An underground oil storage facility

A kind of storage equipment and oil technology, which is applied in the direction of separation method, filtration separation, liquid distribution, transportation or transfer device, etc. It can solve the problems of filter plate clogging, high energy consumption, and low efficiency of oil storage, so as to avoid clogging of residues, Improve the purity and improve the effect of removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

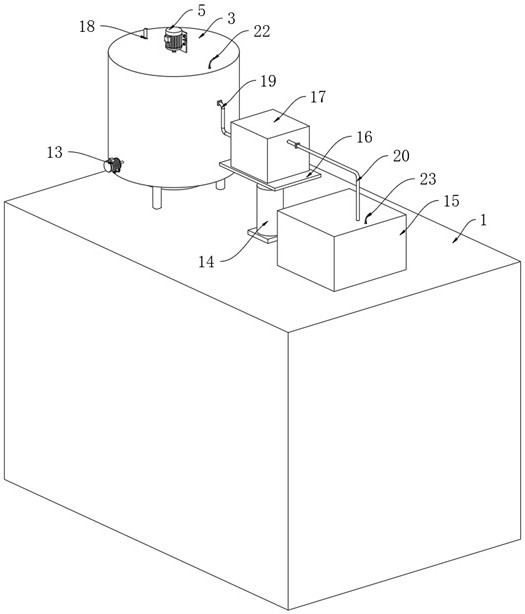

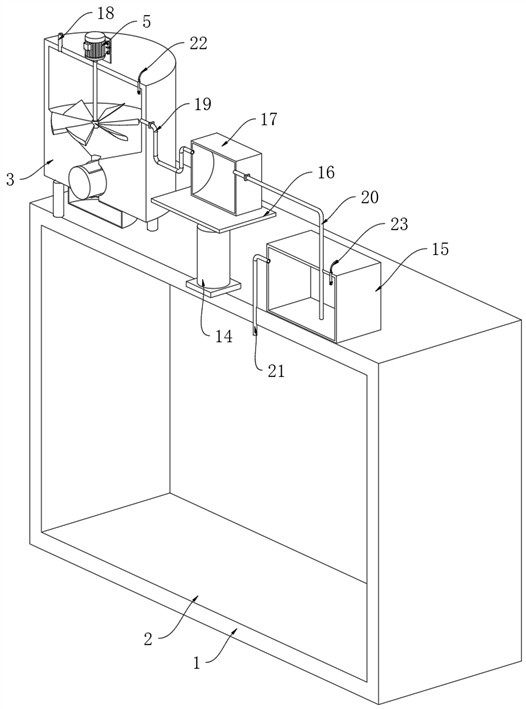

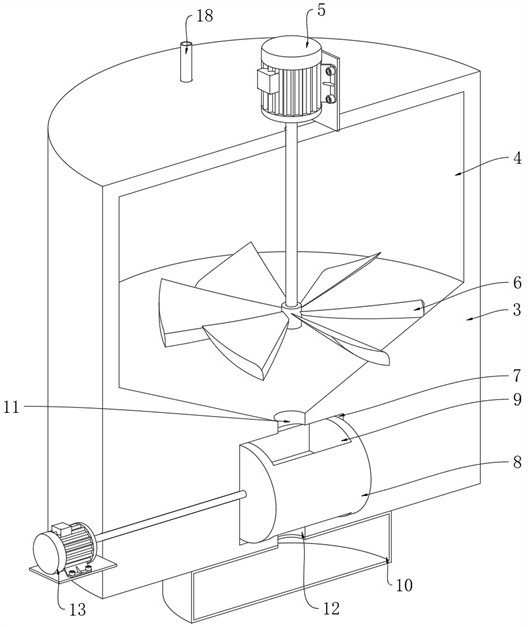

[0016] refer to Figure 1-5 , an underground oil storage device, comprising a foundation 1, characterized in that an oil storage depot 2 for storing oil is opened in the foundation 1, and a centrifugal tank 3, an electric telescopic rod 14 and an overflow tank 15 are respectively fixedly installed on the upper end surface of the foundation 1 , and the electric telescopic rod 14 is located between the centrifuge tank 3 and the overflow box 15, a centrifuge chamber 4 is coaxially opened in the centrifuge tank 3, and the bottom wall of the centrifuge chamber 4 is conical, and the level of the bottom wall of the centrifuge chamber 4 is The elevation is above the overflow box 15, the centrifuge chamber 4 is provided with a centrifugal mechanism, the centrifuge tank 3 is provided with a collection mechanism, the side wall of the centrifuge tank 3 is provided with a transfer mechanism that cooperates with the collection mechanism, and the upper end surface of the electric telescopic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com