Long bar stock fixture for lathe

A long bar and material clip technology, applied in the field of workpiece clamping fixtures, can solve the problems of large workpiece size, short workpiece clamping range, long overhang length, etc., to achieve the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

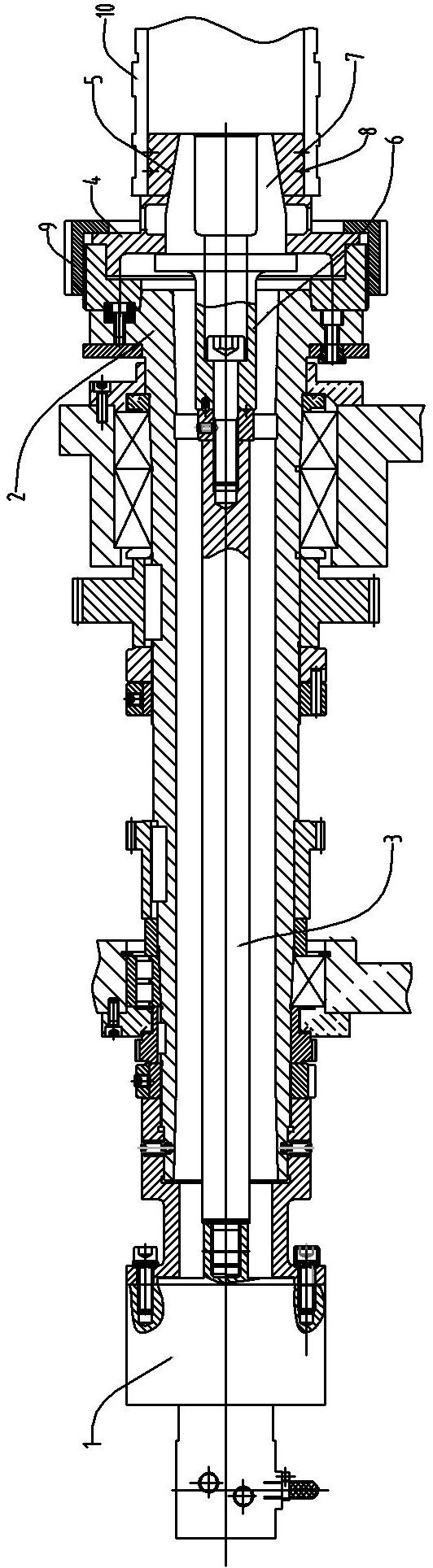

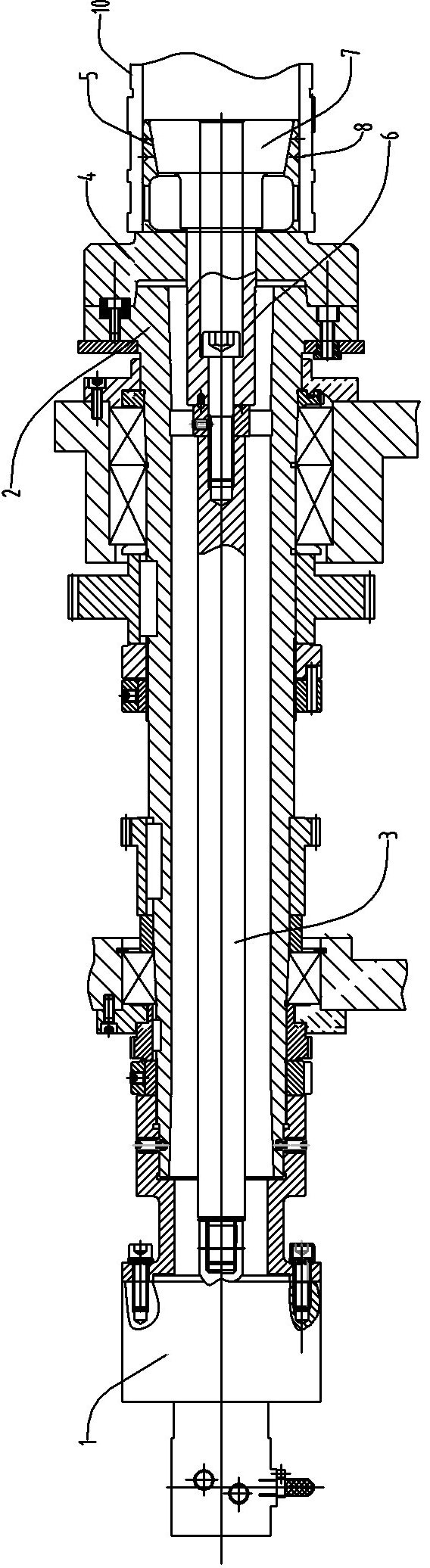

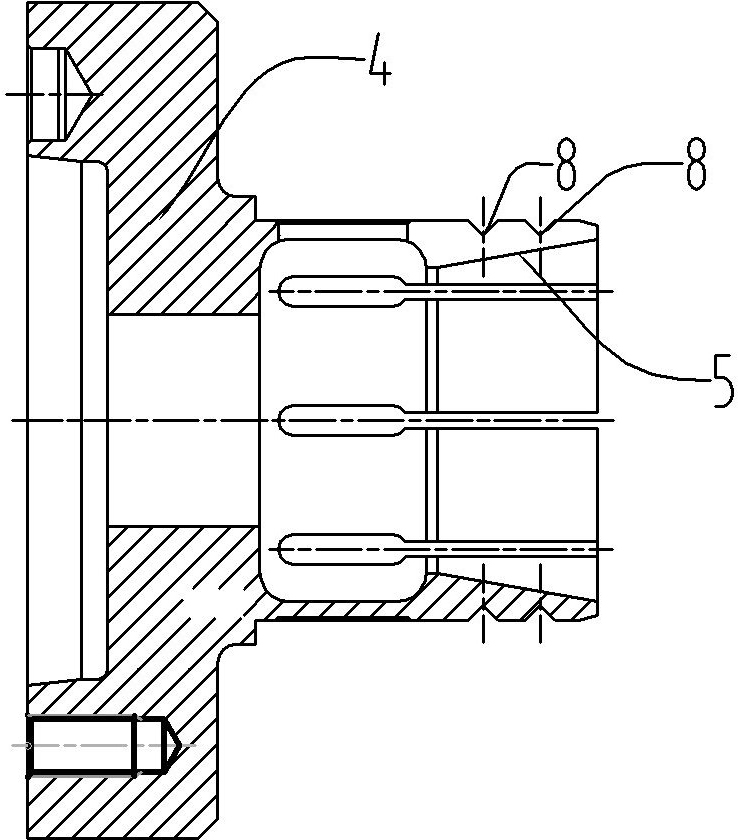

[0012] Such as figure 1 , a long bar material clamp for a lathe, including a clamp body 2 fixed on the spindle head 1, a pull bar 3 is installed inside the clamp body, a spring expansion sleeve 4 is installed on the end of the clamp body, and fixed by a lock nut 9, The end of the spring expansion sleeve is provided with a tapered inner hole 5, the tapered inner hole can face the pull bar, the end of the pull bar is connected to the outer cone mandrel 6, and the end of the outer cone mandrel is provided with a tapered head 7, the diameter of the tapered head Shrinking, facing the tapered inner hole, the other end of the pull bar is connected to the hydraulic cylinder that drives its expansion and contraction, through the hydraulic cylinder to push the pull bar, the tapered head of the outer cone mandrel can be inserted into the tapered inner hole to support the spring expansion sleeve open.

[0013] The above-mentioned long bar fixture for the lathe, when clamping the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com