Machine tool hydraulic pressure station

A hydraulic station and machine tool technology, which is applied in the direction of mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve problems such as aging of hydraulic station parts and pipelines, reduction of hydraulic oil quality, and unstable hydraulic pressure. Achieve the effects of reducing workpiece deformation, reducing consumption, and stabilizing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

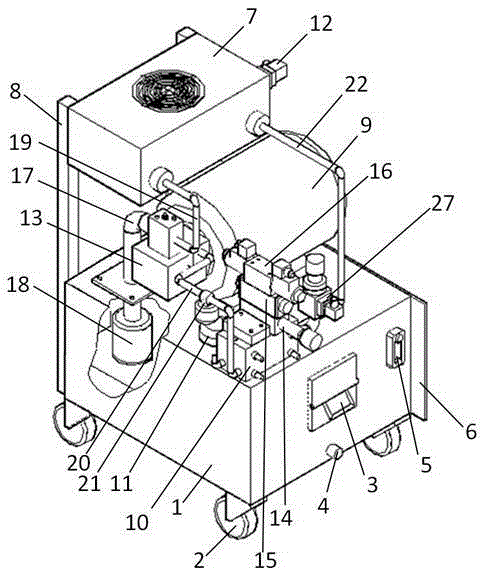

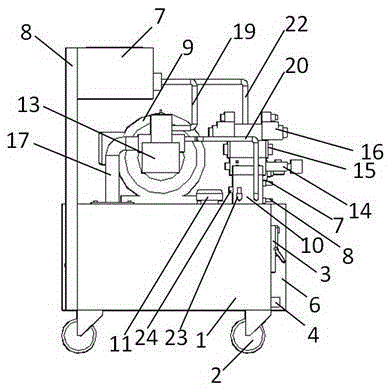

[0029] The machine tool hydraulic station of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

[0030] Such as figure 1 , 2 As shown, a machine tool hydraulic station includes a fuel tank 1 and a radiator 7. A three-phase asynchronous motor 9 and a valve block 10 are installed on the upper surface of the fuel tank 1, and the valve block 10 communicates with the fuel tank 1; the three-phase asynchronous motor 9- A variable displacement pump 13 is installed on the side wall, a pressure reducing valve 14 and a pressure relay 27 are installed above the valve block 10, and a pressure maintaining valve 15 and a solenoid valve 16 are installed on the top of the pressure reducing valve 14 from bottom to top; The pipe 17 communicates with the oil suction port filter 18 arranged inside the oil tank 1, and the other end communicates with the radiator 7 and the valve block 10 through the radiator oil inlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com