A kind of embroidery lining film removal process

A technology of embroidery and lining film, which is applied in the field of embroidery, can solve problems such as lining film residue, and achieve high-quality removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

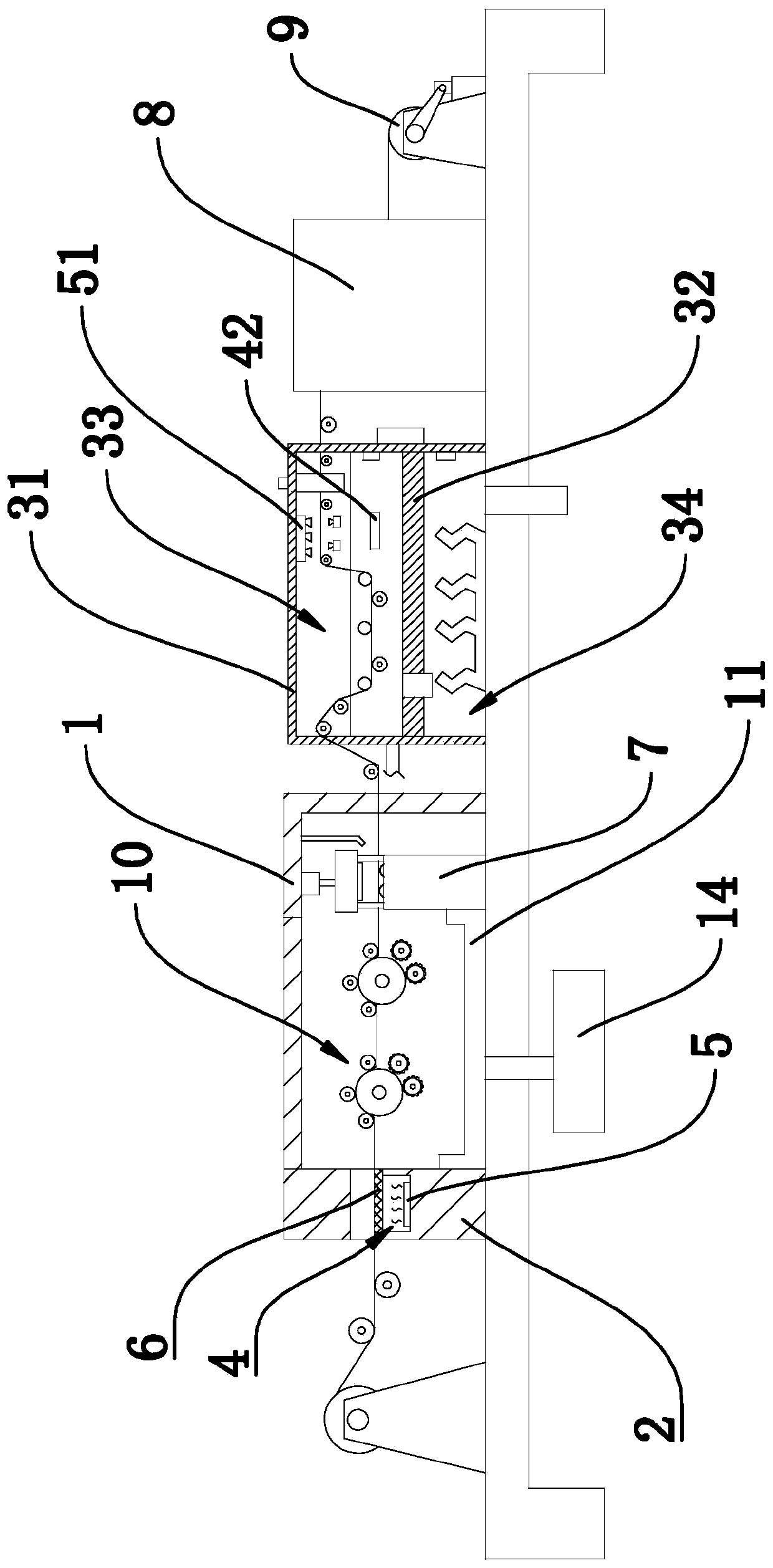

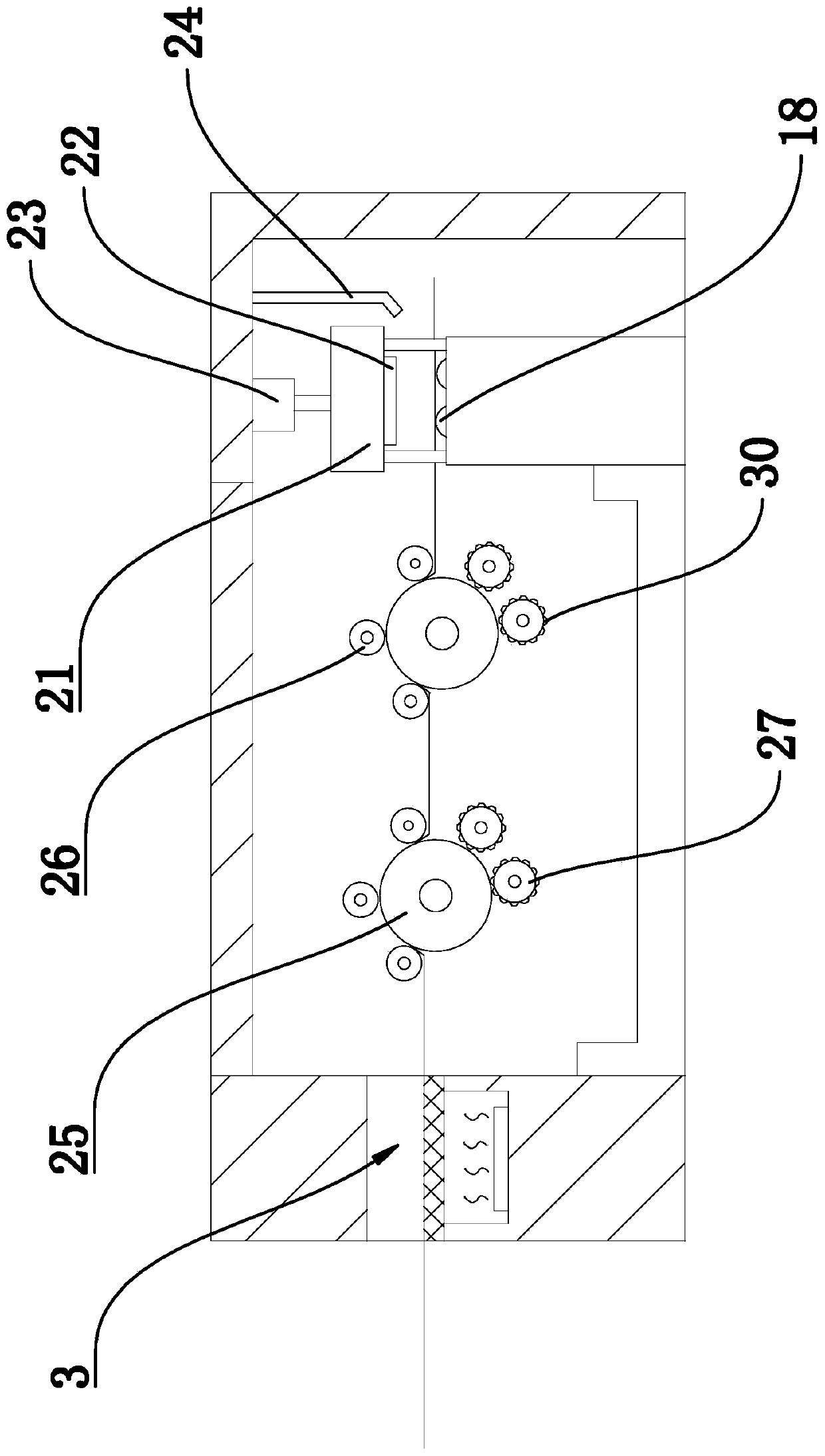

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

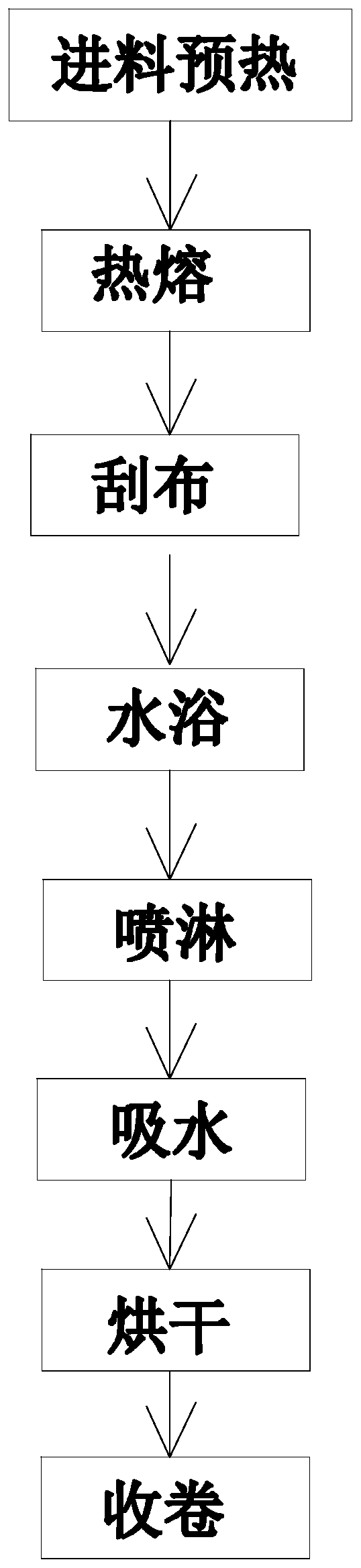

[0040] Such as Figure 1 to Figure 9 As shown, the invention provides a kind of embroidery lining film removal process, comprises the following steps:

[0041] Feeding preheating: Wind the embroidered cloth with lining film on the feeding roller, and transfer the embroidered cloth to the feeding table 2 of the hot-melt box 1 through the leading roller, so that the embroidered cloth is attached to the feeding table 2 On the mesh plate 6 and conveyed forward along the mesh plate 6, the feeding table 2 is heated to generate hot air, and the hot air passes through the mesh plate 6 and acts on the lower surface of the embroidered cloth to preheat the embroidered cloth;

[0042] Hot-melt: transfer the embroidered cloth into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com