Pipeline cleaning method and device

A technology for cleaning pipes and cleaning devices, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problem of ineffective cleaning of dirt and other problems, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

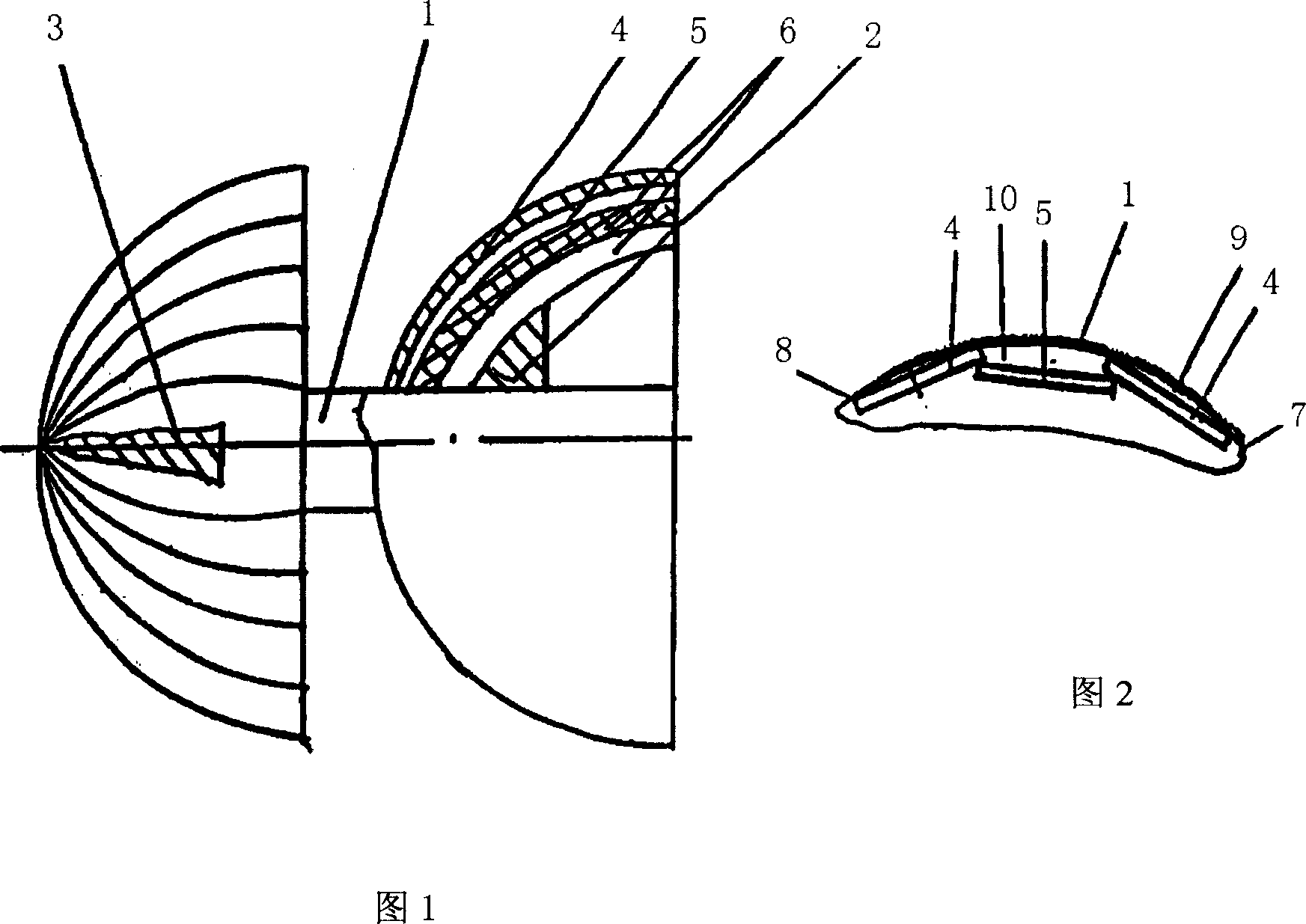

[0061] The device shown in Figures 1 and 2 includes a shaft 1 with shaft sleeves 2, 3, on which elastic sheets 4, 5 and elastic soft sheets 6 are arranged in a staggered manner. The elastic sheets 4 and 5 are in the shape of thin sheets, and their edges 8 are in contact with the pipe wall 7 to form fan-shaped gaps 9 with the pipe wall. The upper elastic sheet 4 forms a gap 10 with the lower elastic sheet 5 and the tube wall 7 . The slot 9 has a smaller cross-section than the slot 10 .

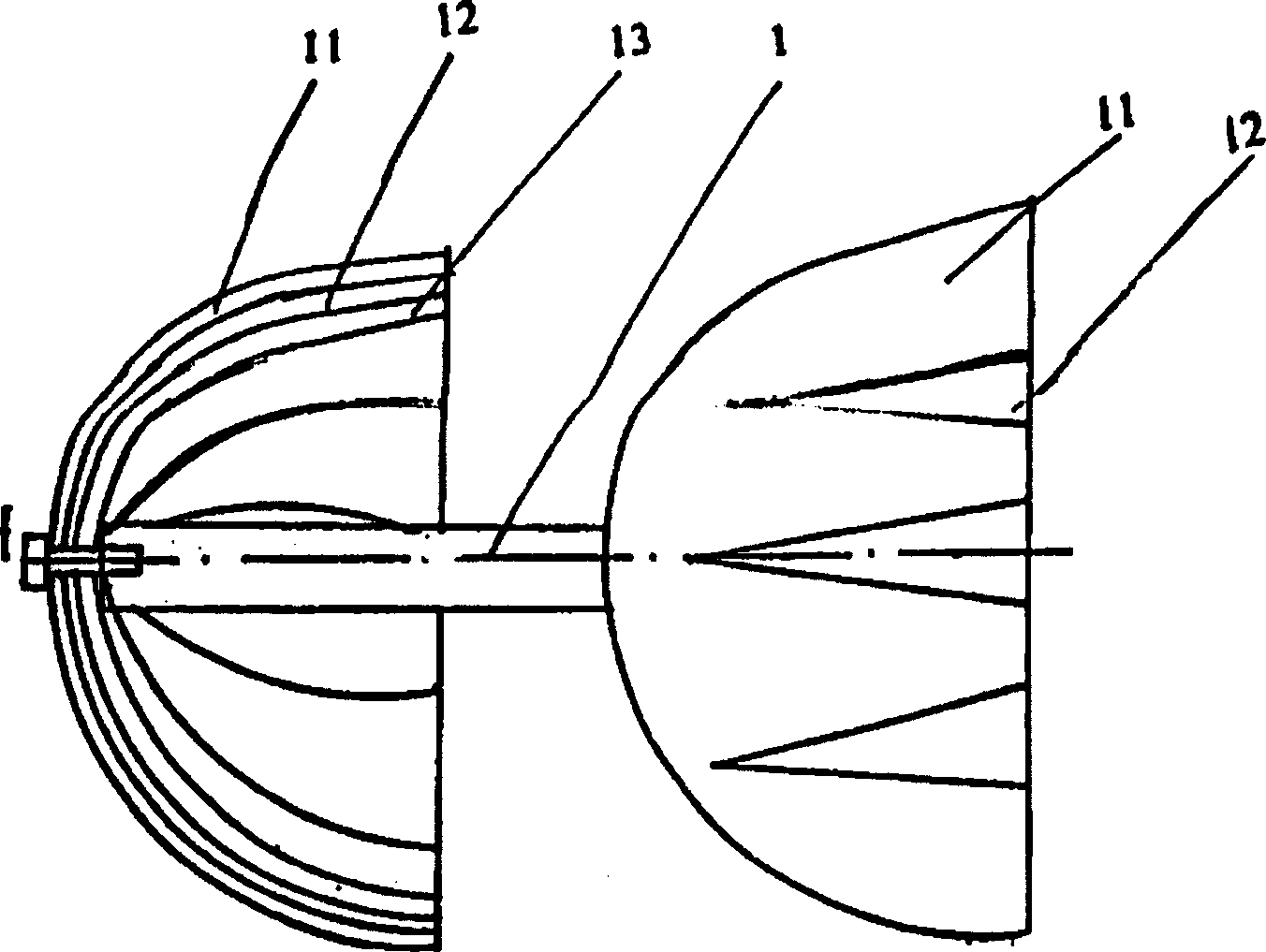

[0062] image 3 The shown device includes a shaft 1 on which bowl-shaped elastic sheets 11 with grooves 12 and elastic soft sheets 13 are arranged in a staggered manner.

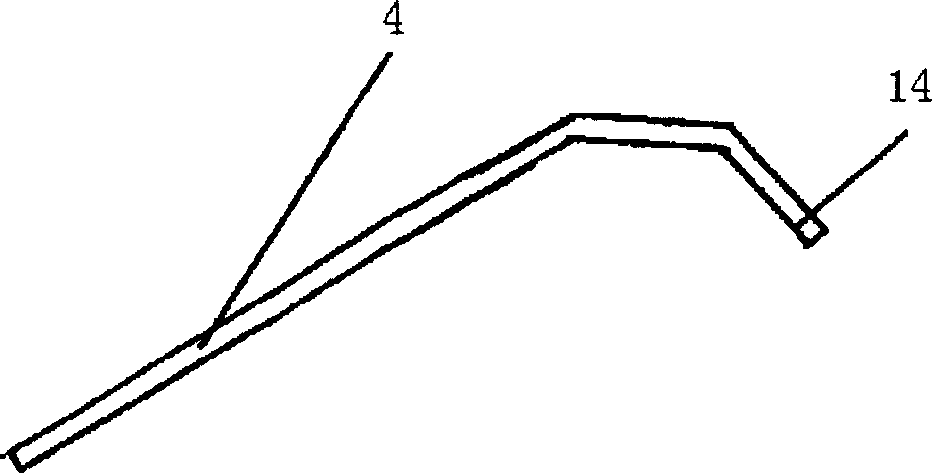

[0063] Figure 4 The elastic sheet 4 ( 5 ) with bent ends 14 is shown.

[0064] Figure 5 The device shown comprises a cleaning device 15 and balls 16 (several) installed in a pipe 17 and is equipped with an air supply system 18 and a pump 19 .

[0065] Figure 6 Represent upper elastic piece 4, and its end is triangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com