Rubber compound high in safety performance of processing and technology thereof

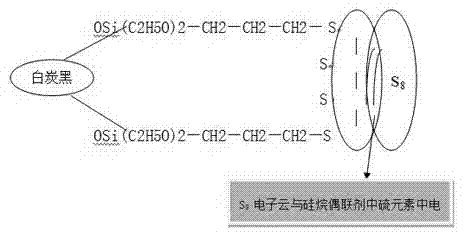

A technology of safety performance and rubber mixing, applied in the field of rubber mixing, can solve the problems of reduced chemical activity, accelerated vulcanization rate, adverse effects on the quality of semi-finished products, etc., and achieves the effect of prolonging scorch time, ensuring safety performance, and changing the feeding sequence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

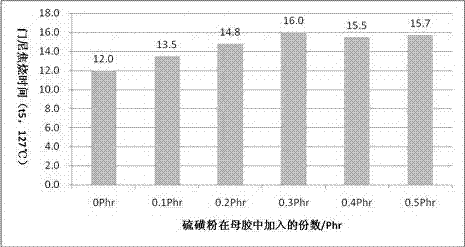

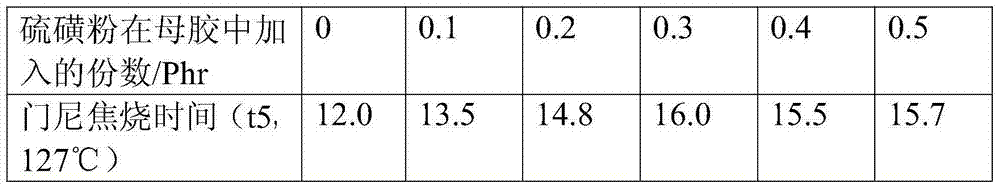

[0024] A kind of mixed rubber with high processing safety performance is composed as follows according to parts by weight:

[0025] Masterbatch ingredients: 80 parts of raw rubber, 50 parts of white carbon black, 5 parts of carbon black, 8 parts of silane coupling agent, 3 parts of resin, 5 parts of zinc oxide, 0.5 part of stearic acid, 0.1 part of sulfur, other components : 9 servings

[0026] Final mixing ingredients: masterbatch, 0.5 parts of sulfur, 0.5 parts of accelerator.

[0027] Among them, other components are anti-aging agent, white carbon black dispersant, process oil; accelerator is accelerator CZ / CBS and accelerator DPG.

[0028] A rubber mixing process with high processing safety performance comprises the following steps:

[0029] (1) One-stage mixing: add 80 parts of raw rubber to the F305 internal mixer, mix and press the top bolt for 30 seconds, lift the weight, add 50 parts of white carbon black, 8 parts of silane coupling agent, press the top bolt for 50 ...

Embodiment 2

[0034] A kind of mixed rubber with high processing safety performance is composed as follows according to parts by weight:

[0035] Masterbatch ingredients: 100 parts of raw rubber, 70 parts of white carbon black, 10 parts of carbon black, 12 parts of silane coupling agent, 5 parts of resin, 8 parts of zinc oxide, 2.5 parts of stearic acid, 0.5 parts of sulfur, other components : 11 servings

[0036] Final mixing ingredients: masterbatch, 0.5-2.5 parts of sulfur, 0.5-1.8 parts of accelerator.

[0037] Among them, other components are anti-aging agent, white carbon black dispersant, process oil; accelerator is accelerator CZ / CBS and accelerator DPG.

[0038] A rubber mixing process with high processing safety performance comprises the following steps:

[0039] (1) One-stage mixing: add 100 parts of raw rubber to the F305 internal mixer, mix and press the top bolt for 30 seconds, lift the weight, add 70 parts of white carbon black, 12 parts of silane coupling agent, press the ...

Embodiment 3

[0044] A kind of mixed rubber with high processing safety performance is composed as follows according to parts by weight:

[0045] Masterbatch ingredients: 100 parts of raw rubber, 60 parts of white carbon black, 7 parts of carbon black, 10 parts of silane coupling agent, 4 parts of resin, 5 parts of zinc oxide, 2 parts of stearic acid, 0.3 parts of sulfur, other components : 10 servings

[0046] Final mixing ingredients: masterbatch, 2 parts of sulfur, 1.5 parts of accelerator.

[0047]Among them, other components are anti-aging agent, white carbon black dispersant, process oil; accelerator is accelerator CZ / CBS and accelerator DPG.

[0048] A rubber mixing process with high processing safety performance comprises the following steps:

[0049] (1) One-stage mixing: Add 100 parts of raw rubber to the F305 internal mixer, mix and press the top bolt for 30 seconds, lift the weight, add 60 parts of white carbon black, 10 parts of silane coupling agent, press the top bolt for 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com