Ice-surface oil-resistant non-slip shoe material and preparation method thereof

An oil-resistant and anti-slip technology, which is applied in the field of oil-resistant and anti-slip shoe materials on ice surfaces and its preparation field, can solve problems such as poor mechanical properties, and achieve the effects of low rolling resistance, good oil resistance and anti-slip performance, and low ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

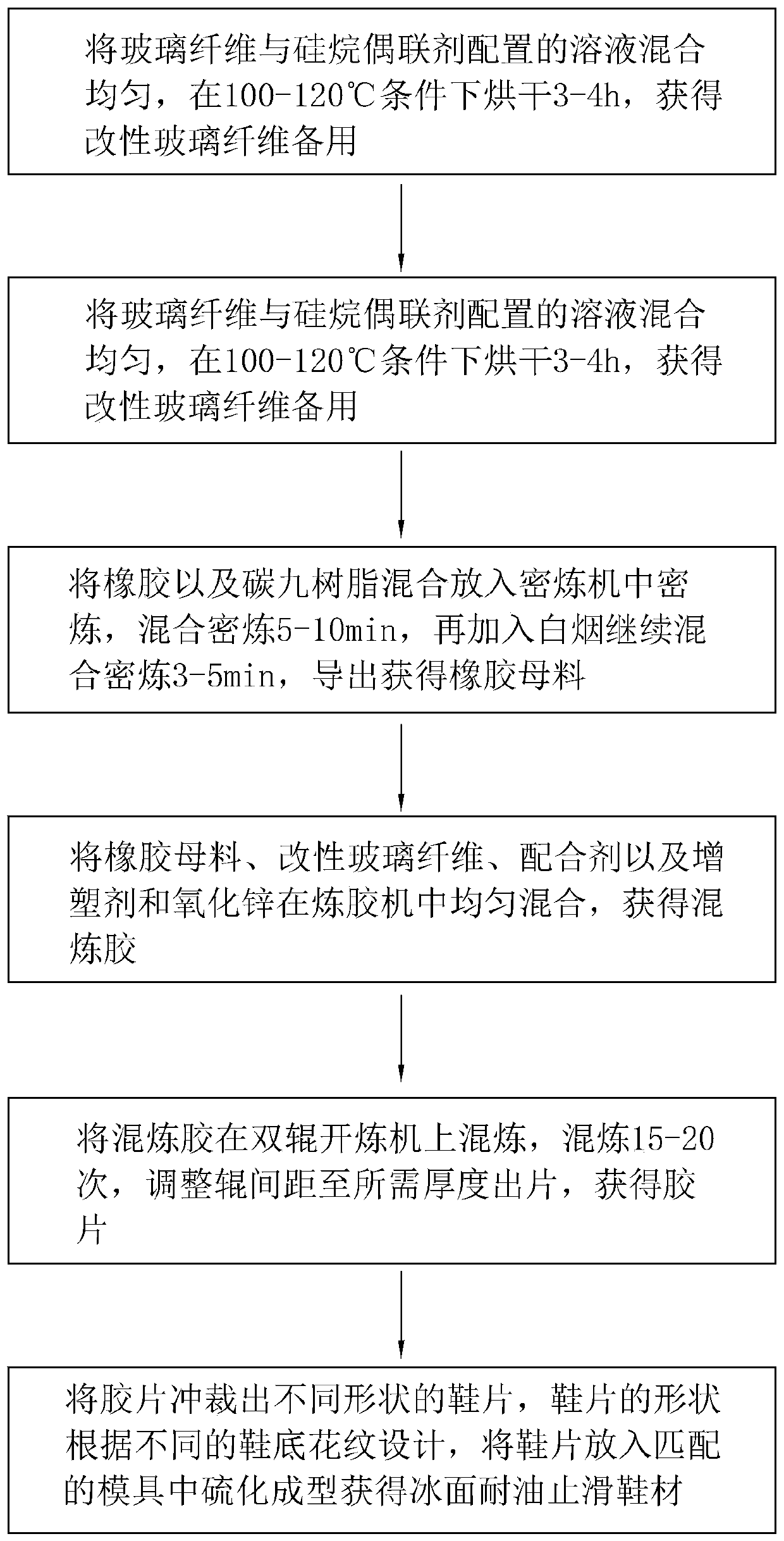

Method used

Image

Examples

Embodiment 1

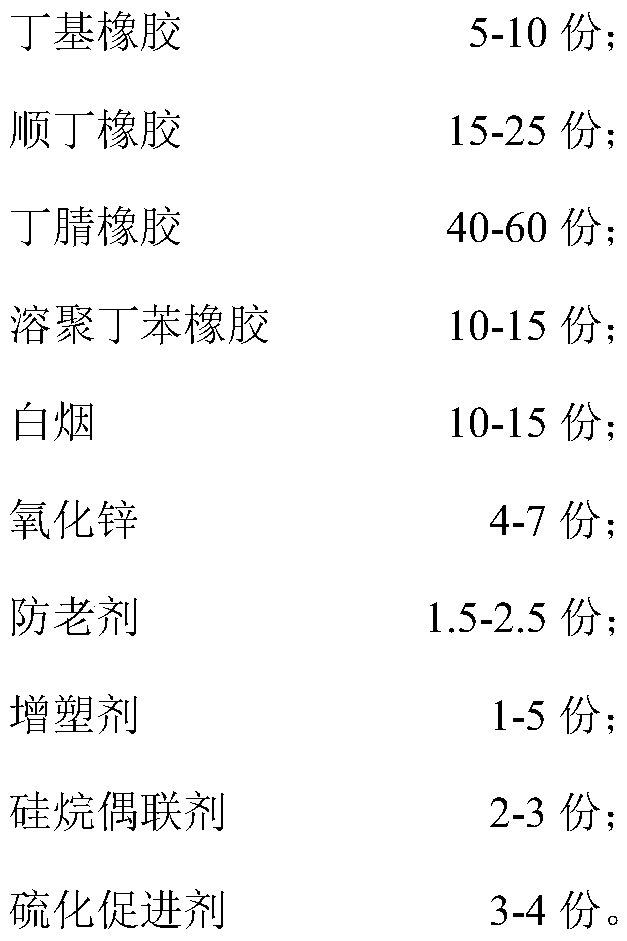

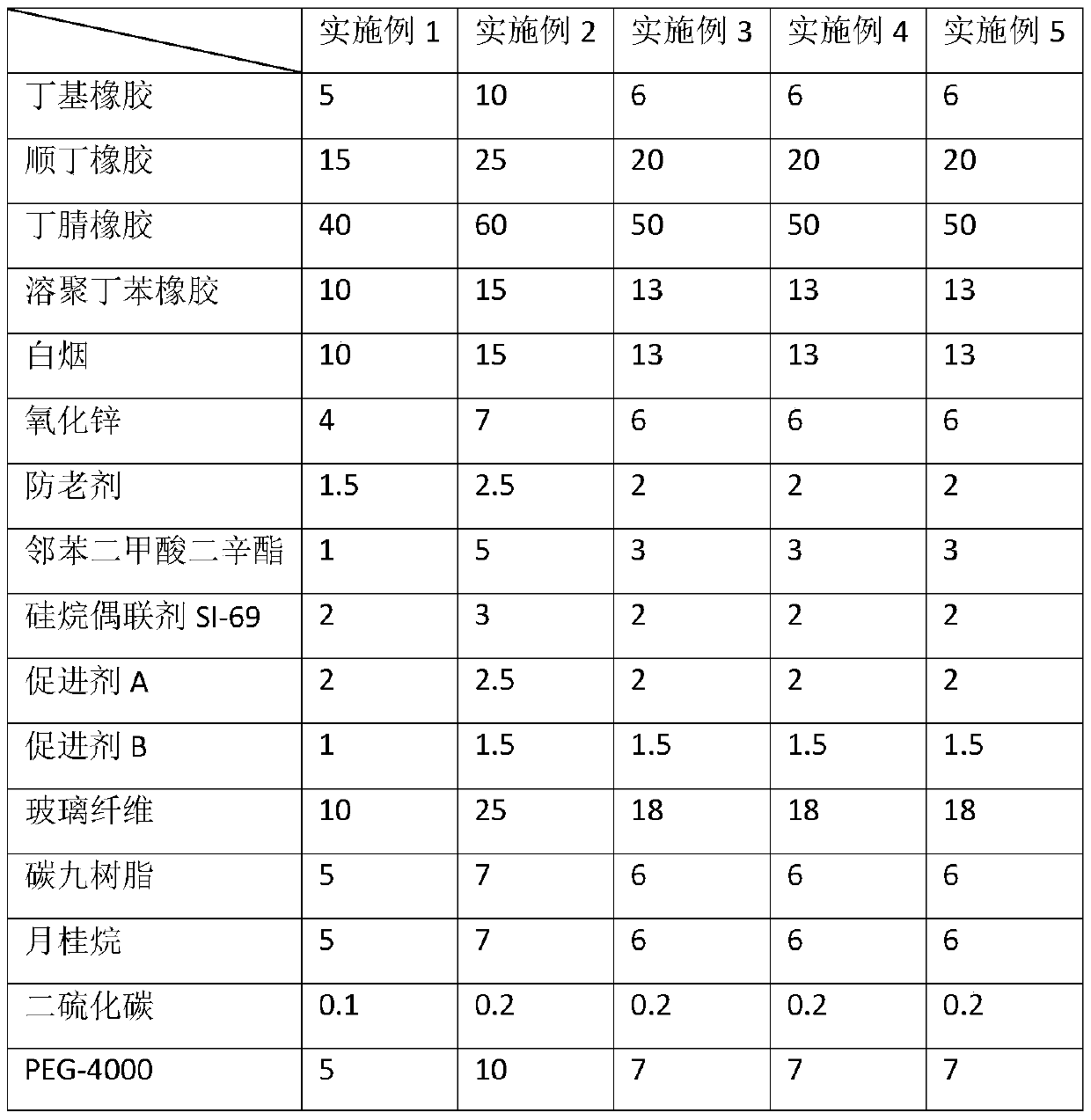

[0048] A kind of oil-resistant anti-slip shoe material on ice, the raw material components are shown in Table 1 in parts by weight. The anti-aging agent adopts anti-aging agent RD, the accelerator A adopts accelerator DTDM, and the accelerator B adopts accelerator MBS. The preparation method of this oil-resistant non-slip shoe material comprises the following steps:

[0049] Step 1, mix the glass fiber and the solution prepared by silane coupling agent SI-69 evenly, dry at 100°C for 3 hours, and obtain the modified glass fiber for use;

[0050] Step 2, mix and stir laurane, anti-aging agent, vulcanization accelerator (that is, accelerator A+accelerator B), carbon disulfide and REG-4000 evenly to obtain a compounding agent for use;

[0051] Step 3, mix butyl rubber, cis-butadiene rubber, nitrile rubber, solution polystyrene butadiene rubber and carbon nine resin into the banbury mixer, mix and banbury for 5 minutes, then add white smoke and continue to mix and banbury for 3 mi...

Embodiment 2

[0057] The difference from Example 1 is that, in parts by weight, the raw material components are as shown in Table 1. The preparation method of oil-resistant non-slip shoe material comprises the following steps:

[0058] Step 1, mix the glass fiber with the solution prepared by the silane coupling agent SI-69 evenly, and dry it at 120°C for 4 hours to obtain the modified glass fiber for use;

[0059] Step 2, mix and stir laurane, anti-aging agent, vulcanization accelerator, carbon disulfide and REG-4000 evenly to obtain a compounding agent for later use;

[0060] Step 3, butyl rubber, butadiene rubber, nitrile rubber, solution polystyrene butadiene rubber and C9 resin are mixed and put into a banbury mixer for banburying, mixing and banburying for 10 minutes, then adding white smoke to continue mixing and banburying for 5 minutes, When the temperature reaches 125°C, the rubber masterbatch is obtained;

[0061] Step 4, uniformly mixing the rubber masterbatch, modified glass ...

Embodiment 3

[0065] The difference from Example 1 is that, in parts by weight, the raw material components are as shown in Table 1. The preparation method of oil-resistant non-slip shoe material comprises the following steps:

[0066] Step 1. Mix the glass fiber with the solution prepared by silane coupling agent SI-69 evenly, and dry it at 110°C for 3.5 hours to obtain the modified glass fiber for use;

[0067] Step 2, mix and stir laurane, anti-aging agent, vulcanization accelerator, carbon disulfide and REG-4000 evenly to obtain a compounding agent for later use;

[0068] Step 3, mix butyl rubber, cis-butadiene rubber, nitrile rubber, solution polystyrene butadiene rubber and carbon nine resin into the internal mixer for banburying, mix and banbury for 8 minutes, then add white smoke and continue to mix and banbury for 4 minutes, When the temperature reaches 120°C, the rubber masterbatch is obtained;

[0069] Step 4, uniformly mixing the rubber masterbatch, modified glass fiber, compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com