Overlength straight pipeline member cutting method

A super-long straight cutting technology, applied in the direction of metal processing equipment, metal processing machinery parts, turning equipment, etc., can solve the problems that it is difficult to guarantee the processing quality and processing safety, it is difficult to improve production efficiency, and the processing procedure is complicated. Achieve the effects of ensuring processing quality and safety, facilitating processing operations, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

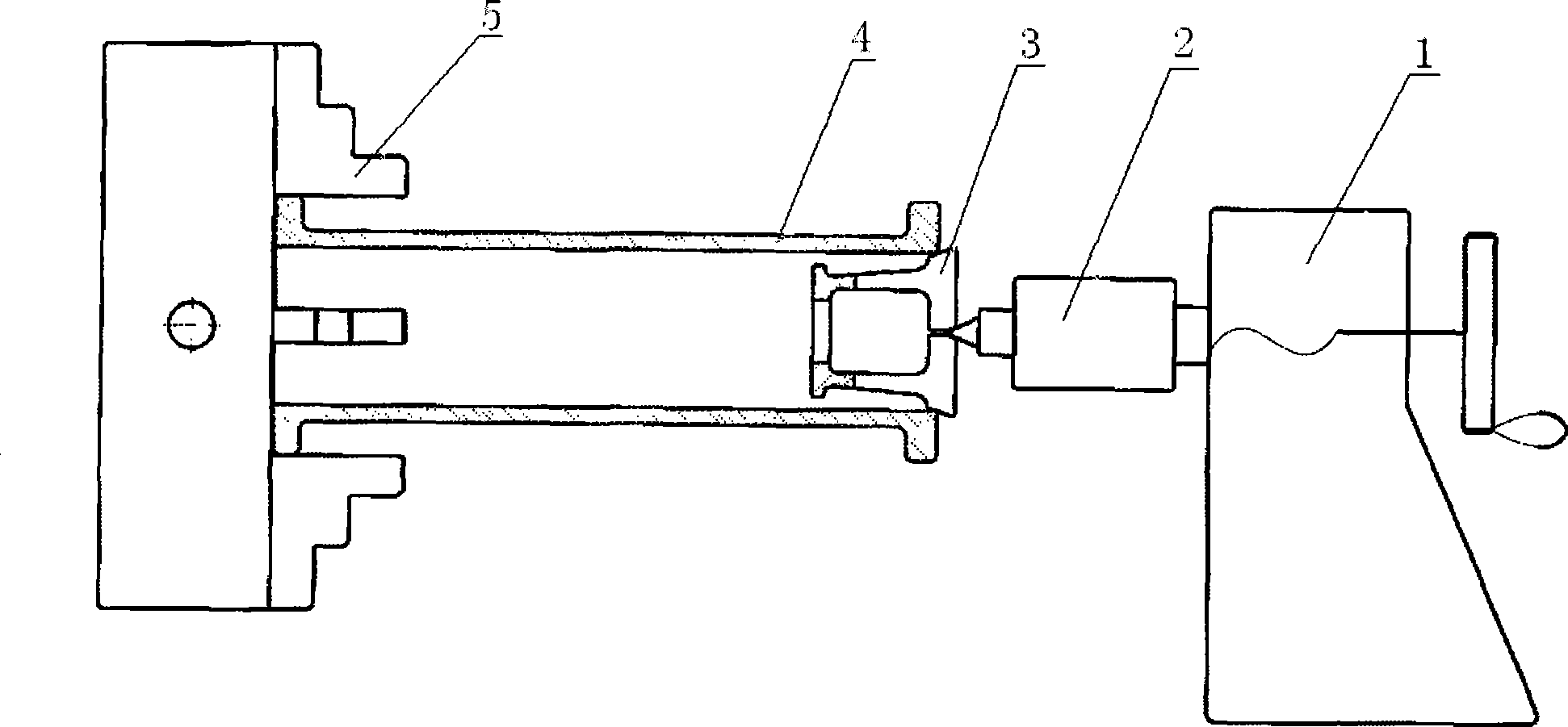

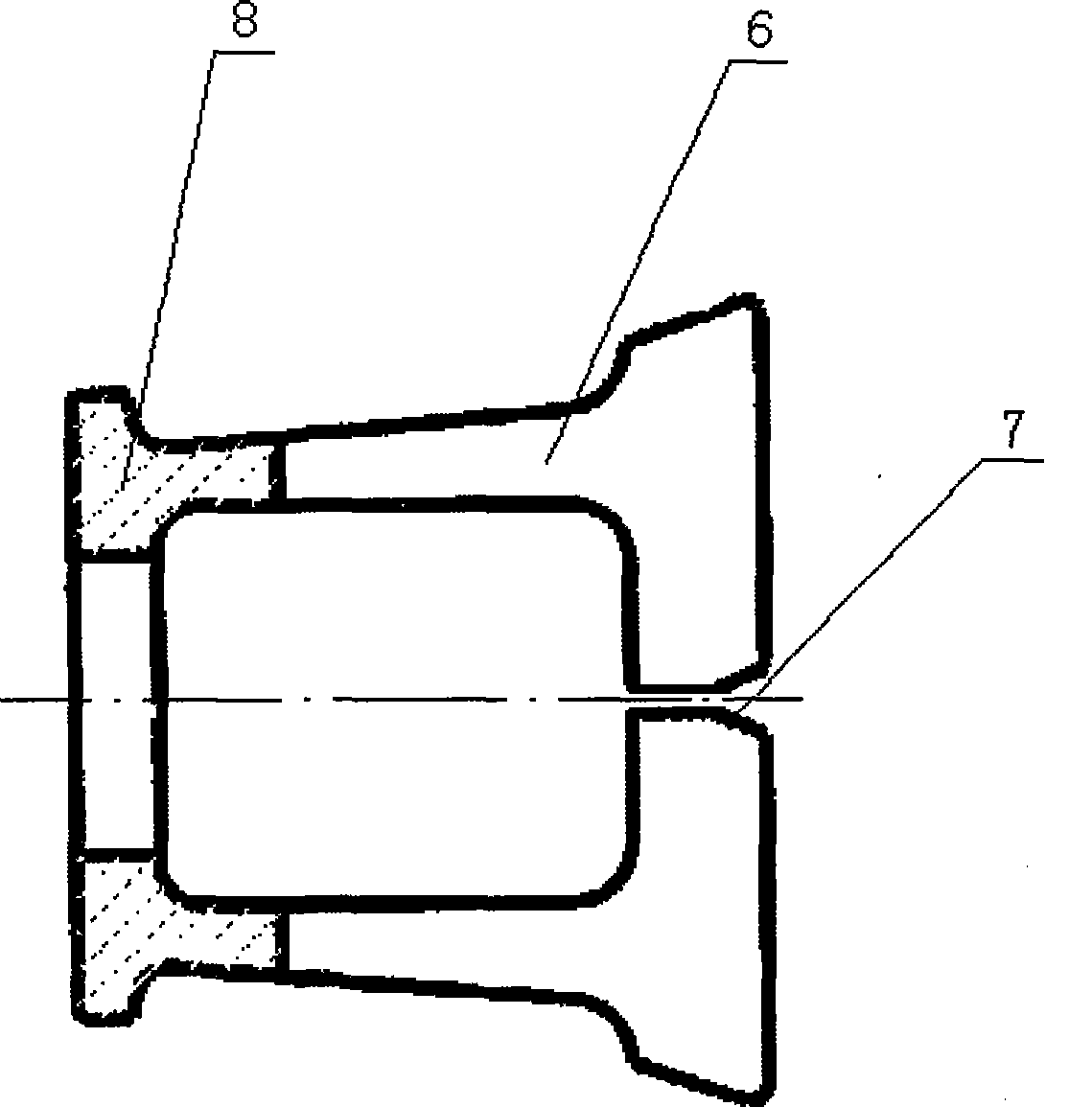

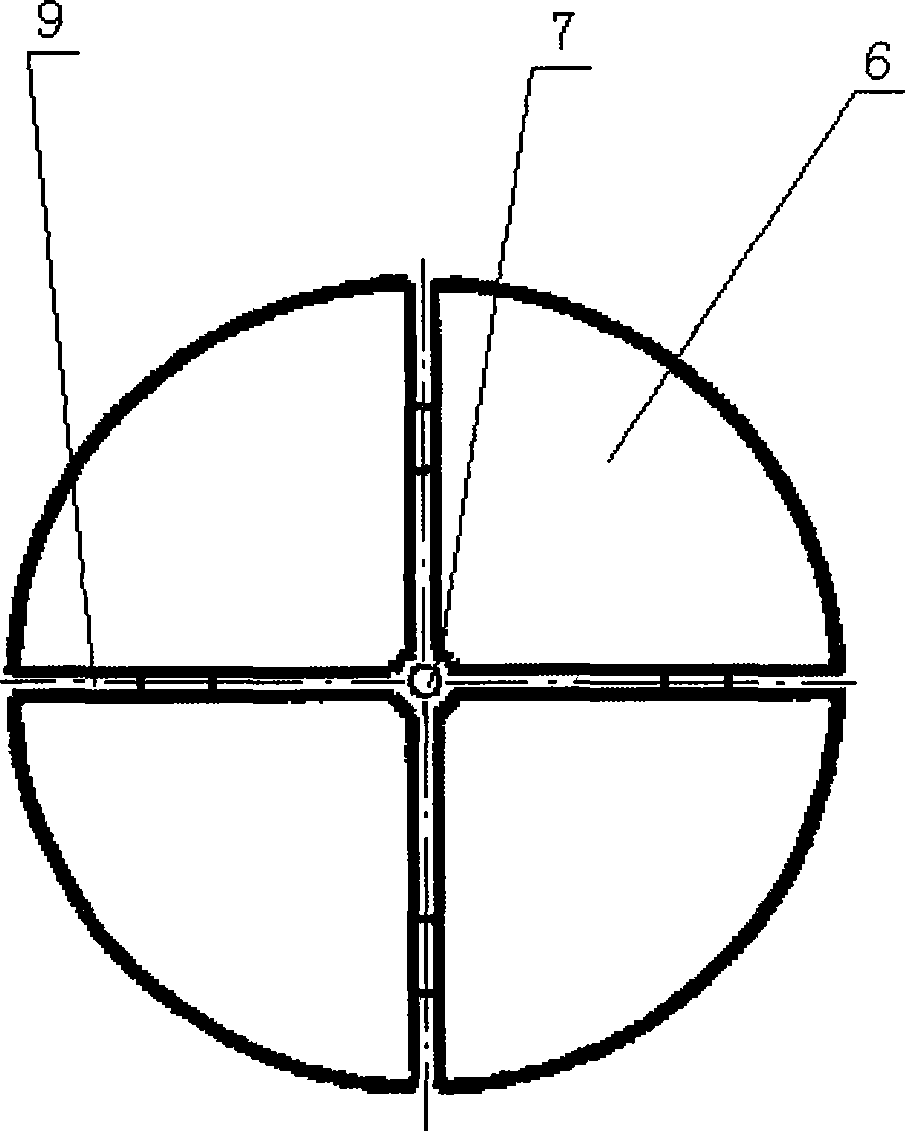

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the cutting processing method of an ultra-long straight pipe fitting of the present invention has the following steps:

[0022] a. Manufacture of the tube end expansion member 3 for ultra-long straight pipe fittings. The tube end expansion member 3 includes a connecting part 8, an expansion piece 6 cut into four equal parts, and an end of the expansion piece 6 There is a thimble hole 7 for the tension member in the center, and a gap 9 is provided between each tension piece 6. The tube end expansion member 3 is made of GCr15 steel, which has undergone surface quenching and quenching and tempering treatment, and requires high surface hardness (HRC55 or above) and elastic toughness; the expansion member thimble hole 7 is compatible with the tailstock thimble The inclination, and has a higher surface and position accuracy. When the end of the tailstock thimble is sleeved with a revolving tension piece, the tension pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com