Gas piping structure of PECVD device

A gas pipeline and gas technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems affecting the process, etc., to prevent the accumulation of particles in the pipeline, and ensure the stability and safety of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

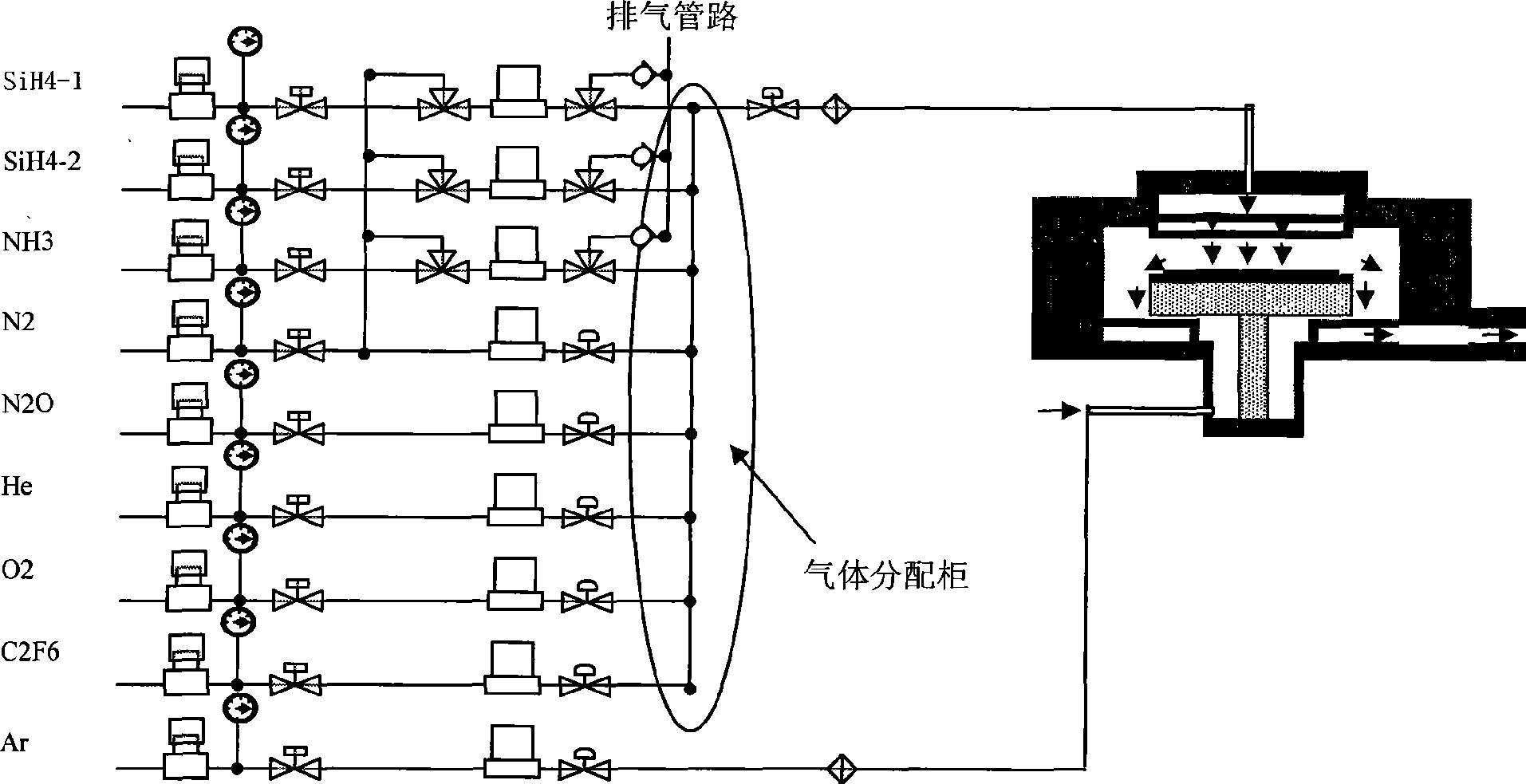

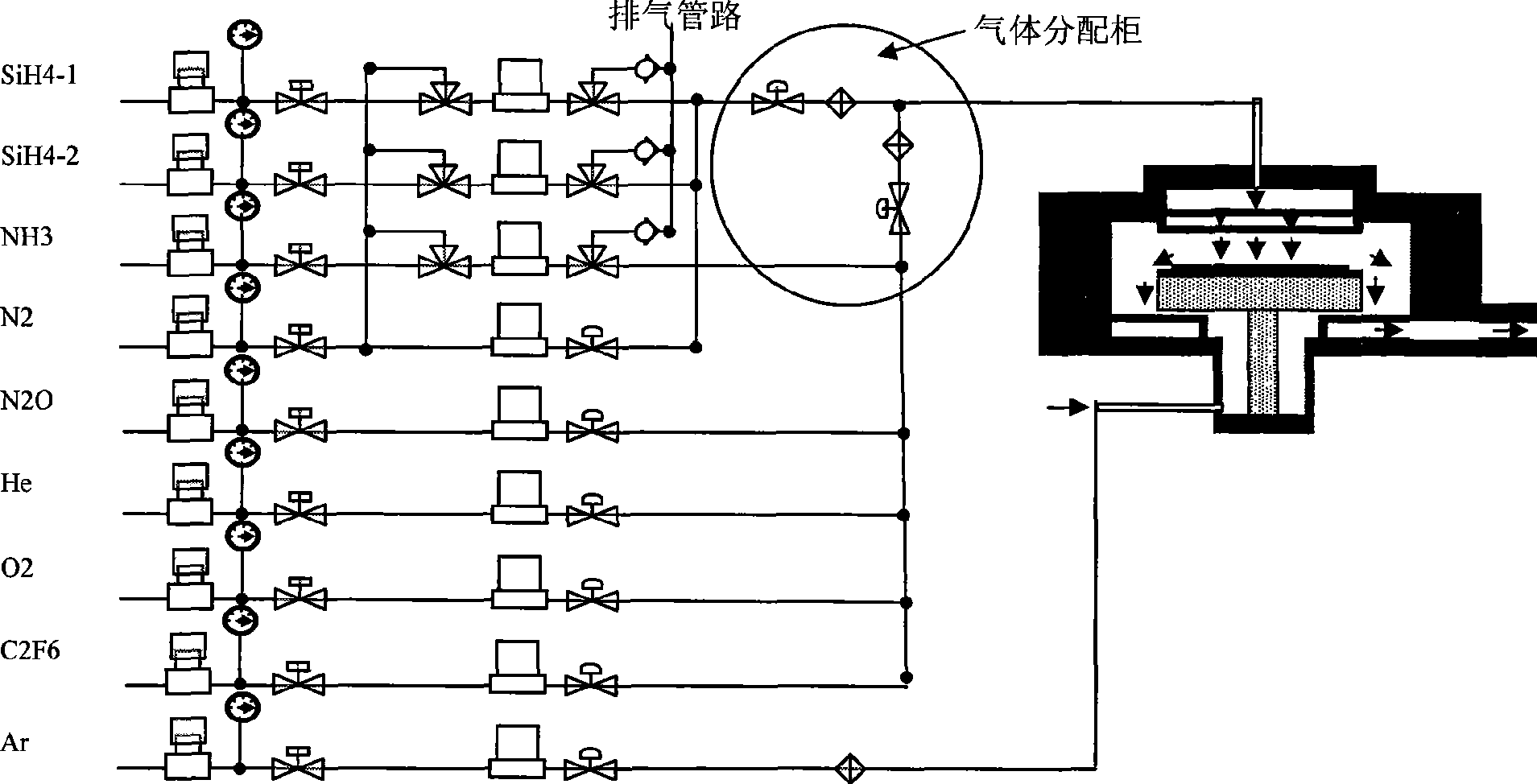

[0009] Such as figure 2 Shown is the gas pipeline structure of the PECVD device of the present invention. In the present invention, all the gas supplied by the upper cavity in the gas pipeline of the existing PECVD device is mixed in the gas distribution cabinet into two-way gas according to the nature of the gas. Access to the mixing structure inside the gas distribution cabinet.

[0010] In the gas pipeline structure of the PECVD device of the present invention, the gas supplied by multiple chambers is fed into the gas distribution cabinet for mixing, and then passed into the rear reaction chamber through the same pipeline; wherein the gas supplied by multiple chambers is divided into reducing gas There are two parts of reducing gas and oxidizing gas, and the reducing gas and oxidizing gas are respectively passed into the gas distribution cabinet through two pipelines for mixing. Reducing gases include: SiH 4 and N 2 , oxidizing gases include: NH 3 , N 2 O, C 2 f 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com