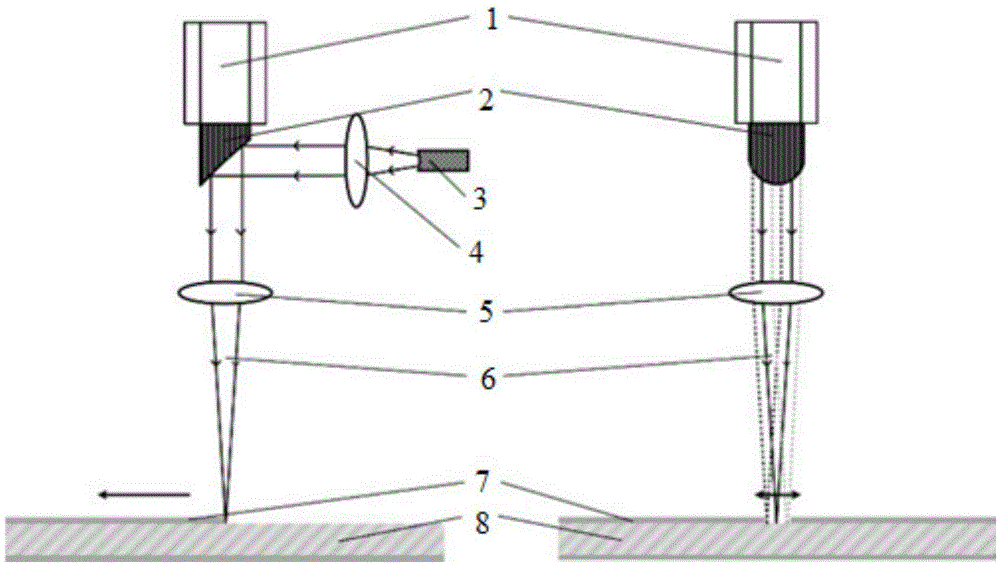

[0045] Place the hot-rolled steel plate with Al-Si coating horizontally. When removing the coating by vibrating mirror laser scanning, first remove the Al-Si coating on one side of the hot-rolled steel plate; then replace the hot-rolled steel plate, and then use vibrating The method of mirror laser scanning removes the Al-Si coating on the other side, such as figure 1 shown. The specific removal steps are as follows:

[0046] Step 1): cleaning the surface of the hot-rolled steel plate to be welded to remove surface oil stains, fixing the cleaned hot-rolled steel plate on the fixture, and the hot-rolled steel plate has an Al-Si coating;

[0047] Step 2): Place the hot-rolled steel plate fixed on the fixture in step 1) horizontally, and adjust the ultrashort pulse laser emitted by the laser to be vertical to the hot-rolled steel plate;

[0048] Step 3): Set the process parameters for ultrashort pulse laser galvanometer removal of Al-Si coating: the laser is ultrashort pulse la...

Embodiment 2

[0054] Place the hot-rolled steel plate with Al-Si coating horizontally. When removing the coating by vibrating mirror laser scanning, first remove the Al-Si coating on one side of the hot-rolled steel plate; then replace the hot-rolled steel plate, and then use vibrating The method of mirror laser scanning removes the Al-Si coating on the other side, such as figure 1 shown. The specific removal steps are as follows:

[0055] Step 1): cleaning the surface of the hot-rolled steel plate to be welded to remove surface oil stains, fixing the cleaned hot-rolled steel plate on the fixture, and the hot-rolled steel plate has an Al-Si coating;

[0056] Step 2): Place the hot-rolled steel plate fixed on the fixture in step 1) horizontally, and adjust the ultrashort pulse laser emitted by the laser to be vertical to the hot-rolled steel plate;

[0057] Step 3): Set the process parameters for ultrashort pulse laser galvanometer removal of Al-Si coating: the laser is ultrashort pulse la...

Embodiment 3

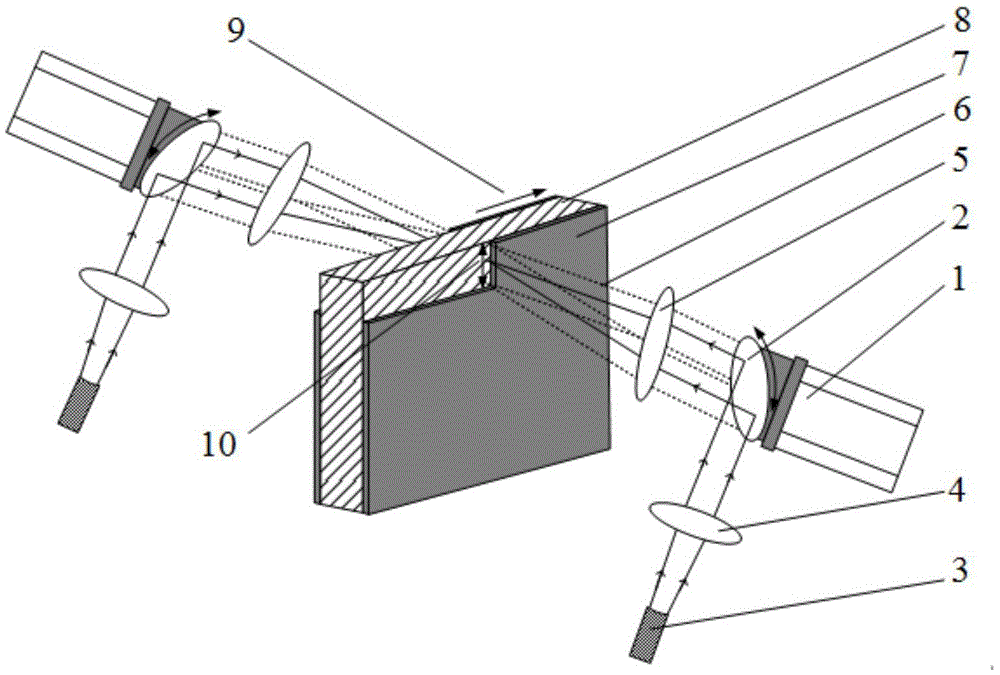

[0063] Place the hot-rolled steel plate with Al-Si coating vertically, and use two ultra-short pulse lasers to remove the coating on both sides of the hot-rolled steel plate synchronously by means of galvanometer scanning, such as figure 2 shown. The specific removal steps are as follows:

[0064] Step 1): cleaning the surface of the hot-rolled steel plate to be welded to remove surface oil stains, fixing the cleaned hot-rolled steel plate on the fixture, and the hot-rolled steel plate has an Al-Si coating;

[0065] Step 2): Place the hot-rolled steel plate fixed on the tooling fixture in step 1) vertically, and adjust the two beams of ultrashort pulse laser emitted by the laser to be perpendicular to the two sides of the hot-rolled steel plate and set them symmetrically;

[0066] Step 3): Set the process parameters of two ultrashort pulse laser galvanometer removal of Al-Si coating: the laser is an ultrashort pulse laser, the pulse period is 30ns, the scanning frequency is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com