High-pressure copper finger touch fixture and clamping finger touch method thereof

A high-voltage copper contact finger and contact finger technology, used in clamping, manufacturing tools, measuring/indicating equipment, etc., can solve the problems of reducing dielectric strength, shortening the service life of copper contact fingers, and poor removal consistency, and improving automation. degree, improve burr removal efficiency and burr removal quality, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

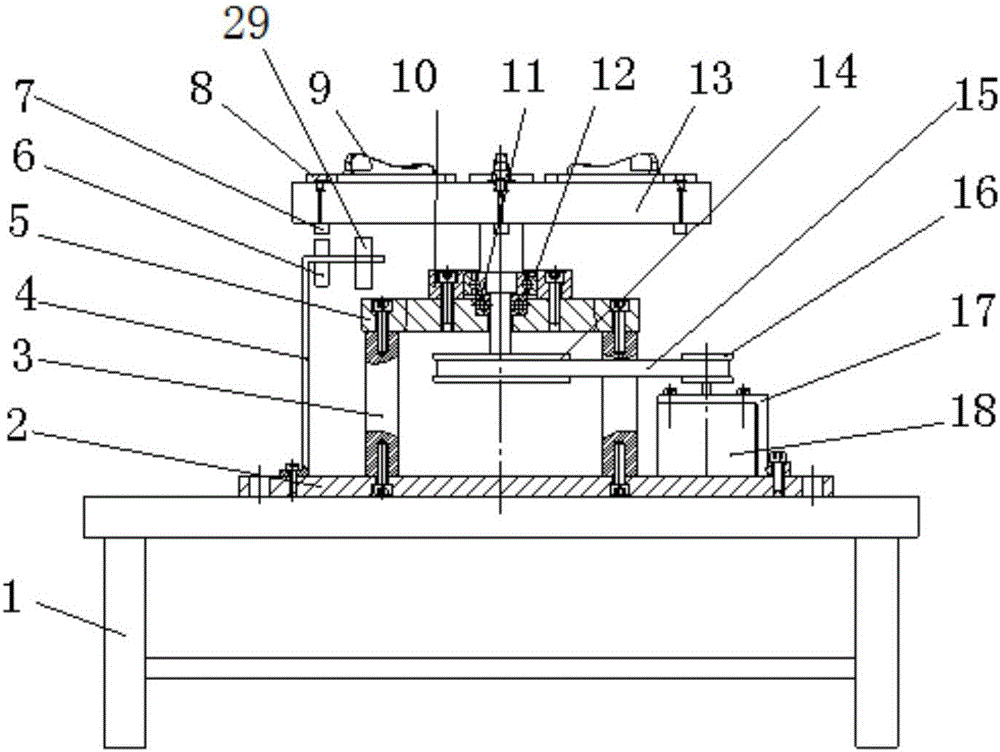

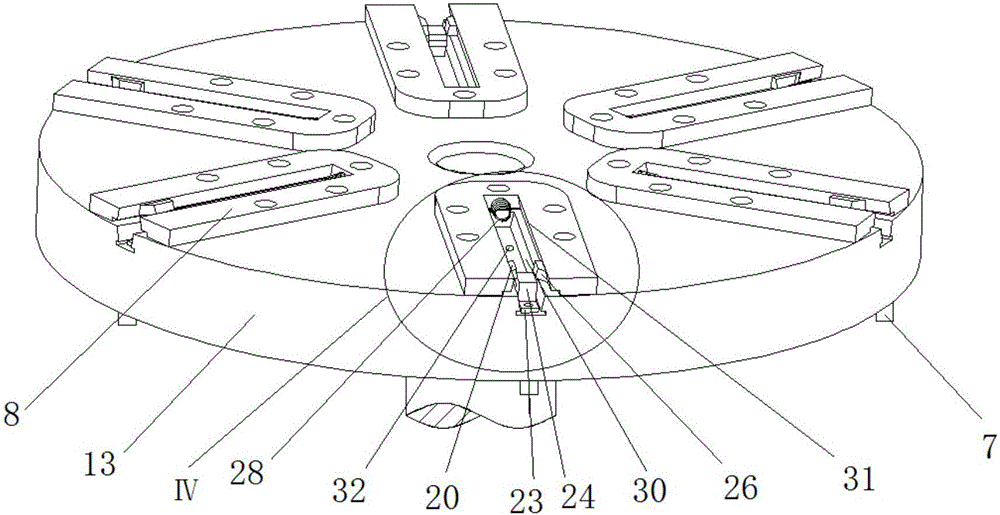

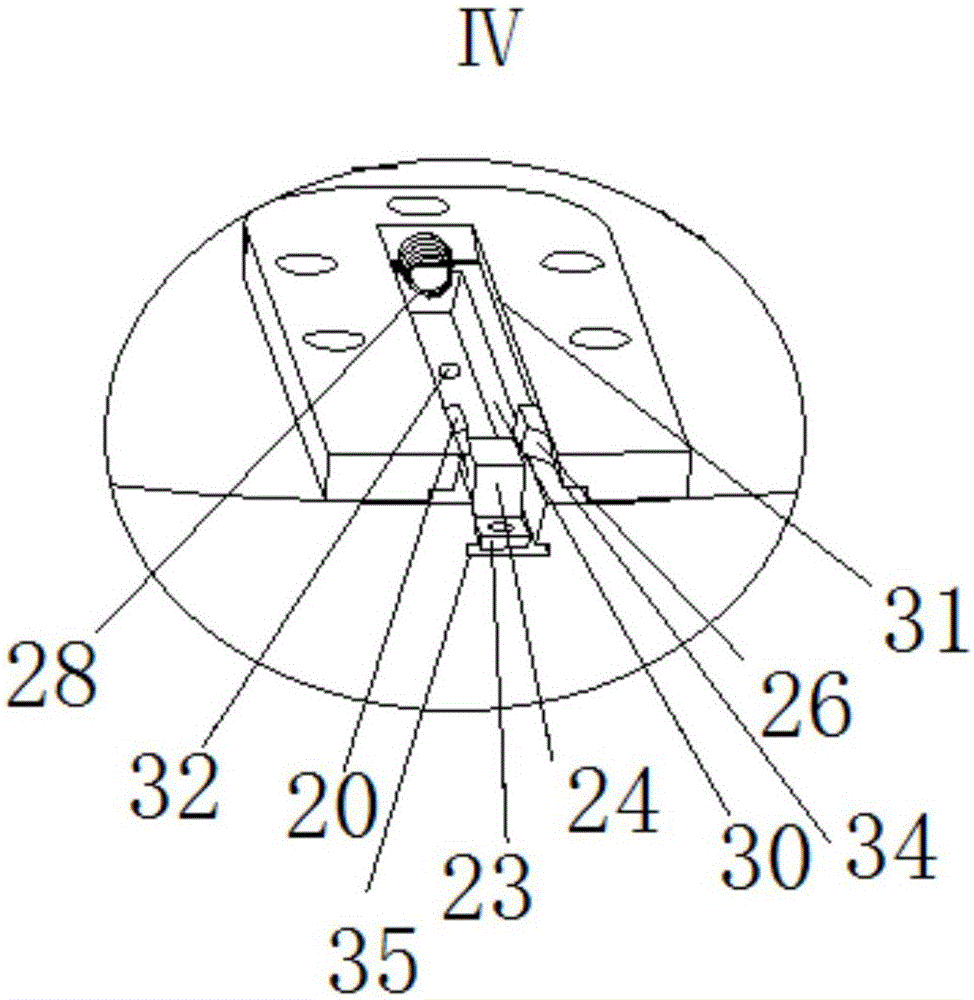

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] The invention provides a fixture for high-voltage copper contacts, such as Figure 1-Figure 9 As shown, it includes a base 2, a detection mechanism and an indexing mechanism are connected to the base 2, and a finger clamping mechanism is connected to the indexing mechanism;

[0034] The detection mechanism includes a sensor mounting frame 4, the sensor mounting frame 4 is connected to the base 2, and a proximity sensor 6 and a photoelectric sensor 29 are installed on the sensor mounting frame 4;

[0035] The stylus clamping mechanism includes a stylus tray 13, on which a stepped shaft is arranged, and two or more than two stylus pressure plates 8 are connected to the stylus tray 13, and the bottom of each stylus tray 13 is provided with There are set screws 7 with the same number and relative positions as the contact finger pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com