Rotating type varying stiffness flexible joint

A flexible joint and variable stiffness technology, applied in the field of robots, can solve the problems of difficult transmission accuracy, complex cam groove design, short working life, etc., and achieve the effects of low cost, easy replacement and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

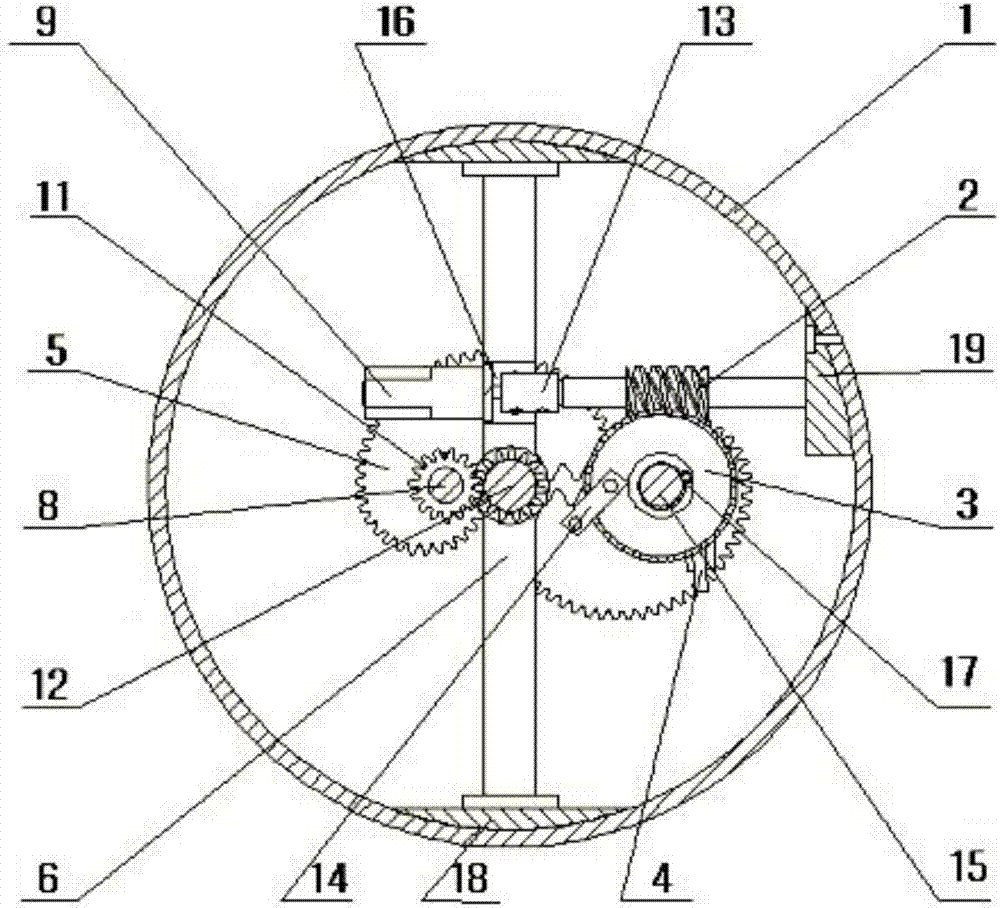

Embodiment 1

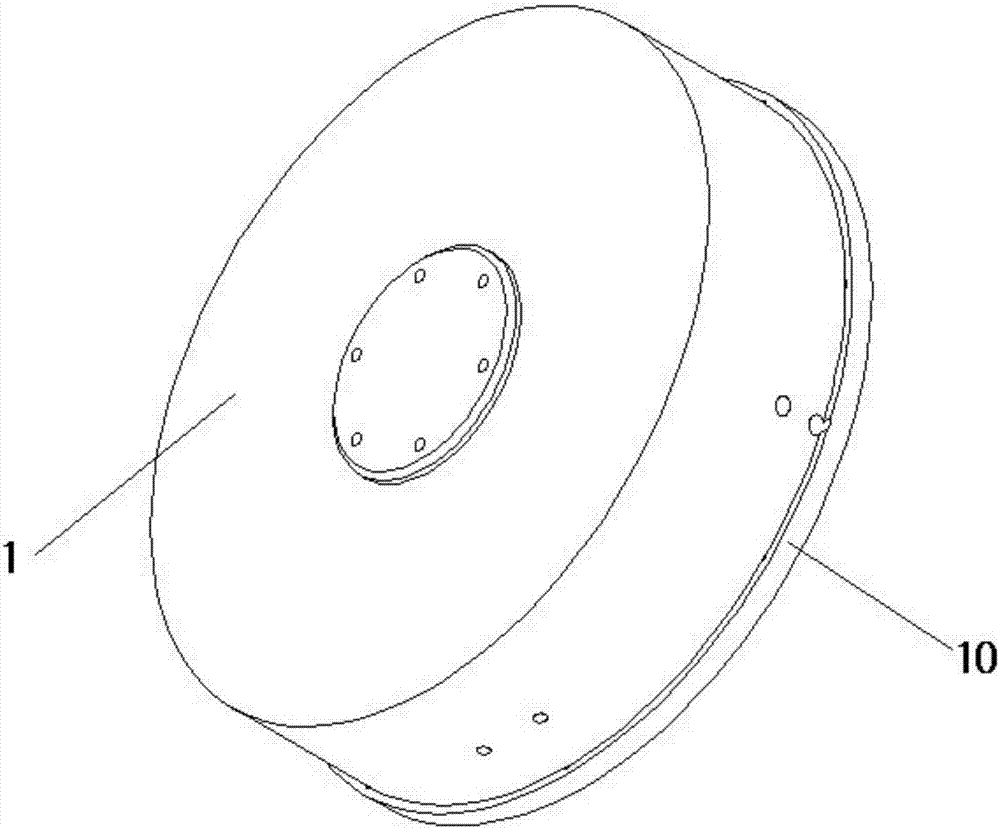

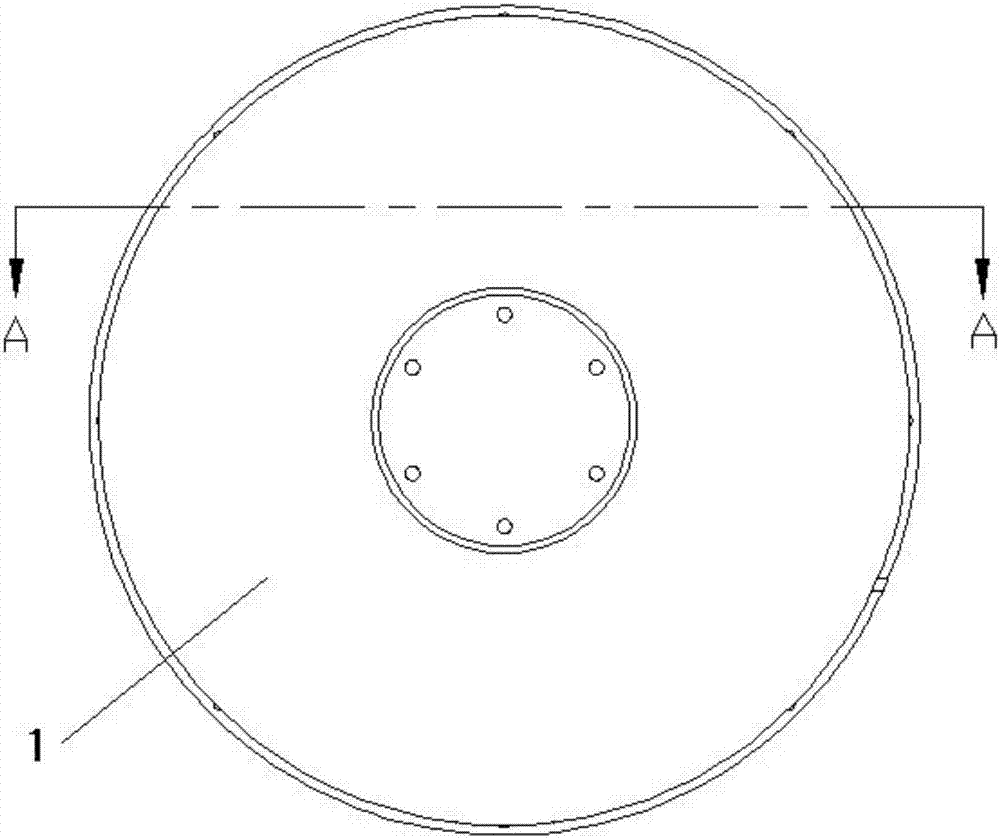

[0032] The rotary variable stiffness flexible joint in this embodiment includes a drive plate 1, an end cover 10, a torsion spring 4, a special-shaped gear set 5, a standard gear set 11, a shaft 15, a shaft 2 8, an output shaft 12, a shaft end fixing frame 6, Worm 2, worm gear 3, DC gear motor 9, coupling 13, connecting plate 14, worm fixing block 19, retaining spring 17, motor mount 16, fixing block 18 and bearing seat 7;

[0033] The drive disc 1 is fixed to the end cover 10, and the end of the drive disc 1 is directly connected to the external motor through the reducer as the input of the flexible joint; the drive disc 1 is provided with a bearing seat 7 and a shaft end fixing frame 6, and the bearing seat 7 It has an integrated structure with the drive plate 1, and the drive plate 1 and the end cover 10 are connected by bolts as a joint shell; the two ends of the shaft end fixing frame 6 are fixed on the drive plate 1 through the fixing block 18, and the end cover 10 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com