Box body angle adjusting device for universal fixture

An angle adjustment device and angle fine-tuning technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of Class A fixtures such as lack of versatility, poor safety, and poor angle locking, so as to save time for inclination adjustment and ensure Effects of improving process safety and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

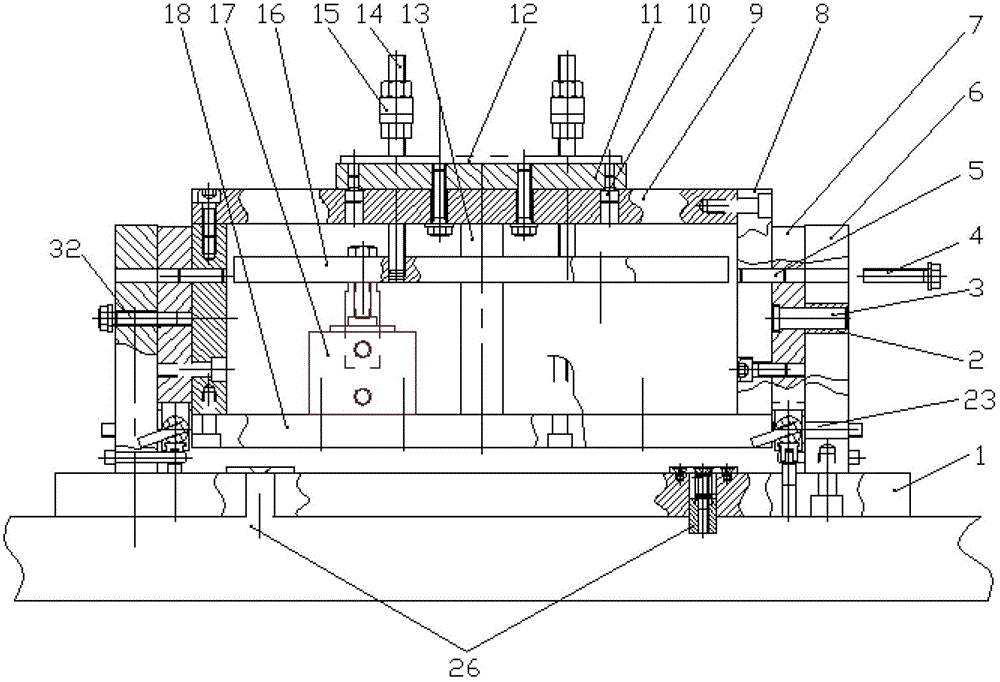

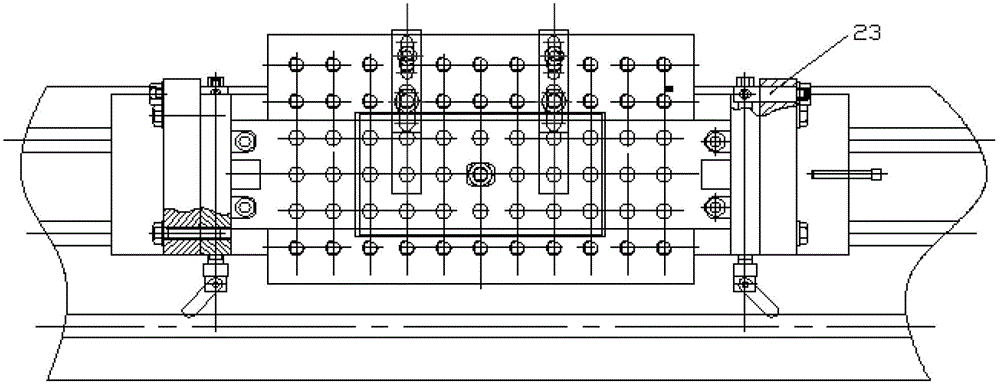

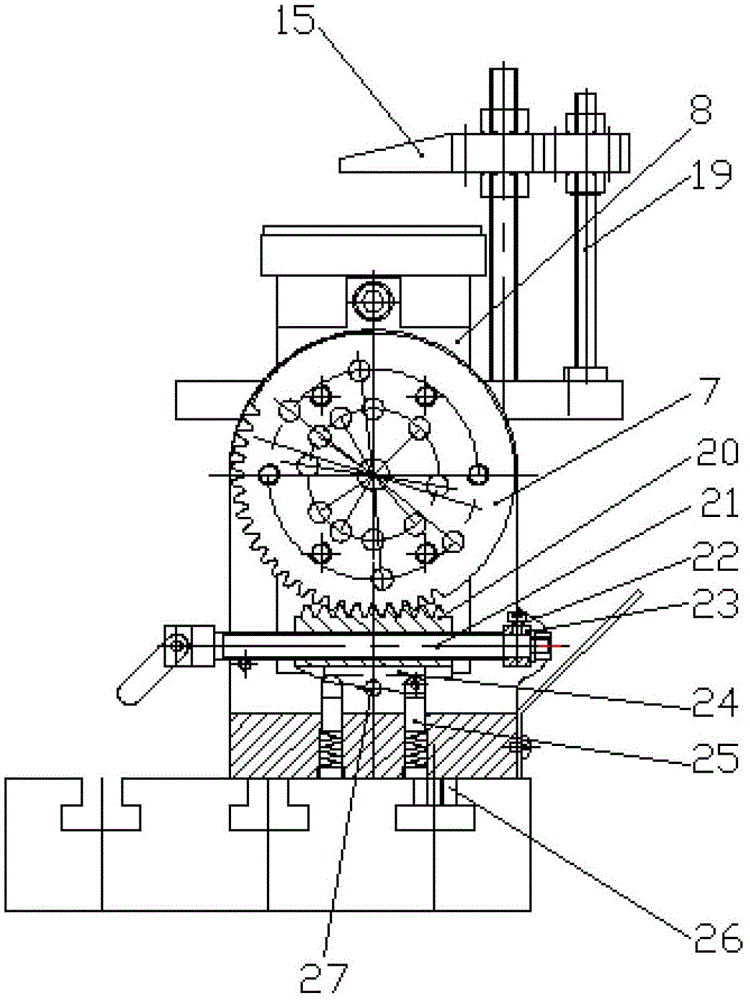

[0027] Figure 1 to Figure 4 Shows the specific structure of the quick-positioning pneumatic compaction tilt angle fine-tuning universal fixture, which includes a bracket installed on the workbench 28, a box body is rotatably connected to the bracket, and the box body includes two side plates 8, two The side plates 8 are parallel to each other, the bottoms of the two side plates are vertically fixed on the cylinder base plate 18, and the tops of the two side plates are vertically fixed with a top plate 9, which is the positioning panel of the flat fixture 11.

[0028] A flat clamp 11 is fixed on the top plate 9 , and the flat clamp 11 is used for installing a workpiece 12 . The flat fixture 11 is provided with workpiece positioning pins 31 for positioning the workpiece 12 . The flat clamp 11 is positioned on the top plate 9 of the box body through the stepped pin 10, and the flat clamp 11 and the top plate of the box body are fixed by bolts.

[0029] The upper and lower ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com