Deburring device for disc type slice part

A deburring and equipment technology, applied in the field of parts processing, can solve the problems of high equipment maintenance costs, difficulty in ensuring machining accuracy, and low machining efficiency, and achieve the effects of ensuring machining safety, improving machining accuracy, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

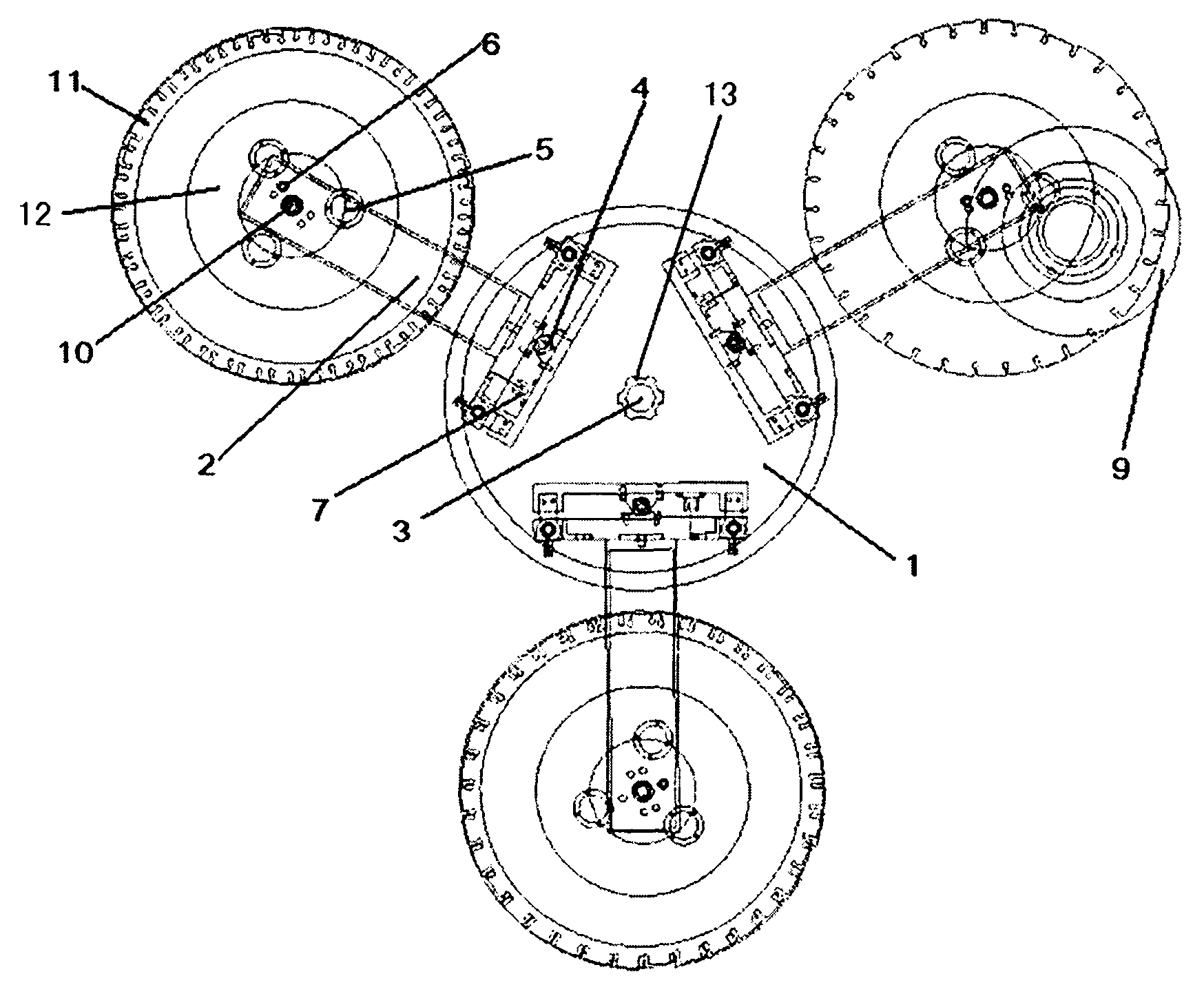

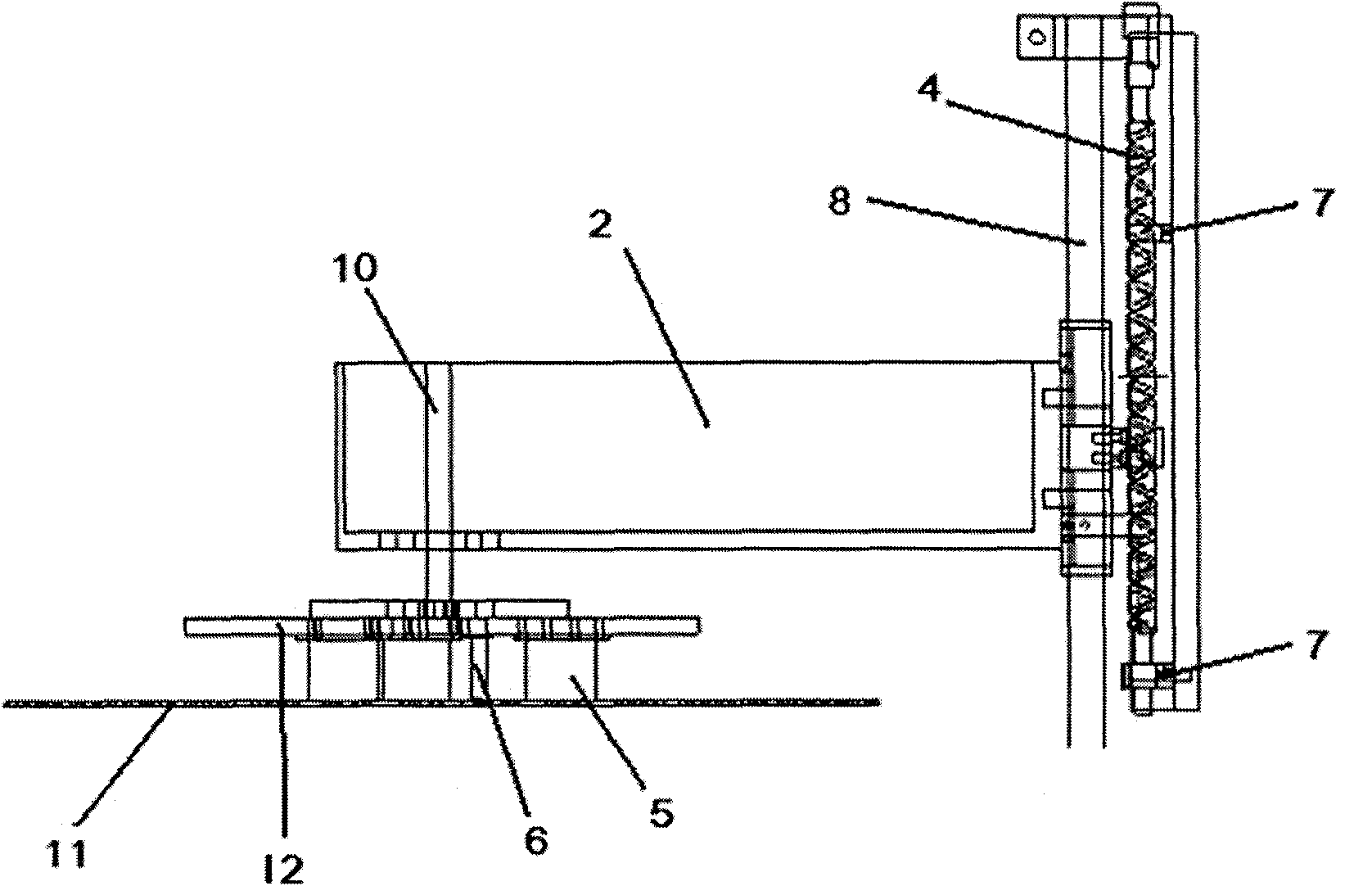

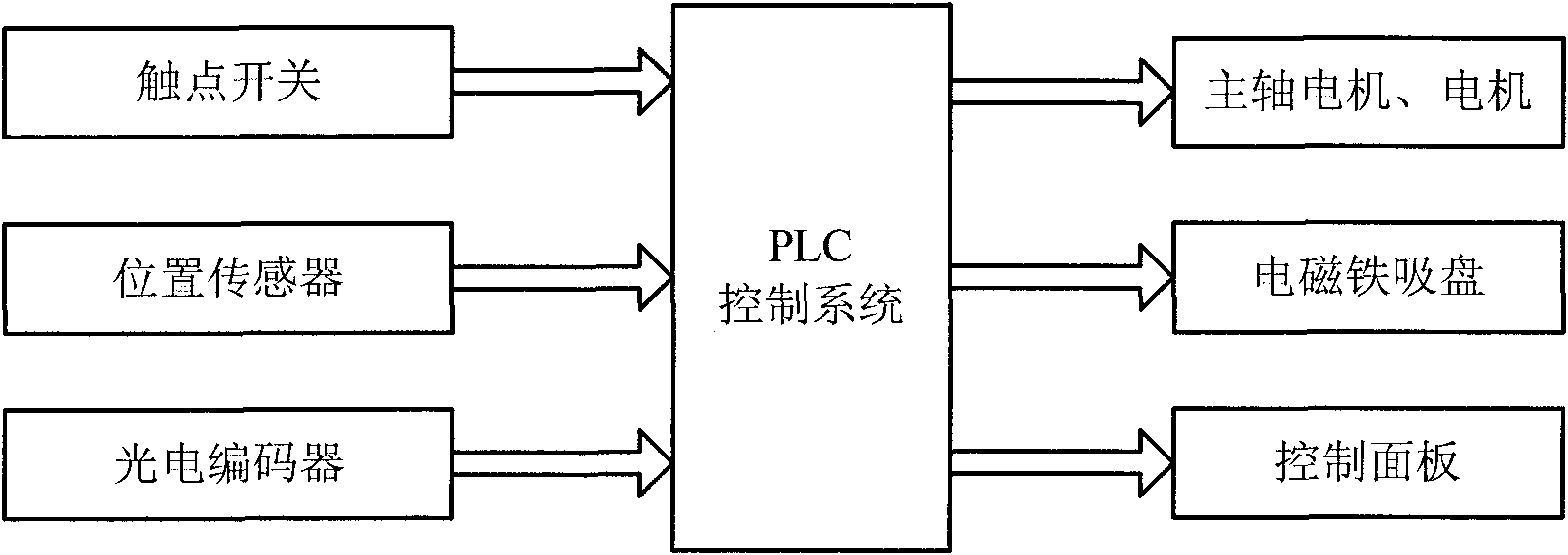

[0026] Such as figure 1 , 2 , 4, the present invention is a kind of equipment embodiment that is used for the deburring of disk type sheet parts, and it comprises bottom platform 1, main shaft 3 and main shaft motor, three lifting devices, control system; Main shaft motor is used for driving bottom platform 1 Rotating around the main shaft 3, the three lifting devices are evenly distributed on the bottom platform 1 with the main shaft 3 as the center of the circle. Each lifting device is equipped with a mechanical arm 2 that radiates outward with the main shaft as the center of the circle. There is a workpiece pick-and-place device, and each workpiece pick-and-place device corresponds to a workpiece pick-up position, a workpiece processing position and a workpiece release position, and a grinding wheel is installed at the workpiece processing position;

[0027] Spindle motor, lifting device, and workpiece pick-and-place device are all controlled by the control system.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com