Rare-earth complex rubber anti-aging agent, and preparation method and application thereof

A rare earth complex, rubber antioxidant technology, applied in the preparation of sulfonic acid, organic chemistry and other directions, to achieve the effect of being suitable for popularization and application, and the synthesis method is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

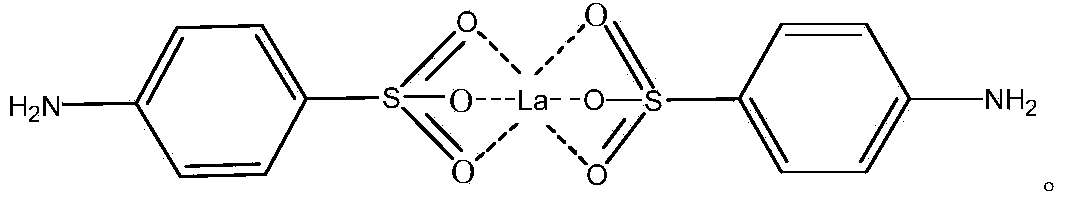

[0022] Dissolve 200 grams of sodium p-aminobenzenesulfonate in 300ml of water, stir in a water bath at 80°C for 0.5h, then add 260g of lanthanum chloride solution whose molar number is equivalent to 50% of the molar number of sodium p-aminobenzenesulfonate, and continue at 80 Stir at ℃ for 8h, filter, wash and dry the obtained product to obtain the target product lanthanum p-aminobenzenesulfonate.

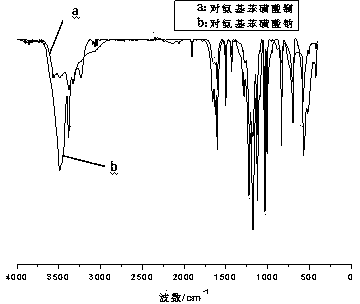

[0023] Elemental analysis: the contents of C, H, N, and S in the product are 28.12%, 2.81%, 5.55%, and 12.52% respectively, which indicates that the chemical formula of the rare earth complex is C 12 h 12 S 2 o 8 N 2 La·2H 2 O. Infrared spectrum such as figure 1 It is shown that the characteristic peaks at 3380cm-1 and 3480cm-1 are still maintained, but the absorption intensity of each group is slightly reduced due to the strong electronegativity of the lanthanum ion. The characteristic peak position of the sulfonic acid cation in the figure, due to the action of the lanthan...

Embodiment 2

[0040] The basic formula of the styrene-butadiene rubber / white carbon black composite material prepared by compounding the rare earth complex lanthanum sulfanilate and 4010NA as the rubber antioxidant is shown in Table 5, and the mixing and vulcanization process is the same as in Example 1.

[0041] Table 5 SBR / SiO 2 Composite material formulation (unit: parts by weight)

[0042]

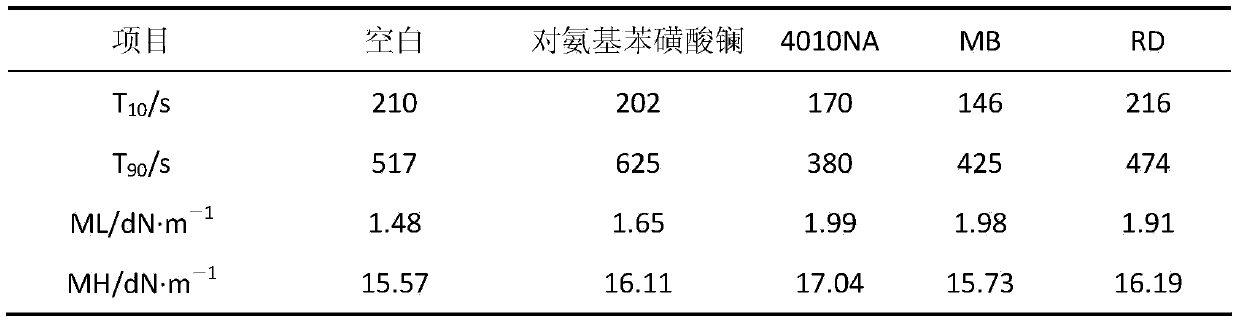

[0043] Table 6 shows that when 4010NA / lanthanum sulfanilate is 1.9 / 0.1 (4010NA-1) or 1.8 / 0.2 (4010NA-2), the scorch time T of the compound 10 It is longer than the compound (4010NA-0) with all 4010NA added, and the positive vulcanization time T 90It is shorter than the rubber compound with all 4010NA added, indicating that the compound use of the two antioxidants has a synergistic effect on vulcanization, which can not only increase the scorch time and improve the processing safety of the rubber compound, but also shorten the normal vulcanization time and increase the vulcanization speed. At th...

Embodiment 3

[0055] The basic formula of the prepared styrene-butadiene rubber / white carbon black composite material is shown in Table 10 by compounding the rare earth complex lanthanum sulfanilate and anti-aging agent MB as the rubber anti-aging agent:

[0056] Table 10SBR / SiO 2 Composite material formulation (unit: parts by weight)

[0057]

[0058] The mixing and vulcanization process is the same as in Example 1.

[0059] Table 11 shows the vulcanization characteristic parameters of p-SBR / lanthanum sulfanilate / MB vulcanizate. It can be seen that with the increase of the amount of lanthanum sulfanilate, the scorch time T 10 and positive vulcanization time T 90 Gradually increased, indicating that the addition of lanthanum sulfanilate can prolong the scorch time of the rubber compound, thus ensuring the processing safety of the rubber compound. At the same time, the addition of lanthanum p-aminobenzenesulfonate can reduce the minimum torque ML of the rubber compound and improve the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com