A gas-assisted laser processing method for removing stealth coatings on aircraft surfaces

A gas-assisted, aircraft surface technology, used in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve problems such as large environmental pollution, hidden dangers, fire safety, etc., to improve processing quality, not damage the substrate, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

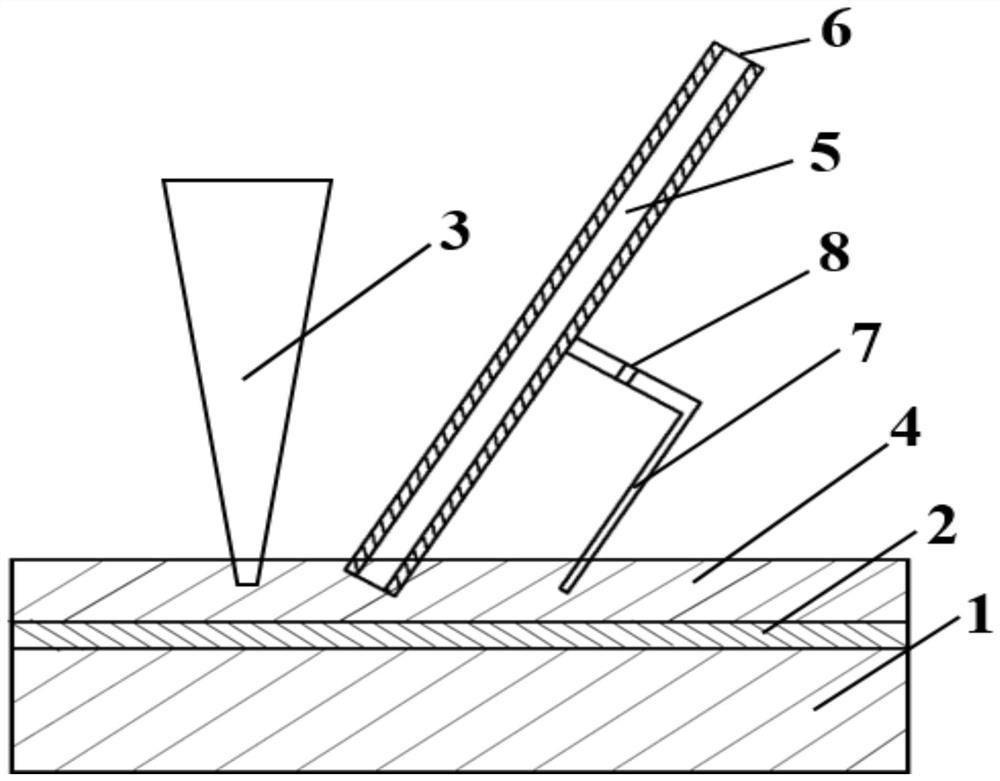

[0030] The gas-assisted laser processing method for removing the stealth coating on the surface of the aircraft of the present invention is as follows:

[0031] The first step is to wire cut the 12024 aluminum alloy aluminum alloy sample to be treated with the stealth coating 2 on the surface to a suitable size, fix it on the working platform through a clamp, and align the coated side with the laser cleaning head 3;

[0032] The second step is to turn on the switch of the gas-assisted protection device, and inject helium gas from the main protective gas inlet and the tail protective gas inlet to form a uniform gas protective layer on the surface area of the stealth coating;

[0033] The third step, using 100W CO 2 The laser removes the stealth coating, and the high-speed movement of the X and Y galvanometers applies the laser energy to the coating surface in a two-dimensional arrangement. A circular laser spot of 5 mm is selected for laser processing, the laser wavelength i...

Embodiment 2

[0038] The first step is to cut the 7075 aluminum alloy wire coated with stealth coating to a suitable size, fix it on the working platform through the clamp, and align the coated side with the laser cleaning head;

[0039] The second step is to turn on the switch of the gas-assisted protection device, and pass neon gas from the main protective gas inlet and the tail protective gas inlet to form a uniform gas protective layer on the surface area of the stealth coating;

[0040] In the third step, a 300W Nd:YAG laser is used to remove the stealth coating. The high-speed movement of the X and Y galvanometers applies the laser energy to the coating surface in a two-dimensional arrangement. A 10mm circular laser spot is selected for laser processing, the laser wavelength is 1064nm, and the output power is 80%. The pulse width is set to 6ns, and the pulse frequency is set to 30Hz. The stealth coating is removed by point-by-point, line-by-line, and surface-by-surface laser scanni...

Embodiment 3

[0044] The first step is to cut the TC4 titanium alloy wire coated with stealth coating to a suitable size, fix it on the working platform through the fixture, and align the coated side with the laser cleaning head;

[0045] The second step is to turn on the switch of the gas-assisted protection device, and argon gas is introduced from the main protective gas inlet and the tail protective gas inlet to form a uniform gas protective layer on the surface area of the stealth coating;

[0046] In the third step, a 500W fiber laser is used to remove the stealth coating. The high-speed movement of the X and Y galvanometers applies the laser energy to the coating surface in a two-dimensional arrangement. A 2mm circular laser spot is selected for laser processing, the laser wavelength is 1030nm, and the output power is 30%. The pulse width is set to 200ns, and the pulse frequency is set to 200kHz. The stealth coating is removed by point-by-point, line-by-line, and surface-by-surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com