Bi-directional positioning clamping fixture

A two-way positioning and clamping technology, which is applied to positioning devices, clamping, manufacturing tools, etc., can solve the problems of waste of resources, inconvenient loading and unloading, and complicated loading and unloading processes, and achieve high positioning accuracy, reduce use costs, and self-locking good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

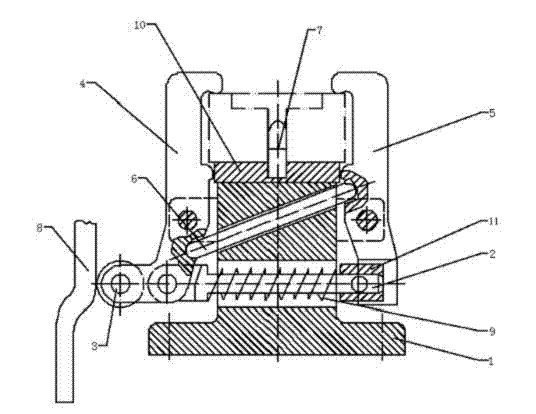

[0015] Such as figure 1 As shown, the present invention provides a bidirectional positioning and clamping fixture, including a fixture body 1, a left jaw 4 and a right jaw 5 hinged to the fixture body, a push rod 2 fixedly connected to the left jaw 4, The strong spring 9 set on the push rod 2, the sleeve 11 arranged at the transmission end of the push rod 2, the cam 8 as a force applying device, and the linkage pin 6 acting as a drive, are characterized in that the clamp body 1 is provided with a horizontal through hole and the inclined through hole, the push rod 2 passes through the horizontal through hole, and its driving end extends to the rectangular slot corresponding to the lower driving end of the right jaw 5, and the linkage pin 6 passes through the inclined through hole and its two ends extend to the left respectively The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com