Pool floating sludge removal device for sewage treatment

A technology for sewage treatment and floating mud, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. Complicated problems, to achieve the effect of easy promotion and implementation, simple structure, and high removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

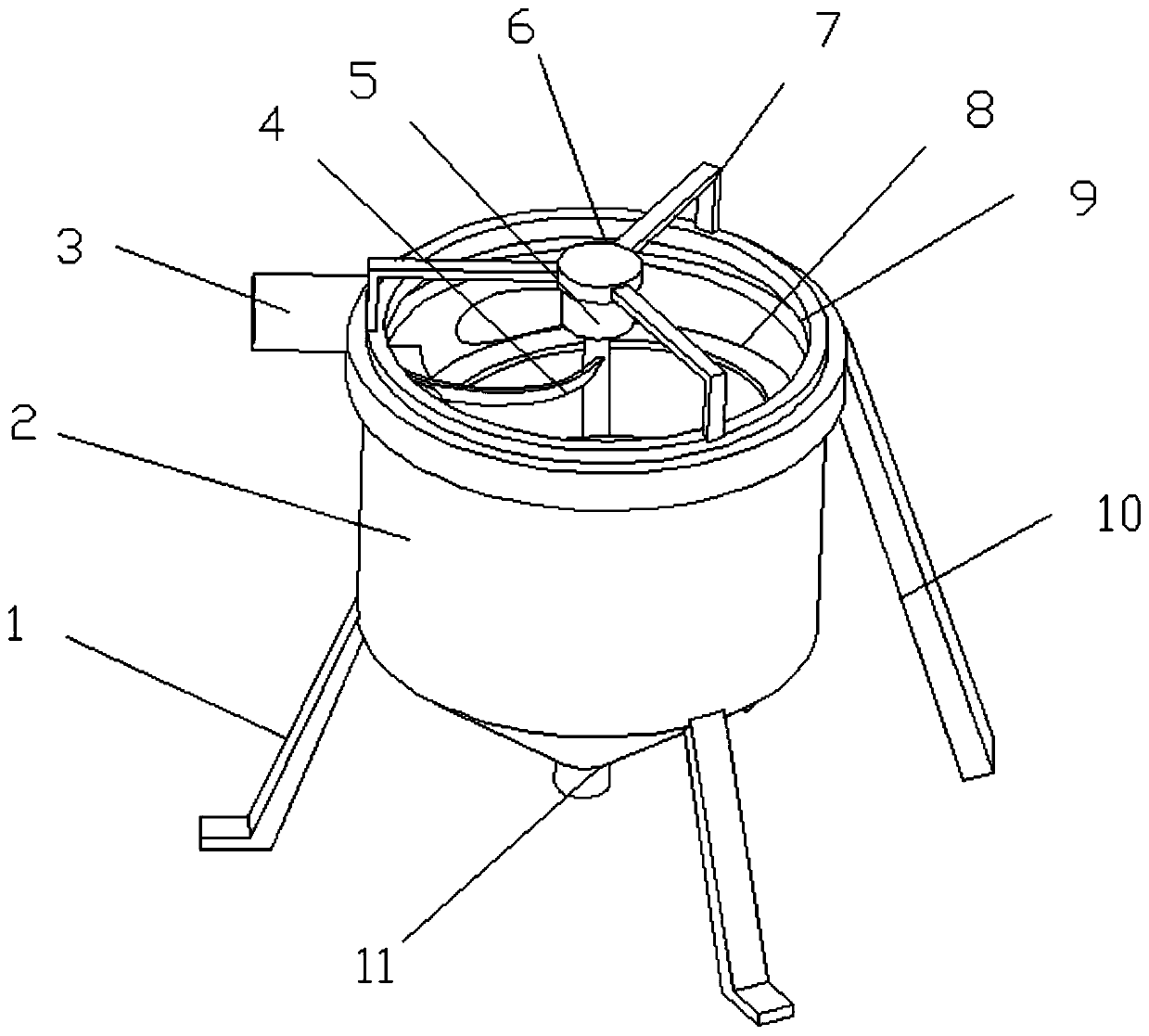

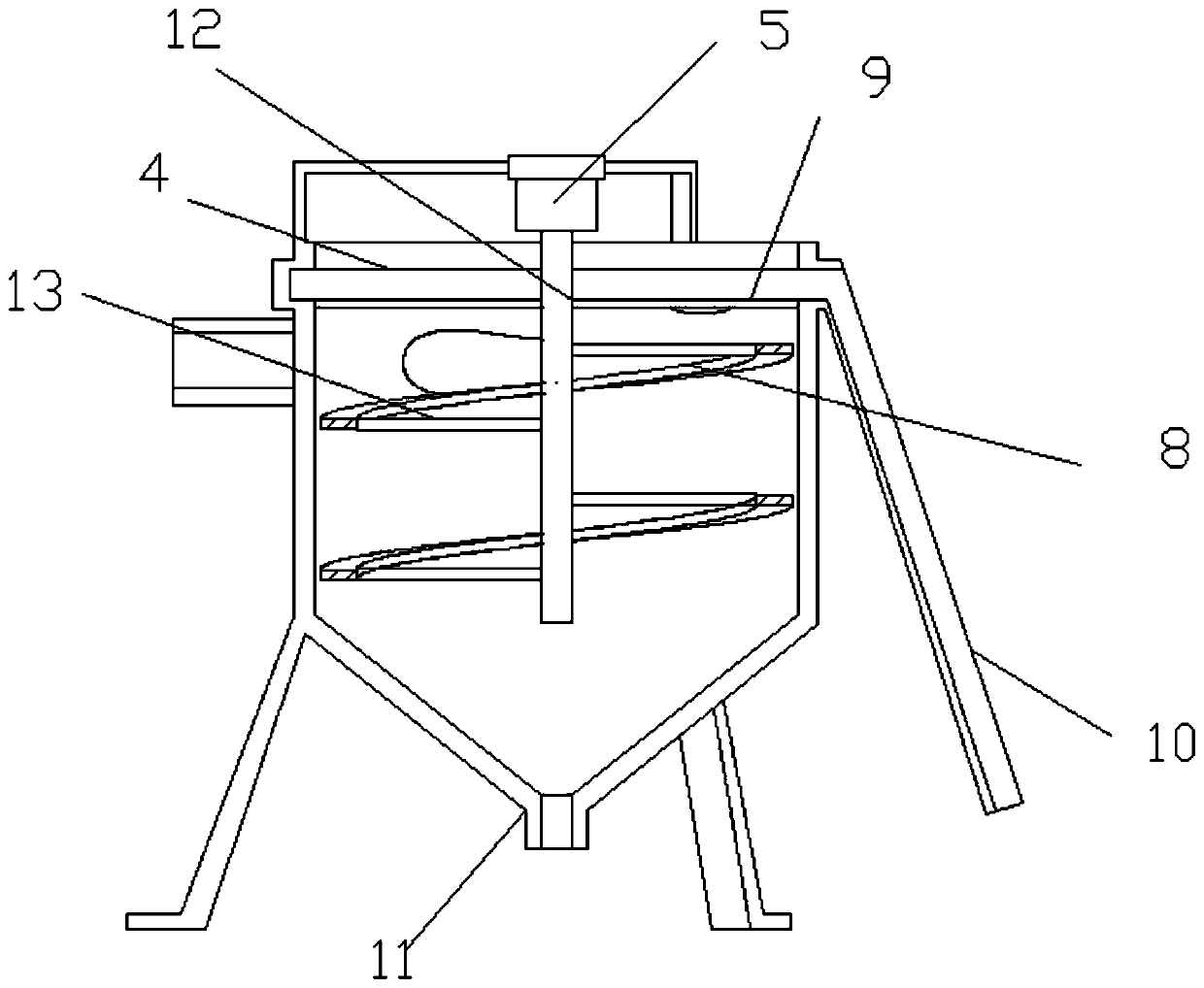

[0026] see Figure 1-3 , a device for removing floating sludge in a sewage treatment pool, comprising a cylinder body 2 and a motor 5 . The bottom of the cylinder body 2 is fixedly provided with several support legs 1, and the support legs 1 have a supporting effect on the cylinder body 2, and the cylinder body 2 can be fixed on the ground through the support legs 1. A water inlet pipe 3 is communicated with the side wall of the cylinder body 2, and sewage enters the interior of the cylinder body 2 from the water inlet pipe 3 for treatment. The top of the cylinder body 2 is fixed to the support frame 7, the middle position of the support frame 7 is fixedly connected with the mounting base 6, the bottom of the mounting base 6 is fixedly mounted with the motor 5, and the output shaft of the motor 5 is coaxially fixedly connected with the rotating shaft 12, and the rotation The shaft 12 is fixedly connected to the inner end of the driving rod 4 and the connecting rod 13, and the...

Embodiment 2

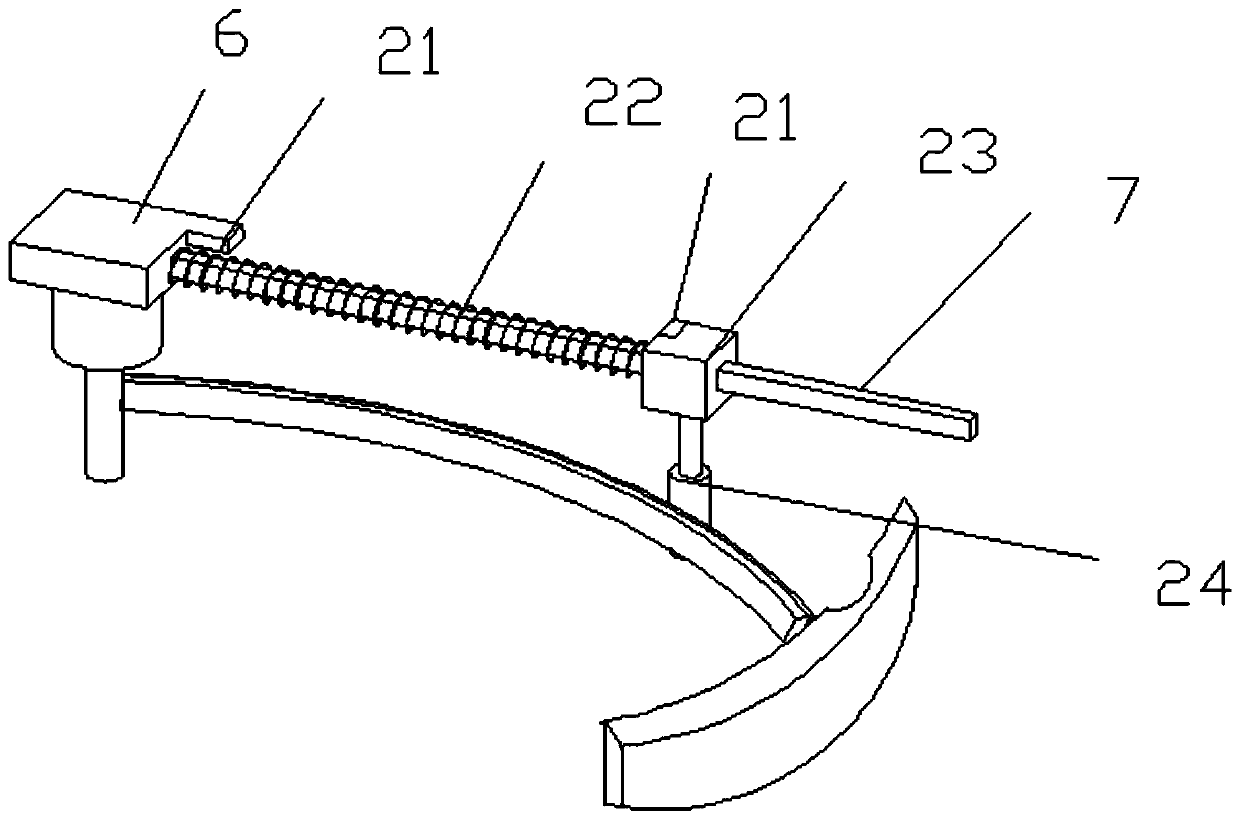

[0030] see Figure 4-5, on the basis of Embodiment 1, the shifting rod 4 includes a rotating plate 16 and a supporting plate 14, the outer ends of the rotating plate 16 and the supporting plate 14 are connected in rotation through a rotating rod 15, and the rotating plate 16 can rotate counterclockwise, so that the floating The slag is dumped inside the collecting tank 9, and the section of the rotating plate 16 is an L-shaped structure, thereby facilitating the collection of scum. The outer end of rotating plate 16 is fixedly connected with protruding rod 17, and protruding rod 17 stretches into the lower edge bottom of material collecting tank 9 and contacts with it, and the lower edge bottom of material collecting tank 9 is provided with protruding 18, when pulling material Rod 4 rotates, and extension rod 17 rotates to the below of protrusion 18, and protrusion 18 extrudes extension rod 17, thereby rotating plate 16 is rotated, and rotating plate 16 is set off, thereby the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com