Preparation method of amino acid surfactant

A surfactant and amino acid technology, applied in the field of synthesis of fine chemical products, can solve the problems affecting the degree of reaction and reaction efficiency, harm to equipment and operators, and temperature rise of the reaction system, etc., and achieve good reaction efficiency, high safety, The effect of precise reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of amino acid surfactant provided by the present invention, the method comprises: carry out contact reaction with the aqueous solution of fatty acid chloride and amino acid and / or amino acid salt in microchannel reactor, obtain amino acid surfactant; Wherein, the microchannel reactor The channel reactor includes a plurality of reaction sheets including microchannel structures.

[0026] In the present invention, the microchannel reactor can adopt any existing microchannel reactor that can be used for liquid phase reaction. Preferably, in order to fully contact and react the aqueous solution of fatty acid chloride and amino acid and / or amino acid salt, the microchannel reactor with the heart-shaped microchannel structure is used for preparation, preferably Corning's Advanced- Reactor G1. The microchannel structure of described heart-shaped structure can for example be image 3 As shown, the microchannel structure includes more than one (for examp...

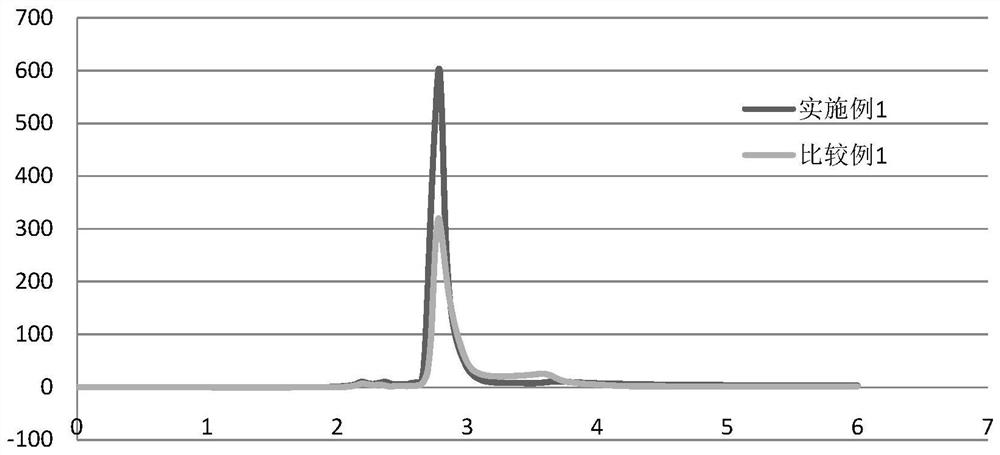

Embodiment 1

[0039] Take 65g of L-glutamic acid powder, add 35g of sodium hydroxide to prepare a 20% by weight amino acid alkaline solution, and make the volume ratio of the solution to the lauroyl chloride solution (concentration: 98% by weight) 5.0:1. , the two solutions are passed into the microchannel reactor through the metering pump, the flow rate of the amino acid alkaline solution is 40mL / min, the flow rate of the lauroyl chloride solution is 8mL / min, the temperature of the reaction piece is 18°C, and the reaction pressure is 0.02MPa, The reaction time was 85s. After the reaction, the product flowed out from the outlet of the microchannel reactor to obtain the crude sodium lauroyl glutamate.

[0040] After diluting the above-mentioned crude product with pure water to an equal volume, purify by ultrafiltration (using an ultrafiltration membrane with a molecular weight cut-off of 200, the pressure is 10MPa, and the temperature is 20°C), and then concentrate under reduced pressure (the...

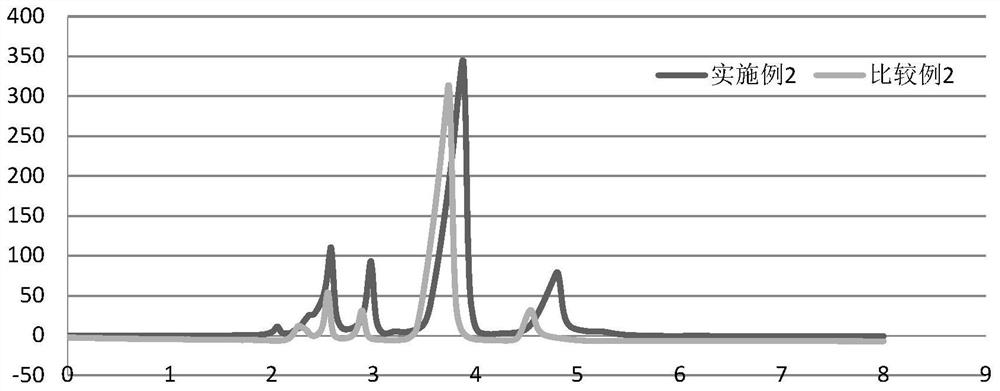

Embodiment 2

[0044] Get L-alanine powder 50g, after adding the sodium hydroxide of 22.5g and be mixed with the amino acid basic solution of 20% by weight, be 5.6:1 with the volume ratio of this solution and cocoyl chloride (concentration is 98% by weight) The method is to pass the two solutions into the microchannel reactor through the metering pump, the flow rate of the amino acid alkaline solution is 22.4mL / min, the flow rate of the cocoyl chloride solution is 4.2mL / min, and the temperature of the reaction plate is set at 20°C. The pressure is 0.02MPa, and the reaction time is 117.8s. After the reaction finishes, the product flows out from the outlet of the microchannel reactor to obtain the crude product of sodium cocoyl alanine.

[0045] After the above-mentioned crude product is diluted with pure water in equal volume, it is purified by ultrafiltration (using an ultrafiltration membrane with a molecular weight cut-off of 150, the pressure is 15MPa, and the temperature is 17° C.) and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com