Patents

Literature

64results about How to "Guarantee processing safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

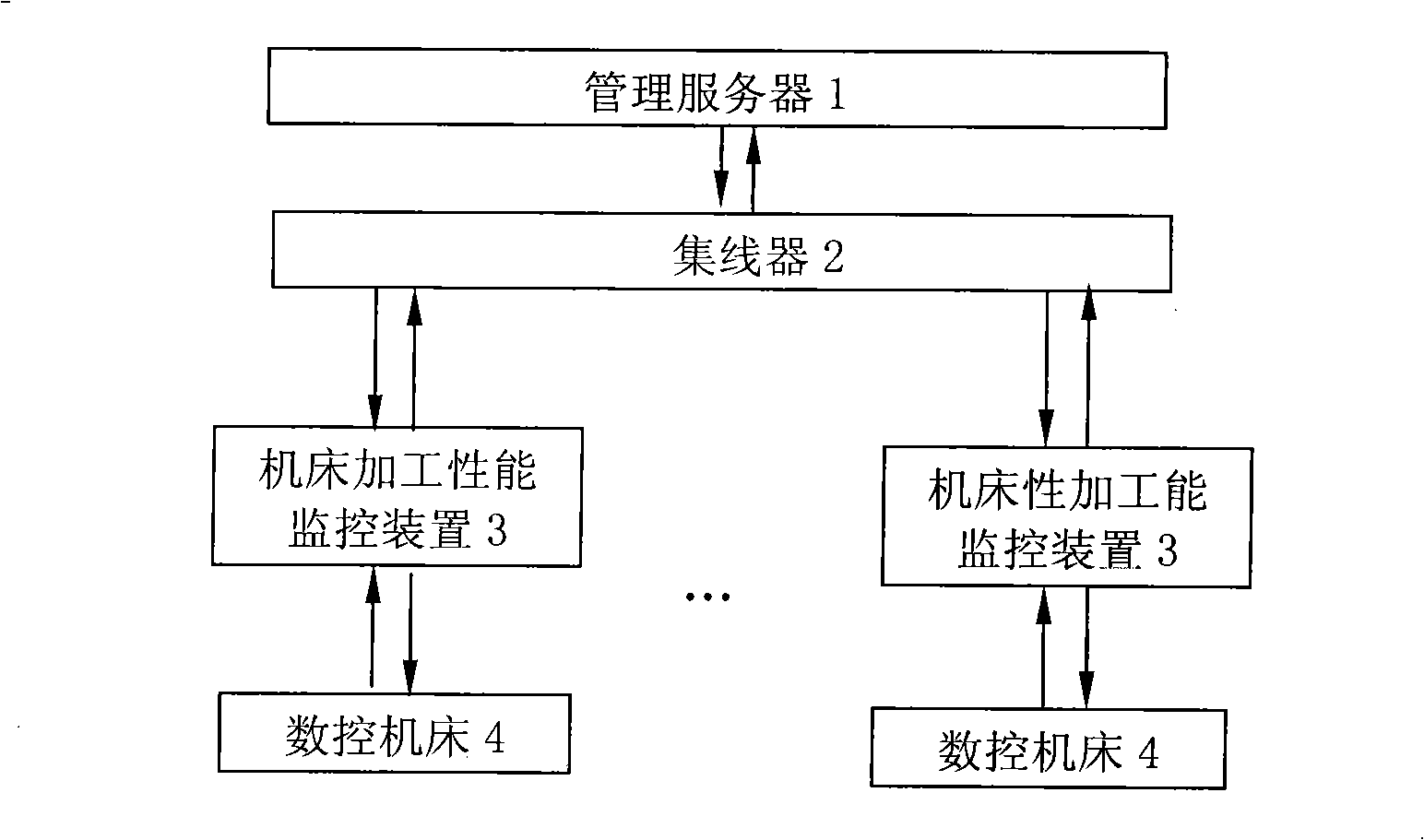

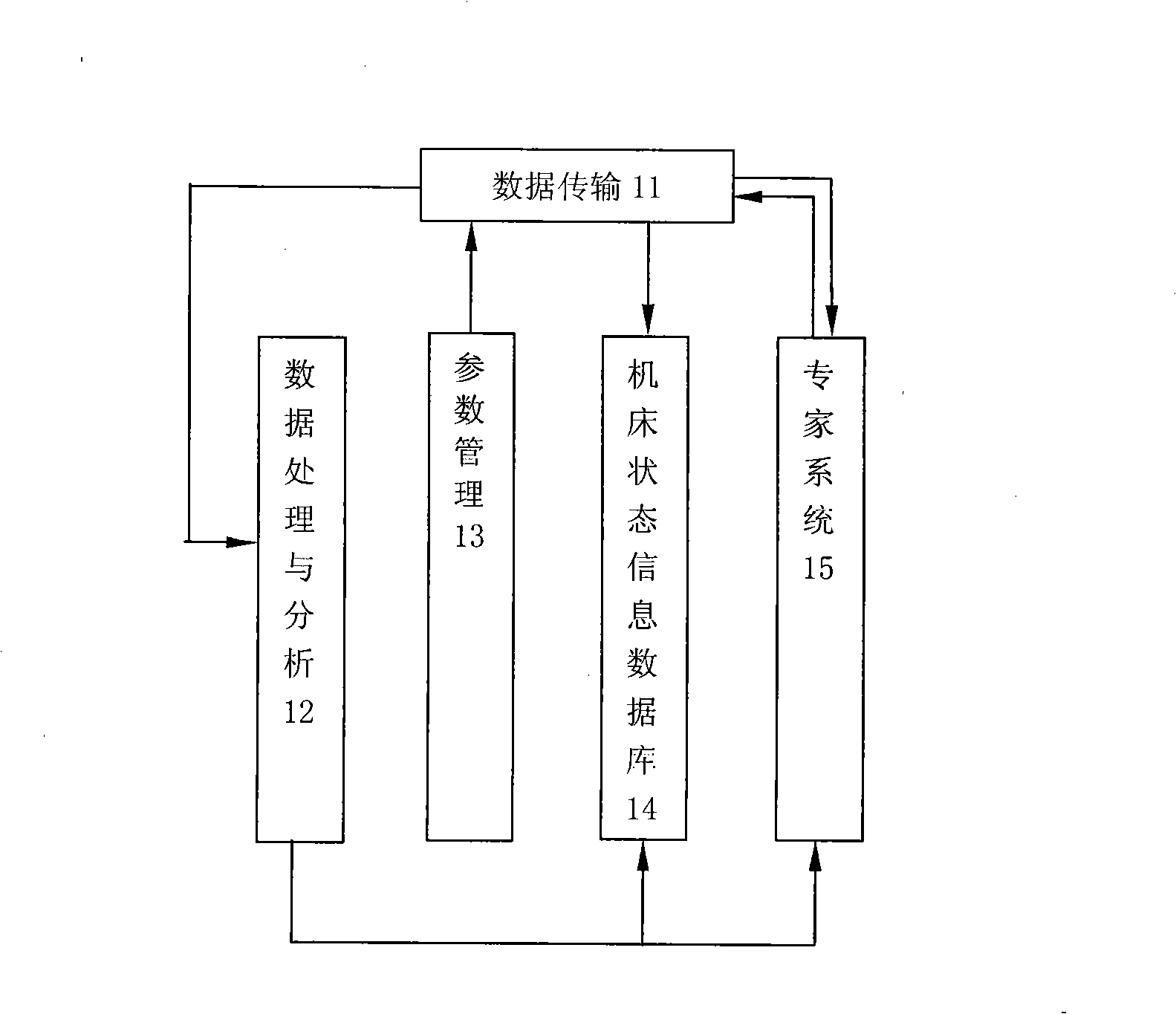

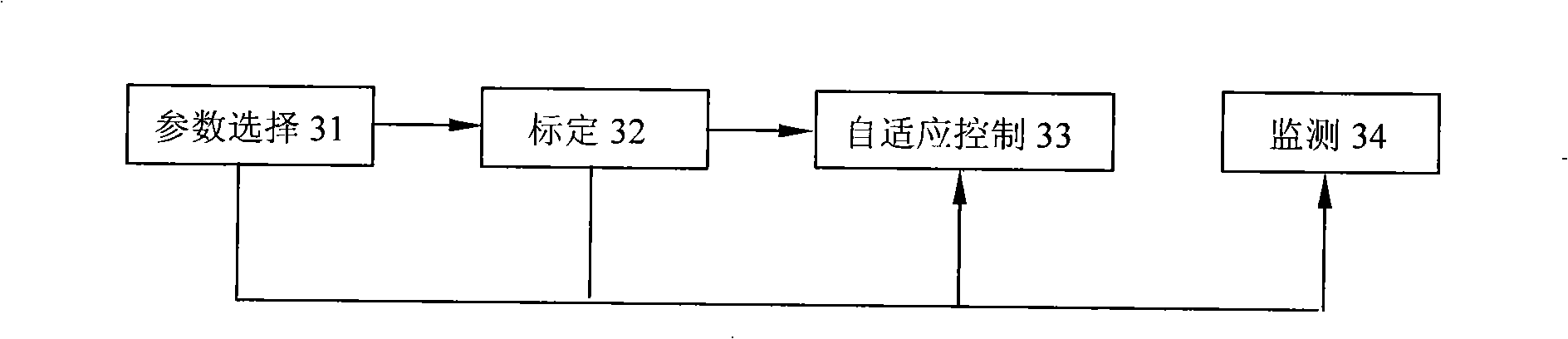

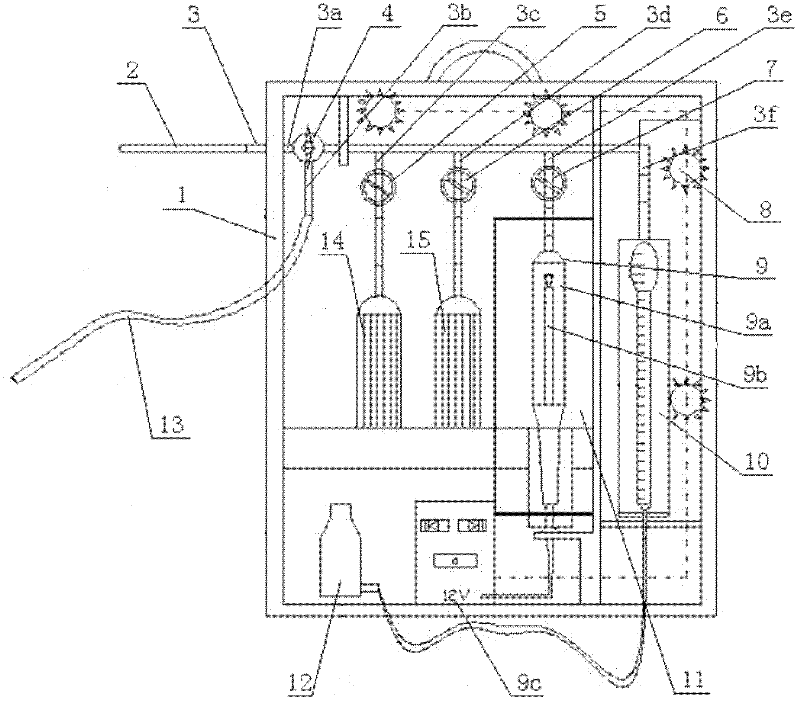

Numerical control machine processability monitoring system

InactiveCN101334656AFocus on statusFocus on processabilityProgramme controlComputer controlIndustrial EthernetNumerical control

The invention provides a numerical control machine tool processing performance monitoring system which is characterized in that monitoring devices on a plurality of machine tools are connected with each other by Ethernet network by a management server; the monitoring device receives the data of the self-state of the machine tool, collects the current of a mainshaft motor and a feeding motor and the vibration quantity of a mainshaft, processes the collected data, compares the processing result with the judgment standard of the machine tool processing performance, emits control instructions to control the processing process according to the given control strategy, and feeds back all relevant information to the management server; the management server analyses the processing performance state and the development trend of the machine tool. The system carries out monitoring to the self-parameters and the in-situ processing state of a plurality of the machine tools, analyses the current processing performance the development trend of the machine tool, and self-adaptively controls the complex processing process, thus effectively ensuring the processing safety and quality.

Owner:HUAZHONG UNIV OF SCI & TECH +1

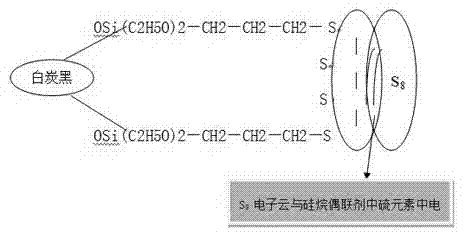

High-temperature-resistant strong-resilience high-safety mixed rubber

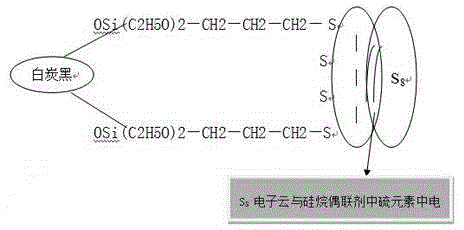

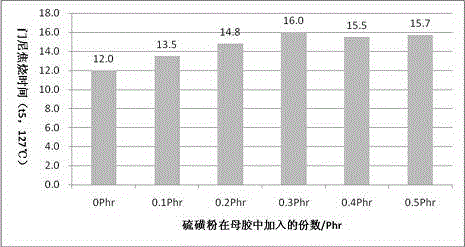

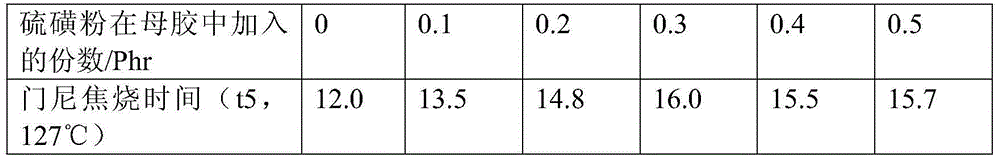

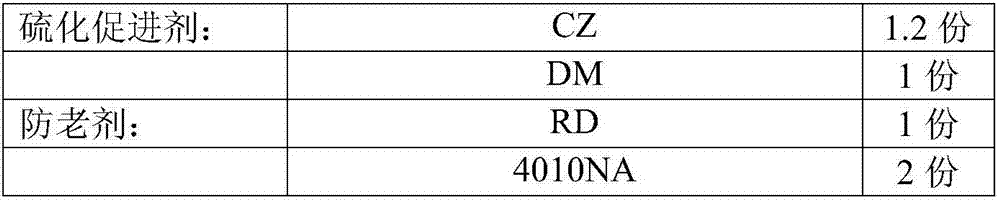

The invention discloses high-temperature-resistant strong-resilience high-safety mixed rubber, and is characterized in that the mixed rubber comprises the following components by the weight percentage: 10-30% of natural rubber, 5-10% of chloroprene rubber, 5-10% of polyisoprene, 4-6% of polybutadiene, 5-15% of white carbon black, 8-12% of a silicon alkyl coupling agent, 10-20% of methyl vinyl silicone rubber, 3-4% of tetravinyltetramethylcyclotetrasiloxane, 1-2% of a catalyst, 1-3% of dimethyl hydroxyl silicone oil, 8-10% of dihydroxydiphenylsilane, 2-3% of a heat stabilizer, 2-3% of a surface modification agent, 5-8% of zinc oxide, 1-2% of stearic acid, 2-6% of sulfur, 1-2% of an accelerator, and 1-3% of other auxiliary agents. The wear resistance is improved, the life problem is overcome, introduction of butyl rubber is known to be capable of improving a wet-skid resistance ability of the mixed rubber, and the obtained mixed rubber has excellent mechanical properties, resilience and high-temperature resistance; and through innovating a rubber mixing technology and changing a feeding sequence, a portion of parts of the sulfur is put in masterbatch rubber to prolong the rubber scorching time, and the rubber processing safety performance is ensured.

Owner:佛山市华勇有机硅有限公司

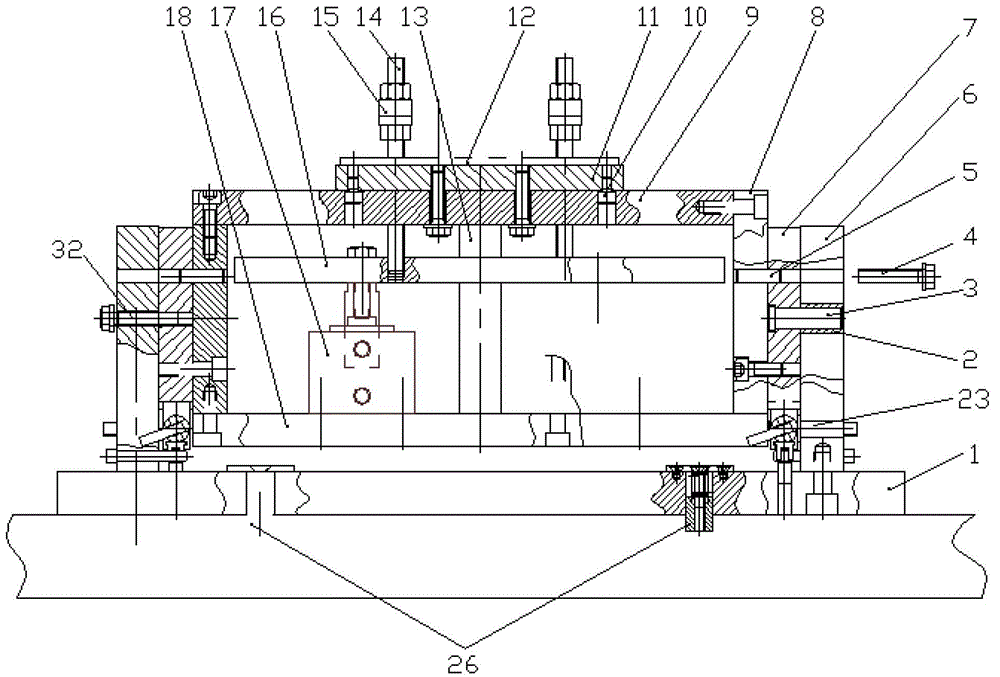

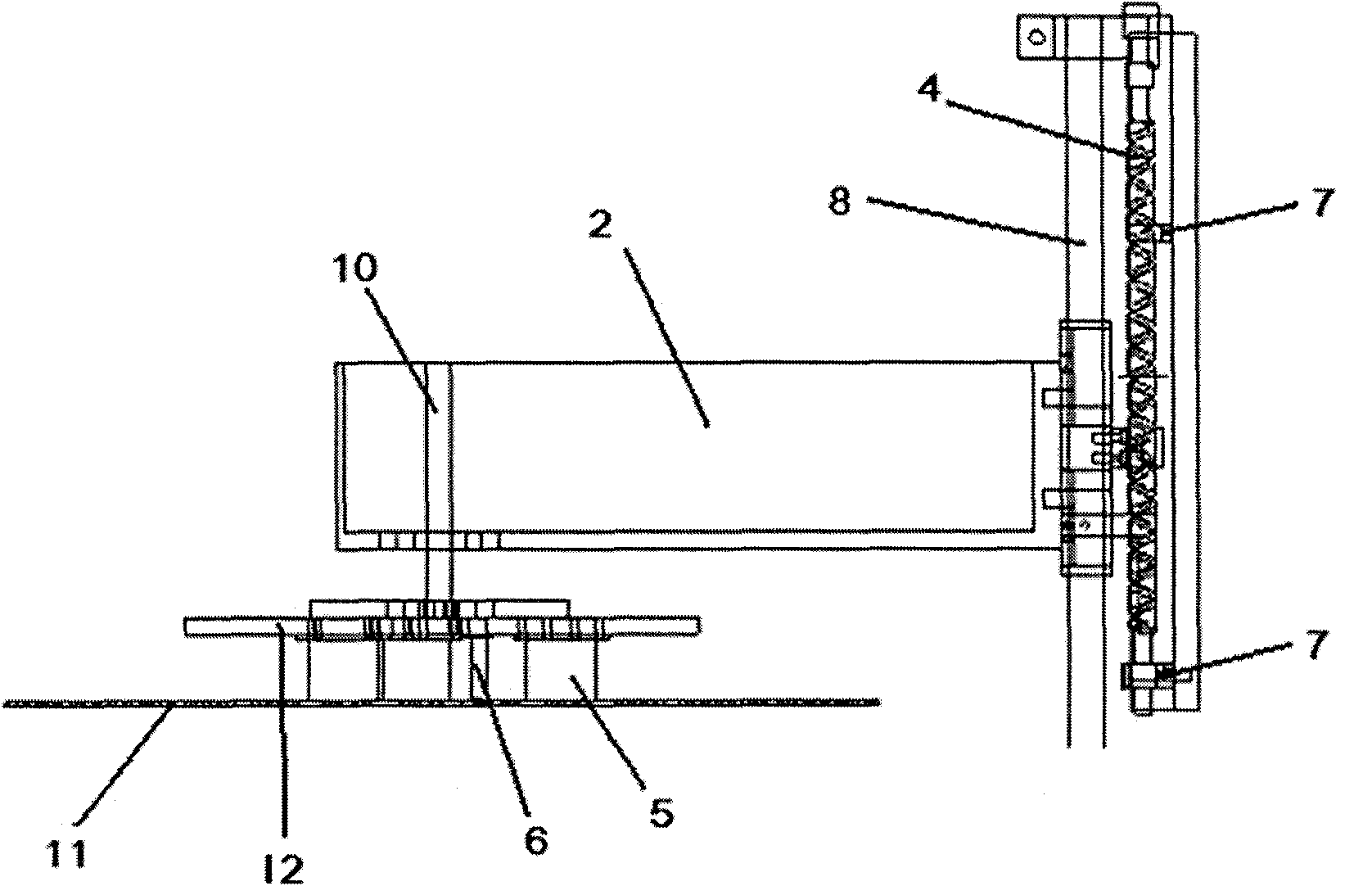

Plain grinding machine

ActiveCN101066581AStrong jacking forceGuarantee machining accuracy and safetyRevolution surface grinding machinesSpecific weightHeadstock

The external grinding machine has one tailstock sleeve set between the tailstock case and the tailstock shaft, and one hydraulic cylinder fixed through a piston rod to the tailstock sleeve. The hydraulic cylinder has cylinder body fixed onto the tailstock case, and the tailstock shaft is connected through the bearings to the tailstock sleeve capable of sliding axially inside the tailstock case. The ends of both the tailstock shaft and the headstock shaft have bidirectional thrust bearing installed. The headstock and tailstock fixing structures of the external grinding machine are used in the external grinding of great size and great specific weight conic and cylindrical workpieces, and have the features of high working quality, high safety, convenient operation, high work efficiency, etc.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

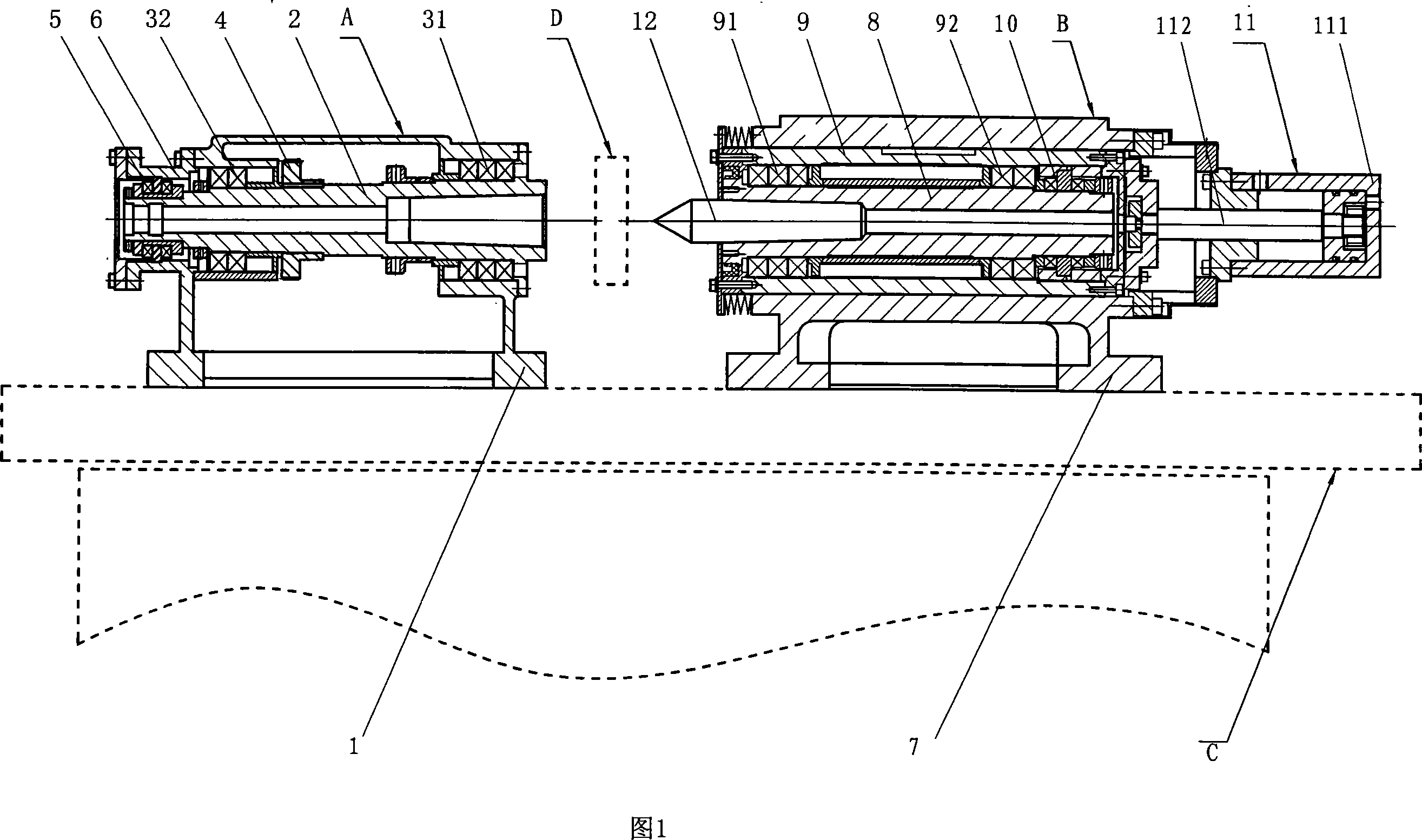

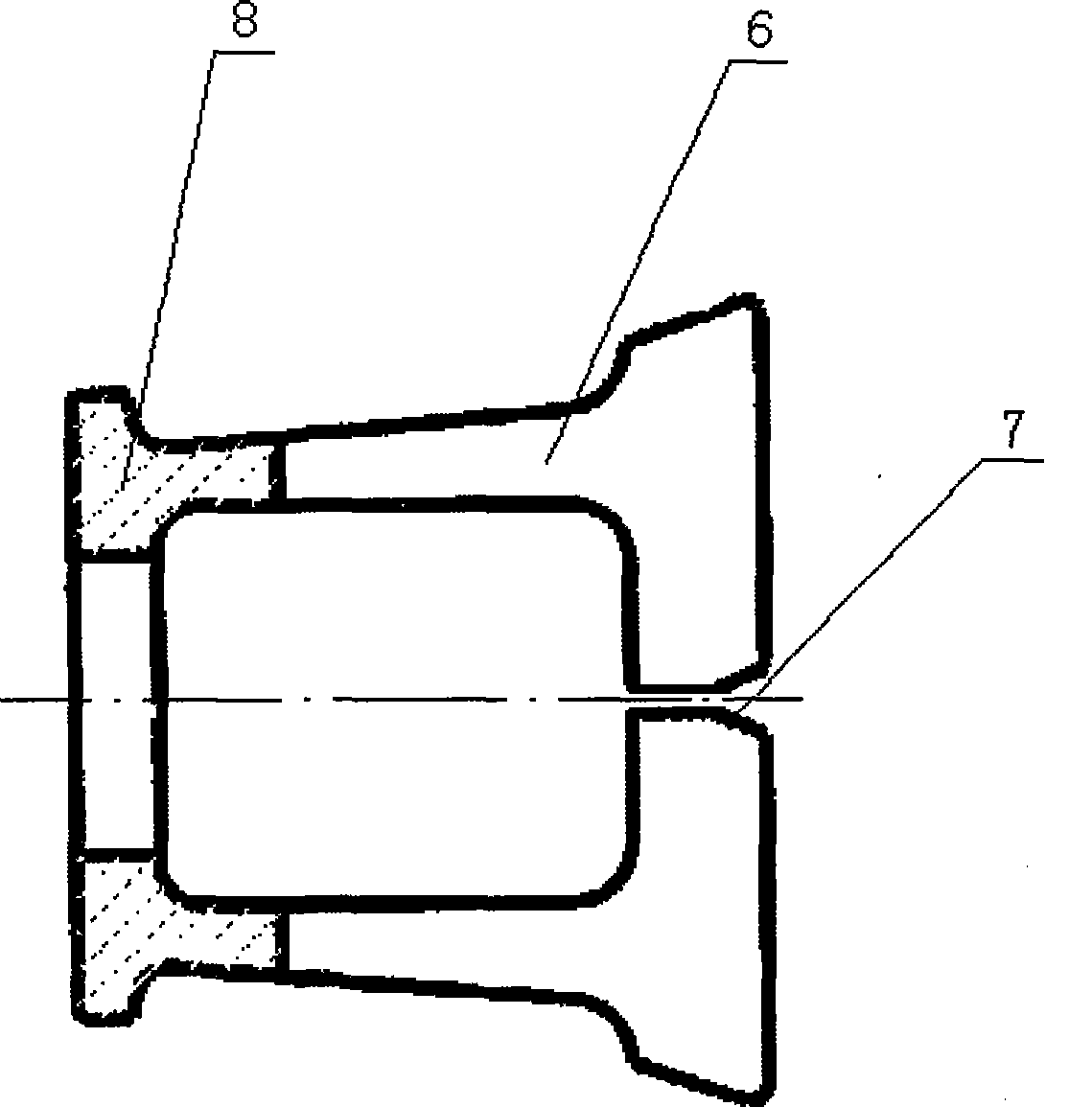

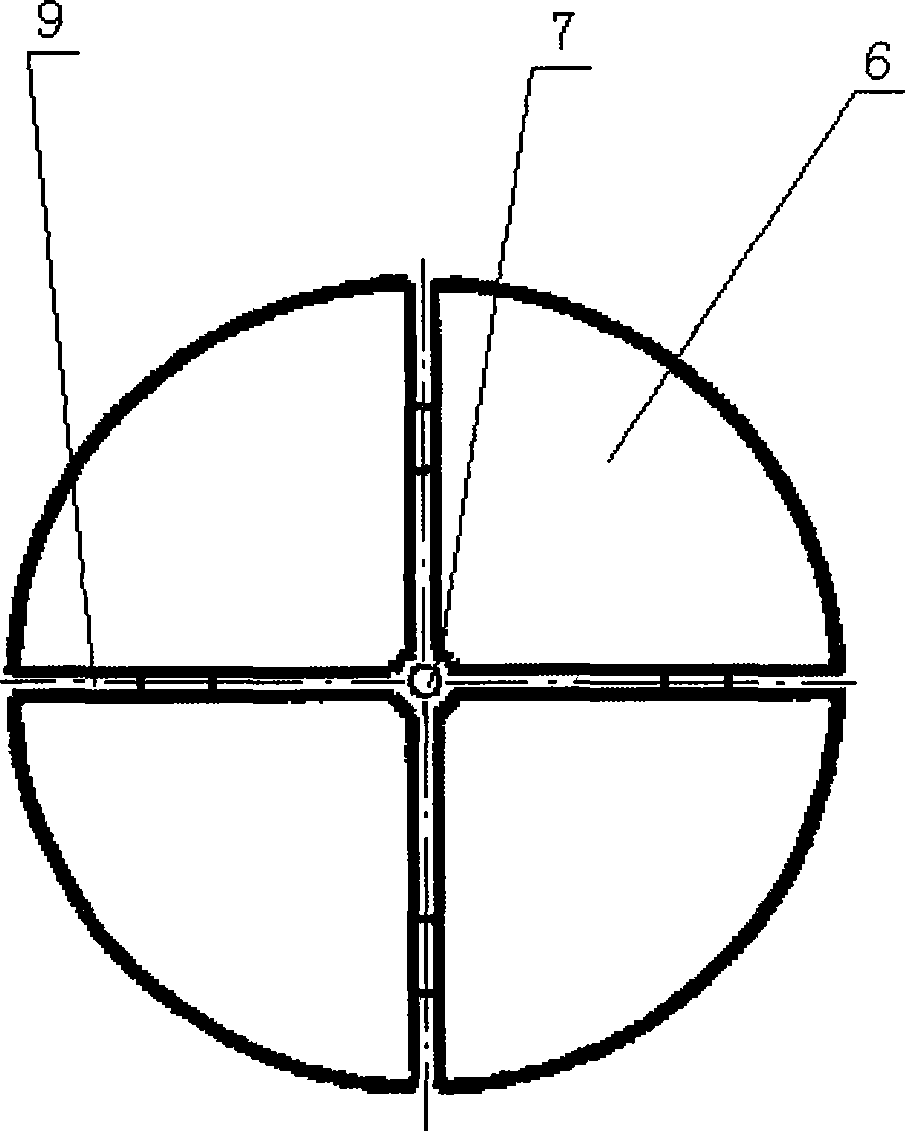

Overlength straight pipeline member cutting method

InactiveCN101367130AEasy to processEasy to operateTailstocks/centresTurning machinesMechanical engineeringEngineering

The invention discloses a method for the cutting processing of an ultra-long straight type pipeline. Firstly, a pipe end expansion piece for the ultra-long pipeline is manufactured, and the pipe end expansion piece consists of a connecting part, at least three expansion pieces evenly arranged and thimble holes arranged in the center of the end parts of the expansion pieces, and a clearance is reserved between each two expansion pieces; a processing pipeline is inserted into a clamping disk, and a pipeline piece is pre-tightened by a claw; the pipe end expansion piece is inserted into the pipeline; the rotary thimbles are pushed in the thimble holes of the pipe end expansion piece; the expansion pieces are expanded and deformed along the radial direction to tightly press against the internal diameter of the pipeline so as to generate the pretension expansion force; and the claw is fastened again; a main shaft is rotated, the cutting feed is performed, and the processing beings. With the mode adopted, the method has the advantages of ensuring the processing quality and safety, improving the production efficiency and lowering the production cost, along with convenient processing operation.

Owner:WUHU JINMAO FLUID TECH CO LTD

High-strength corrosion resistance distribution box used for electric power

The invention relates to a distribution box, which includes a box body, a box cover, and a fastening mechanism for movably connecting the box body and the box cover. The raw material components of the box body and the box cover are as follows, all in parts by weight: polyethylene resin 40-60 20-30 parts of phenolic resin, 2-10 parts of elastomer, 0.1-15 parts of graphene, 3-7 parts of silicon carbide, 1-10 parts of silane coupling agent, 12-15 parts of semi-reinforced furnace black, calcined 10-12 parts of pottery clay, 6-12 parts of surface-treated Kevlar chopped fibers, 5-7 parts of nanomolybdenum disulfide (MoS2), 0.5-3 parts of aluminum oxide, 3 parts of polydimethylsiloxane ‑5 parts, 0.5‑2.5 parts of flame retardant, 1‑3 parts of dispersant. In the preparation process of the distribution box body and the box cover of the present invention, the raw materials and the proportions, together with the processing technology, make the distribution box box and the box cover of the present invention have excellent flexibility, mechanical properties and corrosion resistance, and at the same time It has good thermal conductivity, improves the performance of the distribution box as a whole, is not easy to age, has sufficient rigidity, and has a long service life, reducing maintenance costs.

Owner:DONGA POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

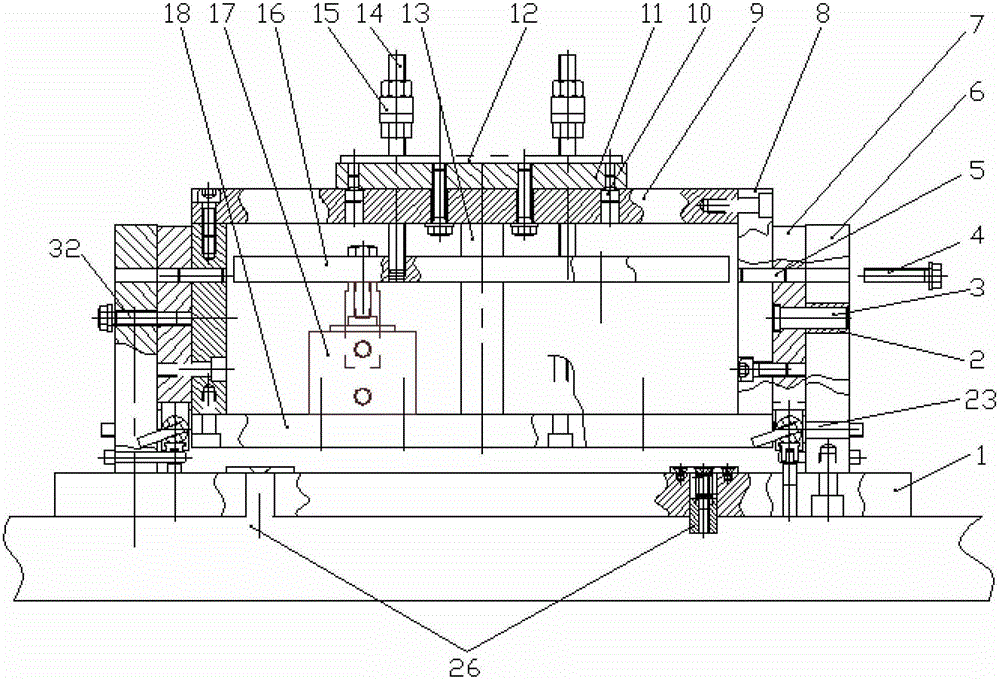

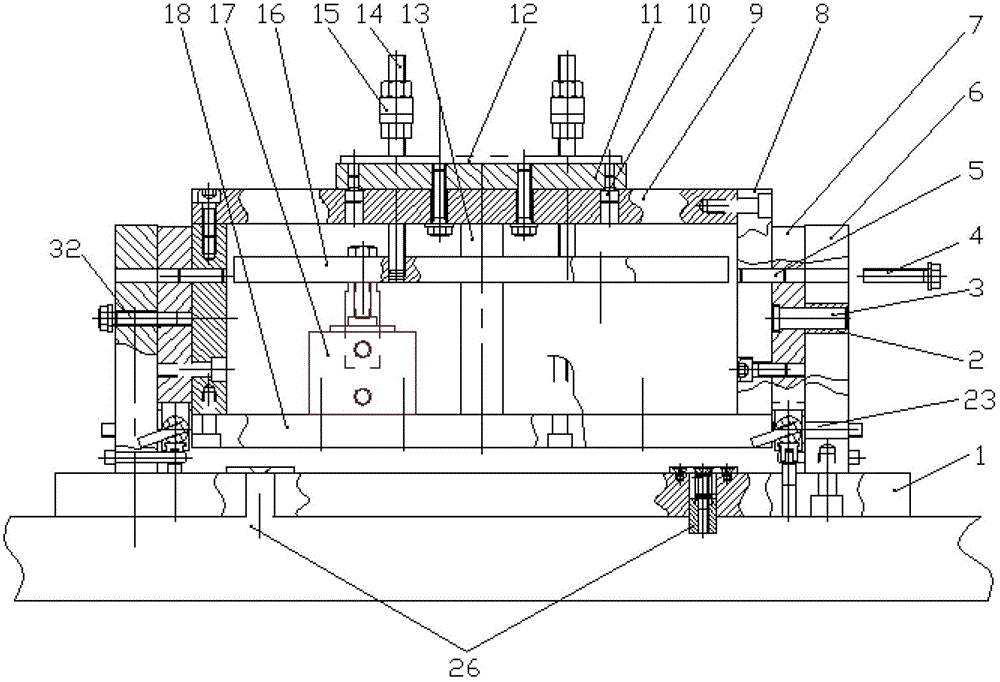

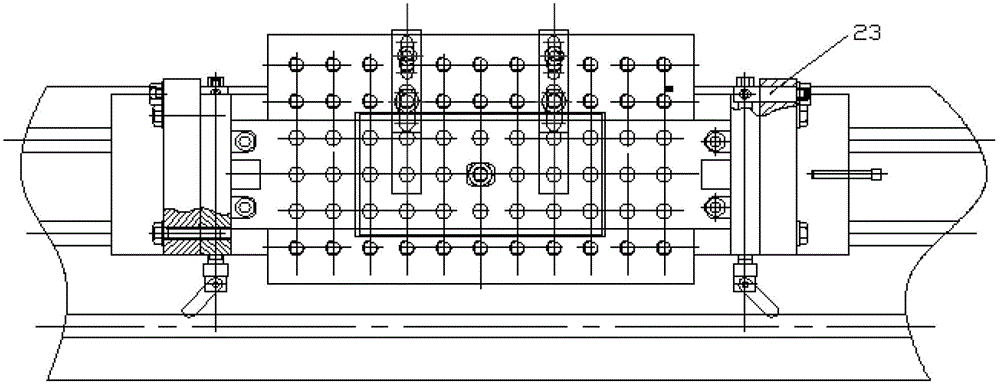

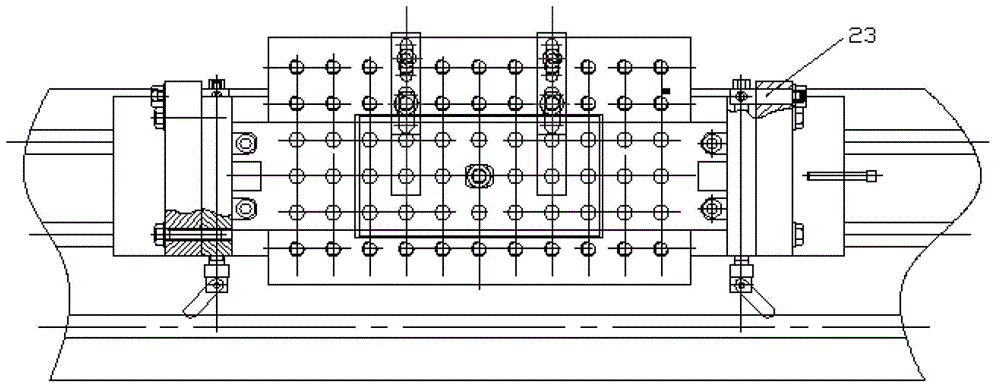

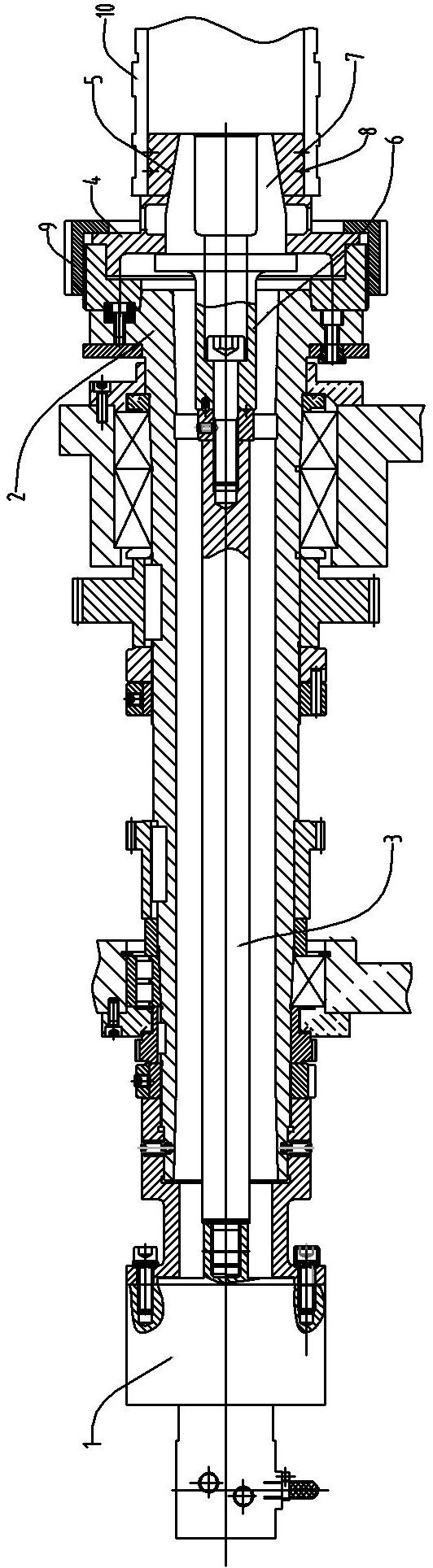

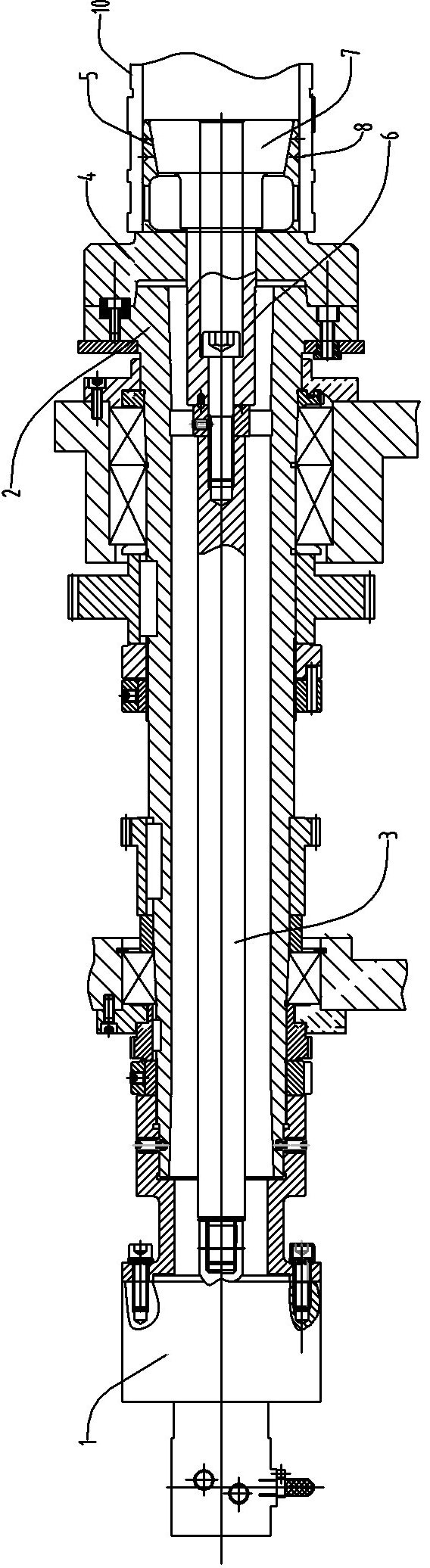

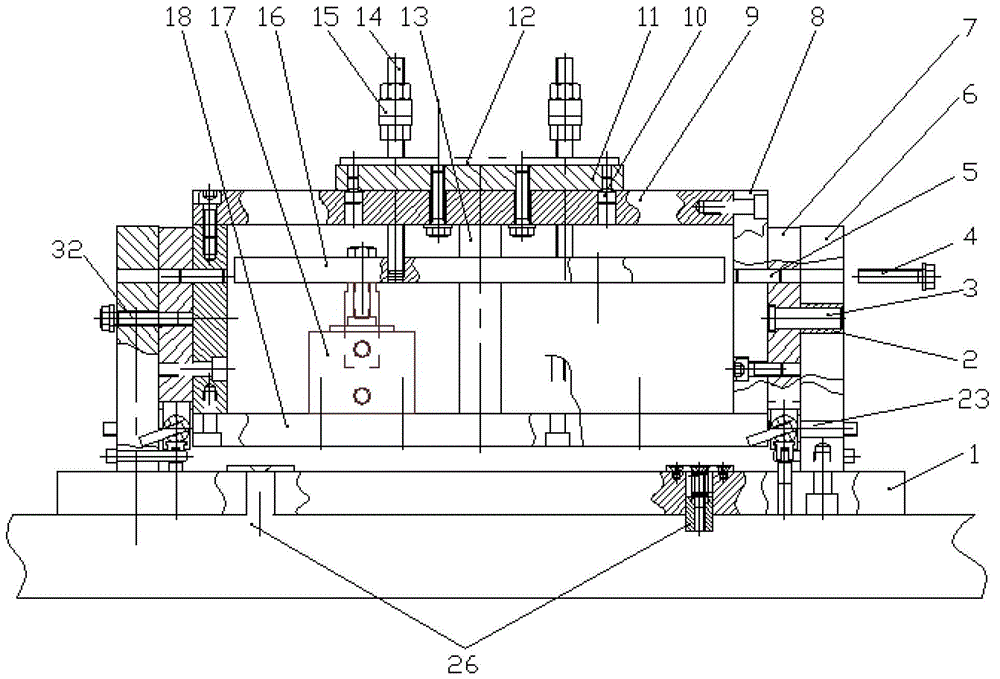

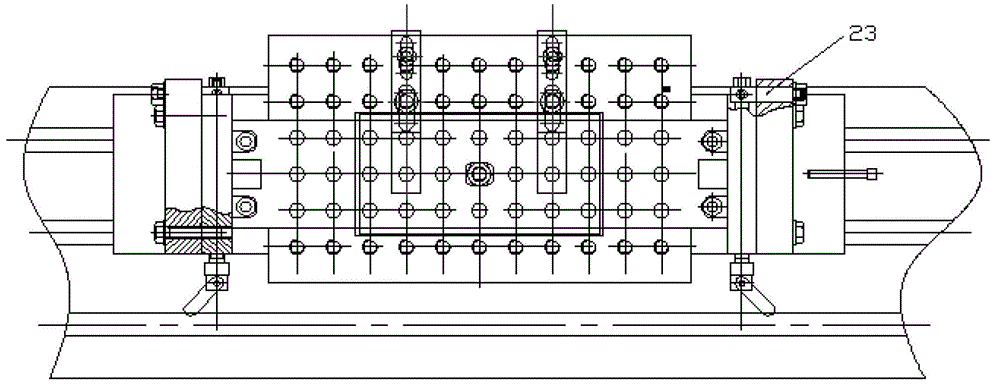

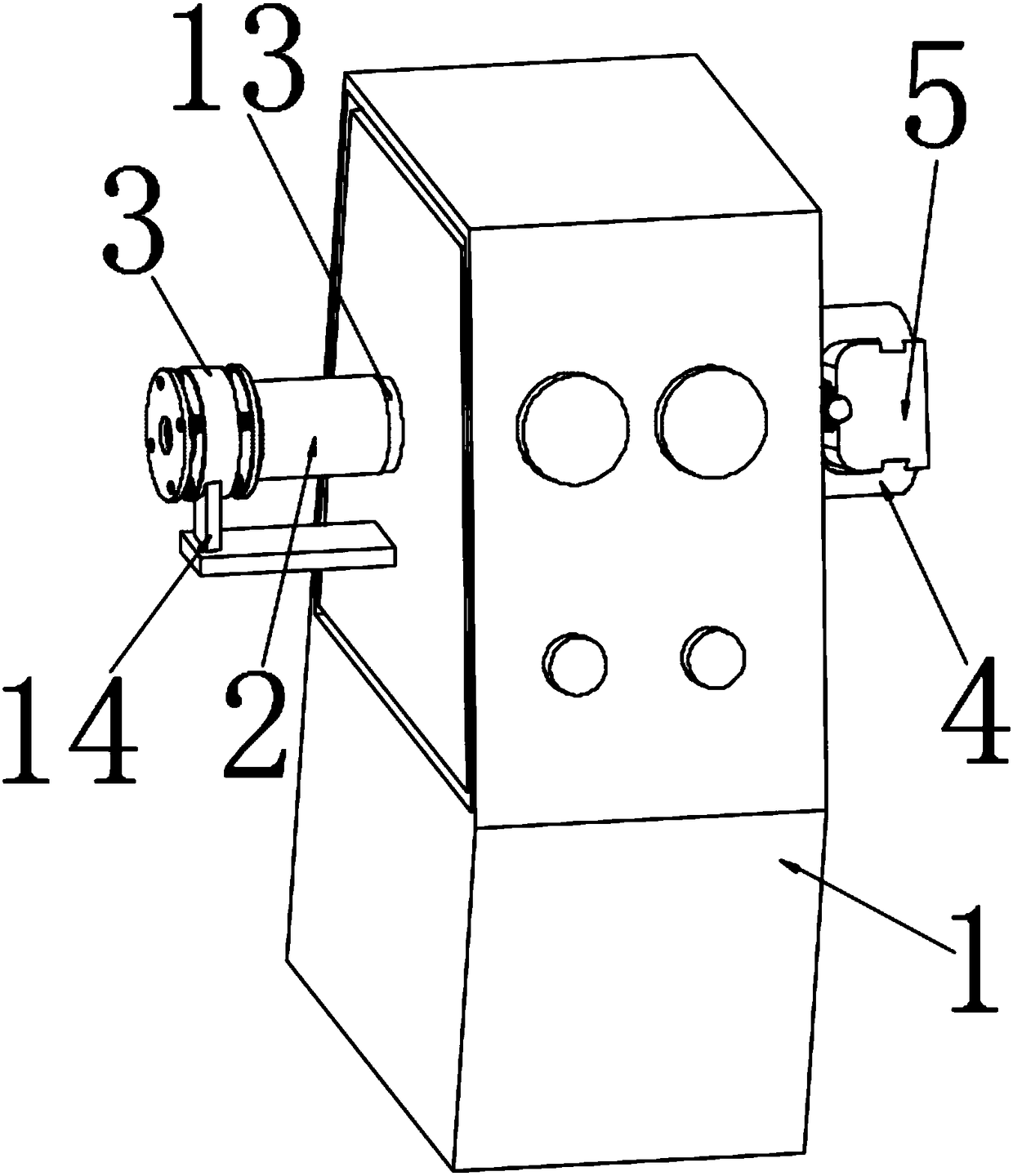

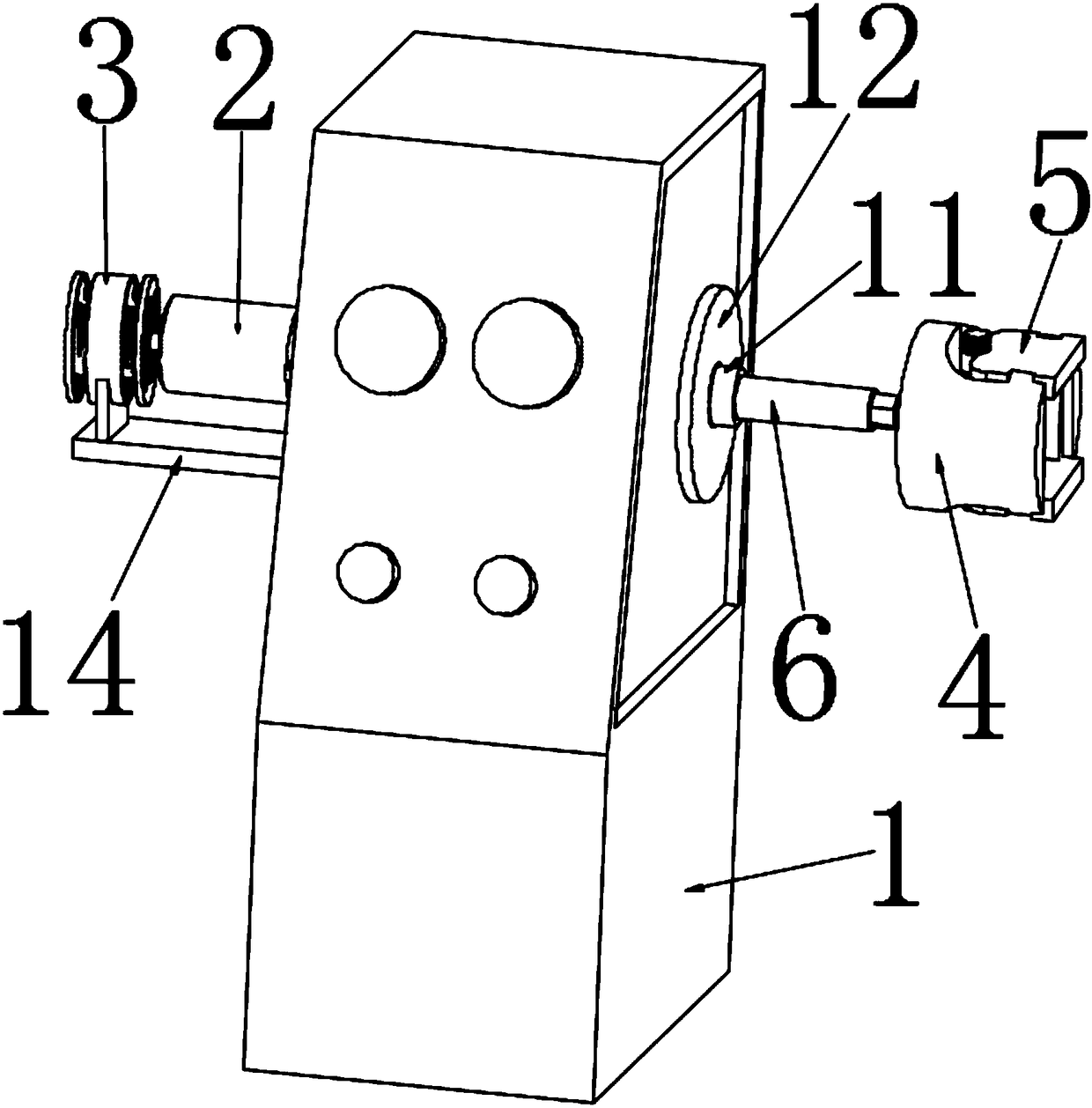

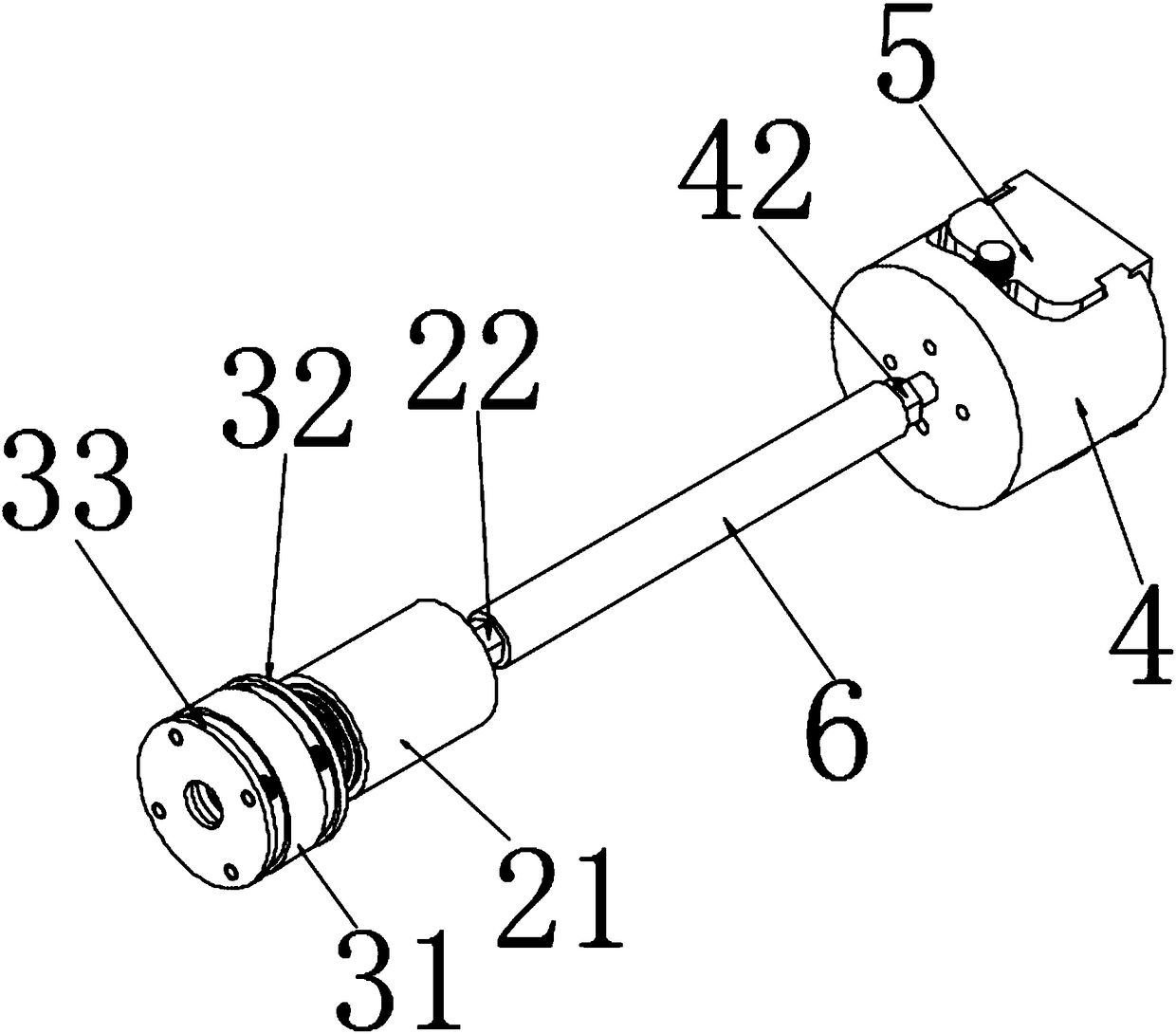

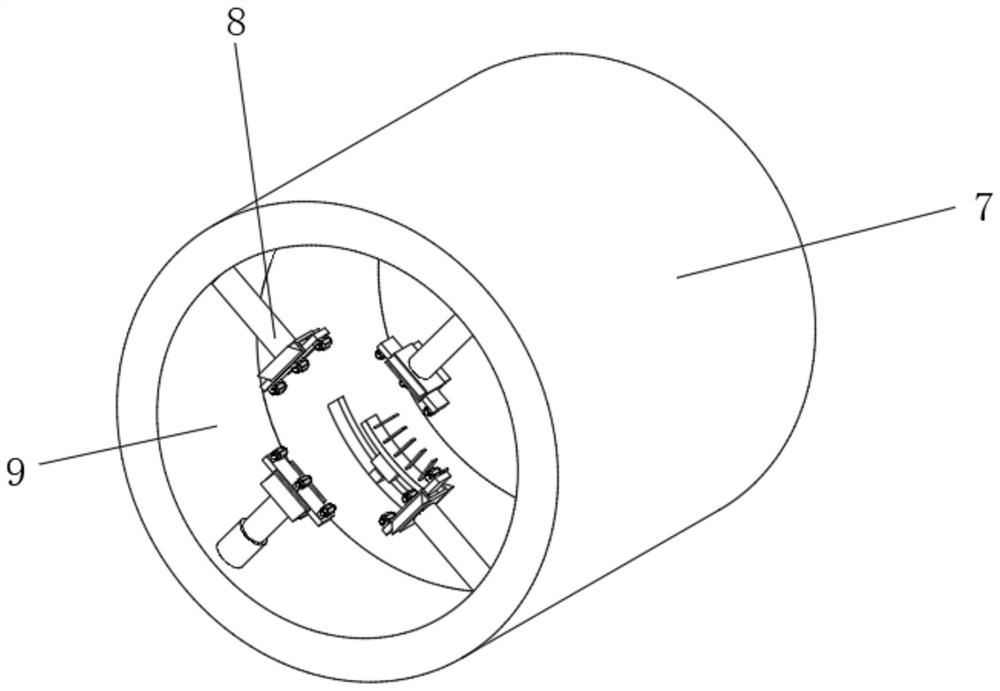

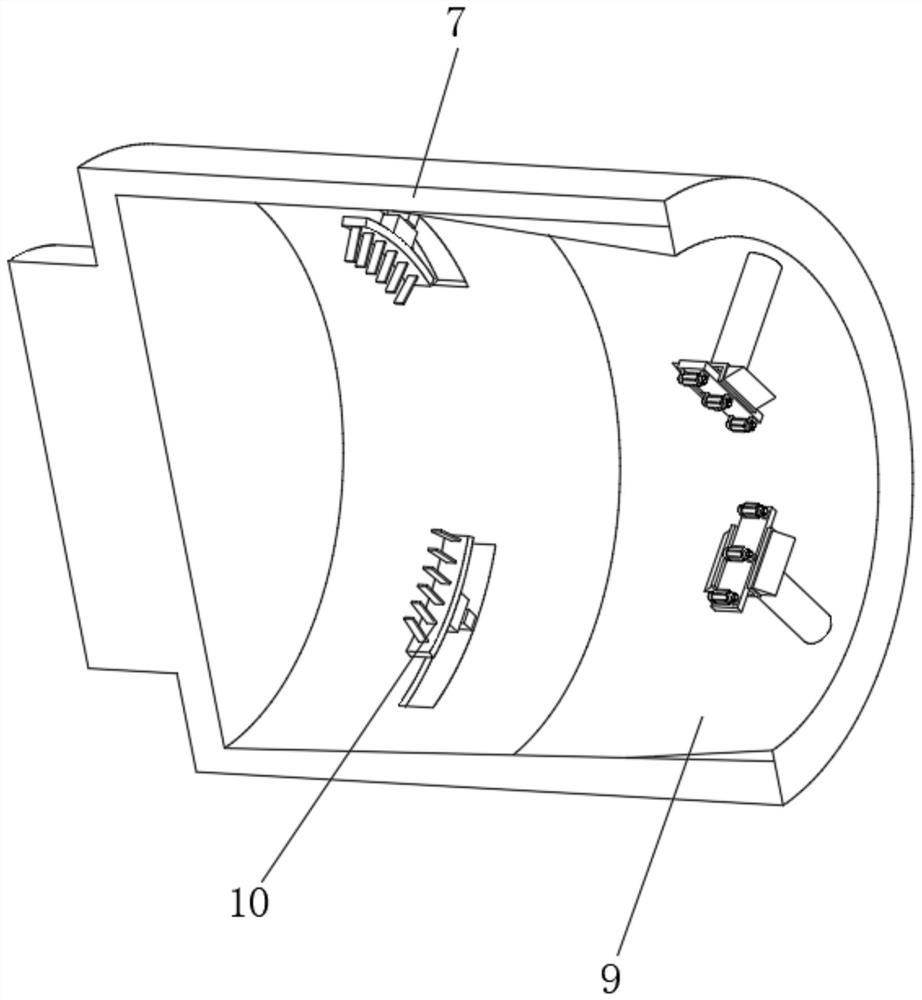

Clamp device for machining long-cylinder thin-wall part

InactiveCN104959844AGuaranteed machining accuracyGuarantee processing safetyWork clamping meansPositioning apparatusEngineeringThin walled

The invention discloses a clamp device for machining a long-cylinder thin-wall part. The clamp device is composed of end caps, pull rods and a pressing nut. The end caps comprise the left end cap and the right end cap. The pull rods are threaded-face pull rods and comprise the left pull rod and the right pull rod. The left pull rod is connected with the left end cap, and the right pull rod is connected with the right end cap. The pressing nut is installed on the right end cap. The clamp device for machining the long-cylinder thin-wall part is low in manufacturing cost and convenient and reliable to operate, the machining precision and the machining safety of the long-cylinder thin-wall part can be ensured, and the qualification rate and the machining effect of the part can also be improved.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Rapid-positioning and pneumatic-compressing universal fixture capable of slightly adjusting inclination angle

ActiveCN103143967ARapid positioningQuick compressionPositioning apparatusMetal-working holdersBody angleEngineering

The invention discloses a rapid-positioning and pneumatic-compressing universal fixture capable of slightly adjustable inclination angle, which comprises a bracket mounted on a workbench, wherein a box body is rotationally connected with the bracket; a flat fixture is fixed on a top plate of the box body and used for mounting a workpiece; the box body is provided with a pneumatic compressing mechanism for compressing the workpiece; and a box body angle adjustment device is arranged between the box body and the bracket. The universal fixture can rapidly position and press the workpiece when medium and small parts are machined; the inclination angle of the fixture can be adjusted; and the universal fixture has the advantages of good universality, high positioning accuracy, good self-locking property, and the like.

Owner:钱汝玉

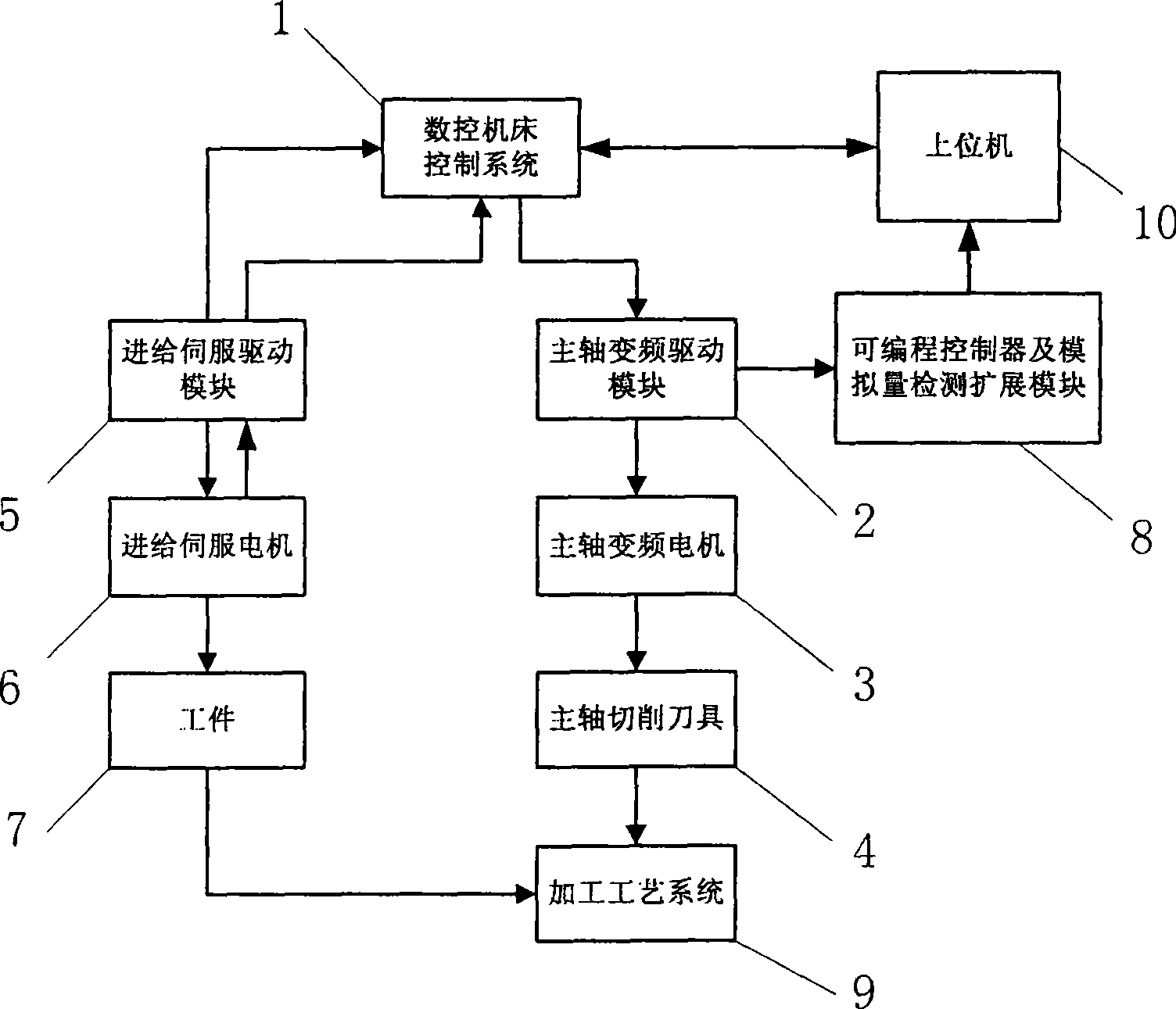

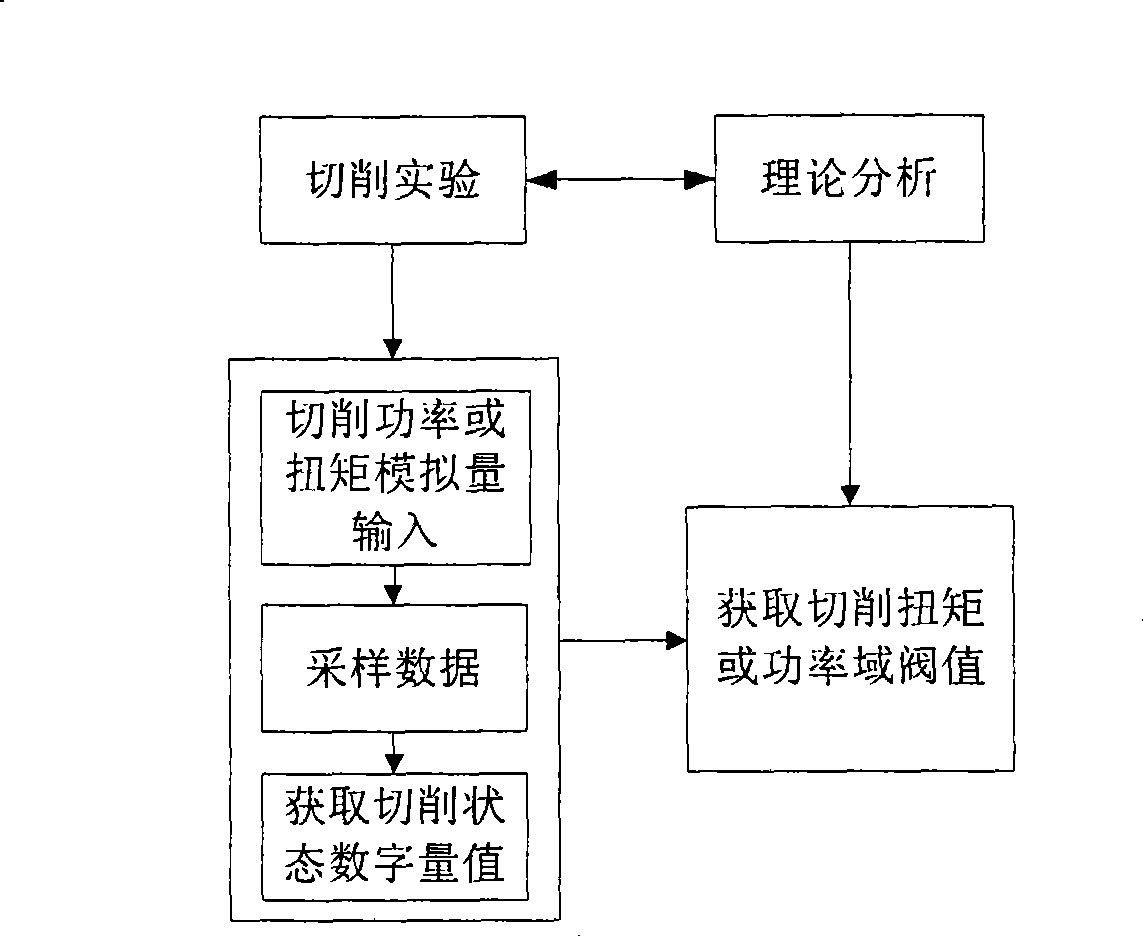

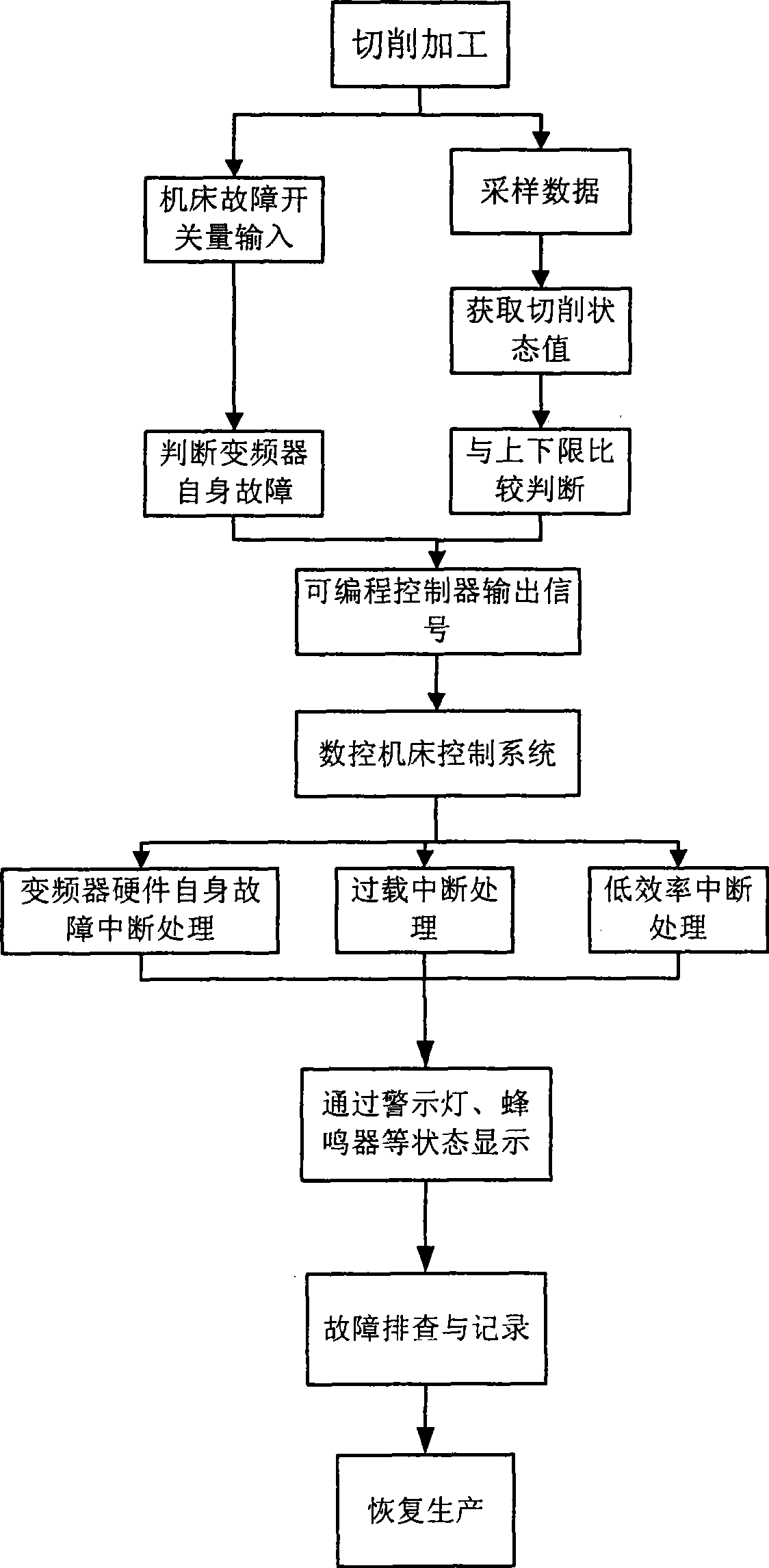

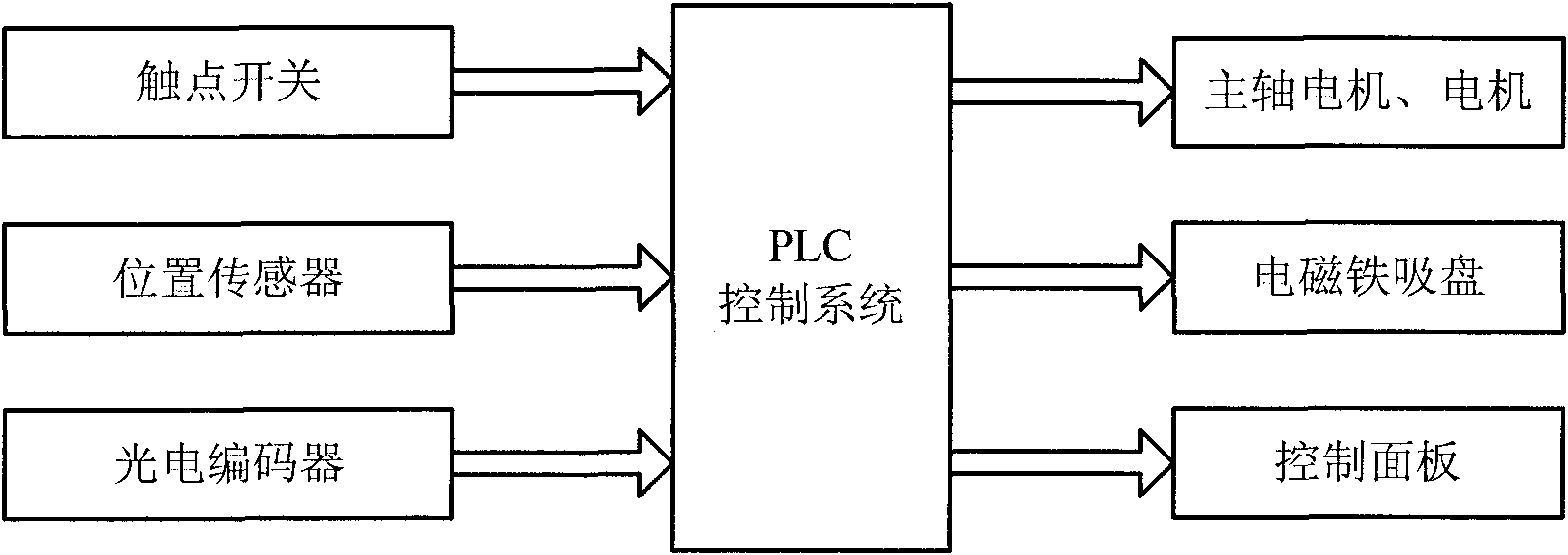

Real-time monitoring system for cutting principal shaft of numerical control gear milling machine tool

InactiveCN101482740AImprove processing efficiencyImprove processing speedProgramme controlComputer controlNumerical controlControl system

A digital control milling teeth machine tool cutting main shaft real time monitoring system comprises a digital control machine tool control system. The invention is characterized in that the servo driving input interface of digital control machine tool control system is connected with a feed servo driving module. The analog voltage output interface of digital control machine tool control system is connected with a main shaft frequency conversion driving module. The output interface of feed servo driving module is connected with driving interface of feed servo motor. The feed servo motor is connected with a workpiece feed device. The driving output interface of main shaft frequency conversion driving module is connected with a main shaft frequency conversion motor. The output interface of main shaft frequency conversion motor is connected with a main shaft cutter. The output interface of main shaft frequency conversion driving module is connected with an input interface of programmable controller and analog quantity detection expansion module. The output interface of programmable controller and analog quantity detection expansion module is connected with a control quantity input interface of upper machine. The control quantity interface of upper machine is connected with a control quantity interface of digital control machine tool control system. The digital control milling teeth machine tool cutting main shaft real time monitoring system of the invention can ensure the processing efficiency and field safety.

Owner:NANJING GONGDA CNC TECH

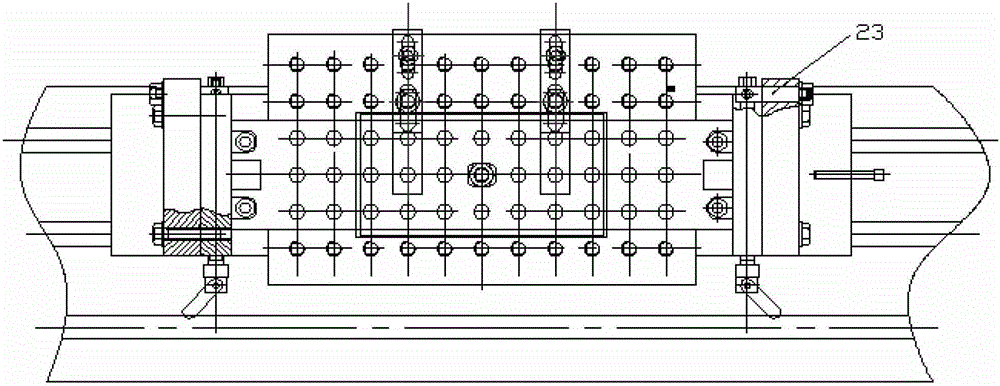

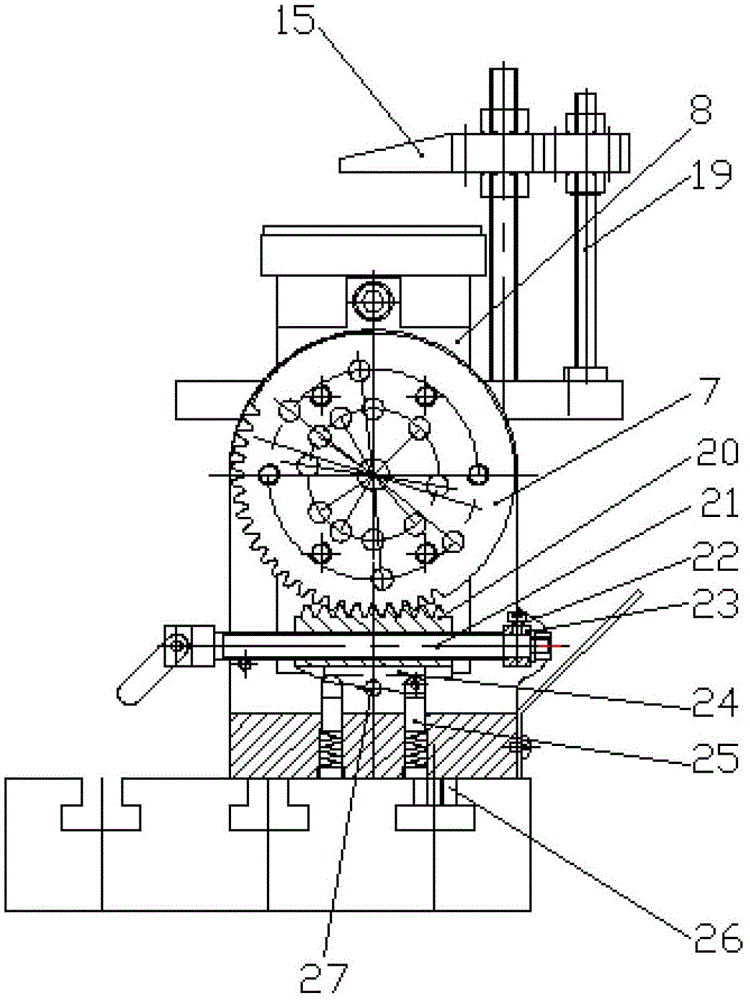

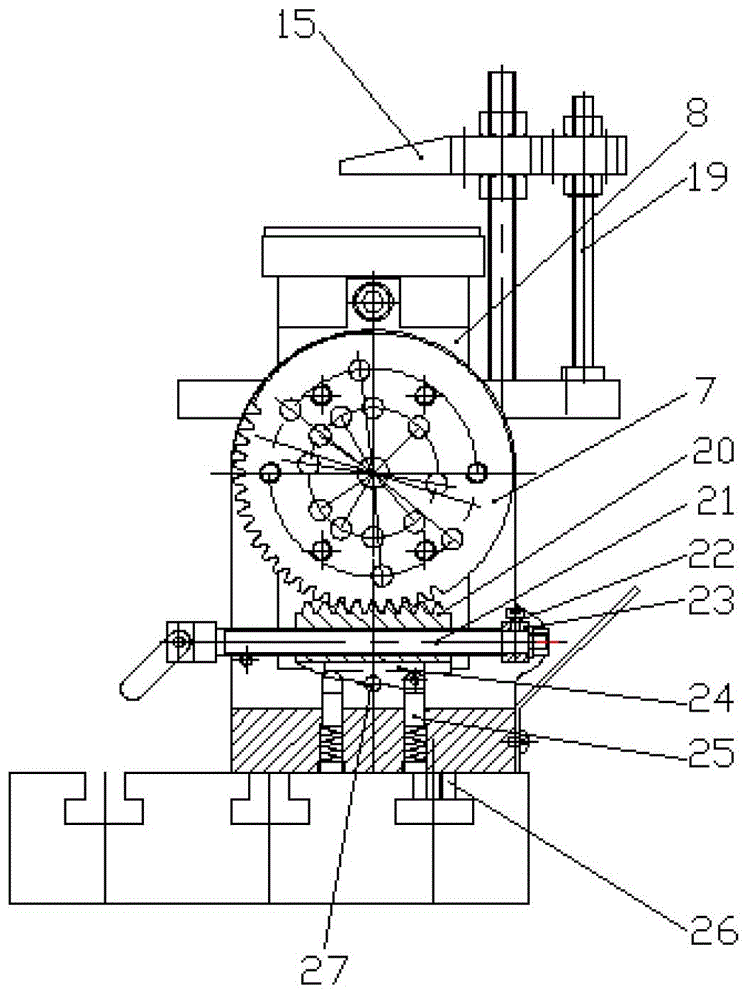

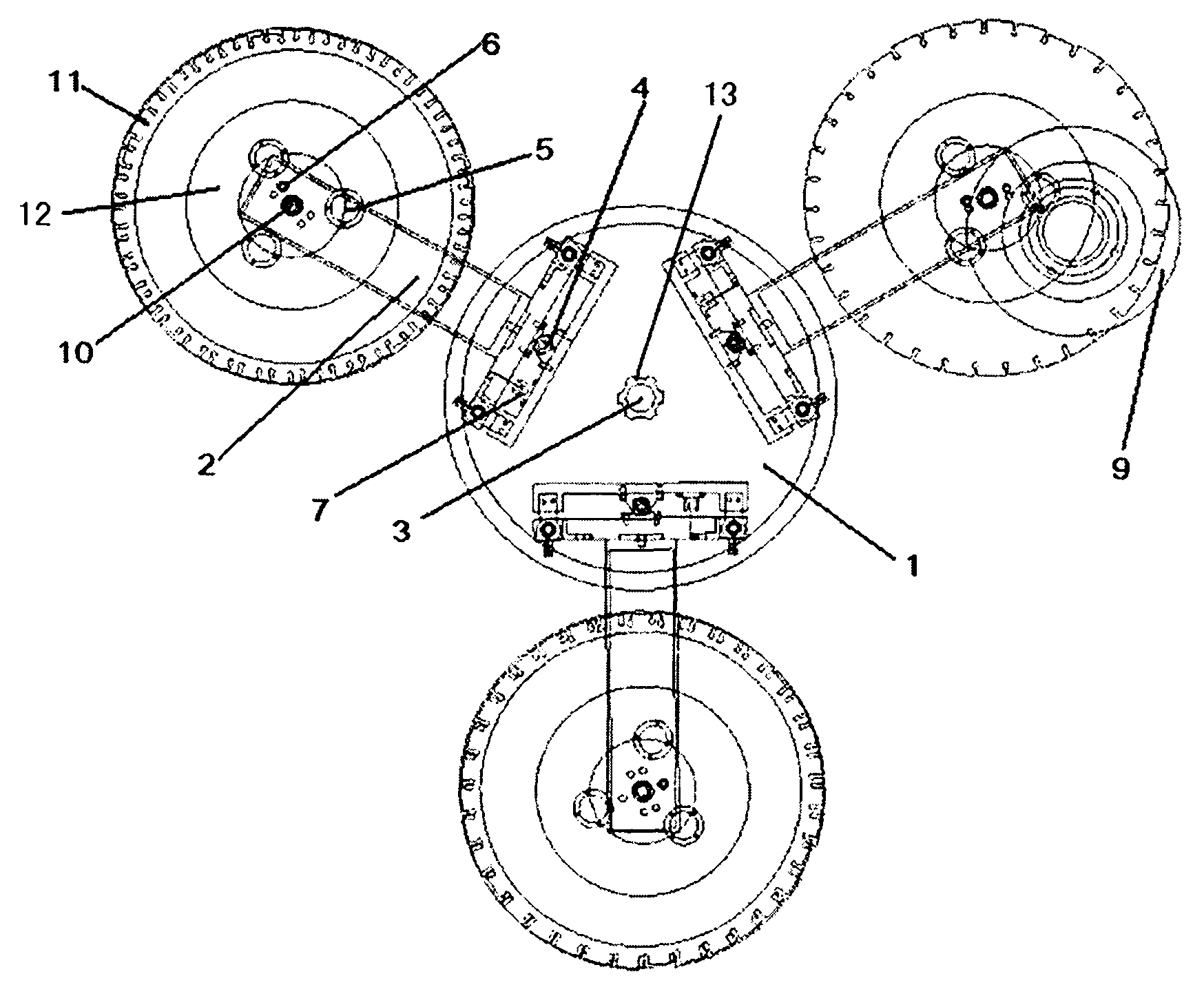

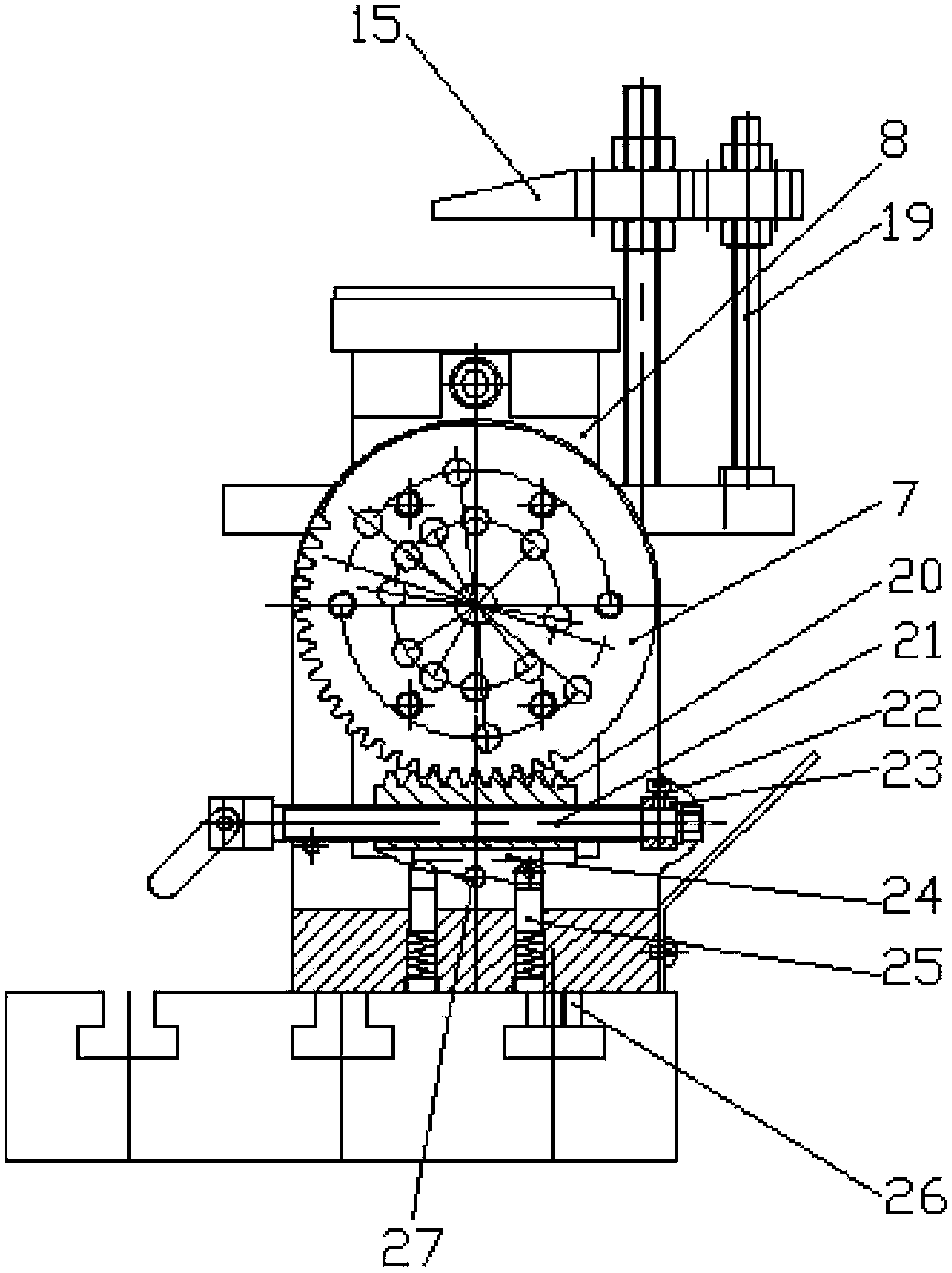

Box body angle adjusting device for universal fixture

InactiveCN103143959AGood self-lockingGuarantee processing safetyPositioning apparatusMetal-working holdersBody angleEngineering

The invention discloses a box body angle adjusting device for a universal fixture, which includes a bracket mounted on a working platform as well as a box body angle fine adjustment mechanism, wherein a box body is rotationally connected onto the bracket; a box body angle fine positioning mechanism is arranged between the box body and the bracket; the box body angle fine adjustment mechanism includes racks arranged under a gear scale division lateral plate and being in threaded connection with a rack fine adjustment bolt; a rack floating structure enables the racks to move vertically, is used for fixing the racks to a position where the racks are meshed with a gear of the gear scale division lateral plate, and is arranged under the rack fine adjustment bolt; and the box body angle fine adjustment mechanism is provided with a gear locking structure used for locking the gear positions. When middle and small parts are machined, the box body angle adjusting device can be used for adjusting the dip angle of the fixture, and has the advantages of excellent self-locking performance and the capability of saving time in adjusting the dip angle.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

Box angle fine adjustment mechanism for universal fixture

InactiveCN103143960AHigh adjustment accuracyEasy to adjustPositioning apparatusMetal-working holdersSelf lockingWorkbench

The invention discloses a box angle fine adjustment mechanism for a universal fixture, which comprises a support mounted on a workbench, wherein side support plates are arranged on the left side and the right side of the support; a box is rotationally connected between the two side support plates; gear indexing side plates are arranged between side plates on the two sides of the box and the side support plates; the gear indexing side plates are fixed with the box; racks are arranged below the gear indexing side plates and are threaded connection with rack fine adjustment bolts; rack floating structures capable of allowing the racks to float up and down and fixing the racks at gear engagement positions of the gear indexing side plates are arranged below the rack fine adjustment bolts; and the box angle fine adjustment mechanism is provided with a rack locking structure for locking positions of the racks. According to the mechanism, the racks are separated from or engaged with gears to achieve coarse adjustment and fine adjustment of an inclination; the adjustment accuracy is high; the adjustment is convenient; the inclination adjustment time is greatly saved; the box angle fine adjustment mechanism is good in self-locking property, so that the processing safety is ensured; and the yield is also increased greatly.

Owner:钱汝玉

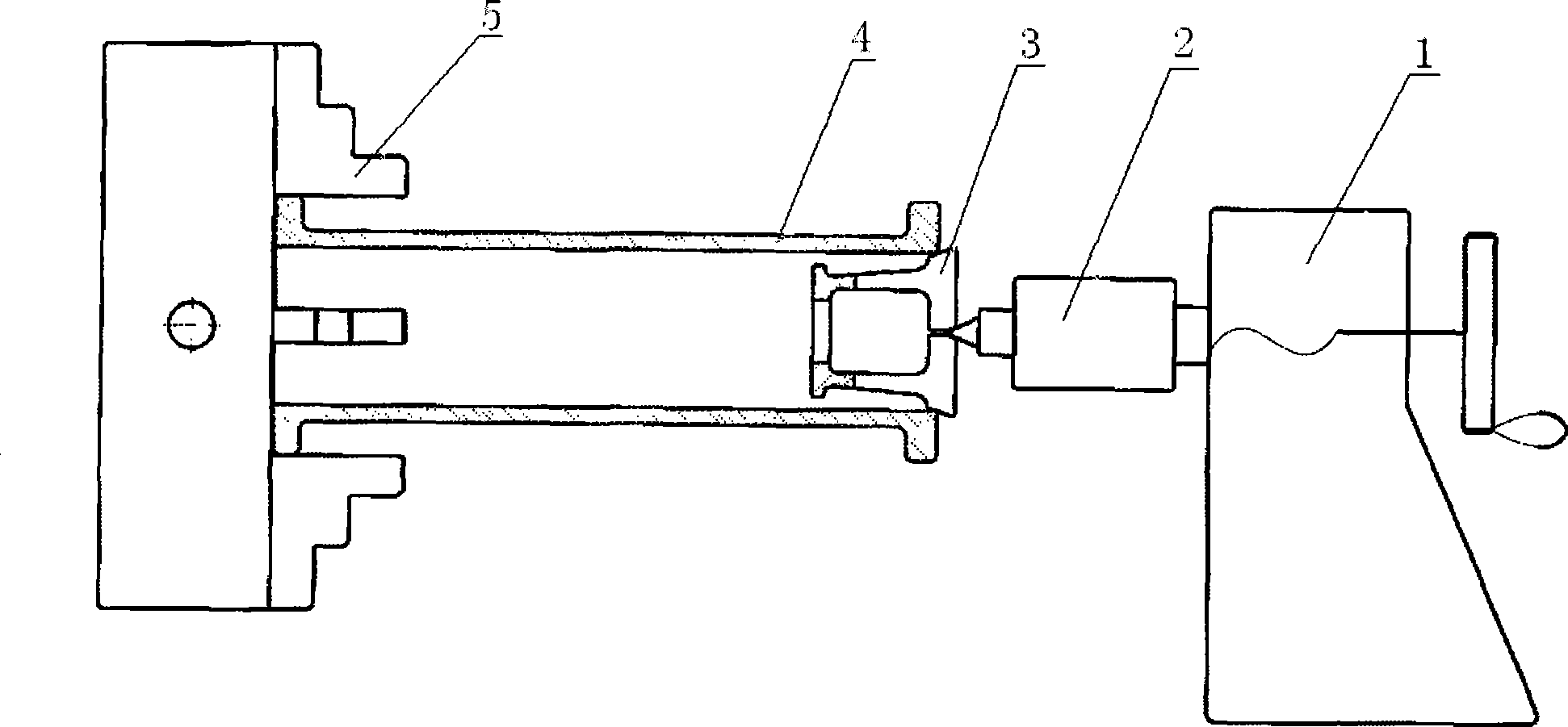

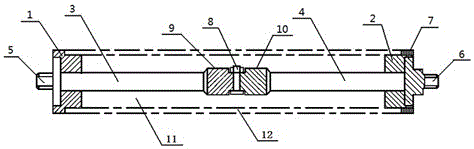

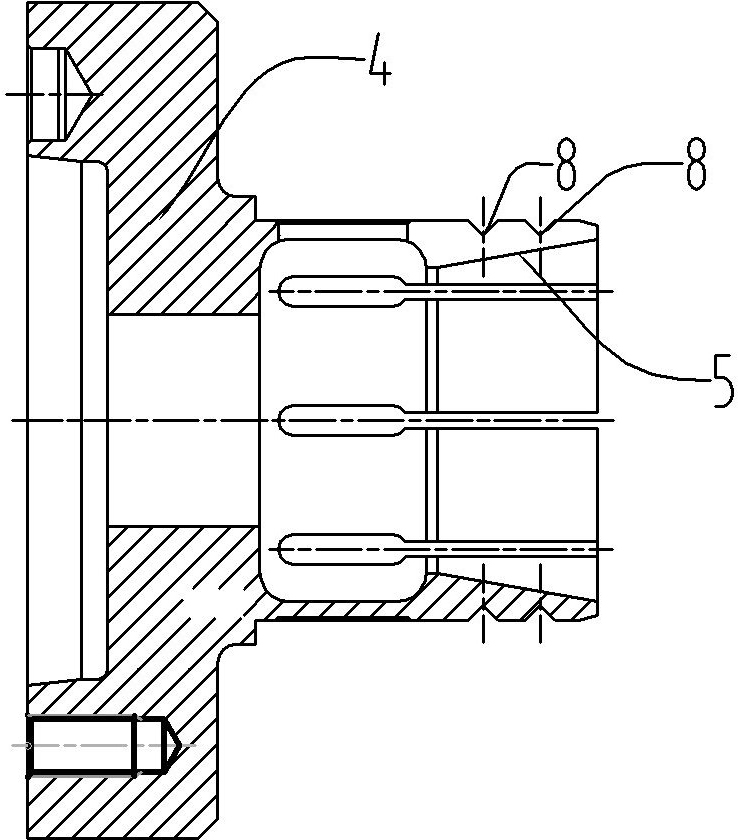

Long bar stock fixture for lathe

InactiveCN102513858AGuaranteed machining accuracyGuaranteed coaxialityPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses a long bar stock fixture for a lathe. The end part of a fixture body is fixedly provided with a spring expanding cover, and the end part of the spring expanding cover is provided with a tapered inner hole. The end part of a pull rod is connected with an outer-cone core shaft, and the end part of the outer-cone core shaft is provided with a tapered head inserted into the tapered inner hole. The other end of the pull rod is connected with a hydraulic cylinder driving the pull rod to stretch out and draw back, and the tapered head of the pull rod is pushed by the hydraulic cylinder so as to open the spring expanding cover. When the fixture clamps a workpiece, the end part of the spring expanding cover is inserted into a shaft hole of the long bar stock workpiece, the hydraulic cylinder is used for driving the pull rod to move, and the tapered head of the end part of the outer-cone core shaft causes the spring expanding cover to be expanded and tightly supported on the inner hole of the workpiece, so that the workpiece is clamped. The fixture is simple and convenient for clamping and is matched with a self-centering center frame and a tailstock with a special cone plug for use. Only the coaxiality of three points, namely the spring expanding cover, the self-centering center frame and the tailstock is ensured, the clamping precision of an overlong bar stock can be ensured, and therefore the processing precision of the workpiece is ensured.

Owner:广州机床厂有限公司

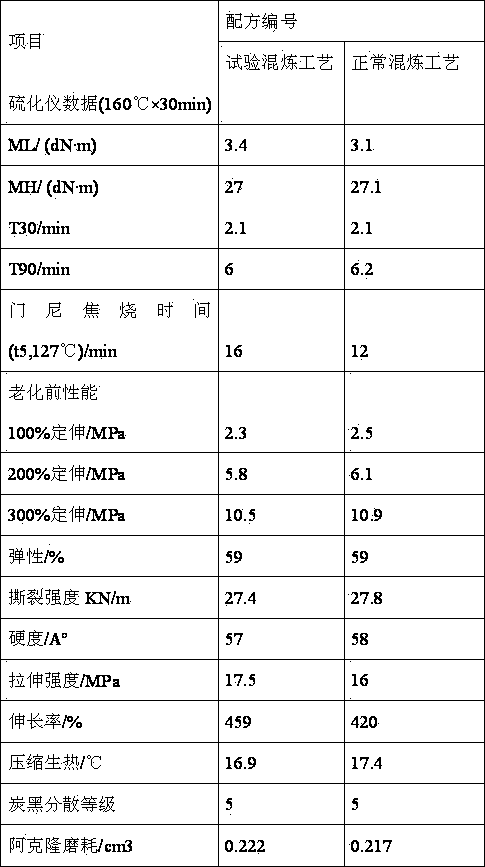

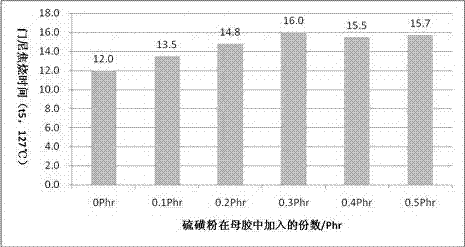

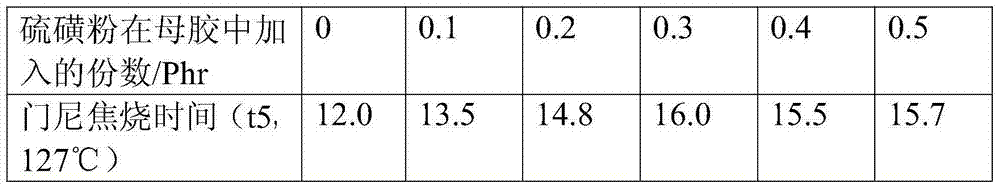

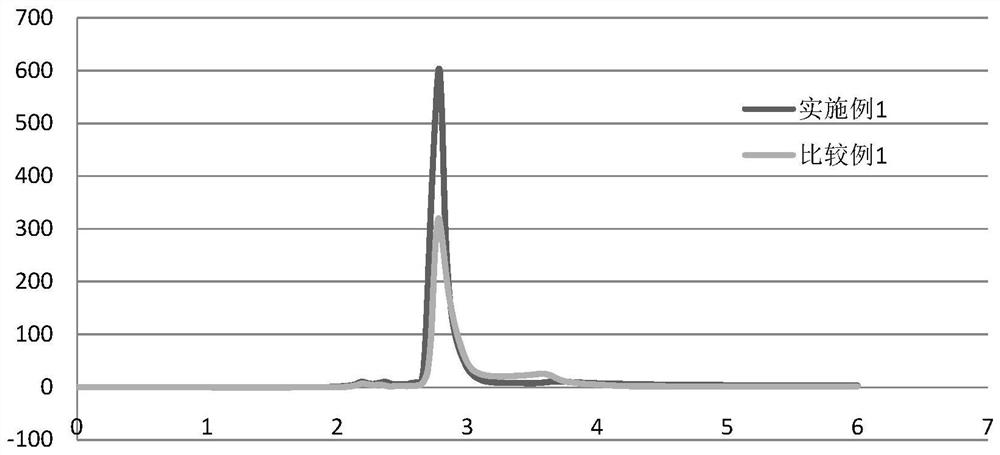

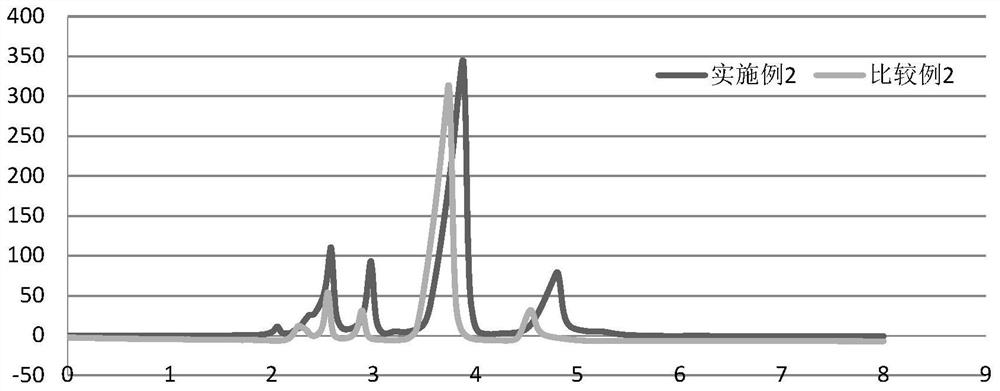

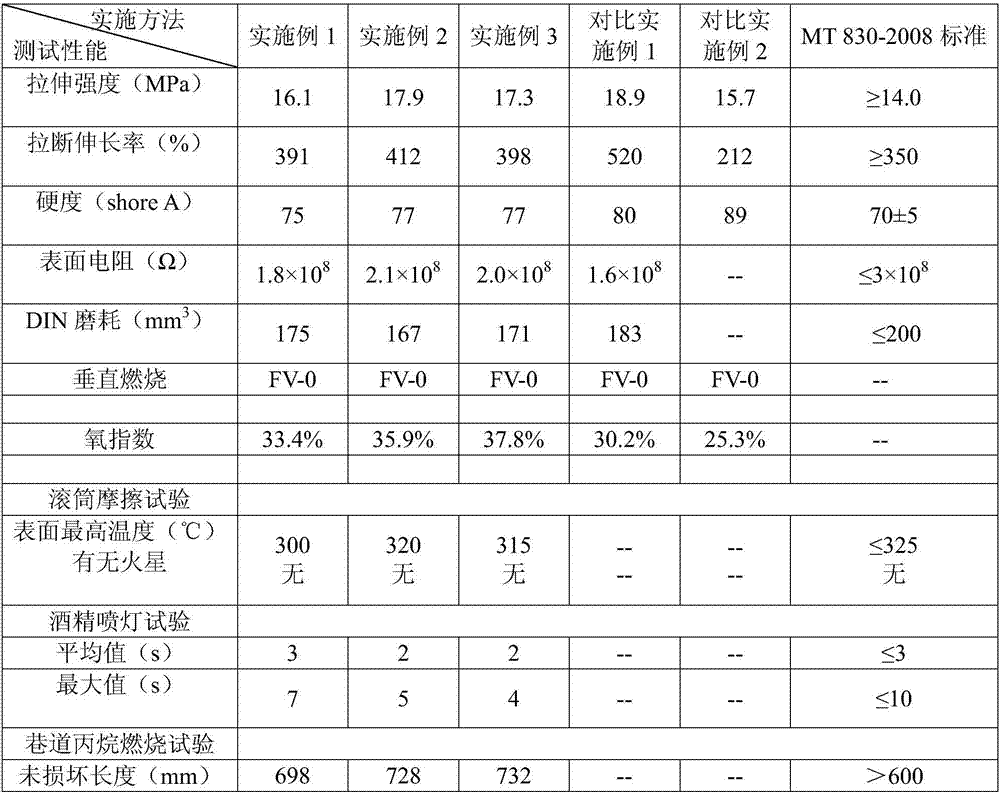

Rubber compound high in safety performance of processing and technology thereof

The invention discloses a rubber compound high in safety performance of processing and a technology thereof. The rubber compound is characterized by comprising the following components by weight: a masterbatch component and 9 to 11 parts of a final compound rubber, wherein the masterbatch component comprises 80 to 100 parts of a crude rubber, 50 to 70 parts of white carbon black, 5 to 10 parts of carbon black, 8 to 12 parts of a silane coupling agent, 3 to 5 parts of resin, 5 to 8 parts of zinc oxide, 0.5 to 2.5 parts of stearic acid, 0.1 to 0.5 part of sulphur and other components; the final compound rubber comprises 0.5 to 2.5 parts of rubber master batch and sulphur, and 0.5 to 1.8 parts of an accelerating agent. The rubber compounding component technology comprises the following steps: (1) first section mixing, (2) second section mixing, (3) third section mixing, and (4) final rubber mixing. Compared with the prior art, through the innovation of the rubber mixing technology, the feeding sequence is changed, part of the parts of sulphur is added into masterbatch, the scorching time of a sizing material is prolonged, and the safety performance of the processing of the sizing material is ensured.

Owner:SAILUN GRP CO LTD

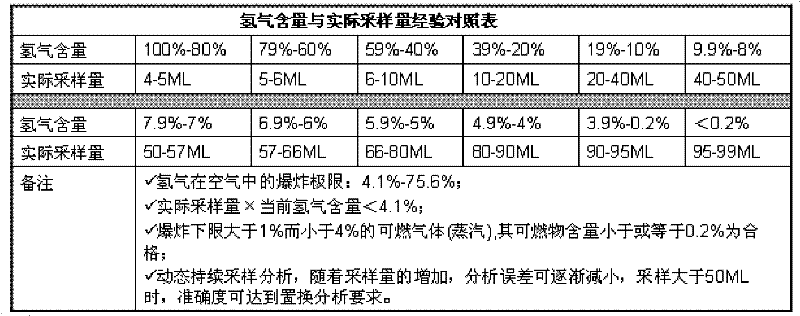

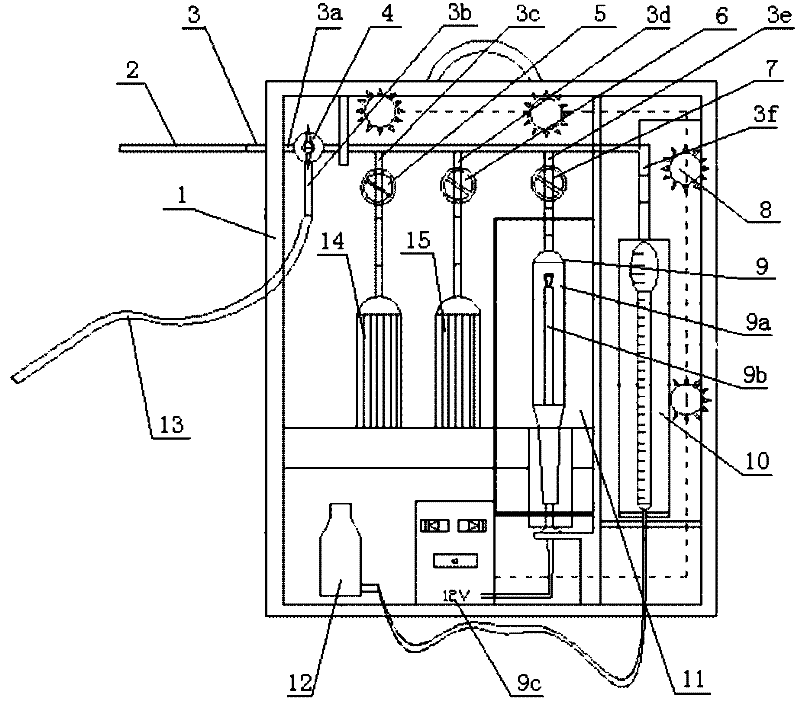

Improved Orsat gas analyzer and analysis method thereof

The invention relates to an improved Orsat gas analyzer and an analysis method thereof. A 1901 type Orsat gas analyzer is used as the basis, a set of gas absorption tubes are disassembled, a burner replaces the gas absorption tubes, and a lighting lamp is added. In accordance with some theoretic and the practical situations such as explosion limit of hydrogen in air, combustible gas residual safe concentration, analysis sampling requirement, dynamical changed hydrogen content and practical analysis experience, a hydrogen content and practical sample amount experience comparison table and a corresponding operating method are independently compiled, so as to keep the advantages of the 1901 type Orsat gas analyzer that: the size is small, the analyzer is conveniently carried over and satisfies the analysis requirement for oxygen and carbon dioxide content, and the analyzer movably analyses on multi points in the light-insufficient outer production environment such as at night, and realizes the advantages of convenience in operation of the content value of the dynamically changed hydrogen in the hydrogen system replacement, continuous analysis during the whole process, short replacement qualified time, reduced use cost of the pure nitrogen gas and low working strength of the analyzer.

Owner:WUXI SEAMLESS OIL PIPE

Preparation method of amino acid surfactant

PendingCN113135833AHigh purityAvoid corrosionOrganic compound preparationTransportation and packagingActive agentChemical products

The invention relates to the technical field of synthesis of fine chemical products, and discloses a preparation method of an amino acid surfactant. The method comprises the steps that fatty acyl chloride and an aqueous solution of amino acid and / or amino acid salt are subjected to a contact reaction in a micro-channel reactor, the amino acid surfactant is obtained, the micro-channel reactor comprises a plurality of reaction pieces, and each reaction piece comprises a micro-channel structure. According to the invention, a continuous operation mode is adopted, two streams of materials are respectively introduced into the micro-channel reactor by utilizing a pump, are preheated and then reach a reaction area for reaction, the materials flow out from an outlet of the micro-channel reactor after the reaction is finished to obtain a crude product, and the crude product is only subjected to membrane filtration and concentration purification treatment to obtain the high-purity amino acid surfactant.

Owner:GUANGDONG HEJI BIOTECH CO LTD

Box angle fine location mechanism for universal fixture

InactiveCN103143953AShorten adjustment timeGood self-lockingPrecision positioning equipmentPositioning apparatusGear wheelSelf locking

The invention discloses a box angle fine location mechanism for a universal fixture, which comprises a support mounted on a workbench, wherein the support is rotationally connected with a box; gear indexing side plates are arranged between side plates of the box and side support plates; the gear indexing side plates are fixed with the box; a circle of indexing holes are circumferentially and uniformly distributed in each gear indexing side plate; indexing location pin holes are formed in the side support plates; and after the box rotates to a set angle, indexing locating pins penetrate through the indexing locating pin holes and the indexing holes to locate the gear indexing side plates. According to the mechanism, the gear indexing side plates can be located by matching of the indexing locating pin, the indexing locating pin holes and the indexing holes, so that an inclination of the box in the fixture can be adjusted and fixed. The mechanism is good in self-locking property, ensures processing safety, greatly increases the yield, and can also save the inclination adjustment time greatly.

Owner:钱汝玉

Wear-resisting anti-slipping electrician ladder for electric power construction

InactiveCN106046507AImprove impact resistanceImprove wear resistanceLaddersAgricultural engineeringWear resistance

The invention relates to a wear-resisting anti-slipping electrician ladder for electric power construction. The wear-resisting anti-slipping electrician ladder comprises two ladder legs and a pedal plate connected between the two ladder legs; rubber anti-slipping sleeves sleeve the tops of the ladder legs; hooks and containing barrels are arranged at the two sides of the upper parts of the ladder legs respectively; the ladder legs are made of bamboo; the pedal plate is made of high-strength wear-resisting plastic. The pedal plate provided by the invention has good heat dissipation performance, the safety of the ladder is guaranteed, and the service life is prolonged; the ladder is not easy to age, enough in rigidity and long in service life; the maintenance cost is reduced and the ladder is firm and durable on the basis of guaranteeing portability. The rubber anti-slipping sleeves enhance the wearing resistance, so that the anti-slipping performance of the rubber anti-slipping sleeves is enhanced.

Owner:郭秀珍

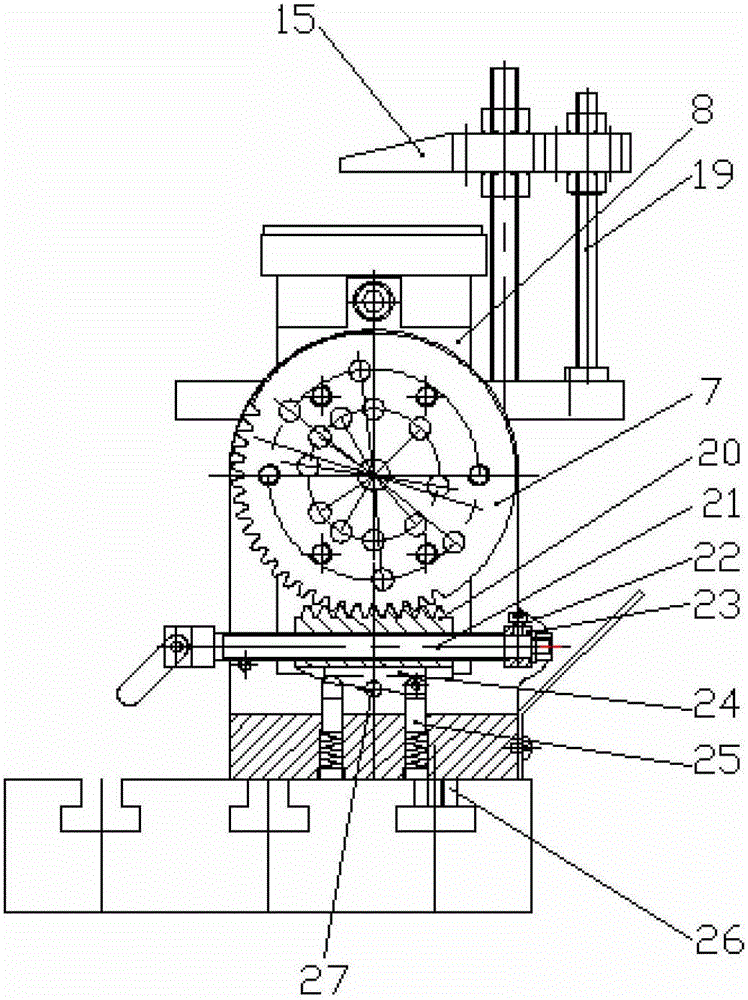

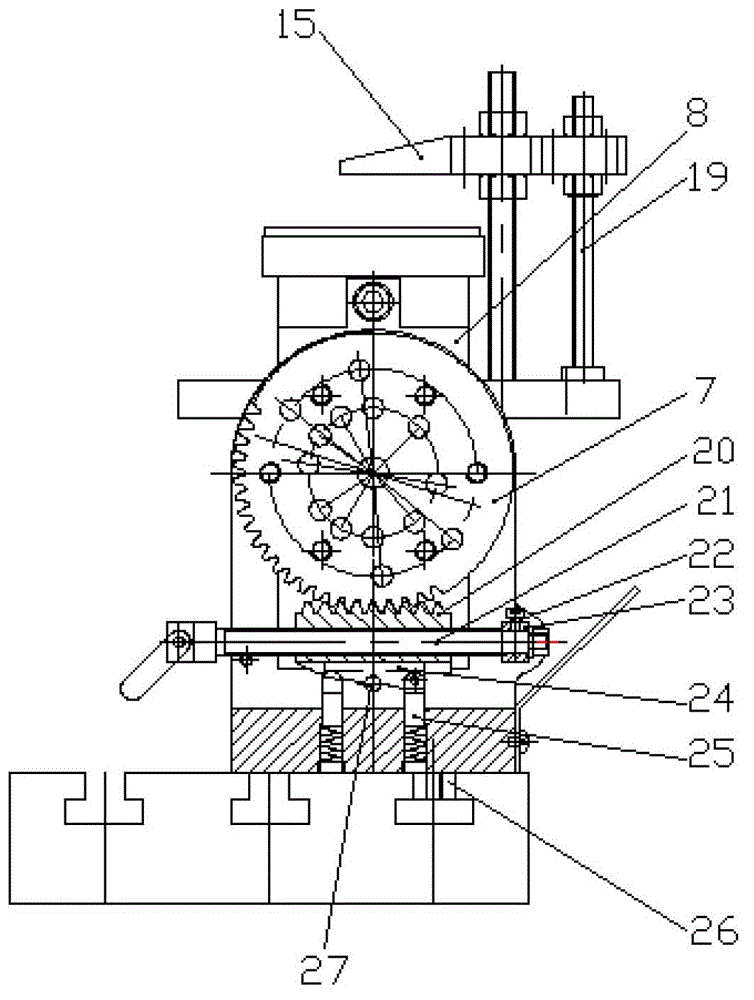

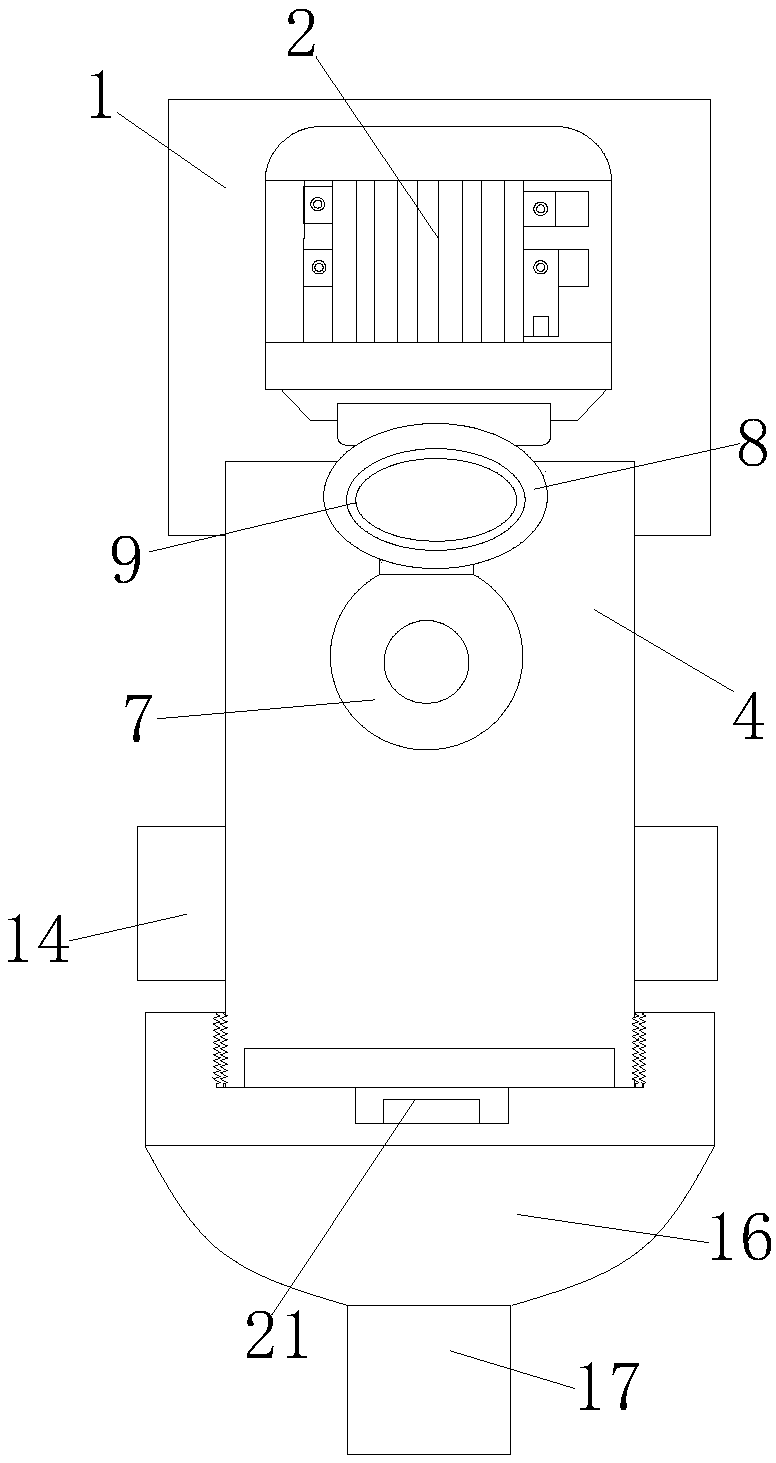

Deburring device for disc type slice part

InactiveCN101829935AIncrease productivityGuarantee processing safetyEdge grinding machinesElectric machineryEngineering

The invention relates to a deburring device for a disc type slice part, comprising a bottom platform, a spindle, a spindle motor, three lifting gears and a control system, wherein the spindle motor is used for driving the bottom platform to rotate around the spindle, the three lifting gears are evenly distributed on the bottom platform by taking the spindle as a circle center, mechanical arms which radiate outwards by using the spindle as a circle center are respectively arranged on each lifting gear, and the end of each mechanical arm is provided with workpiece picking and placing equipment; a workpiece picking position, a workpiece processing position and a workpiece releasing position are respectively arranged under each workpiece picking and placing equipment correspondingly, grinding wheels are arranged on the workpiece processing position; and the spindle motor, and the lifting gears and the workpiece picking and placing equipment are controlled by the control system. The deburring device has high efficiency, safety and accurate positioning.

Owner:WUHAN BIDA ELECTRICAL IND CO LTD

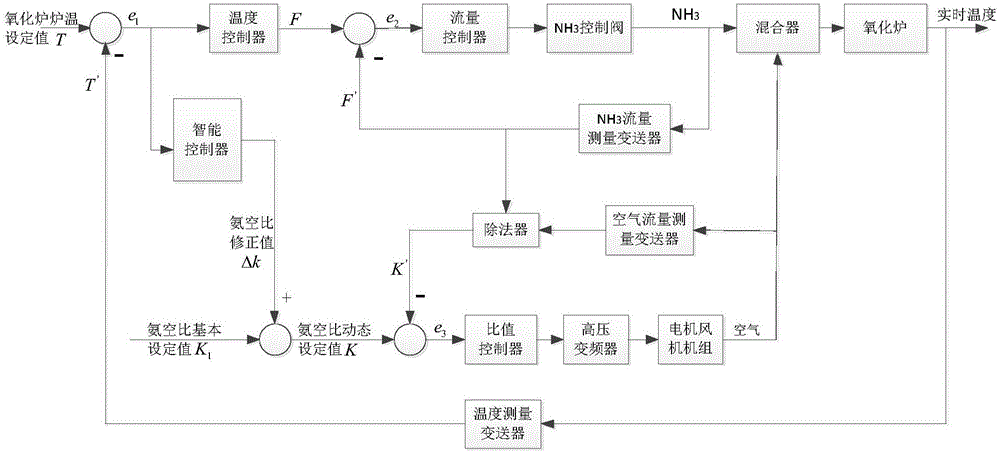

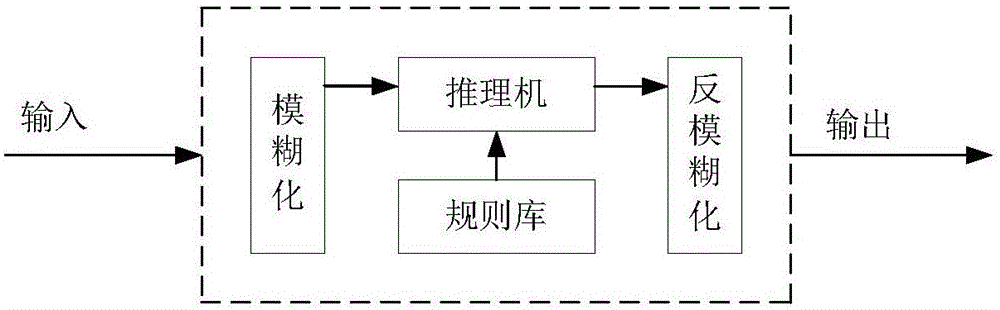

Control system and control method for ammonia-to-air ratio automatic set value in nitric acid production oxidation furnace

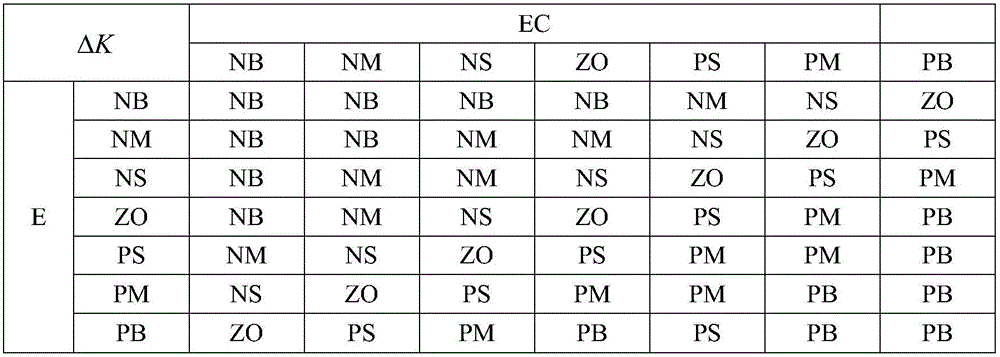

InactiveCN105786055AGood performanceWeaken channel interferenceSimultaneous control of multiple variablesNitric acidTraffic volumeTime ratio

The invention provides a control system and a control method for an ammonia-to-air ratio automatic set value in a nitric acid production oxidation furnace. The system compares the real-time temperature of an oxidation furnace with a set temperature value. A temperature controller outputs a required ammonia gas flow. Ammonia gas which enters the oxidation furnace is adjusted through an ammonia gas control valve. For inputting air according to a preset ratio, The flow ratio between the ammonia gas and the air is used as feedback of an air circuit and is compared with the basic set value of the ammonia-to-air ratio. The input amount of the air is adjusted through a variable-frequency blower fan. When temperature offset of the oxidation furnace occurs because of a disturbance to the system, the temperature of the oxidation furnace can be quickly adjusted through changing the ammonia-to-air ratio. An intelligent dynamic ammonia-to-air ratio correction unit outputs the corrected value of the ammonia-to-air ratio according to the temperature offset and change of the temperature offset. The dynamic set value of the ammonia-to-air ratio is formed through overlapping the corrected value of the ammonia-to-air ratio and the basic set value of the ammonia-to-air ratio. The real-time ratio between the ammonia gas flow and the air flow is compared with the dynamic set value of the ammonia-to-air ratio. Through a ratio controller, the air is kept constant in a new ammonia-to-air ratio.

Owner:CHONGQING UNIV

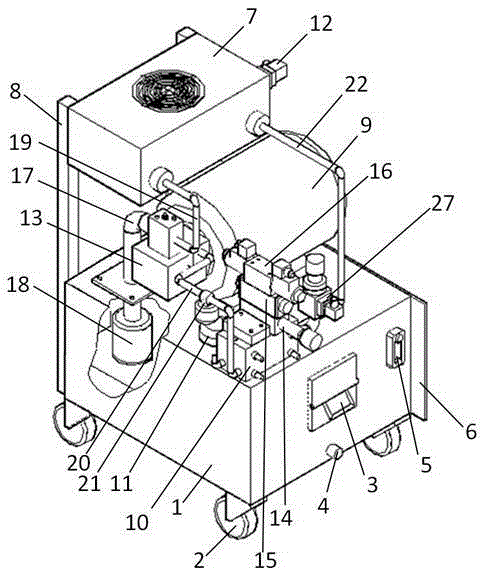

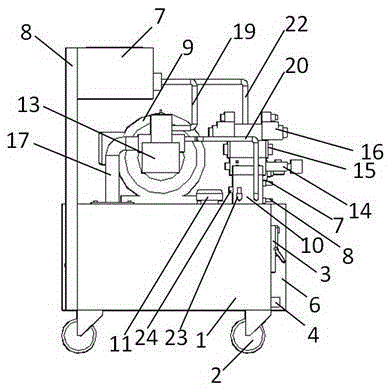

Machine tool hydraulic pressure station

InactiveCN105257609AReduce distortionImprove pass rateServomotorsFluid-pressure actuator componentsSolenoid valveThree phase asynchronous motor

The invention discloses a machine tool hydraulic pressure station which comprises an oil tank and a radiator, wherein a three-phase asynchronous motor and a valve block are mounted on the upper top surface of the oil tank; a variable pump is mounted on one side wall of the three-phase asynchronous motor; a pressure reducing valve, a pressure retaining valve and a solenoid valve are mounted above the valve block from bottom to top in sequence; one end of the variable pump communicates with an oil suction opening filter arranged inside the oil tank through an oil suction tube; the other end of the variable pump communicates with the radiator and the valve block through a radiator oil inlet tube and a main pressure tube; the radiator communicates with the oil tank through a radiator oil return tube; and a knife tower oil port A, a knife tower oil port B, a chuck oil port A and a chuck oil port B are arranged on the side wall of the valve block. According to the machine tool hydraulic pressure station, pressure stability is guaranteed, workpiece deformation caused by pressure stability is reduced, processing safety of equipment is guaranteed, and guarantee is provided for increasing first-pass yield of workpieces; and meanwhile, consumption of hydraulic oil is reduced and waste is reduced.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

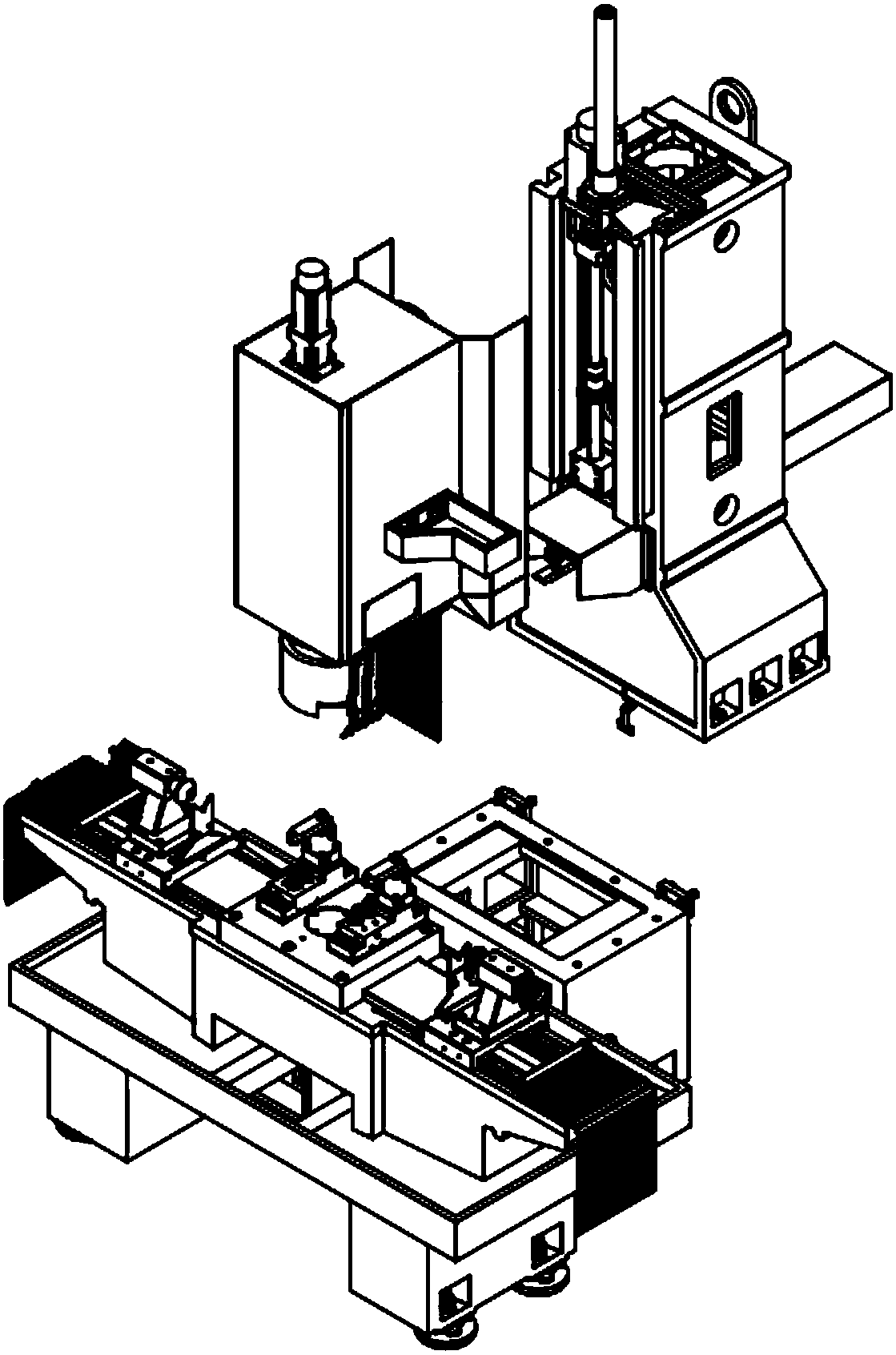

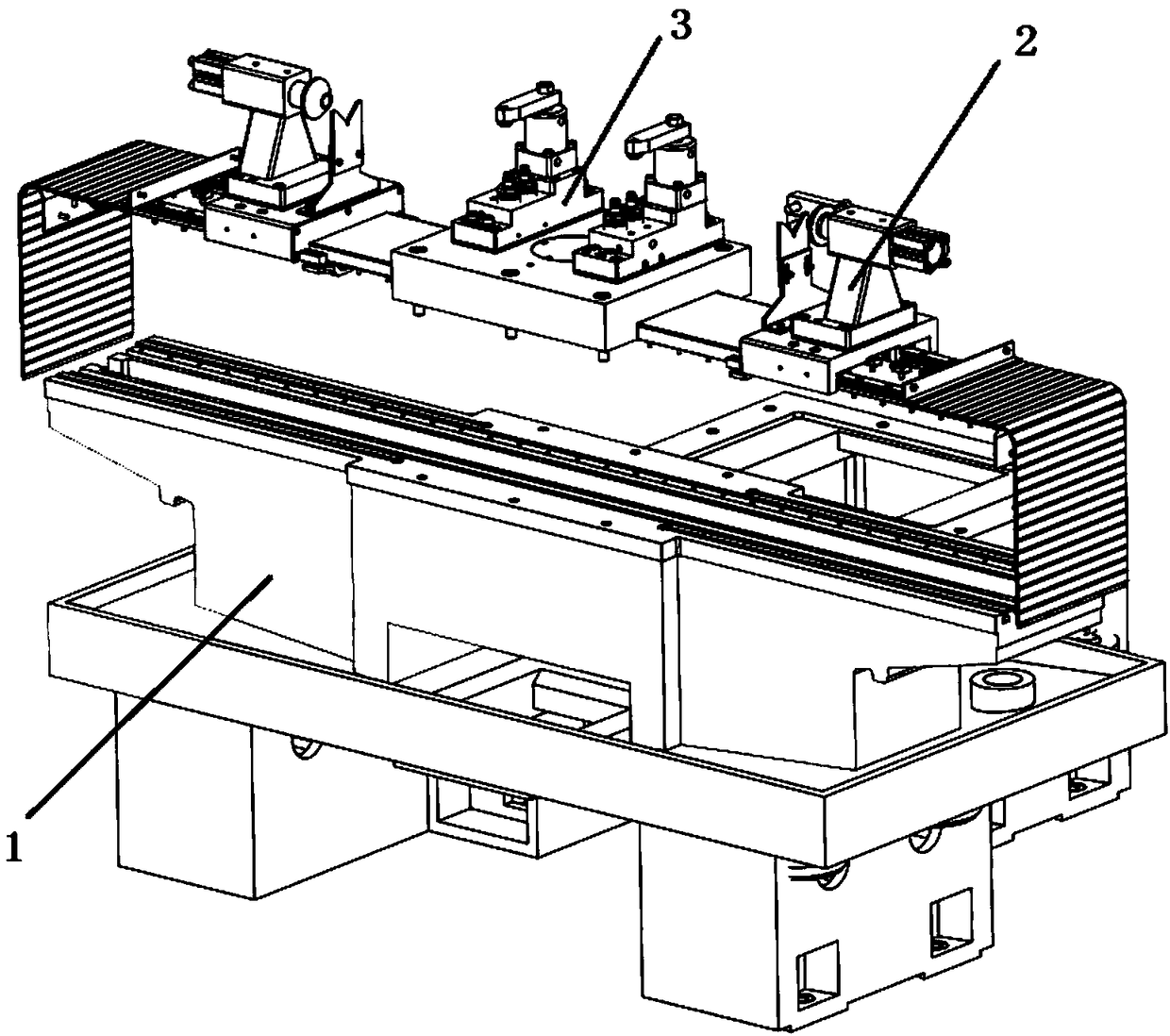

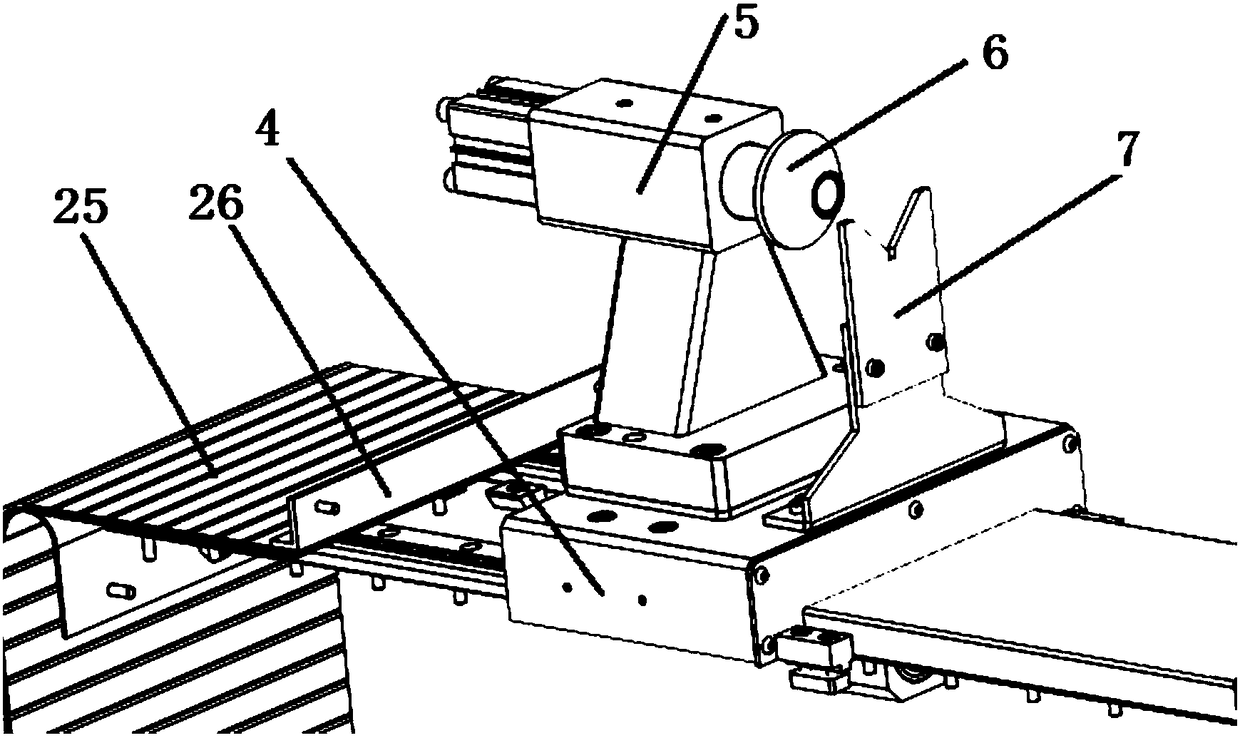

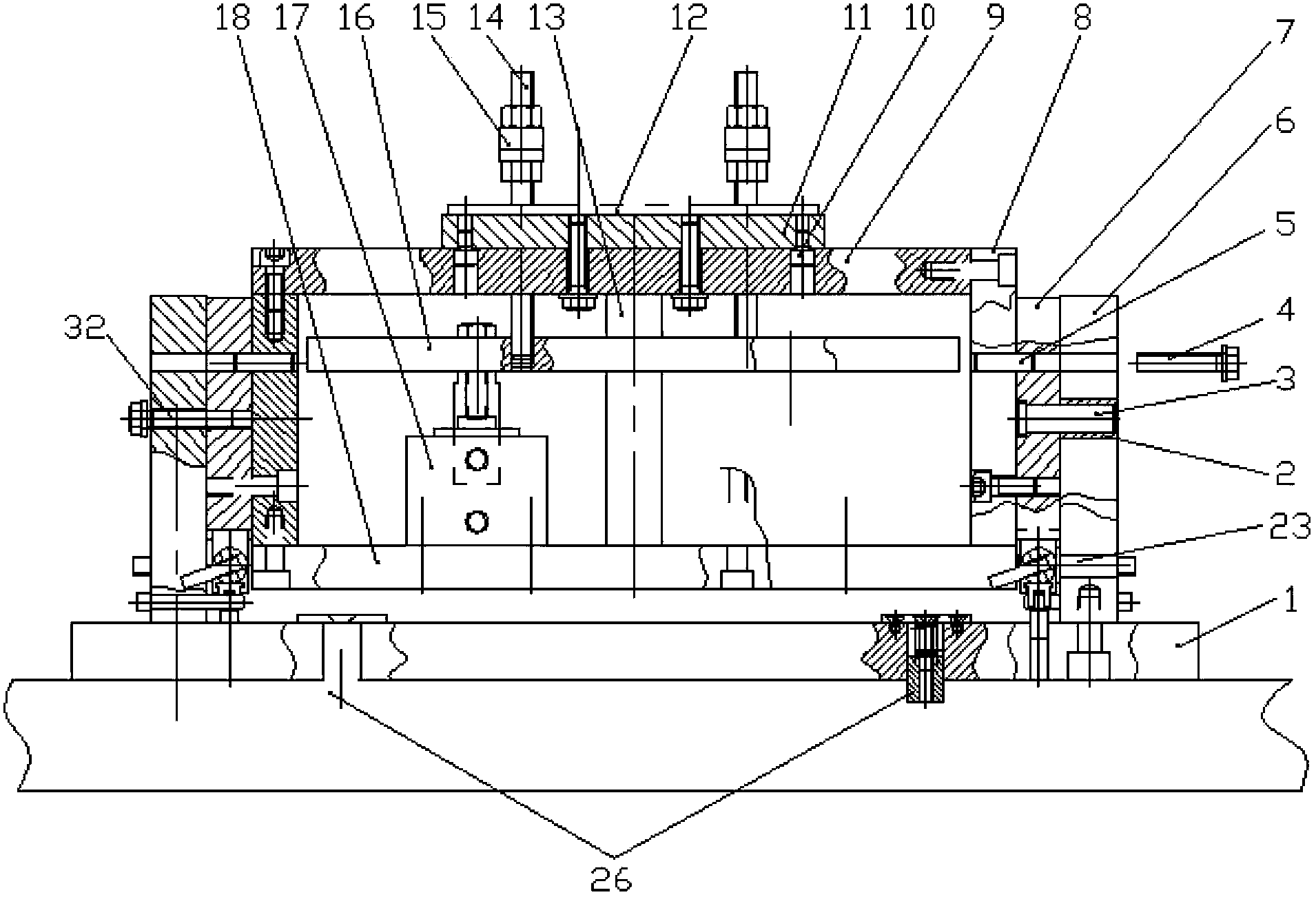

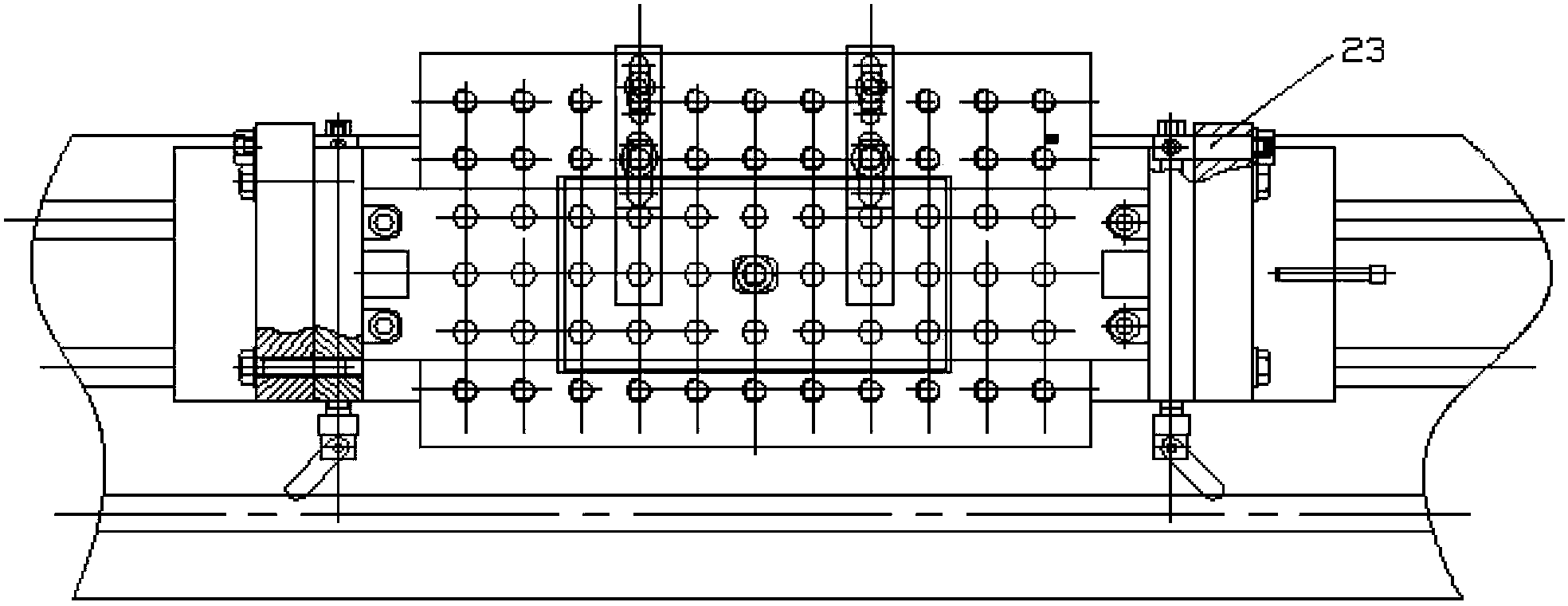

Special equipment for boring-milling machine for machining new-energy automobile rear axle

ActiveCN108296797AAvoid deformationReduce distortionFeeding apparatusLarge fixed membersNumerical controlNew energy

The invention provides special equipment for a boring-milling machine for machining a new-energy automobile rear axle. The special equipment for the boring-milling machine for machining the new-energyautomobile rear axle comprises a lathe bed working table part, a vertical column part and a spindle box part. The vertical column part is arranged on one side of the lathe bed working table part, andthe spindle box part is arranged on the vertical column part and located over the lathe bed working table part. The special equipment for the boring-milling machine for machining the new-energy automobile rear axle is stable in mechanism and easy to operate through the combination of the lathe bed working table part, the vertical column part and the spindle box part, and the universality of machining of a bridge package of the rear axle is great; numerical control is achieved, and the production efficiency is high; accurate machining is ensured by an independently-designed centering levelingmechanism; and it is ensured that a workpiece does not shift during machining by a special hydraulic clamping device and adjustable clamping force, so that inaccurate machining accuracy is avoided, and the problems that machining of the automobile rear axle is limited greatly and the machining precision is not accurate are solved.

Owner:南京嘉玺数控科技有限公司

Rapid-positioning and pneumatic-compressing universal fixture capable of slightly adjusting inclination angle

ActiveCN103143967BImplement standardizationImprove versatilityPositioning apparatusMetal-working holdersBody angleEngineering

Owner:钱汝玉

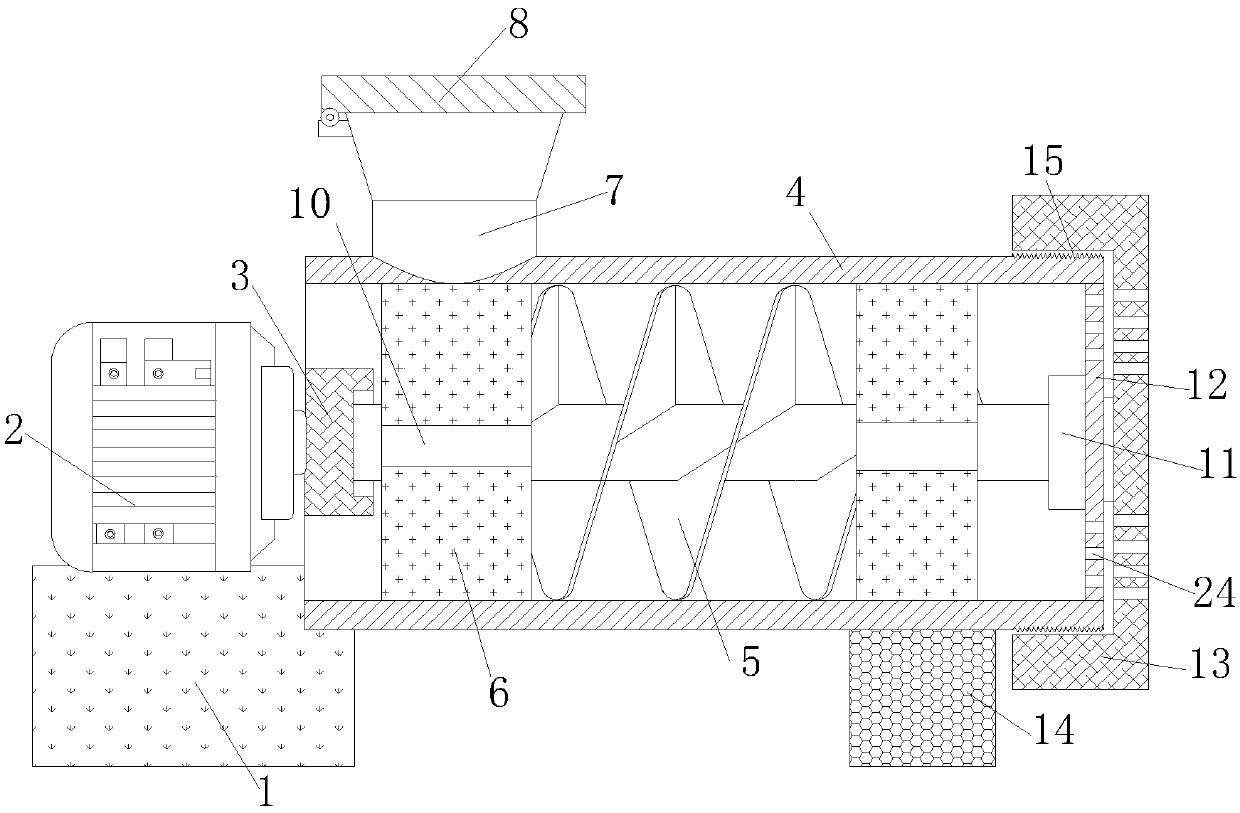

Efficient meat product processing equipment

InactiveCN110710558AEasy to processConducive to subsequent processingSausage filling/stuffing machinesMeat processing devicesBiotechnologyCoupling

The invention discloses efficient meat product processing equipment. The efficient meat product processing equipment comprises a base, a motor is arranged at the top end of the base, a coupling is connected to a rotating head end of the motor, the coupling penetrates through a side wall of a conveying pipe and is coaxially connected with a spiral conveyor arranged in the conveying pipe, a left side of a bottom end of the conveying pipe is fixed to the base, a vertical column is arranged on the right side of the bottom end of the conveying pipe, cutting devices are arranged on the inner walls of the two sides in the conveying pipe correspondingly, each cutting device comprises a sleeve, sliding blocks in inverted-T shapes are arranged on the outer walls of the two sides of each sleeve correspondingly, and every two sliding blocks are matched with a sliding groove formed in the inner wall of the conveying pipe. According to the efficient meat product processing equipment, through the twoarranged cutting devices, meat pieces are subjected to first-time cutting and mincing when falling into the conveying pipe from a feeding pipe, and are chopped again by the cutting devices when conveyed to the other side of the conveying pipe by the spiral conveyor, the meat pieces are chopped more evenly through two times of cutting treatment, and the processing efficiency is improved.

Owner:漳州市好亦鲜食品有限公司

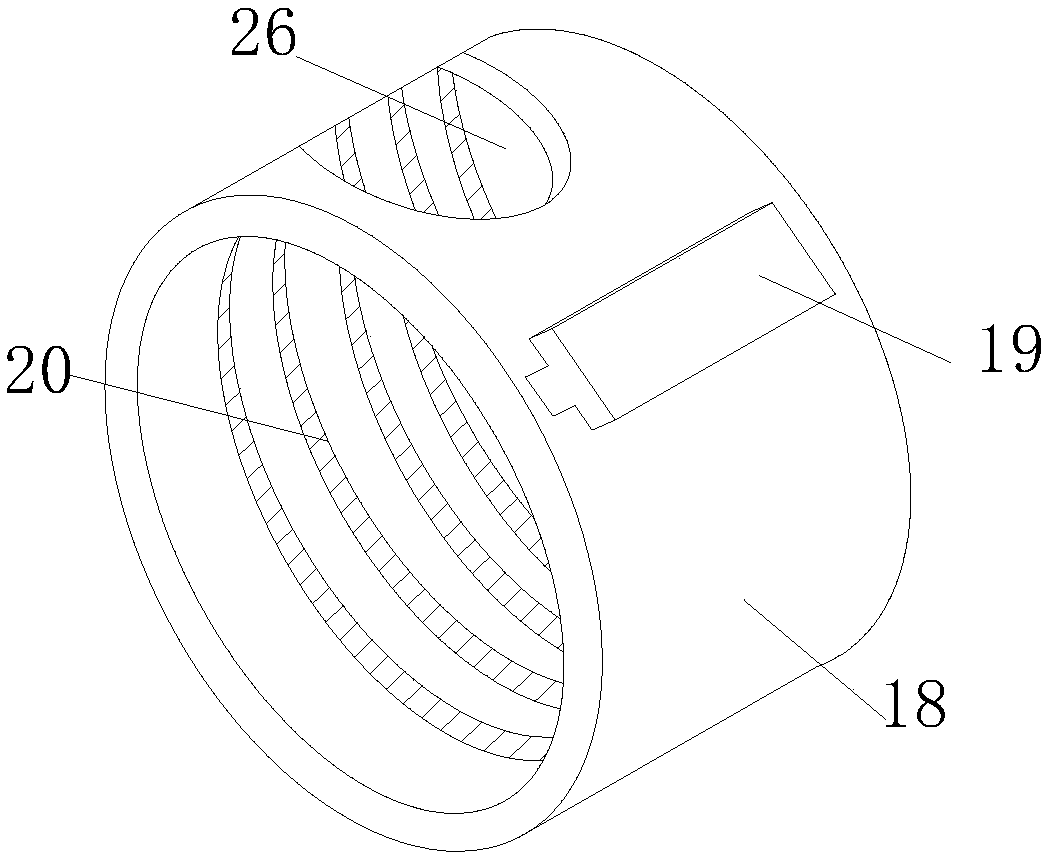

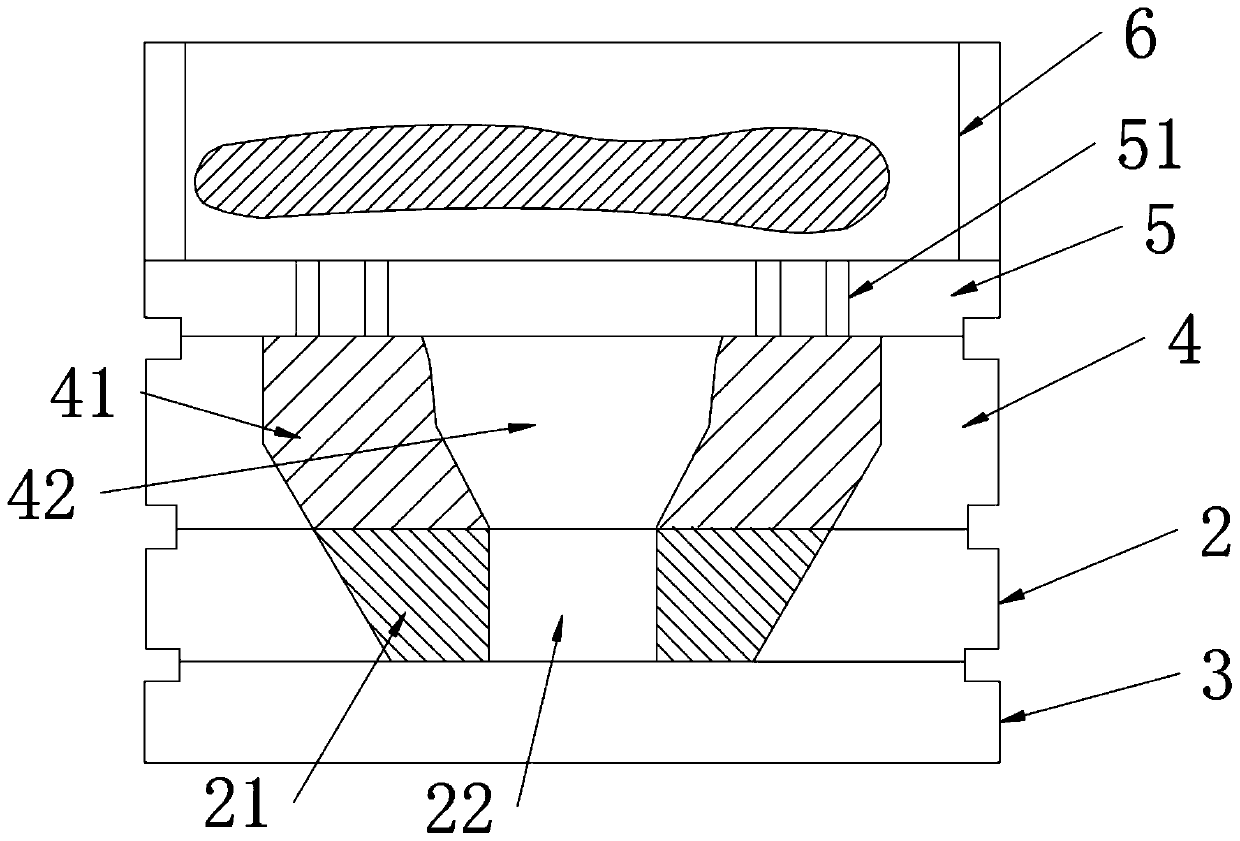

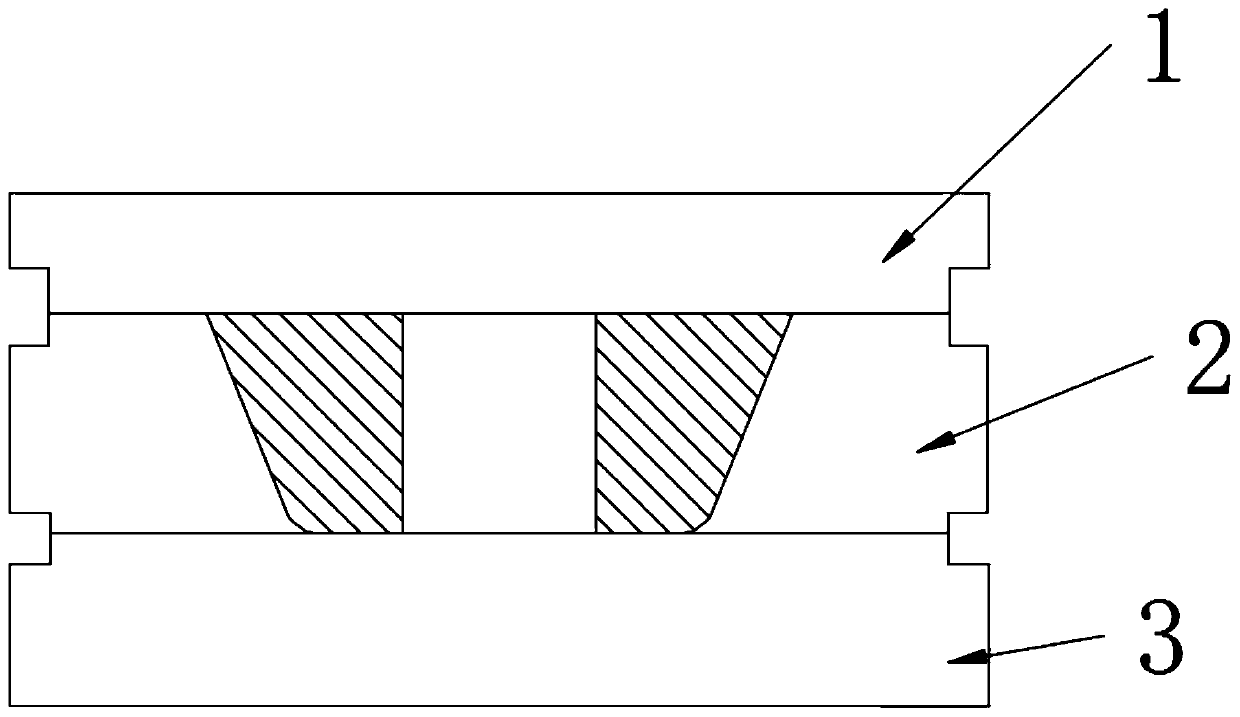

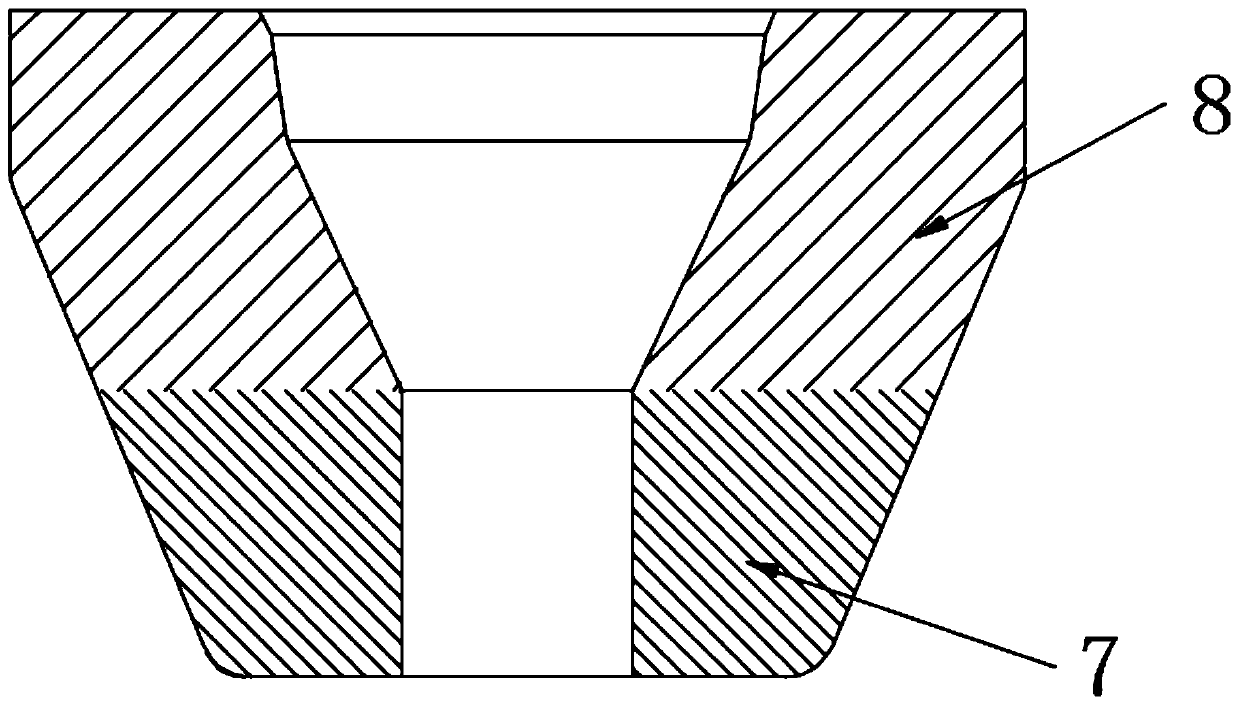

Rotary rubber core rubber formula, production mold and production method thereof

The invention discloses a rotary rubber core rubber formula, a production mold and a manufacturing method thereof, and relates to the technical field of rubber products. The rotary rubber core rubberformula comprises a rubber material A formula for a supporting end and a rubber material B formula for a sealing end. Through the formula, a rubber material B with strong abrasion resistance and a rubber material A with good fluidity can be respectively produced, and are respectively used for manufacturing the supporting end and the sealing end. A mold comprises a sealing end mold and an integralforming mold which are respectively used for manufacturing the sealing end and the supporting end. The rotary rubber core rubber formula ensures the compactness of the product while ensuring the safety. At the same time, the rotary rubber core rubber formula only uses the rubber material with strong abrasion resistance at the sealing end, thus reducing the material cost of the whole rotating rubber core and having higher economic value.

Owner:四川新为橡塑有限公司

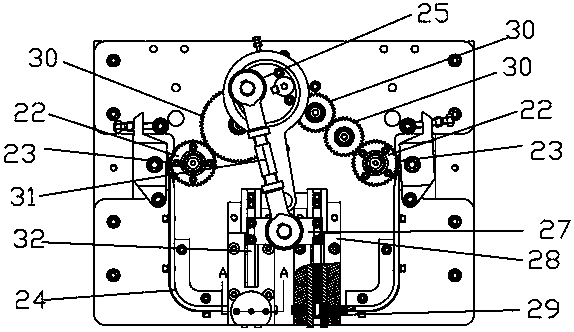

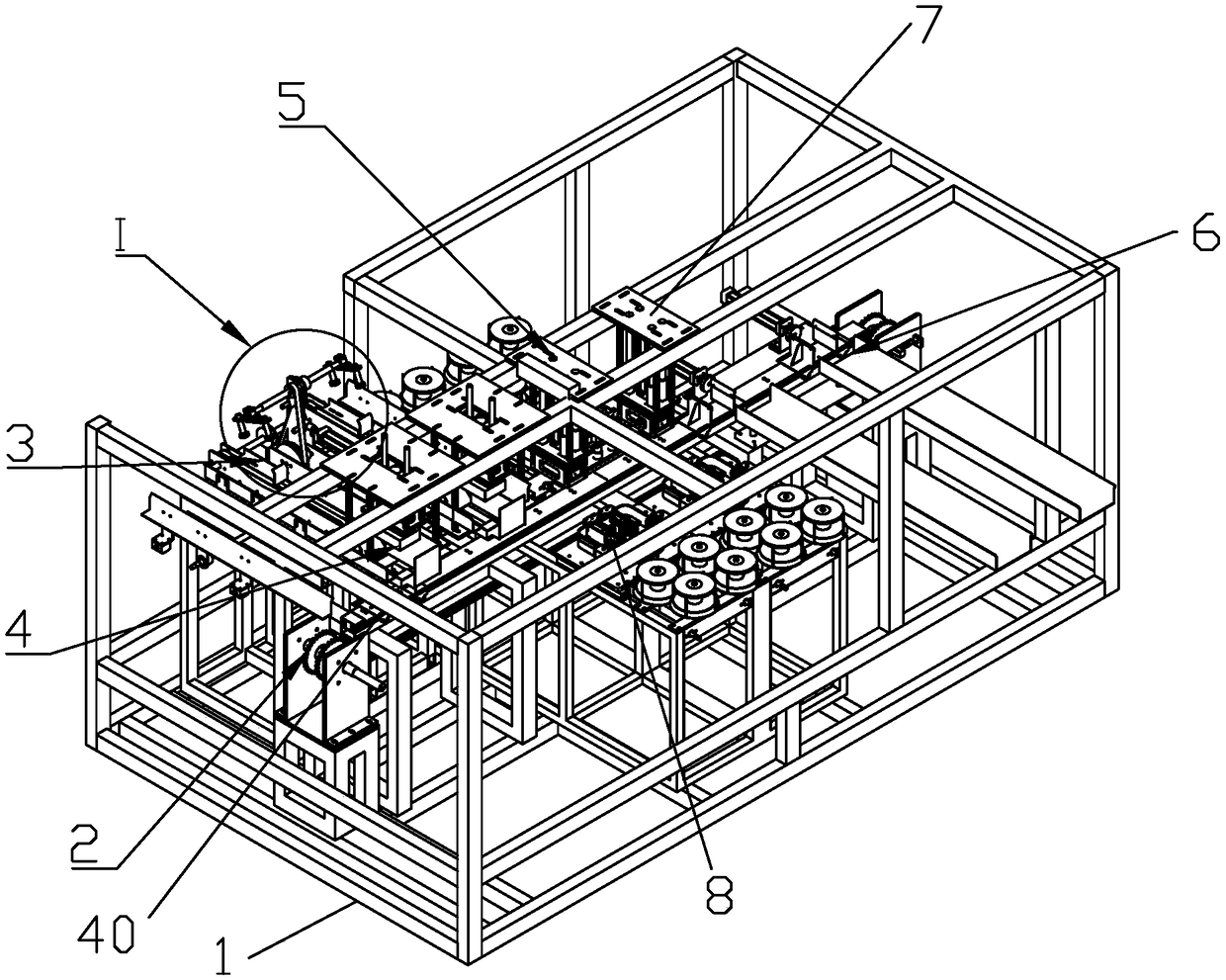

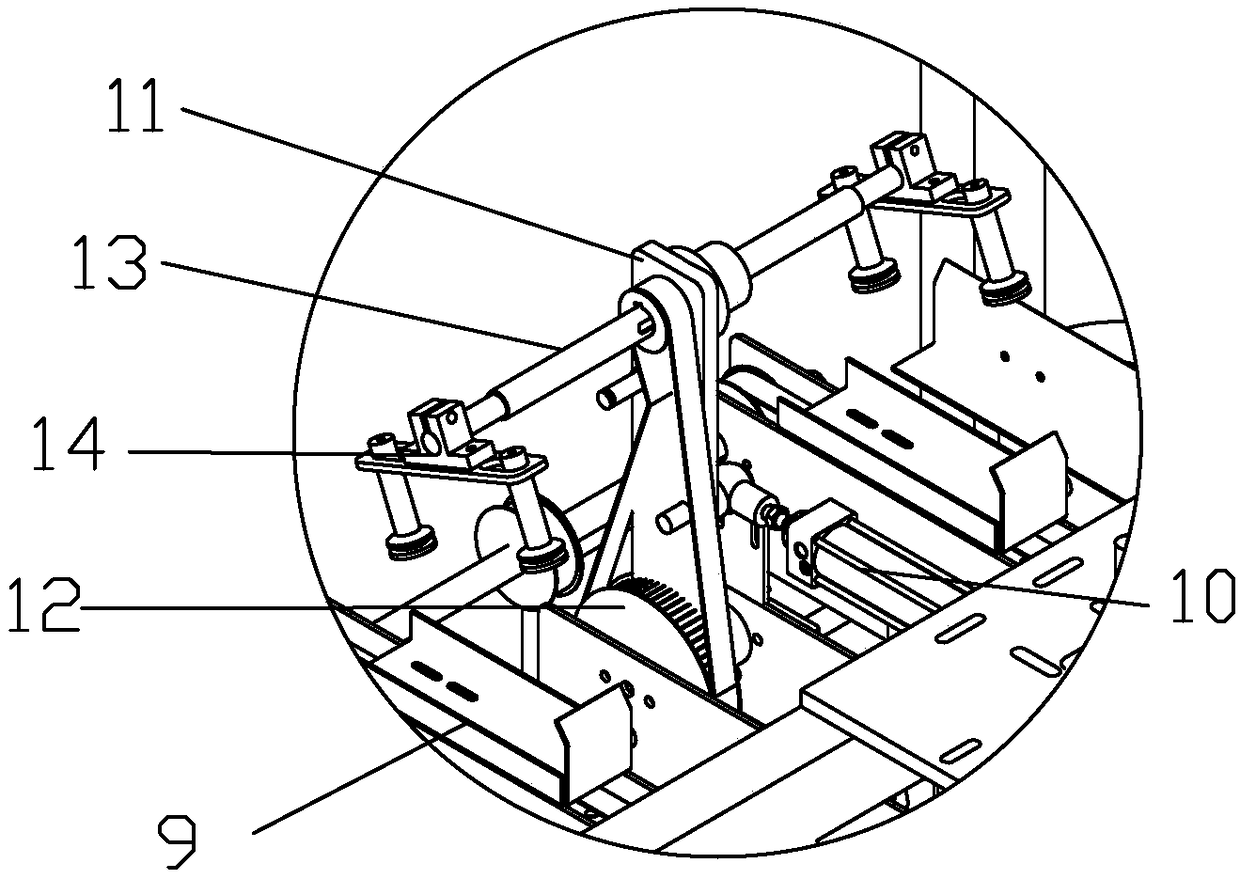

Automatic hat box forming and nailing machine with good and efficient and stable performance

ActiveCN108638576AExcellent performance, high efficiency and stabilityHigh degree of automationBox making operationsPaper-makingCartonAssembly line

The invention discloses an automatic hat box forming and nailing machine with good and efficient and stable performance. The automatic hat box forming and nailing machine comprises a rack, a transmission module, a feed module, a forming module, a nailing module and a discharge module, wherein the transmission module is fixedly installed in the middle of the rack and penetrates through the whole rack in a horizontal direction from left to right, the feed module, the forming module, the nailing module and the discharge module are arranged on the rack in sequence from left to right, the nailing module comprises a nailing internal mold mechanism and a nailing machine head mechanism, and the nailing internal mold mechanism is matched with the nailing machine head mechanism. The machine has theadvantages of the simple structure, scientificity, convenience, high pertinence and high degree of automation, and the full-automatic nailing problem of a hat box is preferably solved. According to the nailing machine, the manufacturing requirement of hat cartons (boxes) on a large scale is effectively solved, the labor cost is reduced, the processing safety is guaranteed, energy consumption is reduced, and the rejection rate of scraps of paper is reduced. In addition, the automatic hat box forming and nailing machine is conveniently matched with an automatic packing assembly line due to highefficiency, and the requirement of the occupation of land for stacking the cartons is effectively reduced.

Owner:杭州尚昌德智能科技有限公司

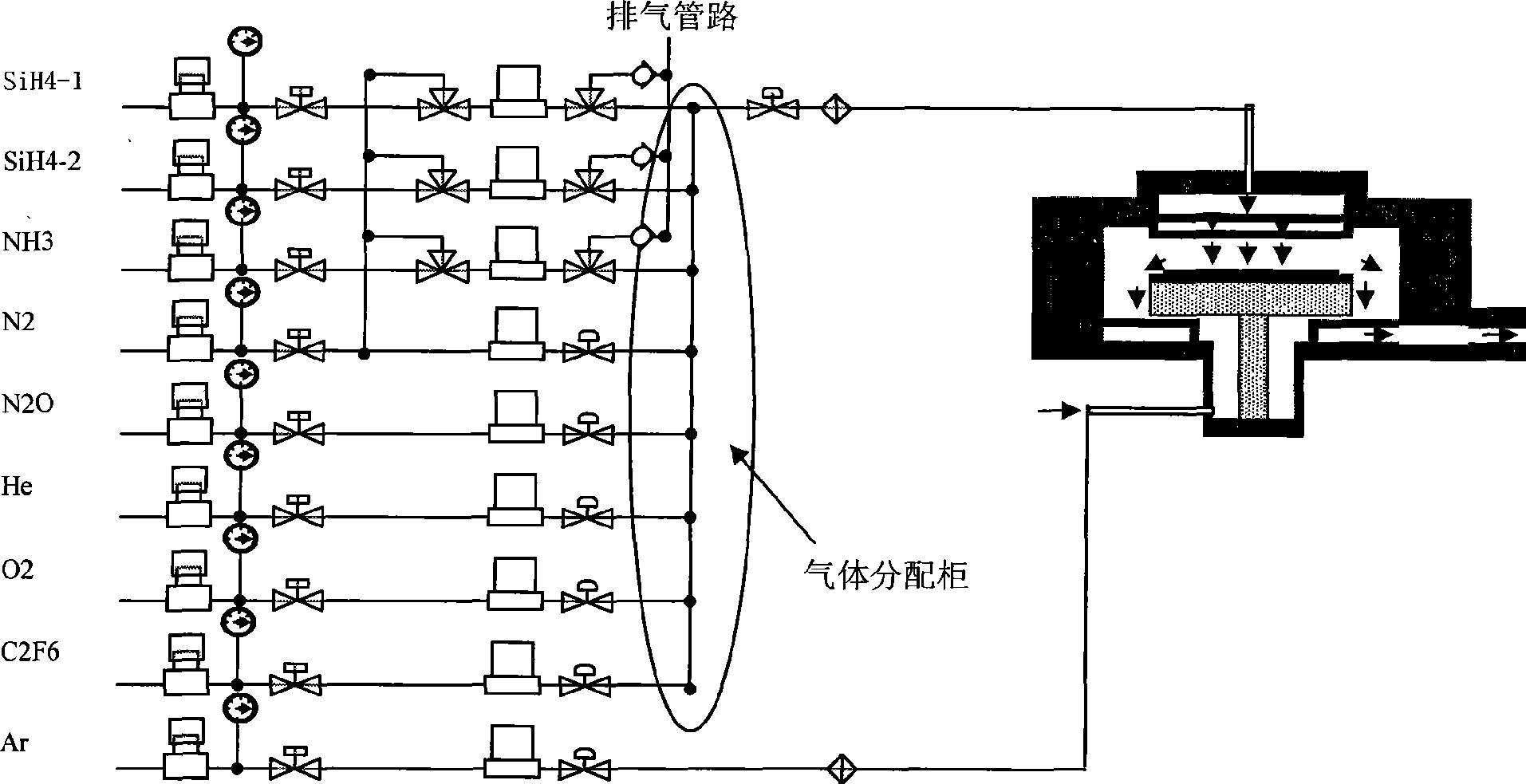

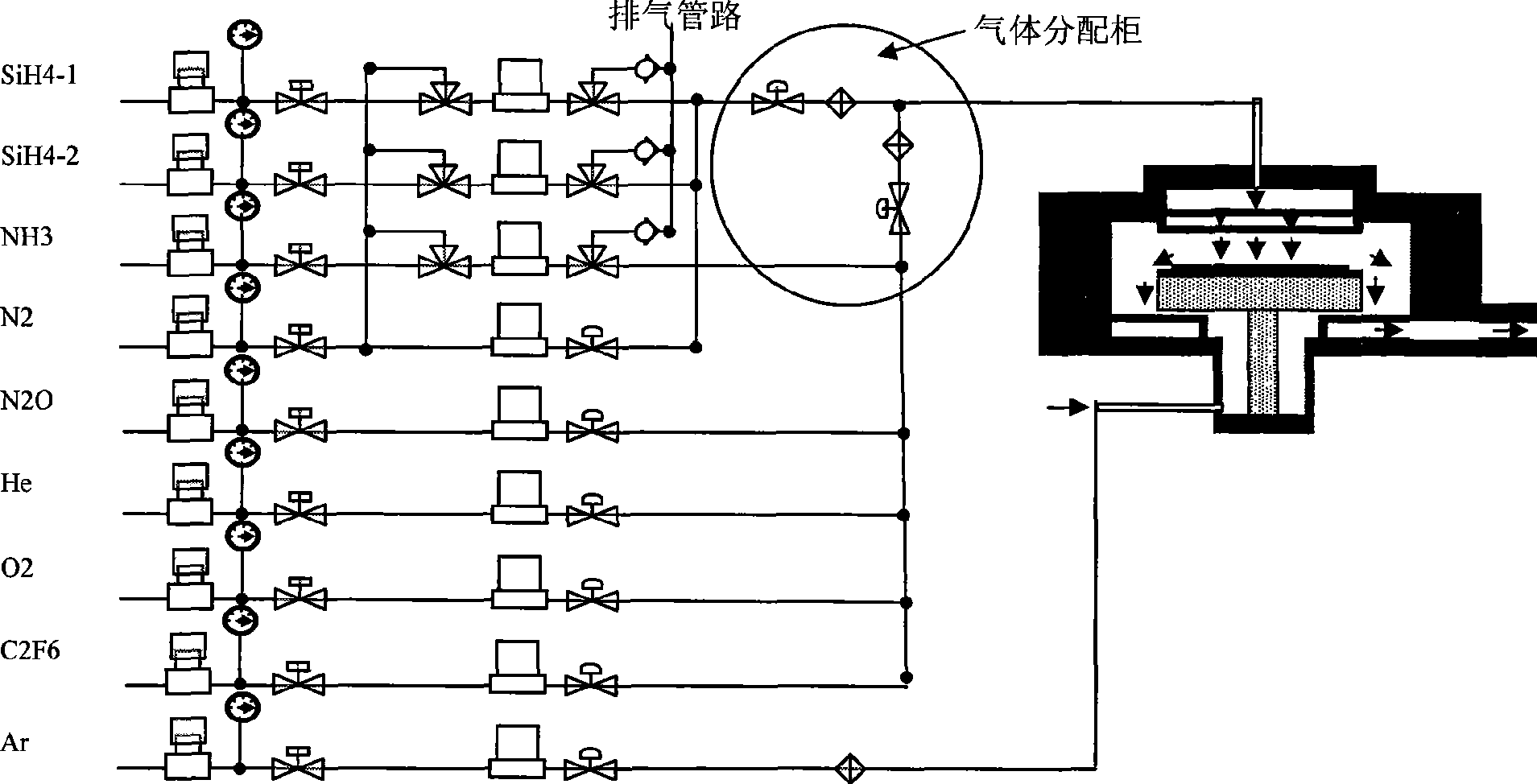

Gas piping structure of PECVD device

InactiveCN101445917AAvoid accumulationEnsure process stabilityChemical vapor deposition coatingParticle packingProduct gas

The invention discloses a gas piping structure of a PECVD device; after being added into a gas distribution cabinet to be mixed, the gases supplied by multipath upper chambers are added to a rear reaction chamber through the same pipeline; the gases supplied by multipath upper chambers are divided into reducing gases and oxidizing gases; and the reducing gases and oxidizing gases are respectively added to the gas distribution cabinet to be mixed by two pipelines. Because the invention adds the strong reducing gases and strong oxidizing gases in different pipelines, the particle packing of pipelines can be effectively avoided, which ensures the safety and stability of techniques.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

Rubber compound high in safety performance of processing and technology thereof

Owner:SAILUN GRP CO LTD

Cover rubber used for low-temperature vulcanized high-performance halogen-free flame-retardant laminated conveyor belt, and preparation method thereof

The invention relates to a low-temperature vulcanized high-performance halogen-free flame-retardant laminated conveyor belt cover rubber, and belongs to the technical field of conveyor belt. According to a preparation method, EVM and EBA mixed rubber is taken as a matrix; a peroxide is taken as a cross-linking agent, and an auxiliary crosslinking agent, a silane coupling agent, a filling reinforcing agent, a fire retardant, and other auxiliary agents are added; and high-performance halogen-free flame-retardant laminated conveyor belt is obtained via low temperature (95-120 DEG C) vulcanization using a plate vulcanizing machine. Effective low temperature vulcanization of the low-temperature vulcanized high-performance halogen-free flame-retardant laminated conveyor belt cover rubber can be realized at a relatively low temperature; vulcanization of the low-temperature vulcanized high-performance halogen-free flame-retardant laminated conveyor belt cover rubber at low temperature conditions is capable of protecting the excellent performance of a cover rubber matrix and adopted skeleton materials, ensuring the safety of conveyor belt technology, and increasing production efficiency. The preparation method is capable of solving a difficult problem that the excellent performance of rubber matrix and the skeleton materials is destroyed by relatively high halogen-free flame-retardant cover rubber vulcanization temperature; rubber vulcanization technology is improved; a method is provided for production of special conveyor belt; and company benefit is increased.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD +1

Automatic clamping device of lathe

PendingCN108581522ASimple structureEasy to usePositioning apparatusMetal-working holdersEngineeringMotor shaft

The invention provides an automatic clamping device of a lathe. The automatic clamping device comprises a control mechanism, a power mechanism, a rotating disc mechanism and a clamping mechanism. A core pipe is connected between the power mechanism and the rotating disc mechanism, the power mechanism comprises a motor and a connection ring connected to the rear of the motor, the front end of a motor shaft of the motor is connected with a front chuck, the rear end of the motor shaft of the motor is connected with a connection rod, the control mechanism comprises an electromagnetic disc, a suction disc and a guide disc, the electromagnetic disc is located between the suction disc and the guide disc, an elastic part is arranged between the electromagnetic disc and the suction disc, an elasticpart is arranged between the electromagnetic disc and the guide disc, the outer surface of the guide disc is provided with an annular groove, the annular groove and the connection ring are mutually matched, and the electromagnetic disc, the suction disc and the guide disc are all arranged in the center of the connection rod. According to the automatic clamping device of the lathe, whether the motor is powered on or off can be controlled through the electromagnetic disc, a user can control work of the clamping mechanism through the motor, and the user can clamp workpieces conveniently.

Owner:胡文正

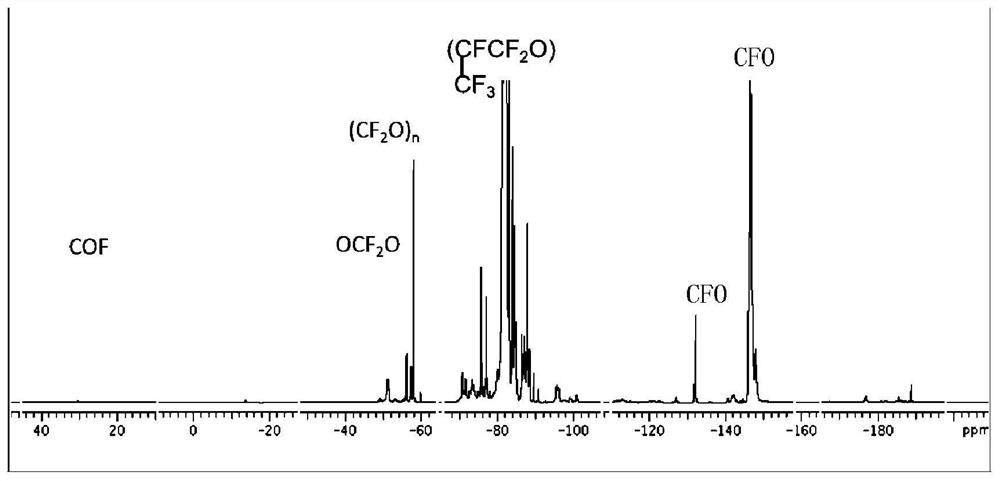

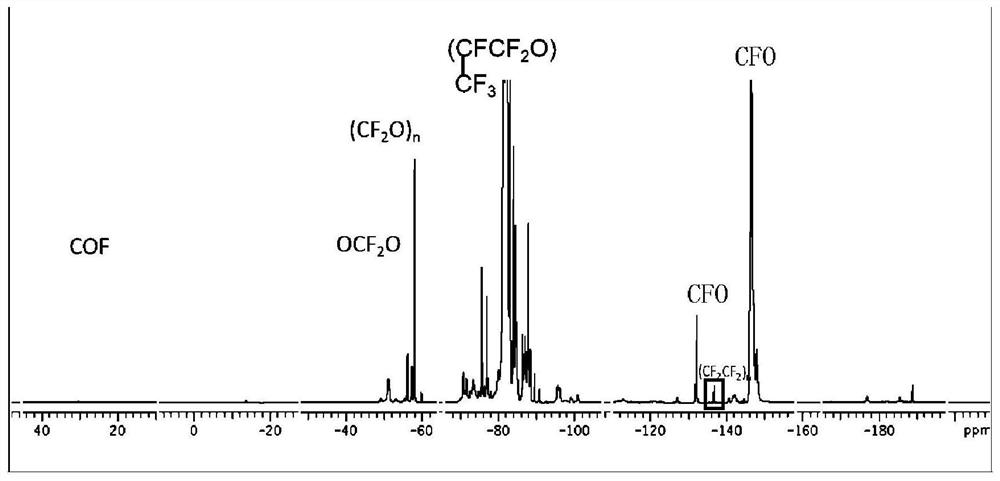

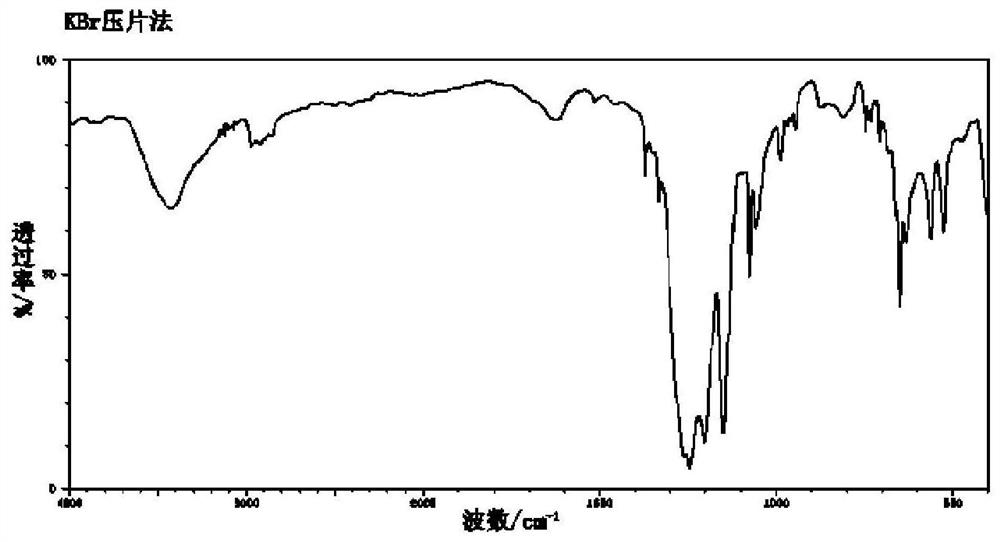

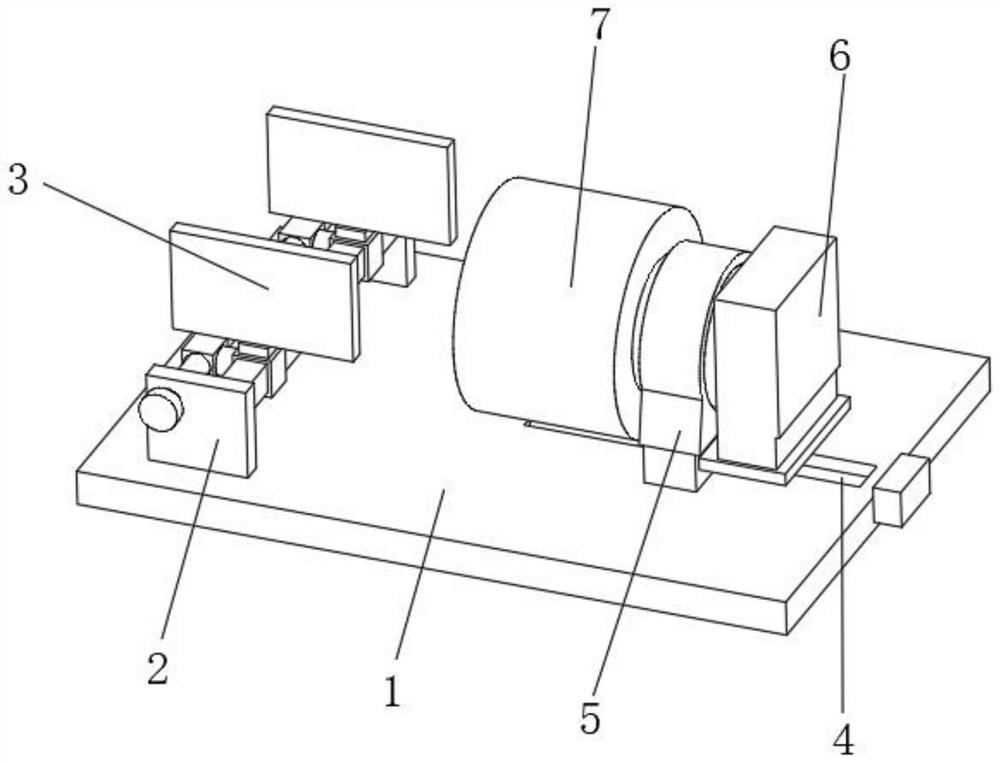

Perfluoropolyether and preparation method thereof

ActiveCN111620972AReduce active oxygen contentReduce lossesChemical/physical/physico-chemical microreactorsPolymer sciencePerfluoropolyether

The invention discloses a perfluoropolyether and a preparation method thereof. The preparation method comprises the following steps: degassing a reaction solution containing a perfluoropolyether intermediate product obtained by oxidative polymerization of fluorine-containing olefin, carrying out polymerization reaction on the degassed reaction solution and a fluorine-containing monomer, and carrying out desolvation on the obtained reaction product to separate a solvent, thereby obtaining a perfluoropolyether product. The method has the advantages of high efficiency, continuity and safety.

Owner:浙江创氟高科新材料有限公司

Irregular-shaped metal part polishing device

PendingCN112548776AEasy to cleanAchieving Sand CleaningGrinding carriagesGrinding drivesPolishingElectric machinery

The invention discloses an irregular-shaped metal part polishing device comprising a supporting carrying platform. A transmission clamp is fixedly connected to the left side of the top of the supporting carrying platform; limiting clamping plates are fixedly connected to the output end of the top of the transmission clamp; a reciprocating walking mechanism is fixedly connected to the middle of theright side of the top of the transmission clamp; a working platform is fixedly connected to the top output end of the reciprocating walking mechanism; a driving motor is fixedly connected to the right side of the working platform; a machining polishing cylinder is fixedly connected to the axis of the left side of the driving motor; polishing adjusting mechanisms are evenly and fixedly connected to the periphery, close to the left side, in the machining polishing cylinder at equal intervals; an inner limiting arc cylinder is fixedly connected to the position, close to the left side, in the machining polishing cylinder; and cleaning adsorption mechanisms are evenly and fixedly connected to the periphery, close to the right side, in the machining polishing cylinder. The irregular-shaped metal part polishing device relates to the technical field of metal part machining. According to the irregular-shaped metal part polishing device, it is guaranteed that impurities after polishing are notdischarged to the outer environment, and centralized cleaning by workers is facilitated.

Owner:段江波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com