Irregular-shaped metal part polishing device

A technology for metal parts and rules, which is applied in the field of grinding devices for irregularly shaped metal parts, can solve the problems of inconvenient recovery of impurities, reduction of the quality of the processing environment, and impurities that cannot be removed by grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

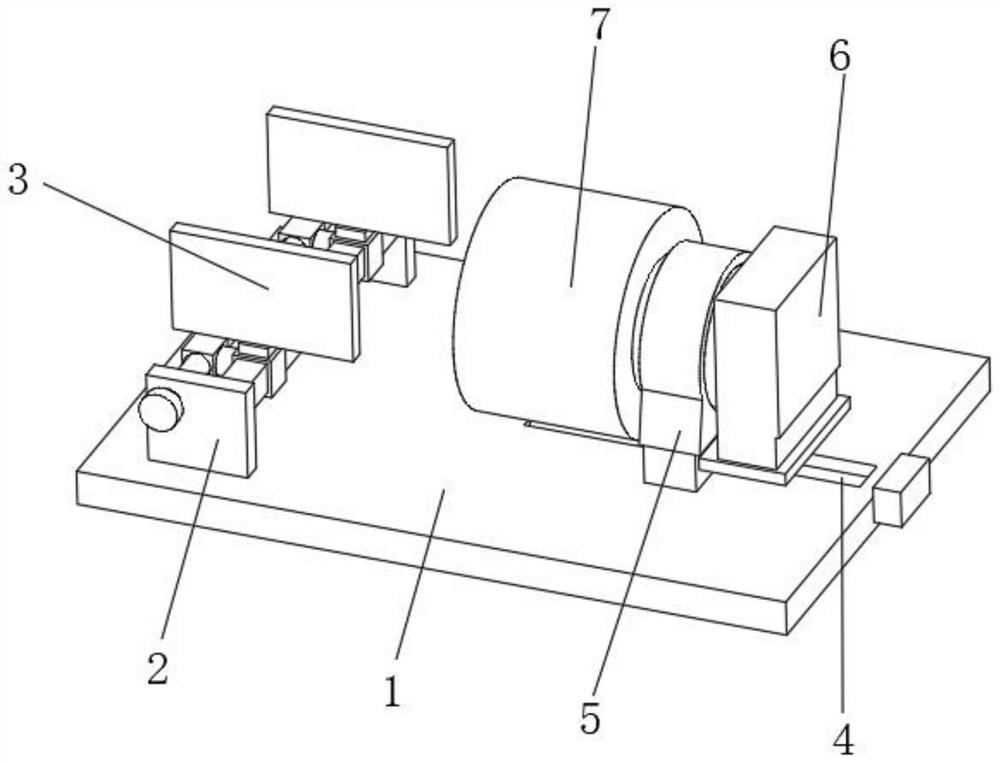

[0040] Such as Figure 1-3 As shown, the present invention provides a technical solution: a grinding device for irregularly shaped metal parts, including a support platform 1, the left side of the top of the support platform 1 is fixedly connected with a transmission fixture 2, and the output end of the transmission fixture 2 top is fixed The limiting splint 3 is connected, the middle position on the top right side of the transmission fixture 2 is fixedly connected with the reciprocating traveling mechanism 4, the top output end of the reciprocating traveling mechanism 4 is fixedly connected with the working platform 5, and the right side of the working platform 5 is fixedly connected with the driving motor 6 , the left axis of the driving motor 6 is fixedly connected with a processing grinding cylinder 7, and the inside of the processing grinding cylinder 7 and near the left side are uniformly and equidistantly fixedly connected with a grinding adjustment mechanism 8, and the ...

Embodiment 2

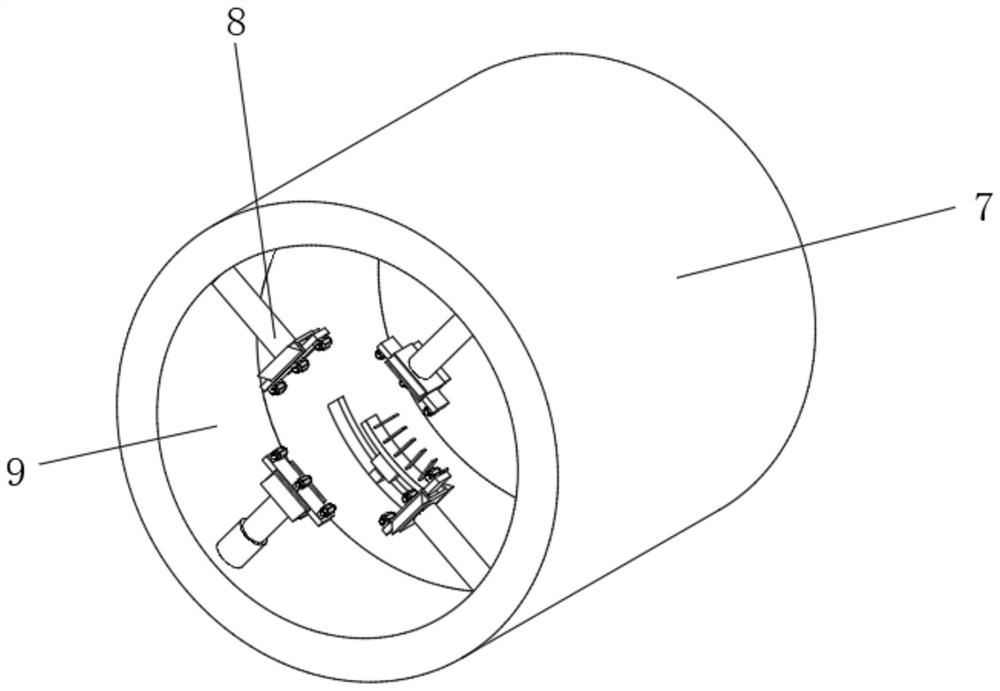

[0042] Such as Figure 4-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a grinding device for irregularly shaped metal parts. The grinding adjustment mechanism 8 includes a spring connecting rod 801, and the bottom end of the spring connecting rod 801 is connected with the grinding cylinder 7. The inner wall is fixedly connected, and the end of the spring connecting rod 801 away from the processing and grinding cylinder 7 is fixedly connected with a movable support groove plate 802, and the internal rotation of the movable support groove plate 802 is connected with an adjustment seesaw 803.

[0043] A support bearing block 804 is evenly and fixedly connected to adjust the horizontal position of the top of the seesaw 803 , and a grinding roller 805 is rotatably connected between two adjacent support bearing blocks 804 . Realize grinding and cleaning the surface of metal parts under the circular drive, and improve the efficiency of...

Embodiment 3

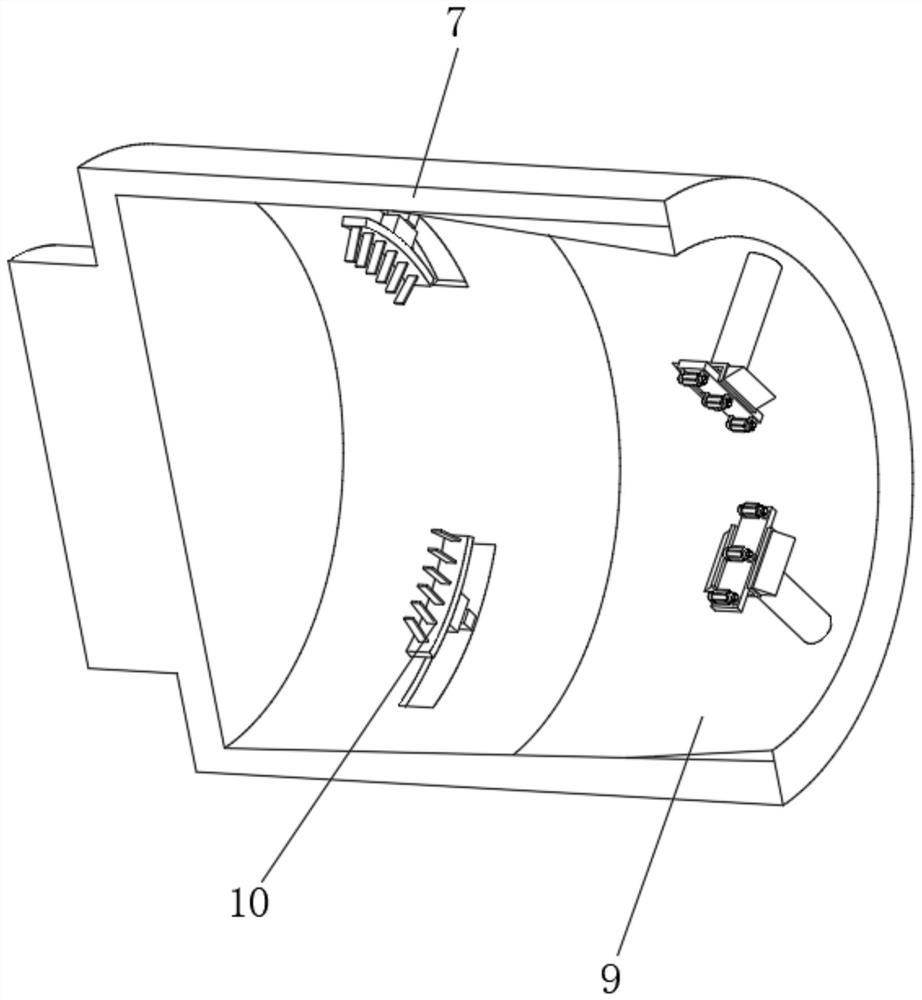

[0051] Such as Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a grinding device for irregularly shaped metal parts. The cleaning and adsorption mechanism 10 includes a movable track 101, and the inner sliding connection of the movable track 101 has Limiting the slider 102 , one end of the limiting slider 102 outside the movable track 101 is fixedly connected with an attached arc plate 103 .

[0052] The top surface of the attached arc plate 103 is uniformly and fixedly connected with a cleaning brush 104 , and the surface of the cleaning brush 104 close to the attached arc plate 103 is provided with an adsorption magnet. Under the action of circular motion, the impurities on the surface of the polished metal parts are separated to avoid damage to the surface of the metal parts caused by the impurities attached during periodic grinding.

[0053] A side near the bottom of the limit slider 102 and an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com