Numerical control machine processability monitoring system

A technology of processing performance and monitoring system, applied in general control system, control/regulation system, program control, etc., can solve the problems of high application technical requirements and cost, complicated control parameter setting, complex structure of adaptive control system, etc. Achieve the effect of reducing management and maintenance costs, ensuring processing safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

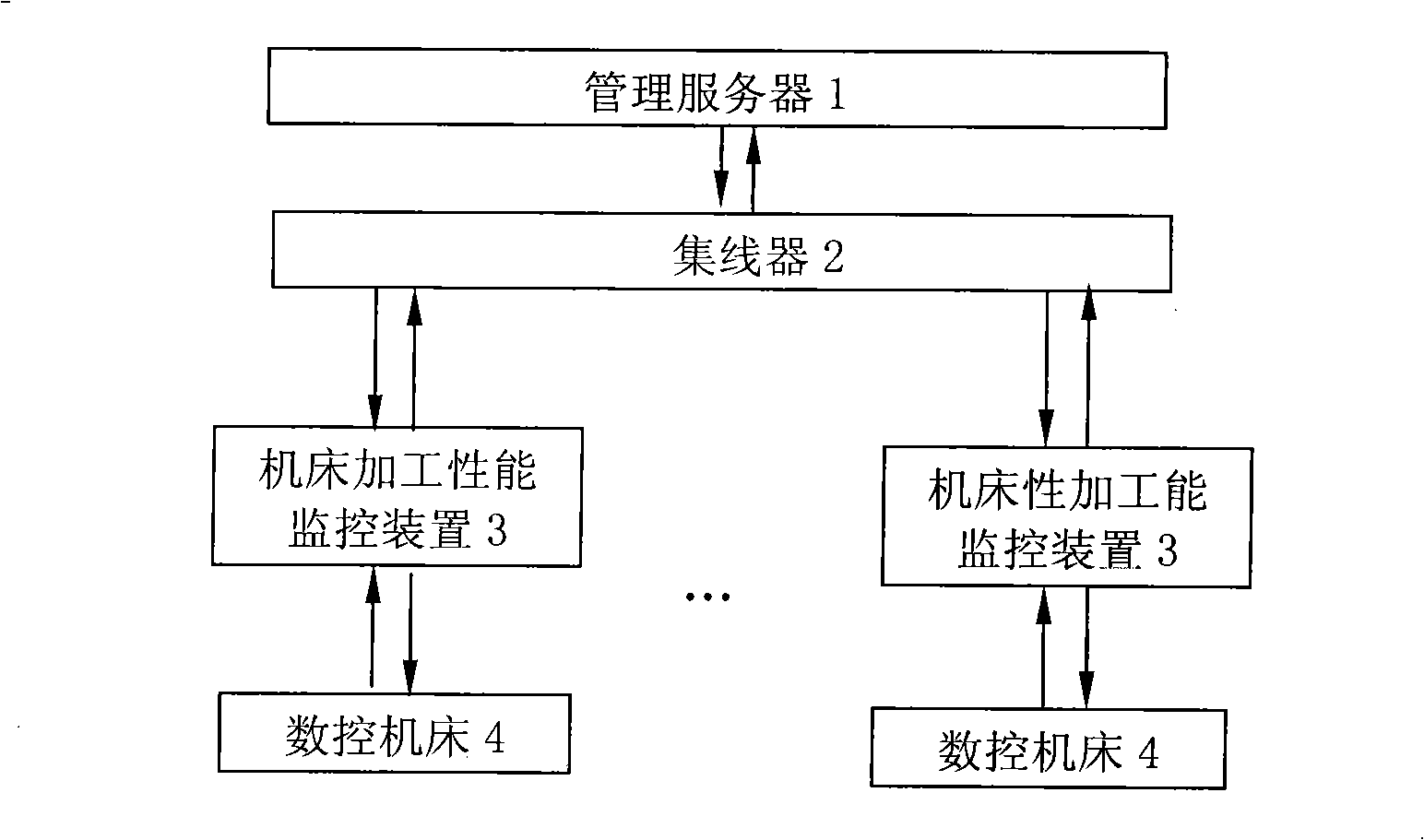

[0017] The system structure of the present invention is as figure 1 shown. The whole system includes four parts: a plurality of monitoring devices 3 , a hub 2 and a management server 1 , and a plurality of monitoring devices 3 are connected to the management server 1 through the hub 2 .

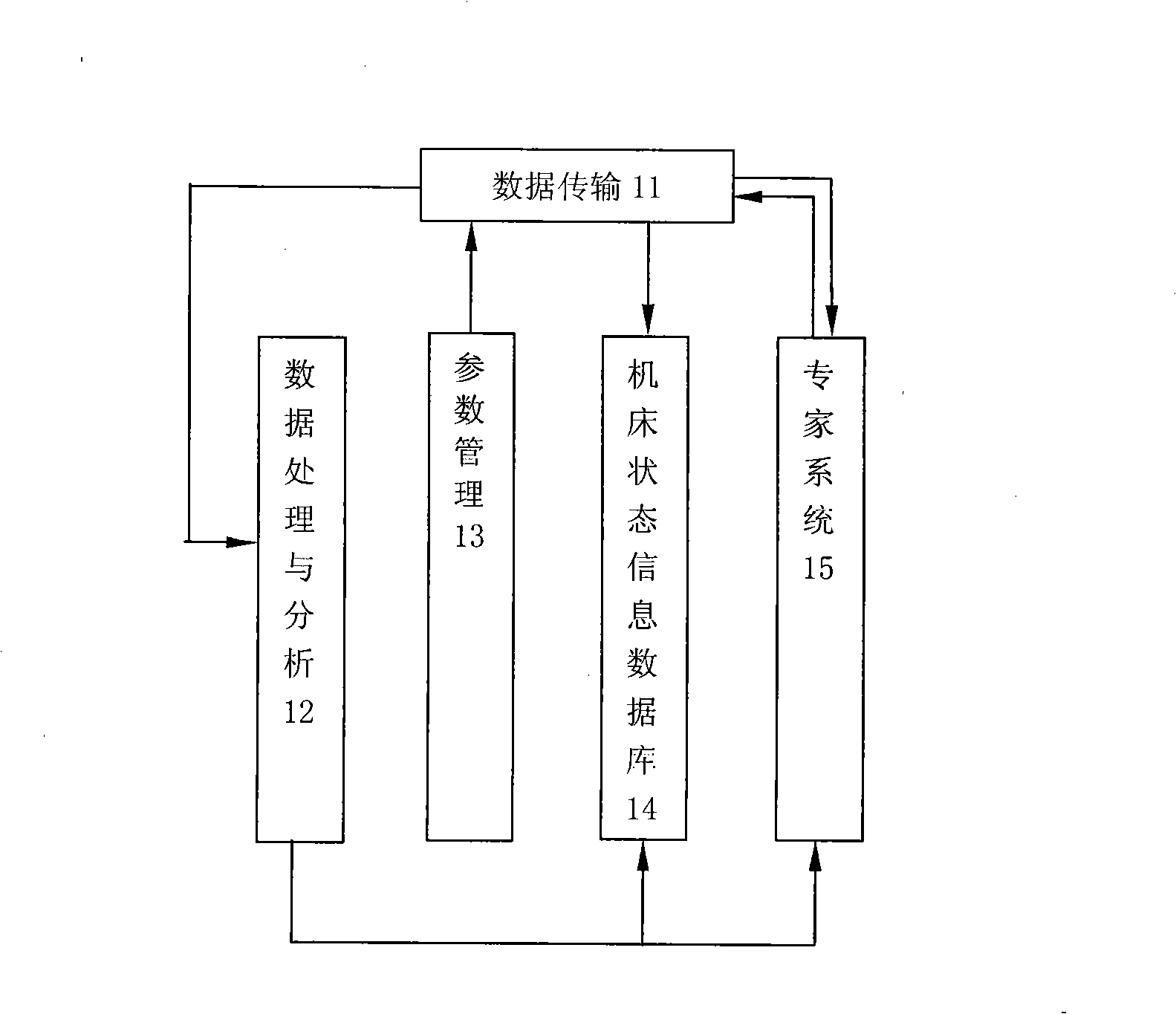

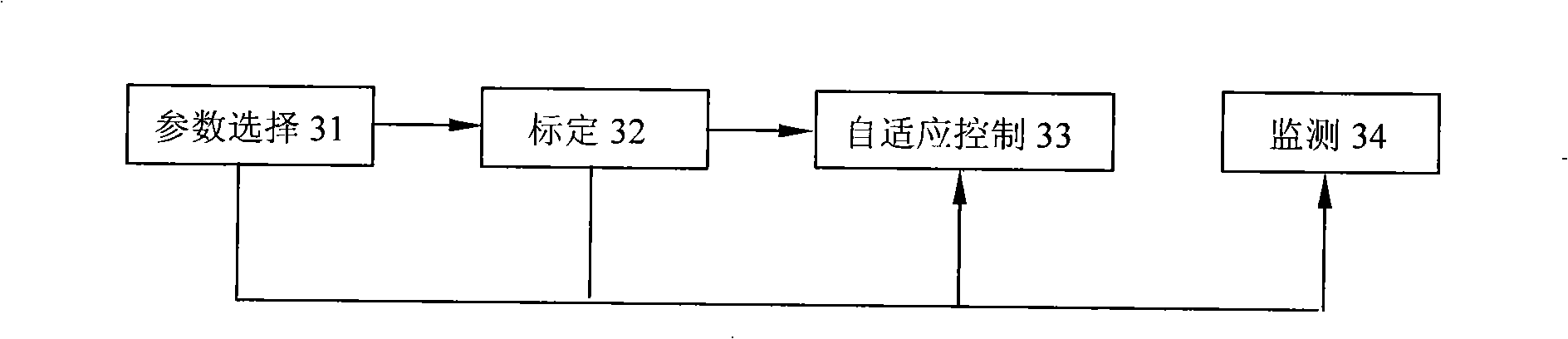

[0018] The monitoring device 3 is installed on the CNC machine tool 4, collects data such as current and vibration in real time, predicts and judges in real time whether the cutting force exceeds the safe range, whether the cutter tooth is damaged or collides and other crisis situations occur, and takes corresponding measures to ensure that the machine tool, cutting tool, etc. and workpiece safety. At the same time, the device can also communicate with the CNC machine tool 4, receive status information from the CNC machine tool 4 itself, and transmit the information, collected data and processing results of the device to the management server 1 in time. The management server 1 processes and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com