Patents

Literature

51results about How to "Play the role of grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

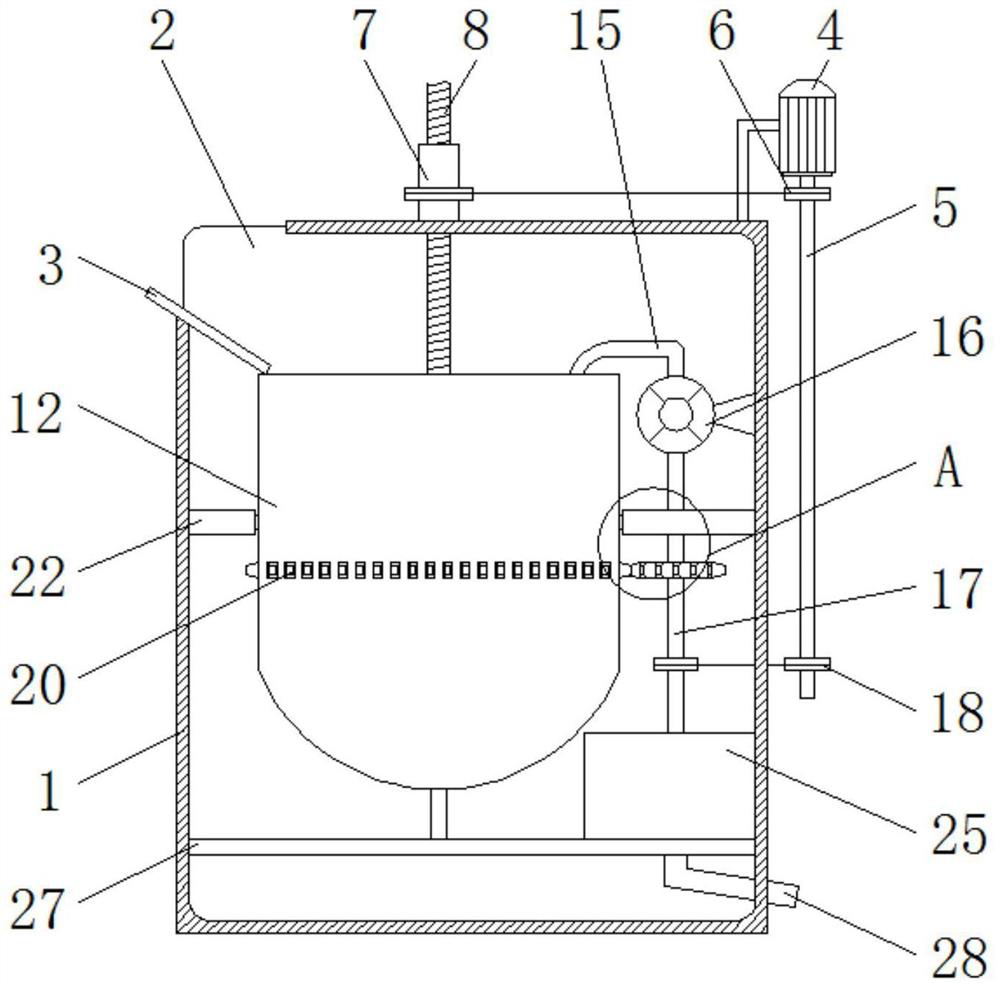

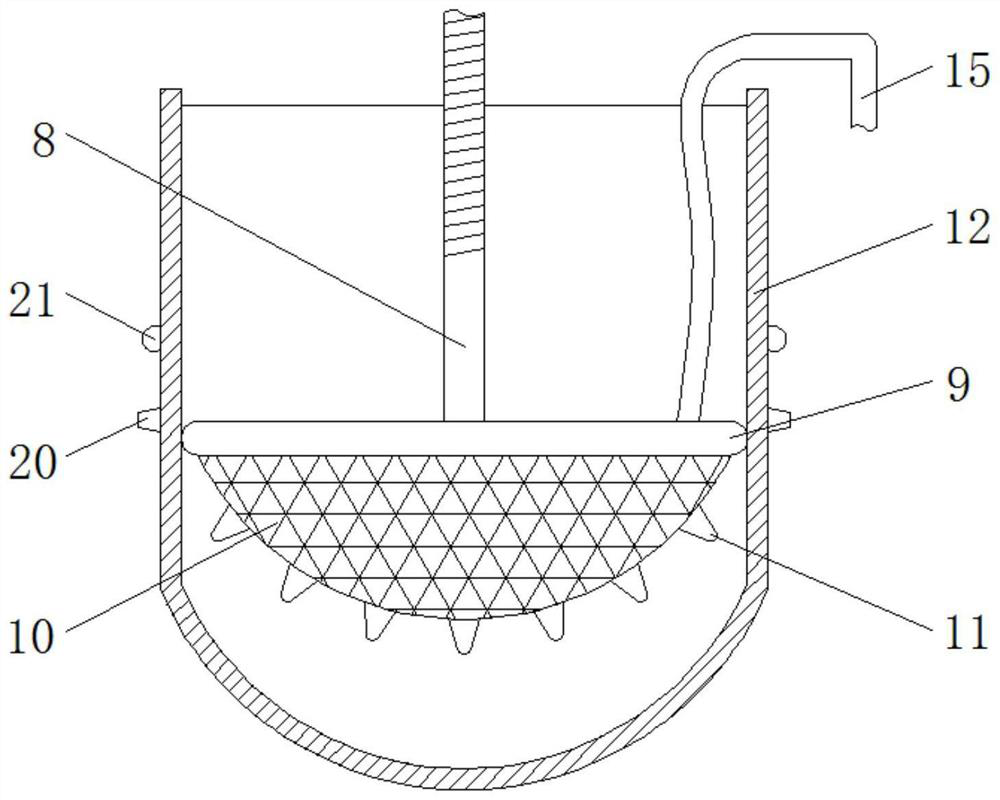

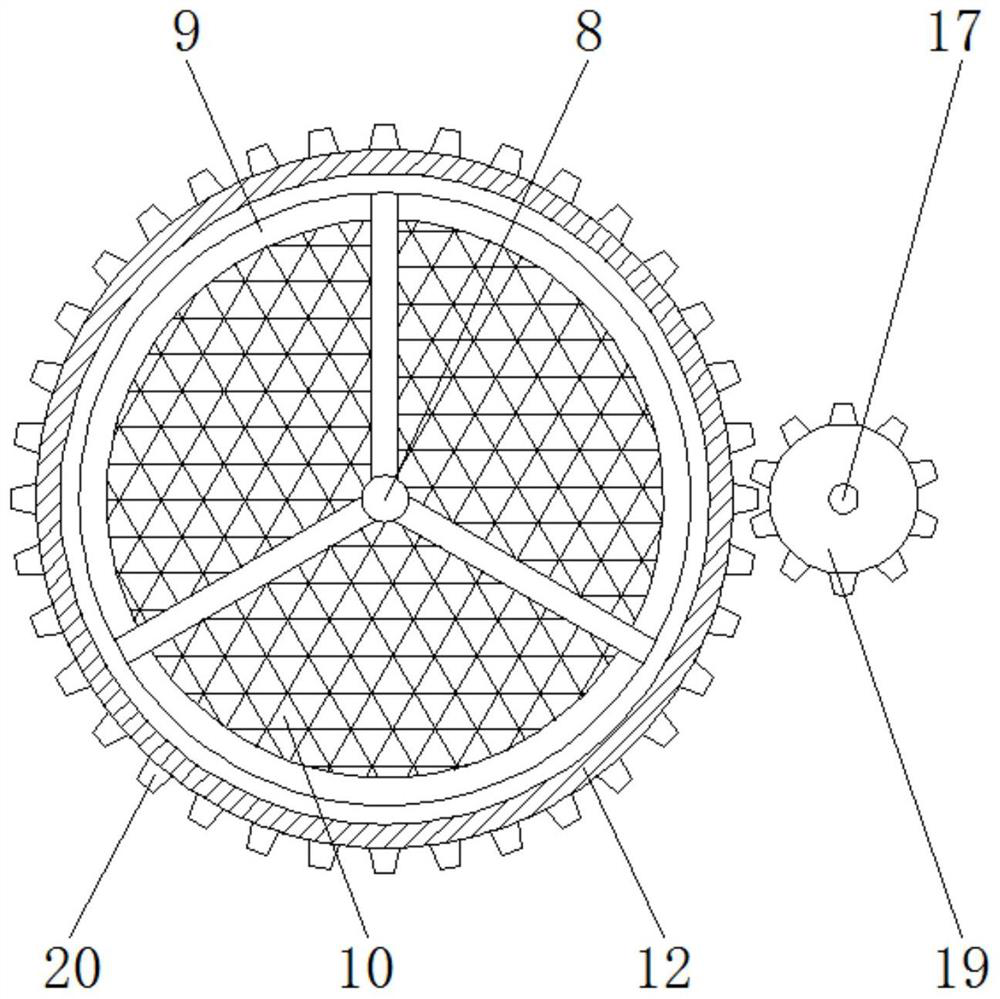

Grape juice extractor

InactiveCN105077520AIncrease contact areaPress the juice thoroughlyJuice extractionGrape wineEngineering

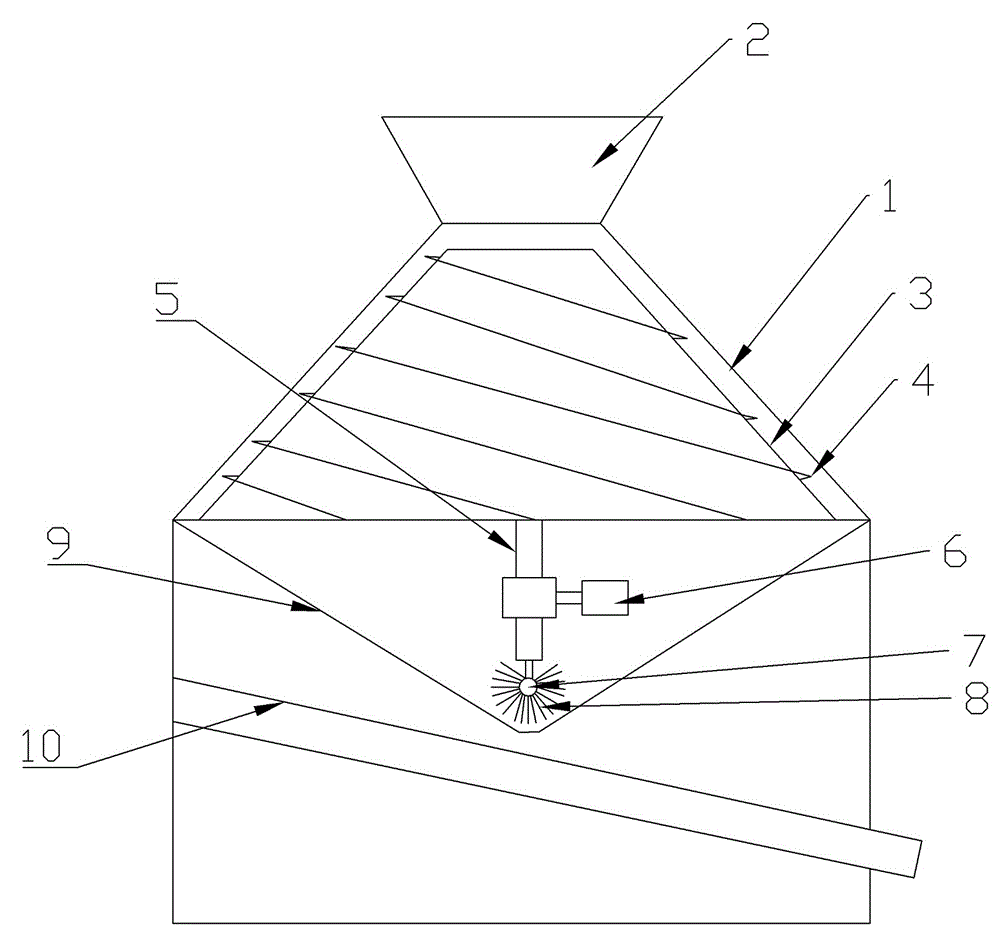

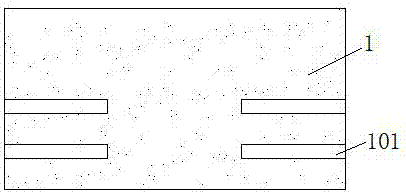

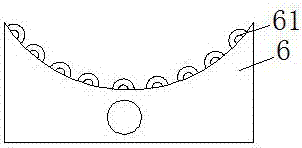

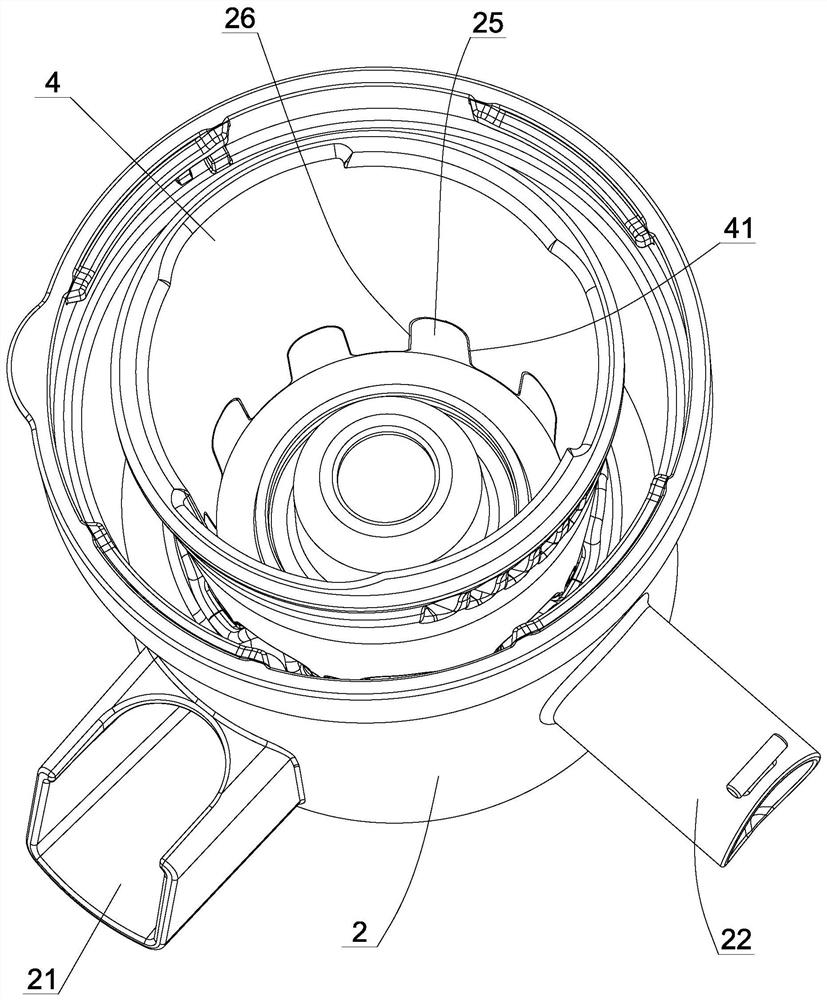

The invention relates to mechanical grape crushing and processing equipment, in particular to a grape juice extractor for grade seed and peel removal. The grape juice extractor for grade seed and peel removal comprises a circular truncated cone shaped grinding box, wherein a circular truncated cone shaped grinding disc matched with the grinding box is arranged in the grinding box, grinding teeth are arranged on the side face of the grinding disc, an axial rotary shaft and a motor are arranged in the grinding disc, and an output shaft of the motor is connected with the rotary shaft. An inlet is formed in the top end of the grinding box, a filtering mechanism is arranged at the bottom end of the grinding box and comprises a filter screen and a stirring ball for stirring grape pomace on the filter screen, the stirring ball is connected with the bottom of the rotary shaft, the filter screen is inverted-cone-shaped, and the top of the filter screen is connected with the bottom end of the grinding box. A conveying trough for receiving juice is arranged under the filter screen. The grape juice extractor makes grape juice in a mechanical way, is high in production efficiency and thorough in juice extraction, is not in contact with the outside in the whole process, is clean and hygienic and is suitable for popularization and application in grape juice production and wine production.

Owner:重庆龙佰绪生态农业开发集团有限公司

Copper-based powder metallurgy brake pad material as well as preparation method and application thereof

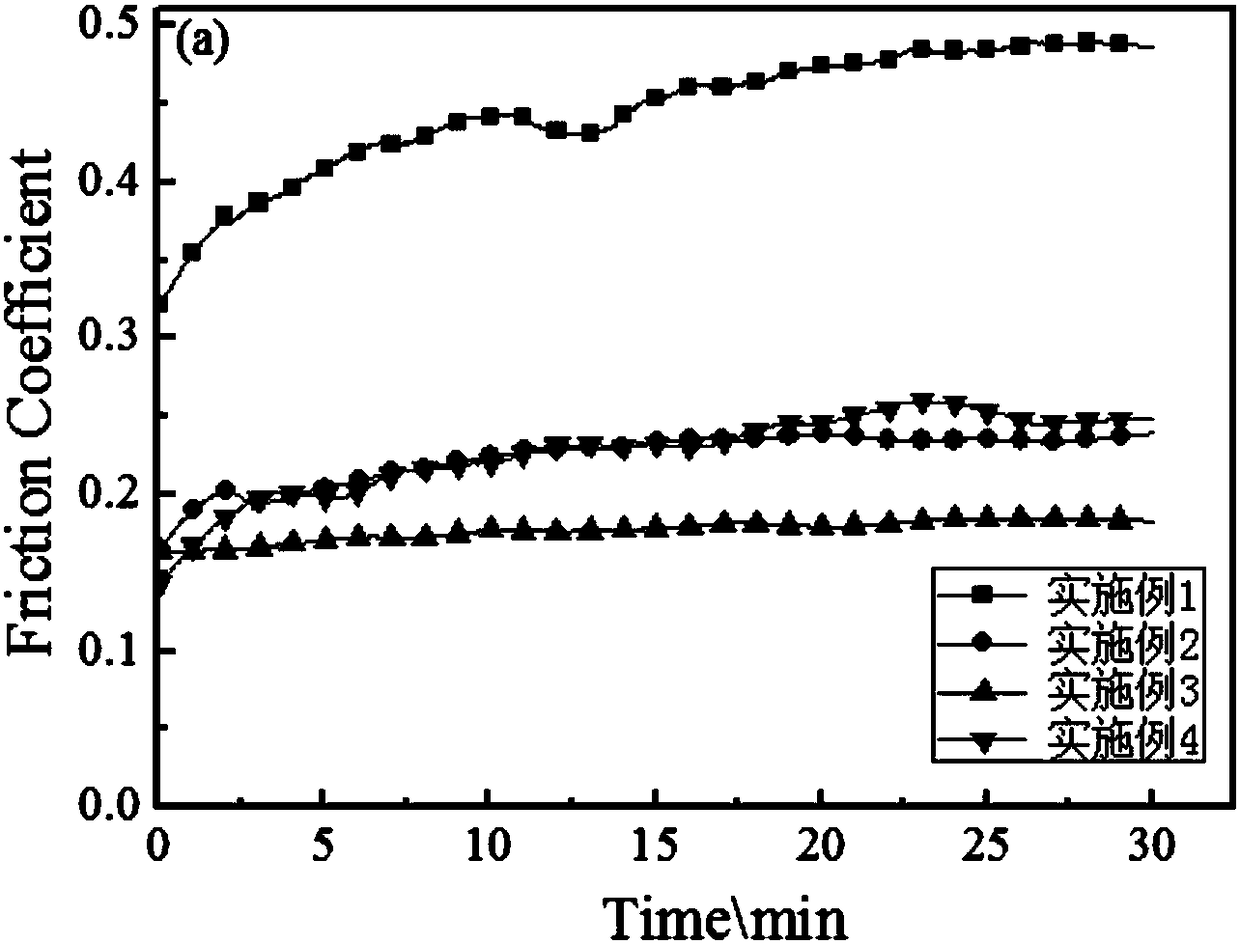

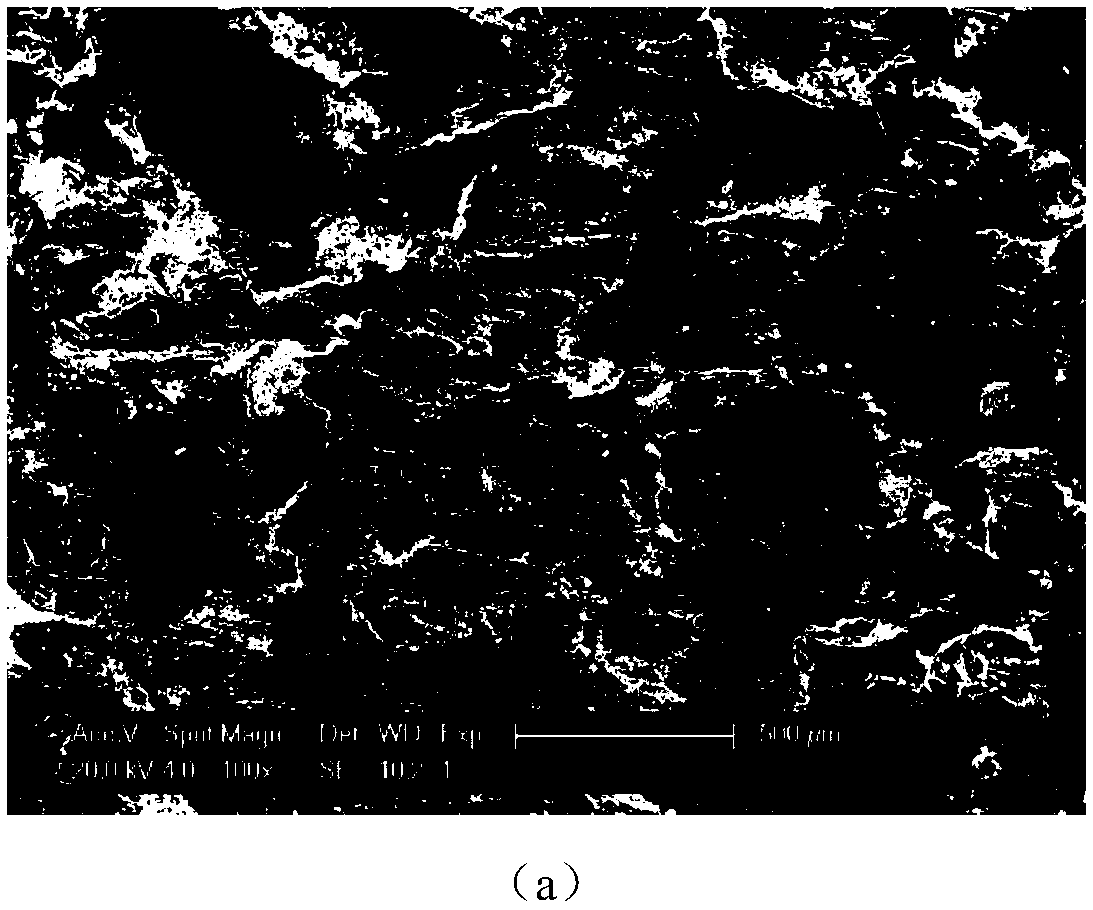

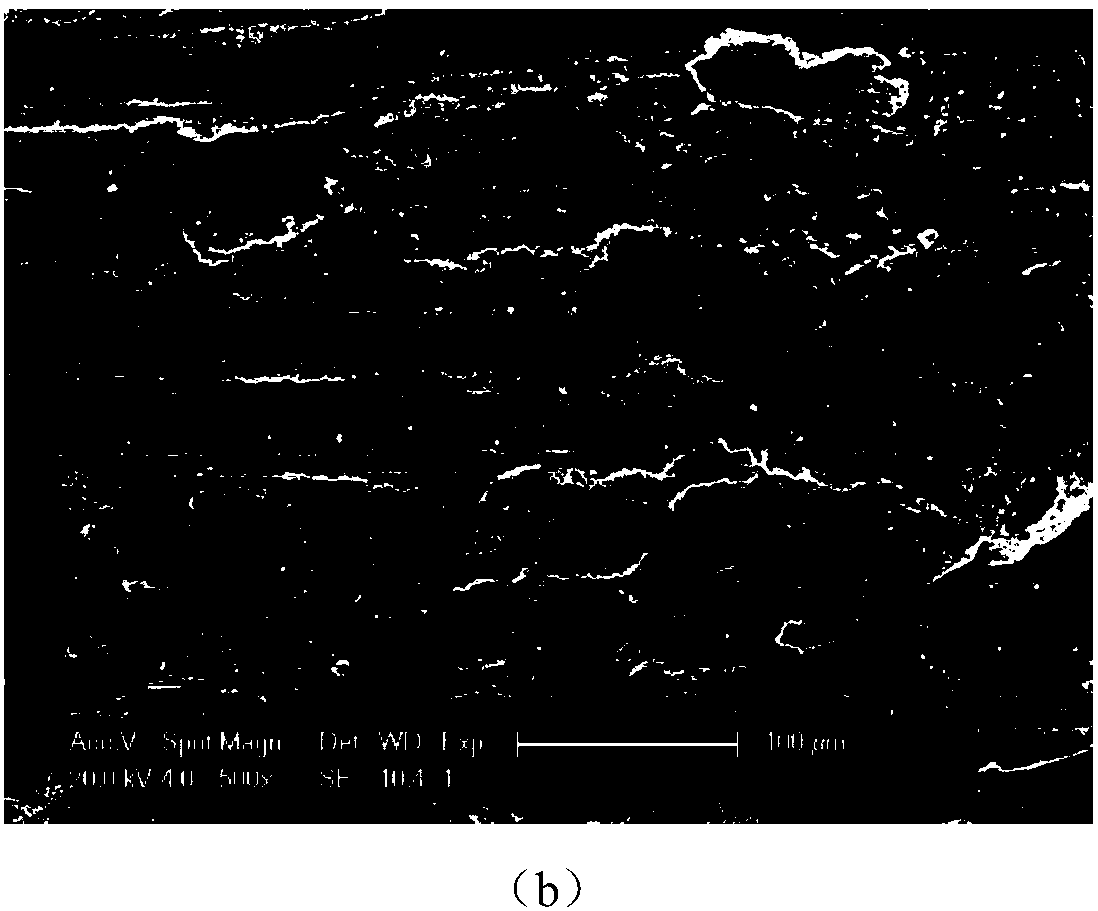

The invention discloses a copper-based powder metallurgy brake pad material as well as a preparation method and application thereof. The copper-based powder metallurgy brake pad material is prepared from the following raw materials in percentage by weight: 54 weight percent to 67 weight percent of copper powder, 13 weight percent of graphite, 4 weight percent to 17 weight percent of iron powder, 8weight percent to 14 weight percent of a ferrochrome alloy, 1 weight percent to 4 weight percent of silicon carbide and 1 weight percent to 4 weight percent of silicon dioxide; the preparation methodof the copper-based powder metallurgy brake pad material comprises the following steps: 1) weighing the raw materials according to the ratio and putting the raw materials into a mixer and uniformly mixing; 2) filling the mixed raw materials into a mold; carrying out hot pressing sintering or spark plasma sintering under the protection of a vacuum atmosphere or nitrogen gas to obtain the brake padmaterial with excellent comprehensive performance. The prepared brake pad material has high density and rigidity, stable friction coefficient, abrasion resistance and excellent comprehensive performance, and can meet the requirements on braking friction plates of high-speed rail trains. The copper-based powder metallurgy brake pad material disclosed by the invention can be used for preparing a brake pad; the preparation method comprises the following steps: taking Q235 as a base material, and compounding and sintering the raw materials for preparing the copper-based powder metallurgy brake pad material and the base material through a hot pressing sintering technology, so as to obtain the brake pad.

Owner:SOUTHEAST UNIV

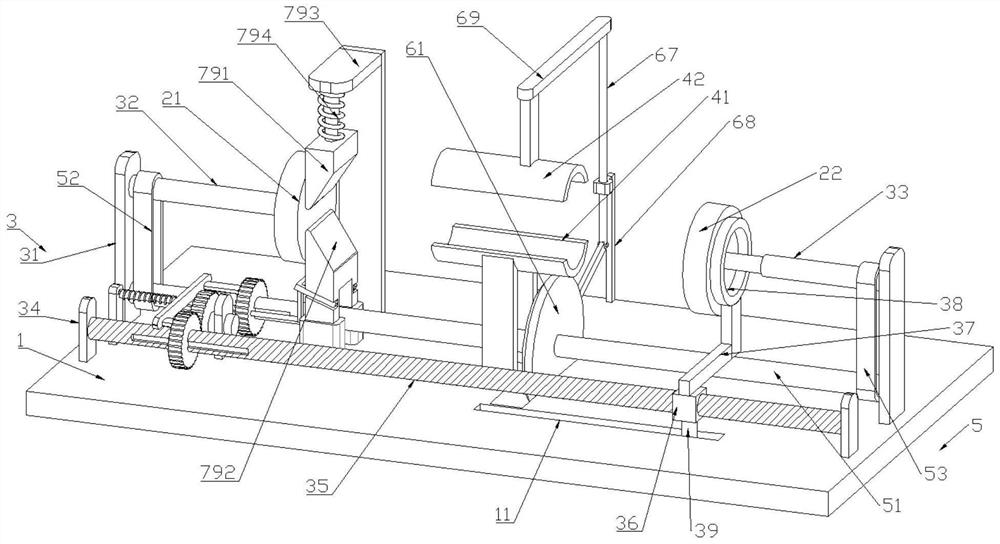

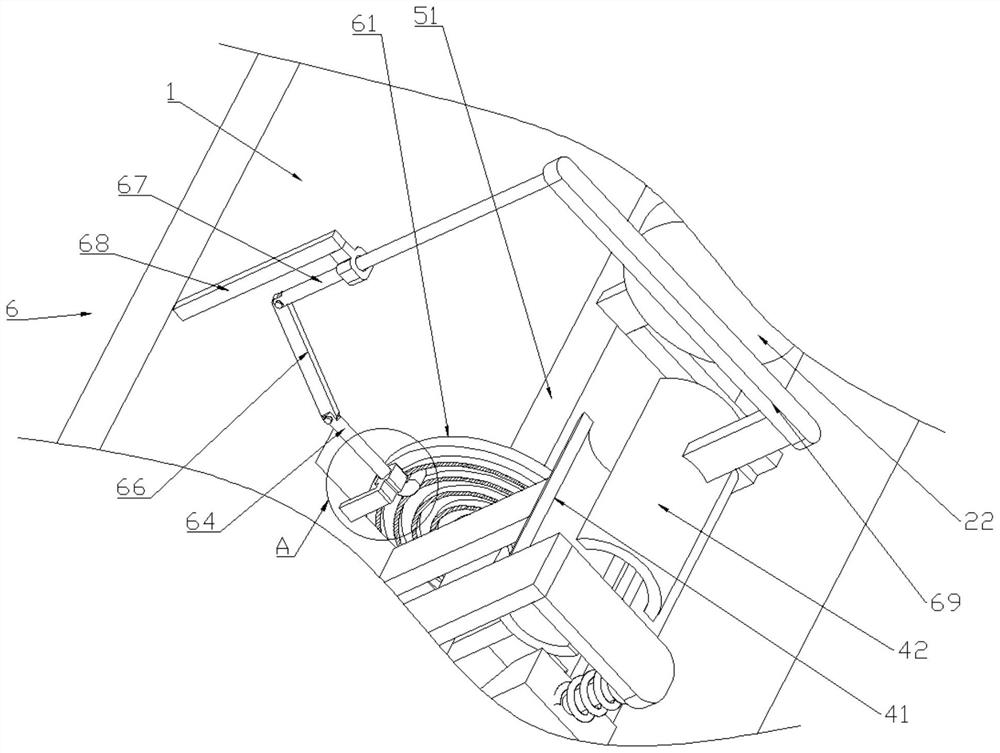

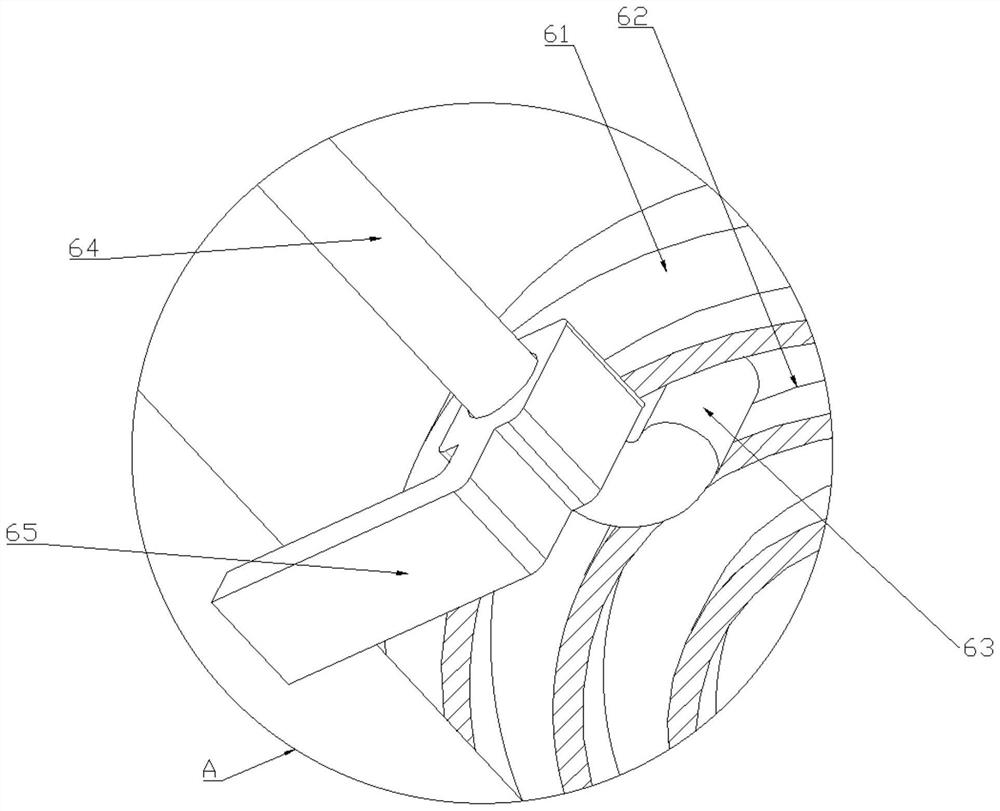

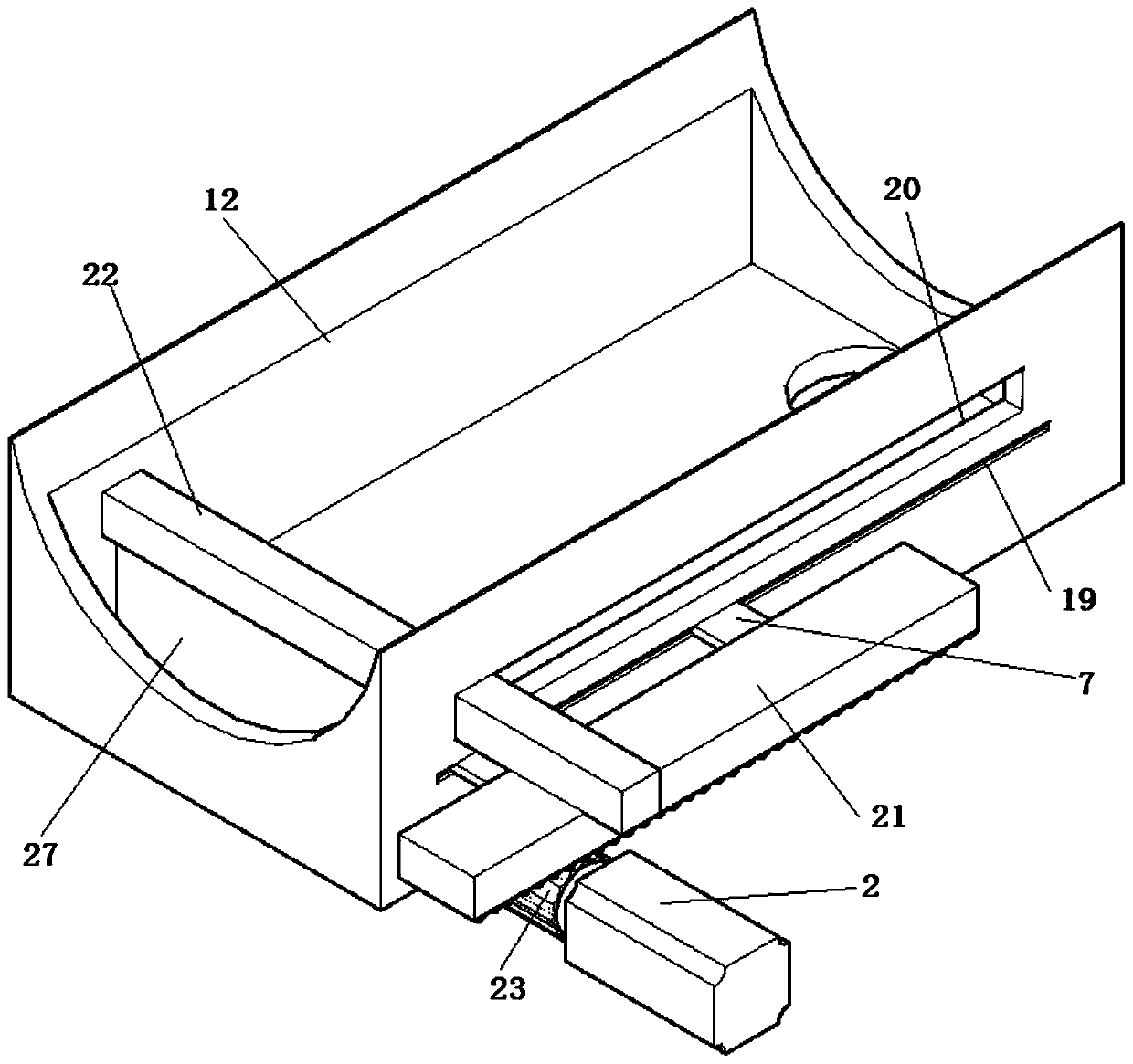

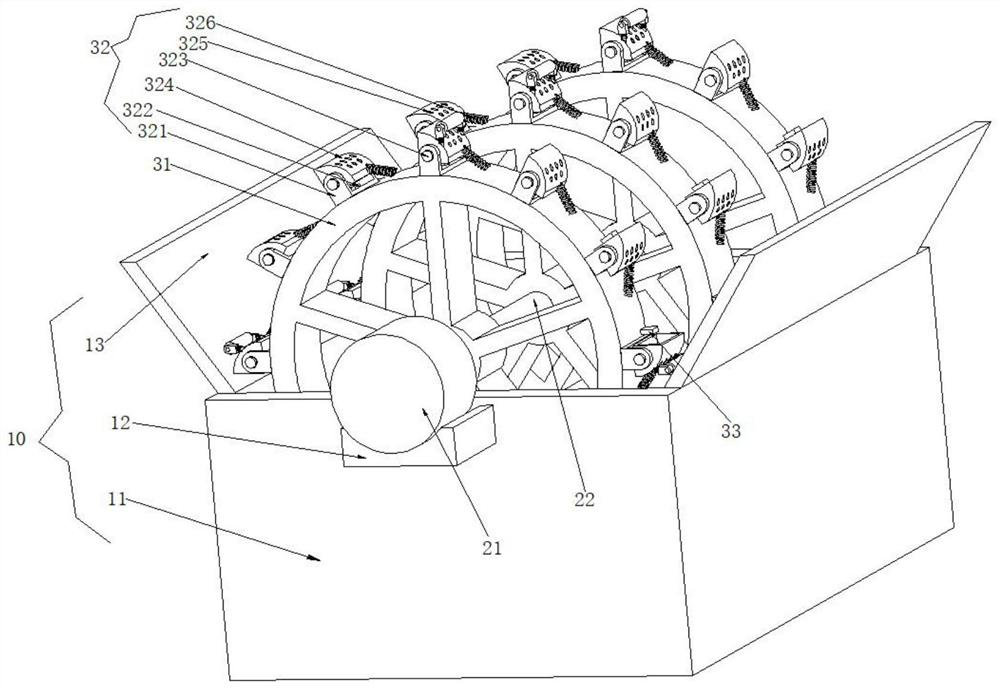

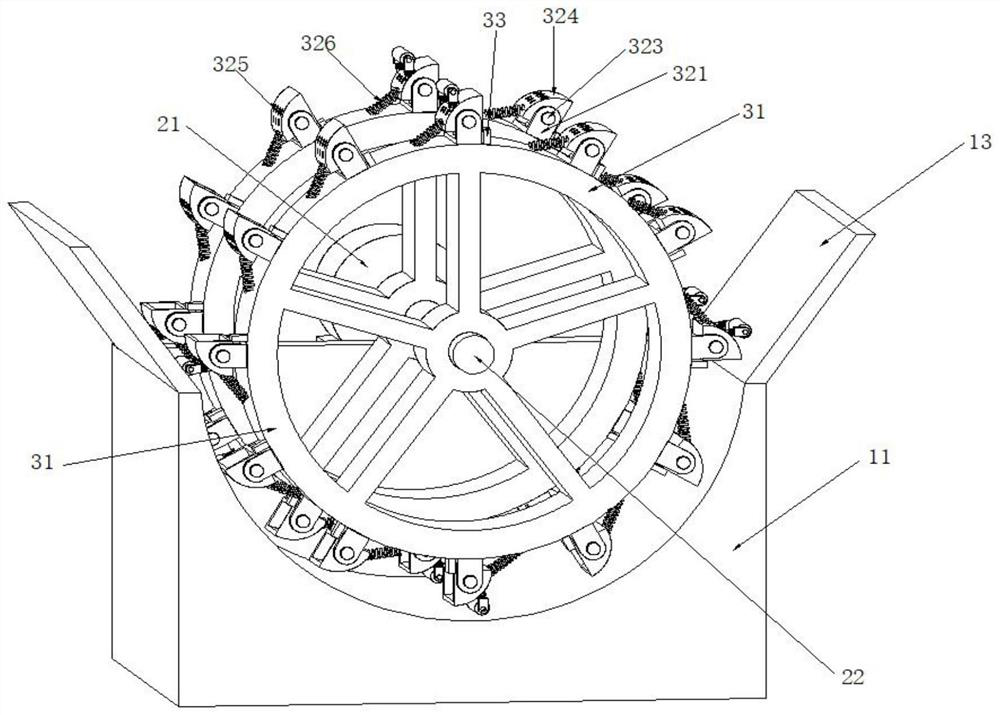

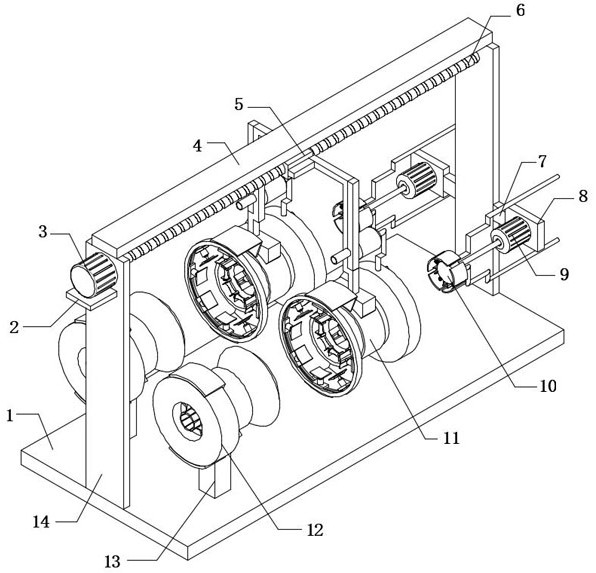

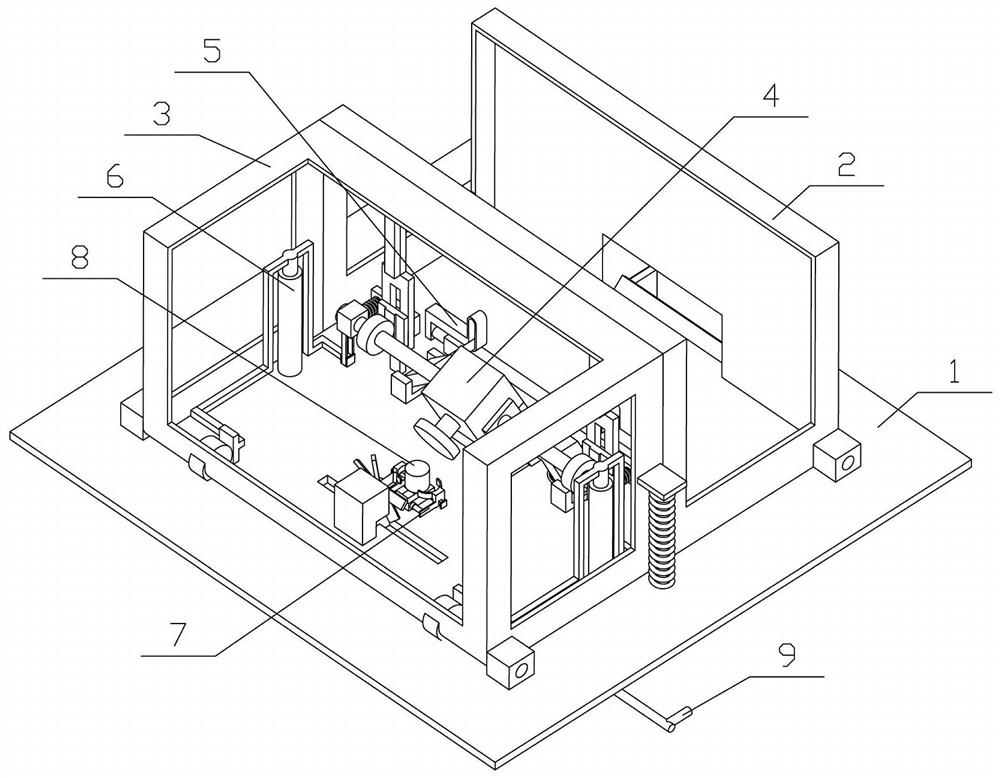

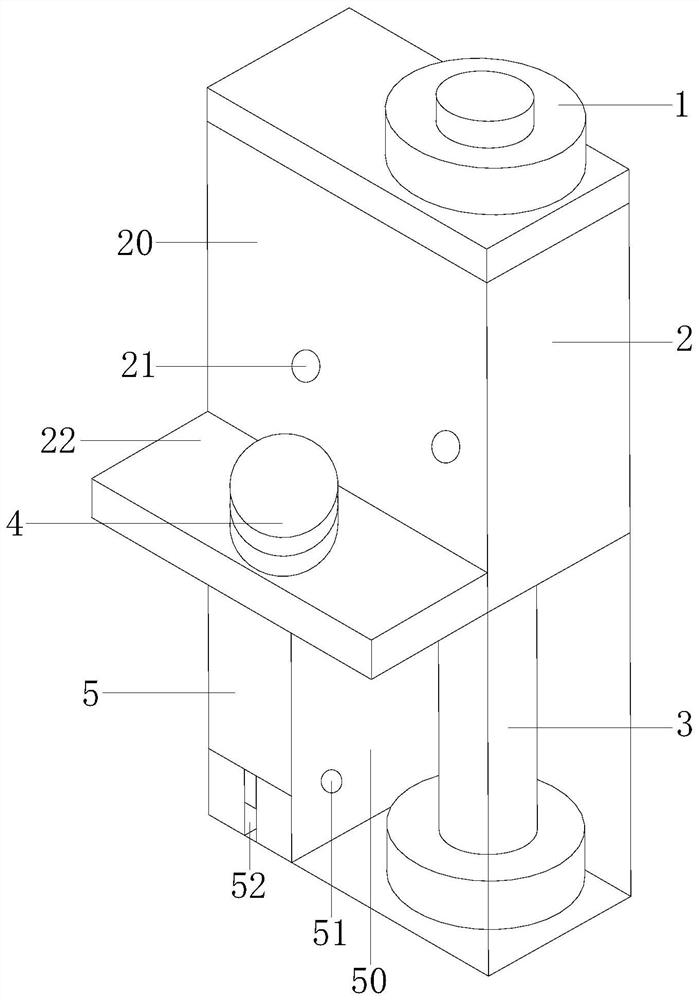

Intelligent grinding equipment for plastic pipe production

ActiveCN114800138APlay the role of grindingImprove comprehensivenessEdge grinding machinesPlastic recyclingEngineeringMaterials science

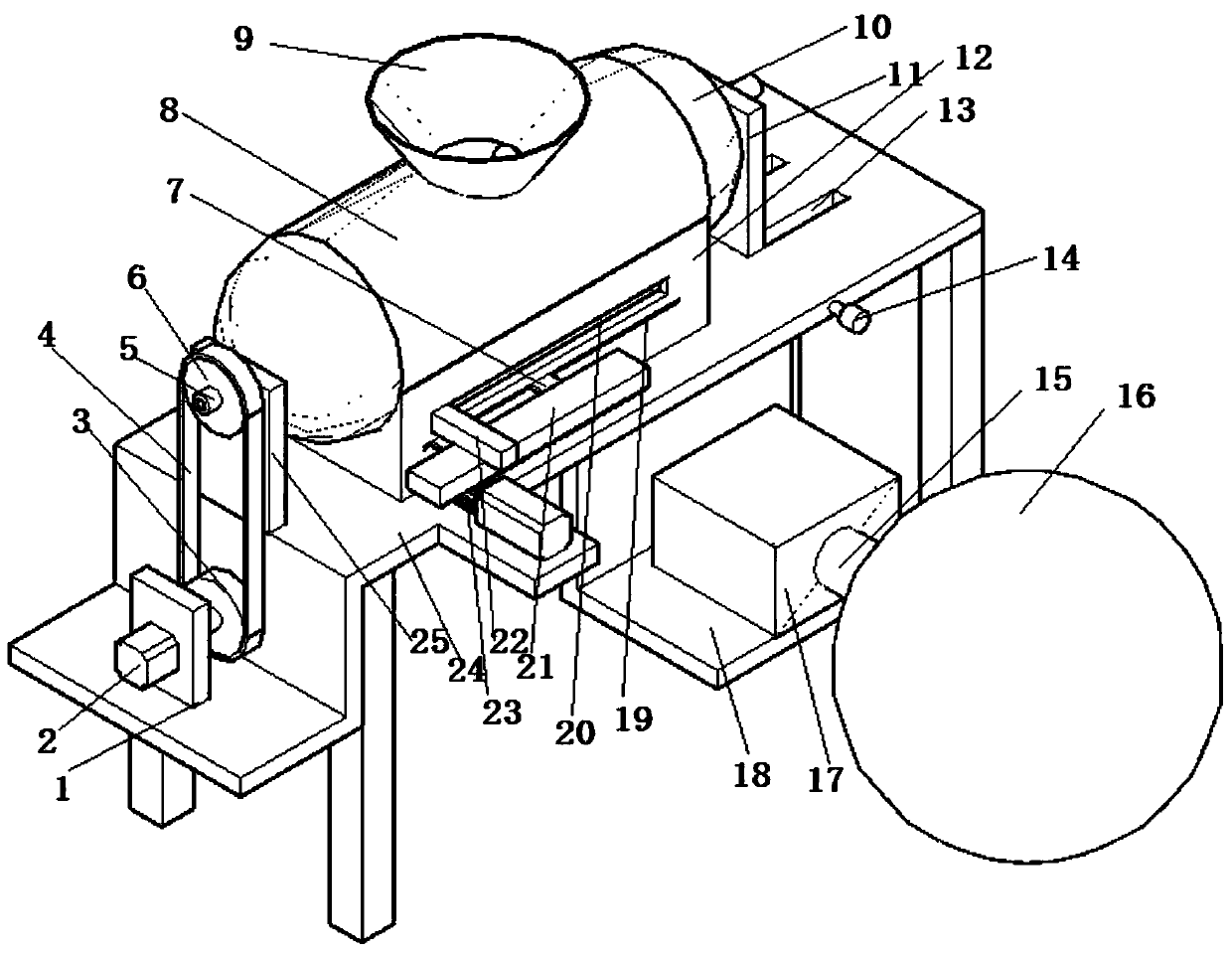

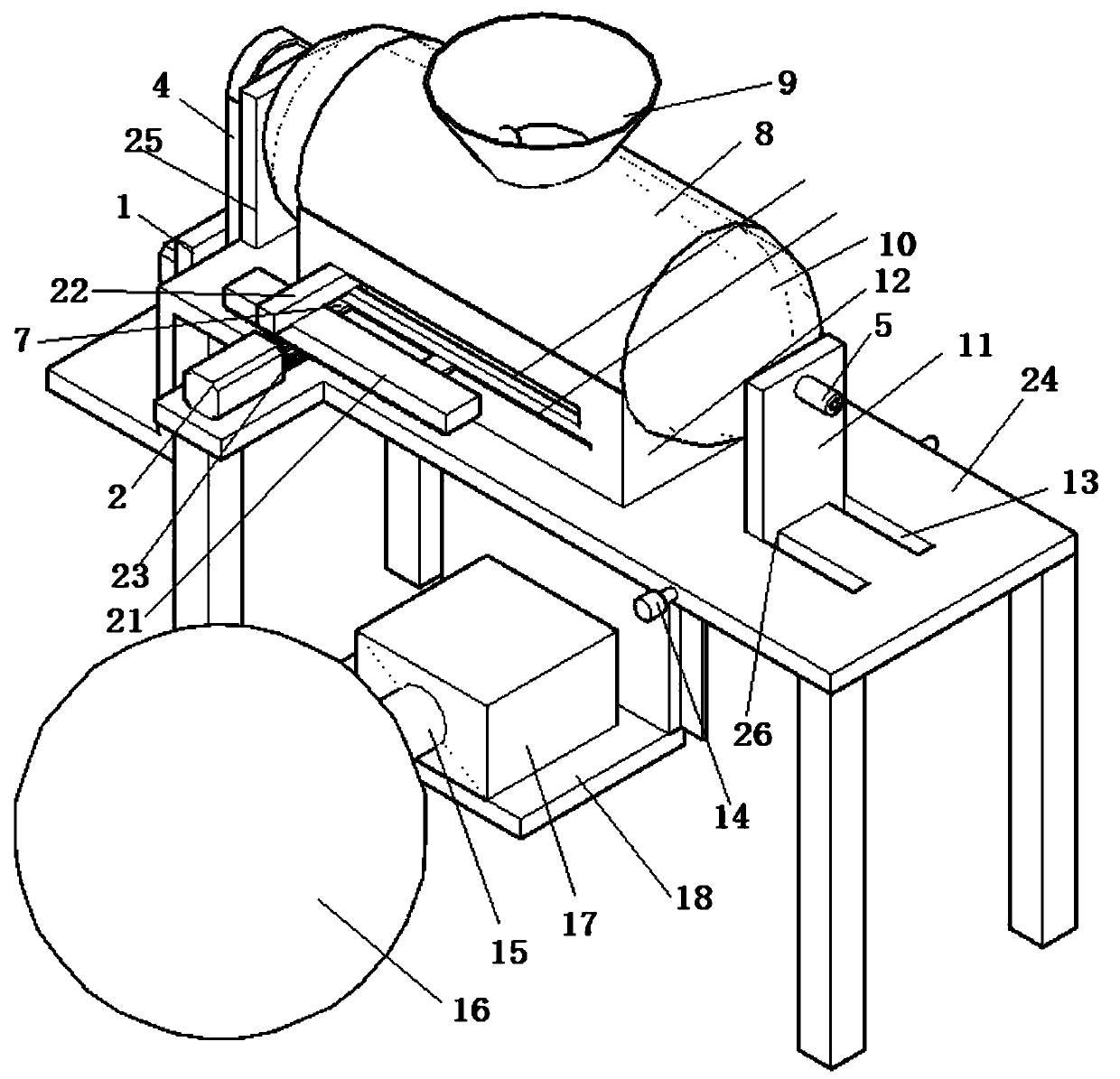

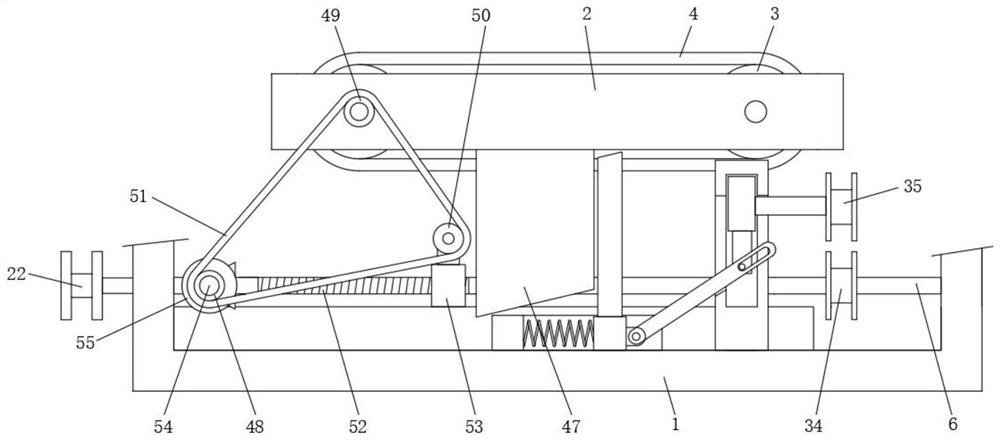

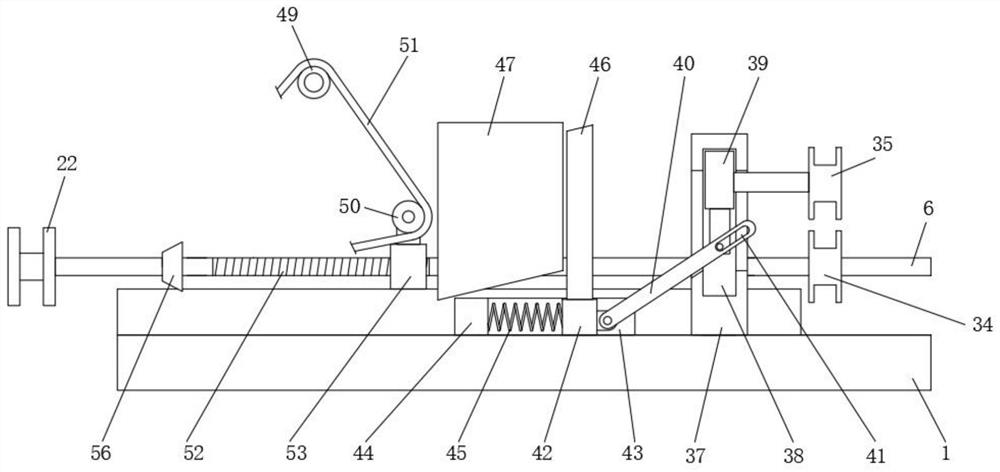

The invention discloses intelligent grinding equipment for plastic pipe production, which comprises a base, and a first circular grinding disc and a second circular grinding disc which are positioned above the base and are used for grinding two ends of a plastic pipe, a positioning clamping assembly used for driving the second circular grinding disc to move towards the side close to the first circular grinding disc to clamp the two ends of the plastic pipe is arranged above the base, and a first arc-shaped grinding plate and a second arc-shaped grinding plate which are used for grinding the surface of the pipe are arranged above the base. The first arc-shaped grinding plate and the second arc-shaped grinding plate are located between the first circular grinding disc and the second circular grinding disc, a supporting column is fixed between the first arc-shaped grinding plate and the base, and the second arc-shaped grinding plate is located above the first arc-shaped grinding plate. According to the device, the positioning and clamping assembly is arranged, so that the second circular grinding disc is conveniently driven to move towards one side close to the first circular grinding disc to clamp the positioning and clamping assembly of the plastic pipe, and the plastic pipe is preliminarily positioned.

Owner:赣州中世建材有限公司

Efficient precision part polisher

InactiveCN106863087APlay a role in anti-slipAvoid damageGrinding carriagesGrinding machinesElectric machineryEngineering

The invention discloses a high-efficiency precision parts grinding machine, which comprises a workbench. Both sides of the top of the workbench are provided with support plates. The top of the support plate is provided with a sliding plate. There is a driver, the bottom of the driver is provided with a grinding disc, the two sides of the top of the workbench are provided with a rotating motor, the inner side of the rotating motor is provided with a drill bit, the surface of the drill bit is sleeved with a fixed plate, and the fixed plate The bottom of the arc clamp is provided with an arc clamp, and the inner cavity of the arc clamp is provided with a pulley. The high-efficiency precision parts grinding machine, through the drive, grinding disc, rotating motor, drill bit, fixed plate, arc clamp, pulley, rolling rotator and rotating shaft, can play a role in the processing of precision parts. The function of grinding the surface, thus avoiding the need to manually rotate and grind the precision parts, thereby reducing work efficiency and consuming a lot of manpower and material resources.

Owner:李明科

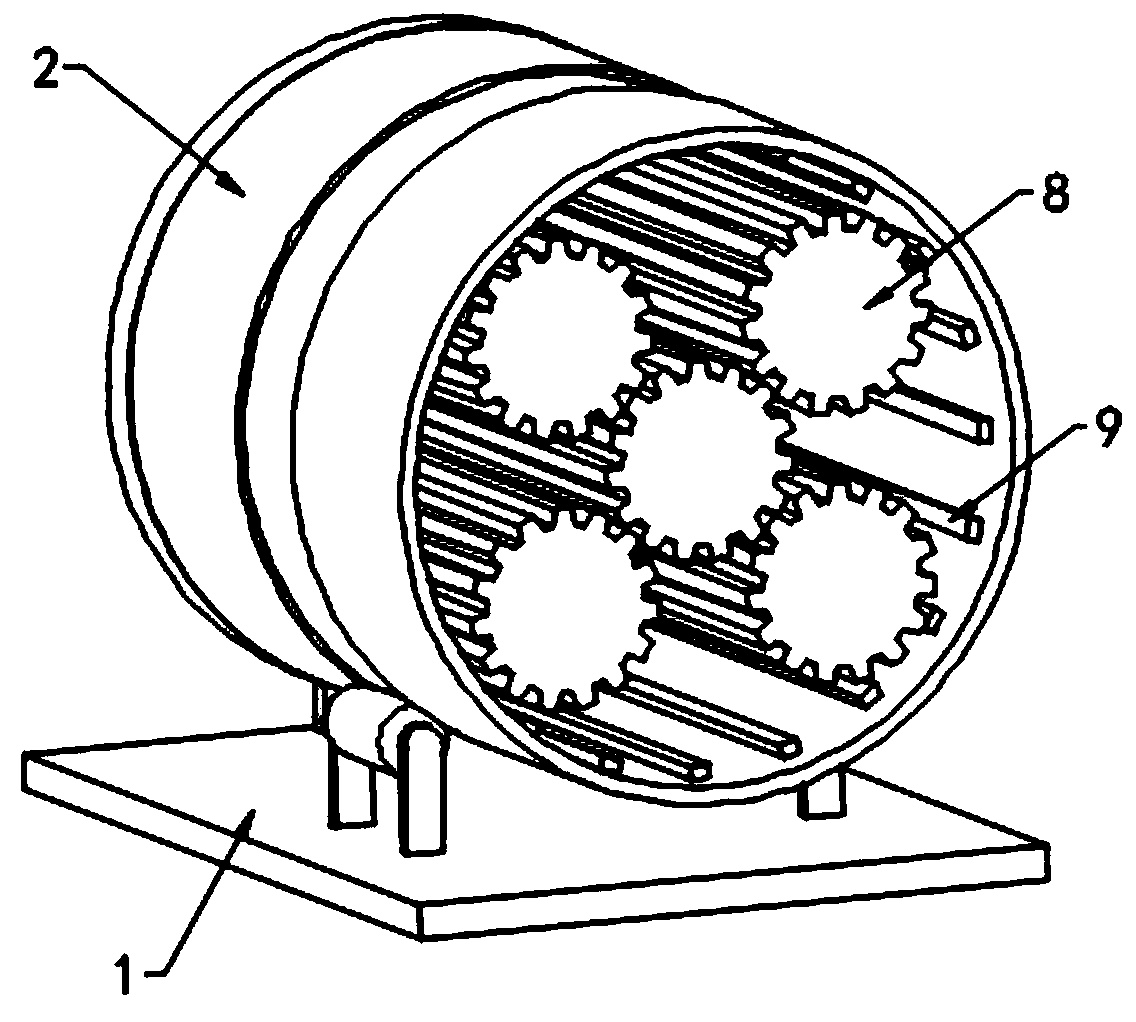

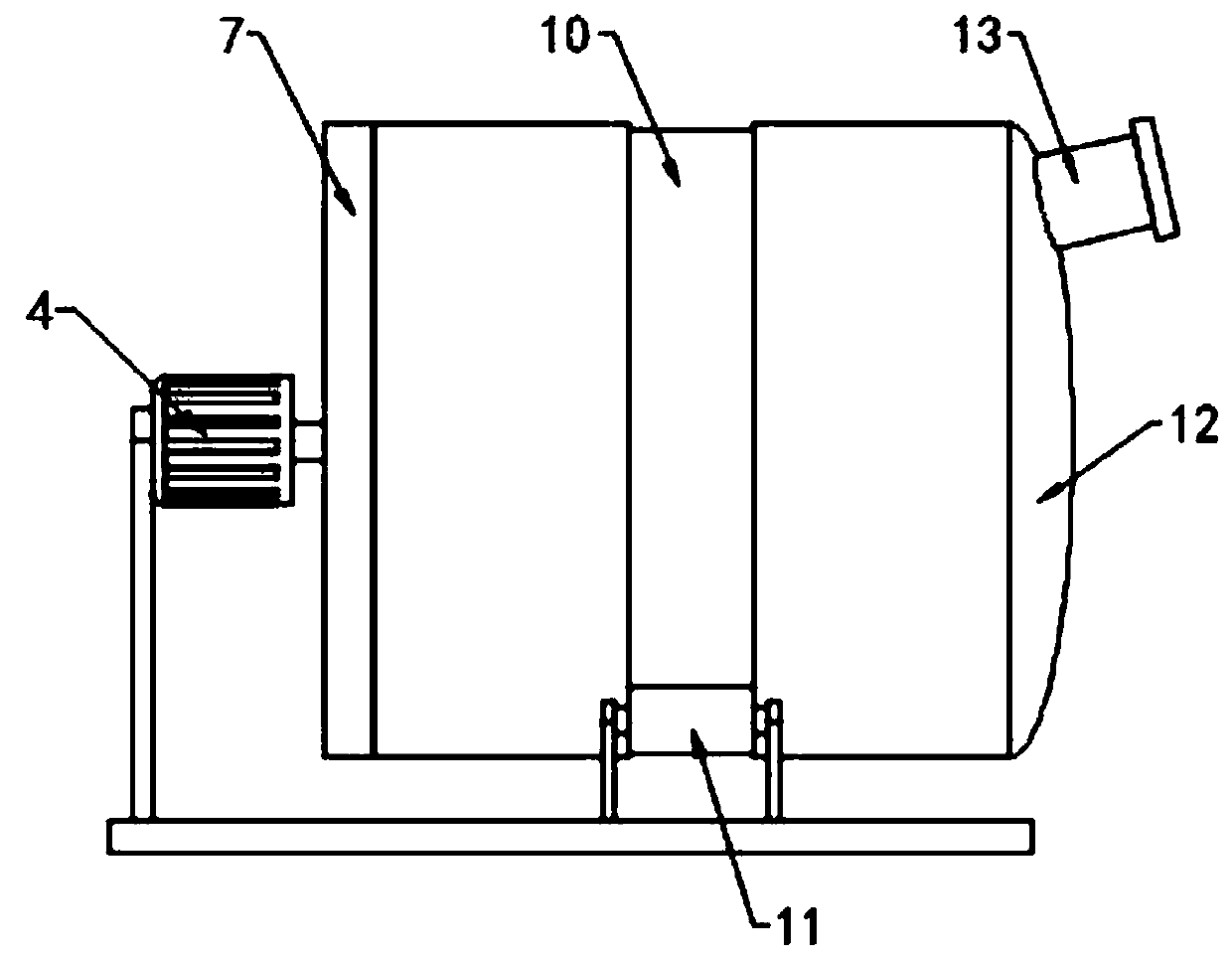

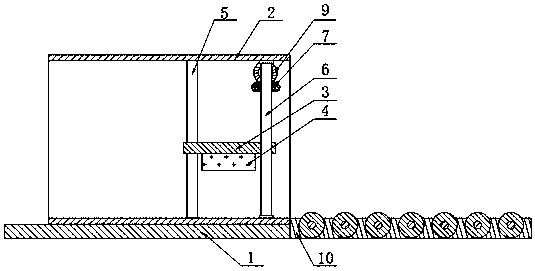

Drum-type shot blasting machine for casting machining

InactiveCN111421457APlay the role of grindingTo achieve the purpose of dust removalEdge grinding machinesPolishing machinesGear wheelDust control

The invention discloses a drum-type shot blasting machine for casting machining. The drum-type shot blasting machine comprises a workbench, a drum with one detachable end is installed on the workbenchthrough a support, a feeding port is formed in the top of the drum, a shot blasting component driven by a driving mechanism is arranged in the drum, and a plurality of dust falling holes are evenly formed in the bottom of the drum; a dust falling box fixed to the workbench is arranged at the bottom of the drum, a dust sweeping component is arranged in the dust falling box, and the bottom of the dust falling box communicates with a dust suction component. During the use of the drum-type shot blasting machine, a casting is added into the drum from the feeding port, a motor drives a rotating shaft to rotate and drives a shot blasting ball to rotate at a high speed, an iron chain is straightened under the action of centrifugal force, and the casting is polished; dust falls into the dust falling box from the dust falling holes in the polishing process, and the motor drives a gear to rotate to drive the rack to move along a sliding rail; the dust is swept to a pipeline and sucked into a dust collecting bag through a dust collector for dust removal, and the purpose of dust removal is achieved.

Owner:HEFEI DEJIE ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

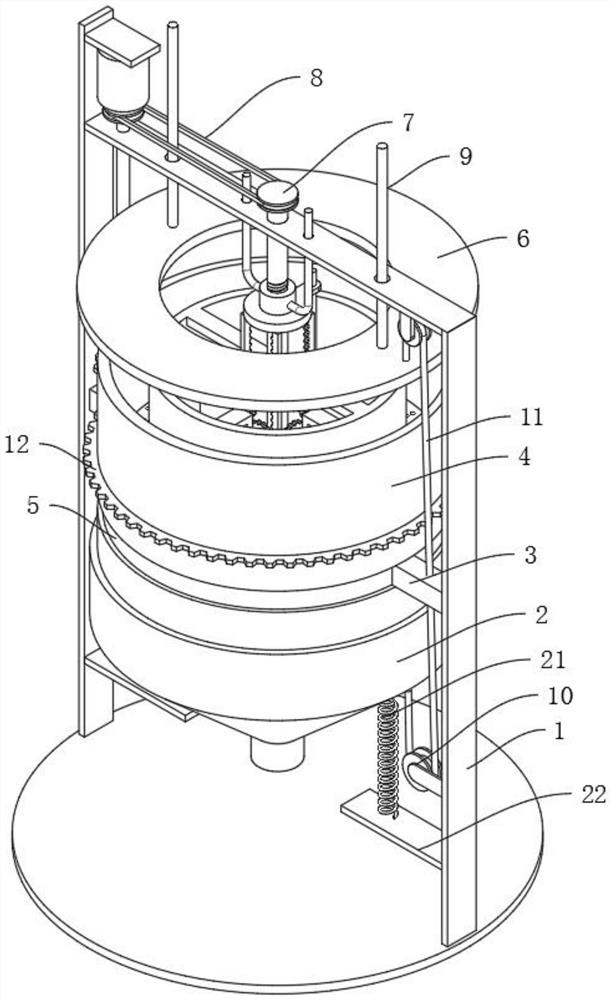

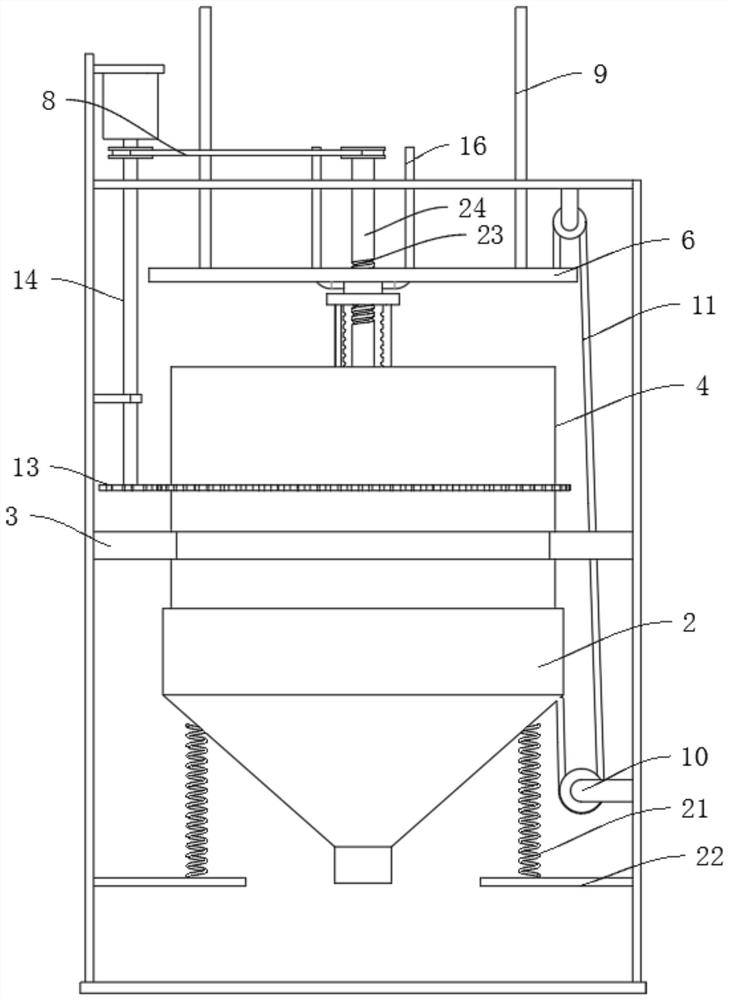

Suspension fertilizer material preparation-based seaweed grinding device capable of achieving continuous feeding

InactiveCN113210043AAvoid accumulationEasy feedingGrain treatmentsAgricultural scienceAgricultural engineering

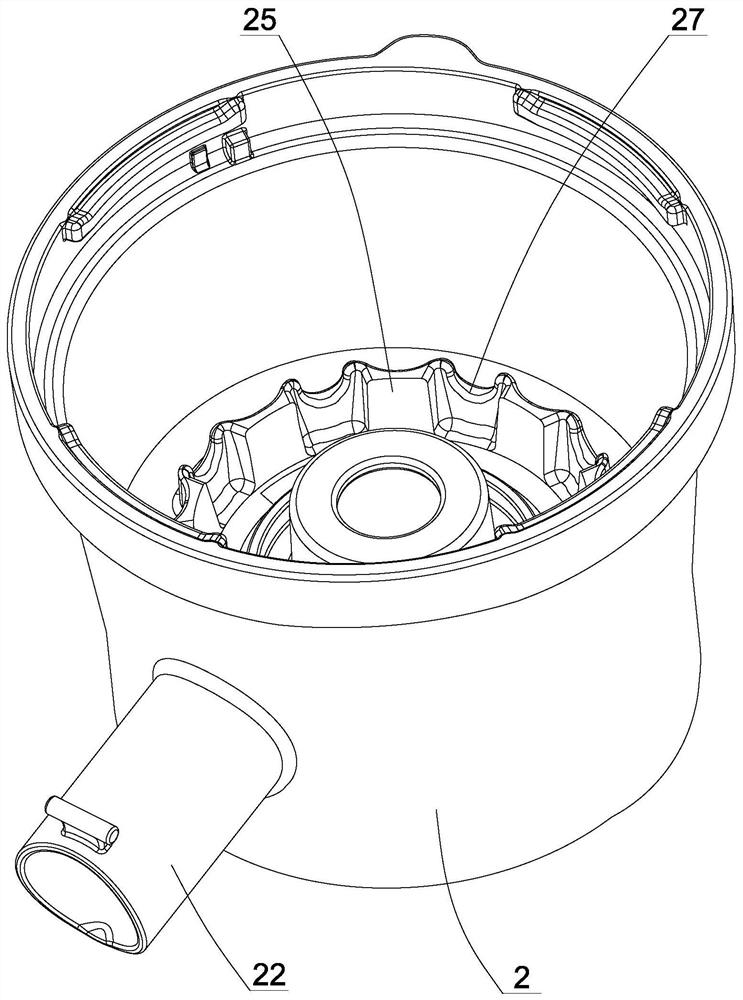

The invention discloses a suspension fertilizer material preparation-based seaweed grinding device capable of achieving continuously feeding. The seaweed grinding device comprises a grinding tank and grinding blocks, wherein support legs with a supporting function are fixedly installed outside the lower side of the grinding tank; a discharge pipe with a discharging function is connected to the lower side wall of the grinding tank in a penetrating manner; a first motor is fixedly connected to the outside of the middle of the lower side of the grinding tank through bolts; a filter shell is fixedly installed at the output end of the first motor; a movable groove is formed in the lower side wall of the filter shell; the grinding blocks are arranged in the filter shell, and the upper end surface of each grinding block is rotationally connected with a movable rod; and an end cover is fixedly installed outside the upper sides of the movable rods. According to the suspension fertilizer material preparation-based seaweed grinding device capable of achieving continuous feeding, continuous feeding is facilitated in the grinding process, the working efficiency is improved, discharging is facilitated in the grinding process, seaweed accumulation after processing is prevented, and the influence on use is avoided.

Owner:安徽农巧施农业科技有限公司

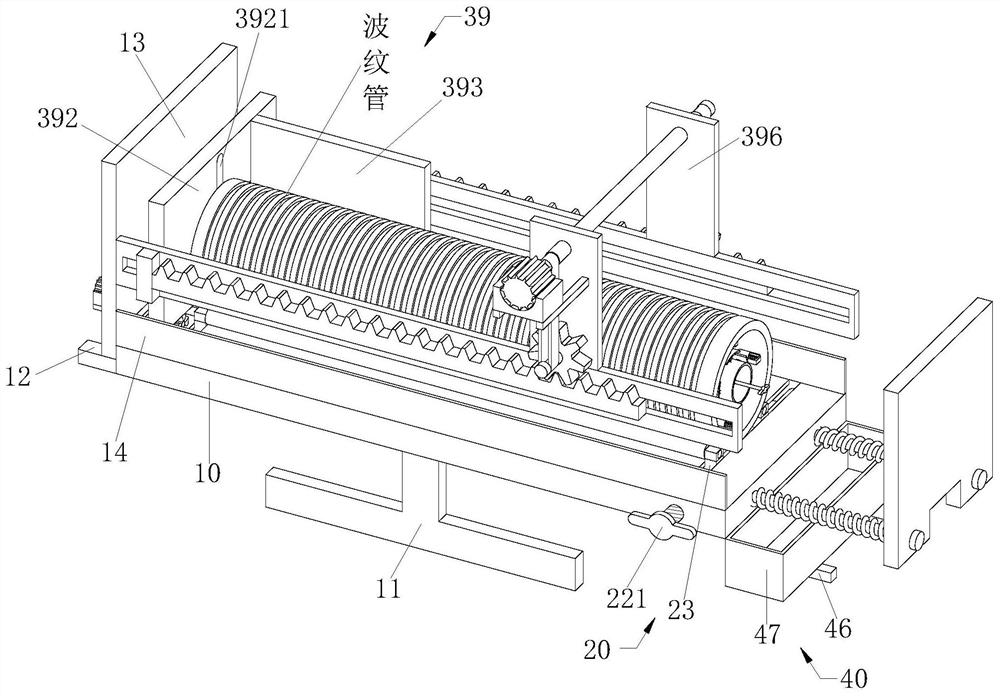

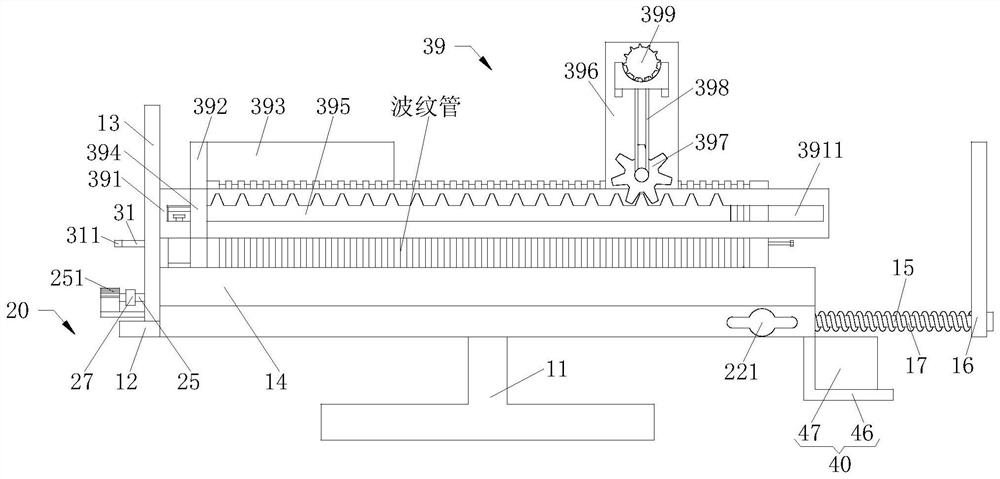

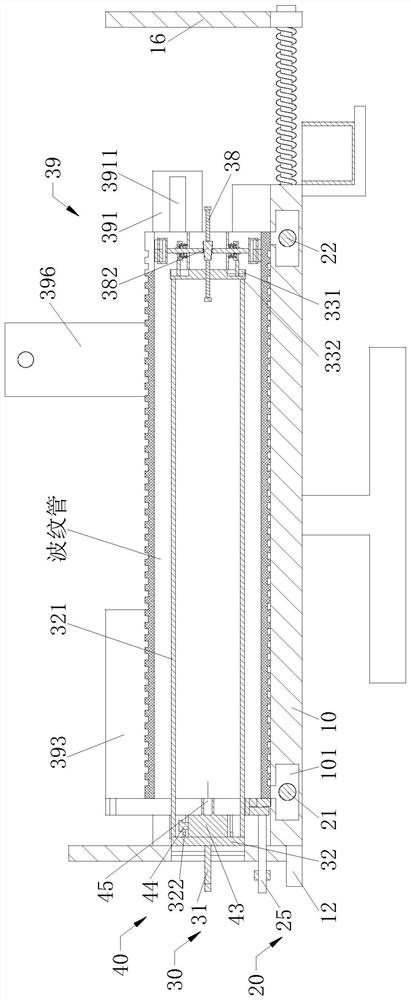

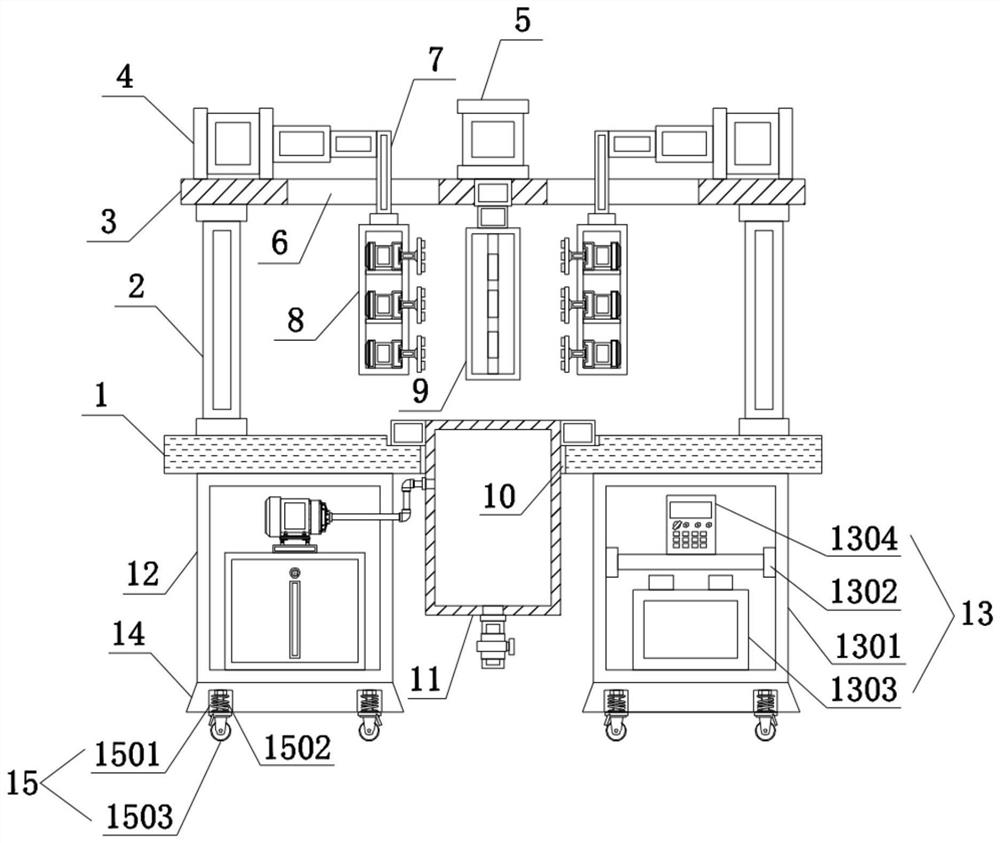

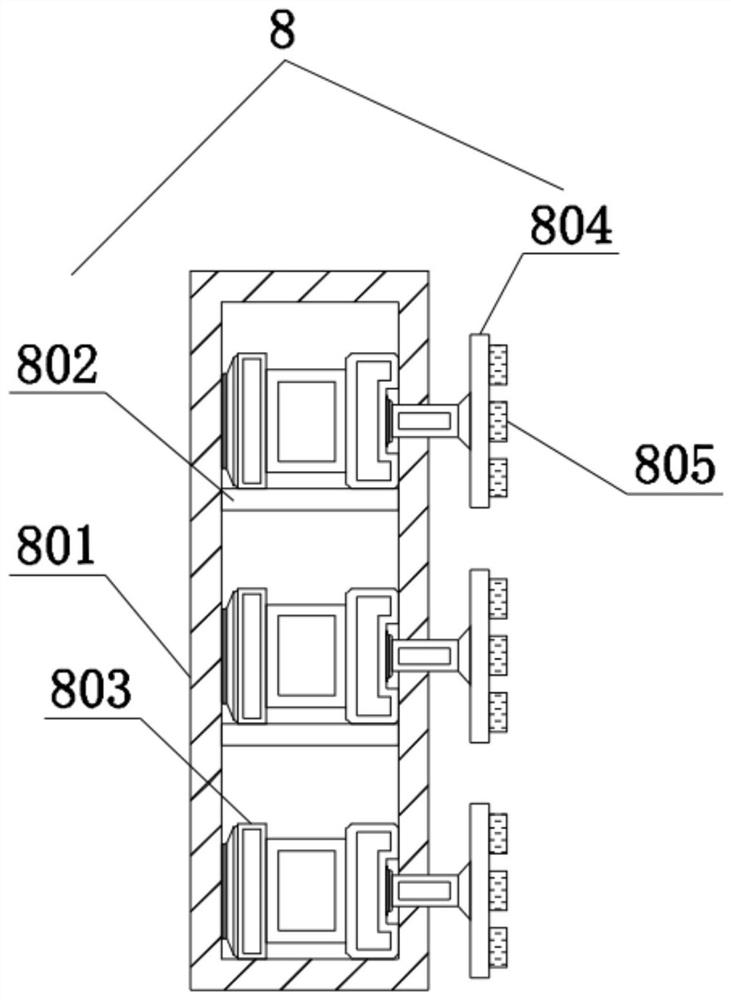

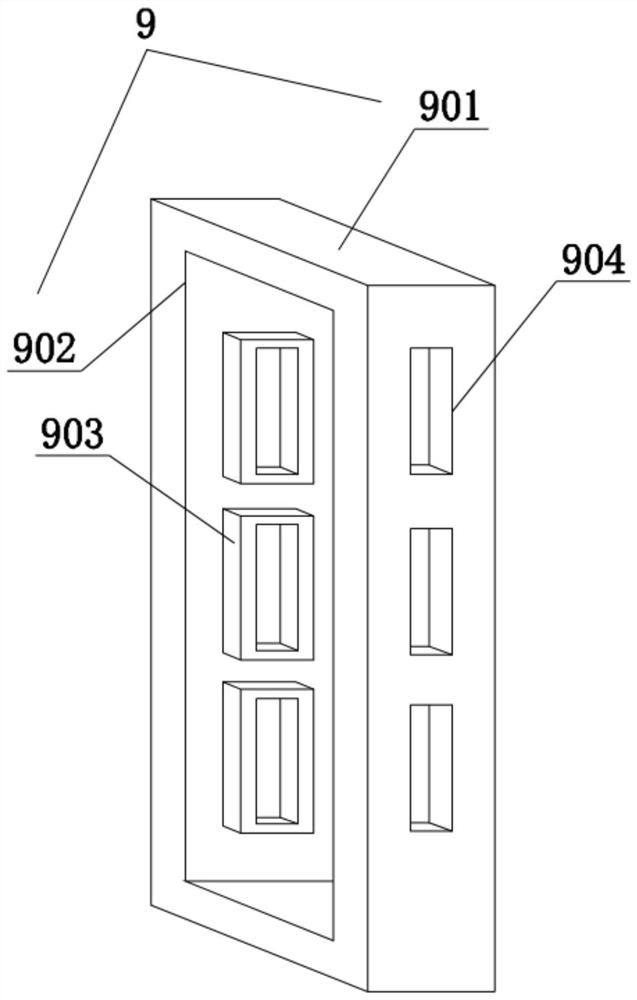

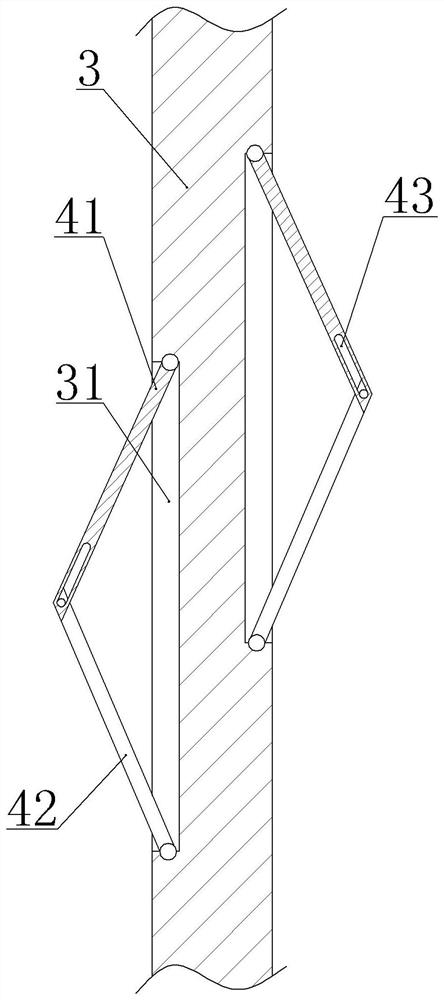

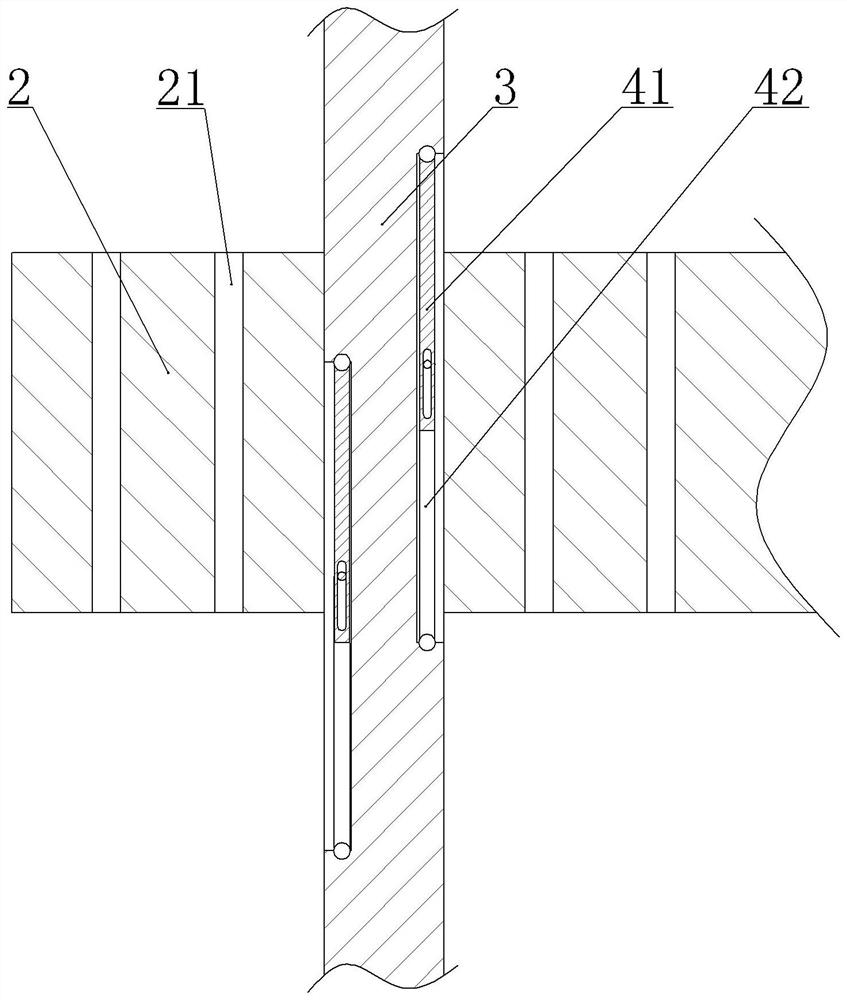

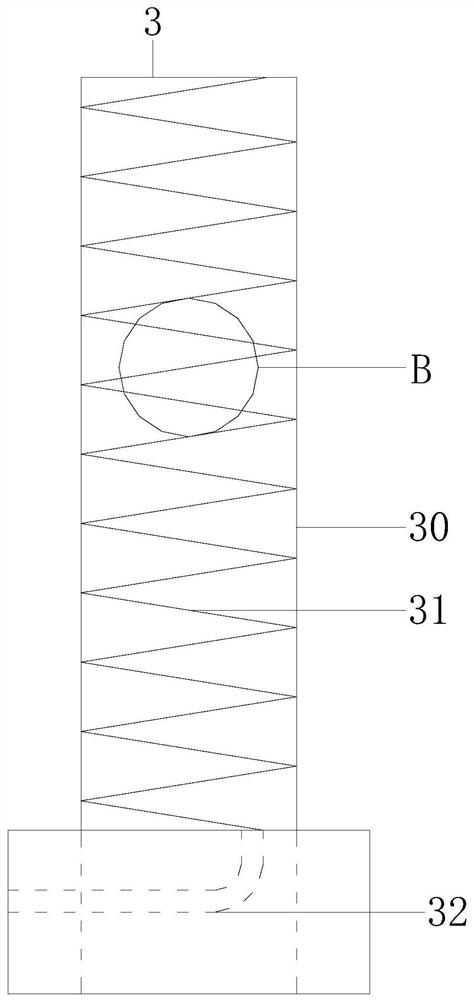

Manufacturing and machining device and machining method for high-density polyethylene HDPE double-wall corrugated pipe

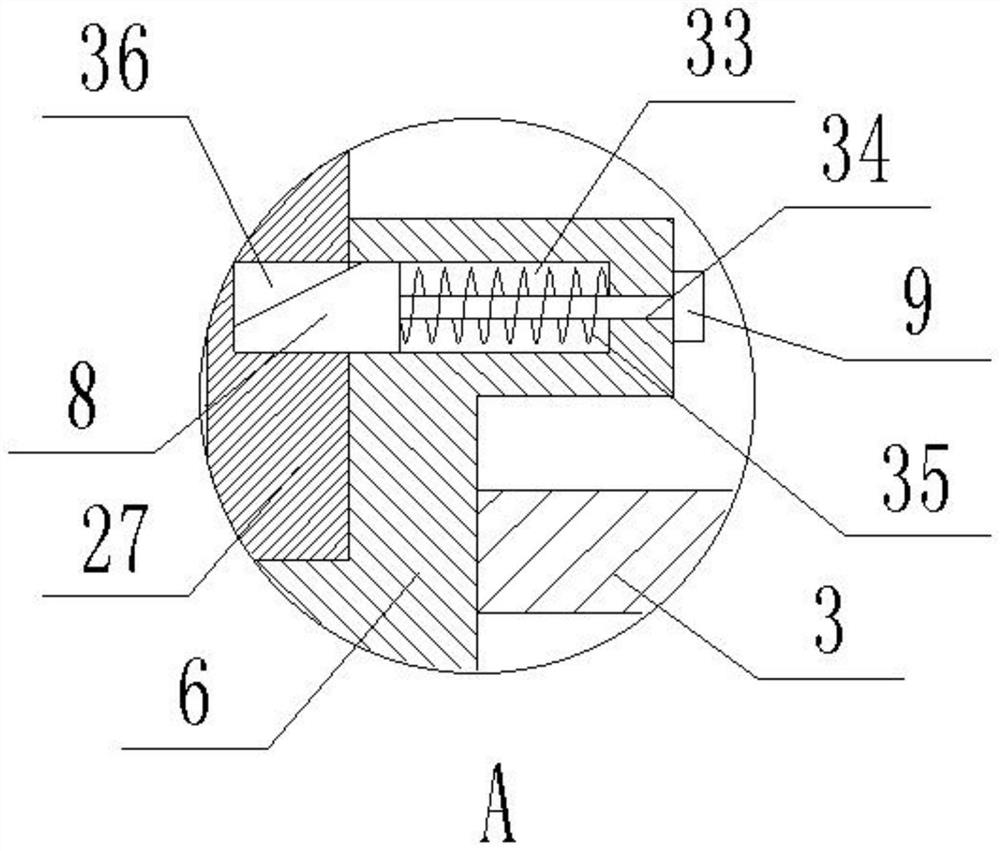

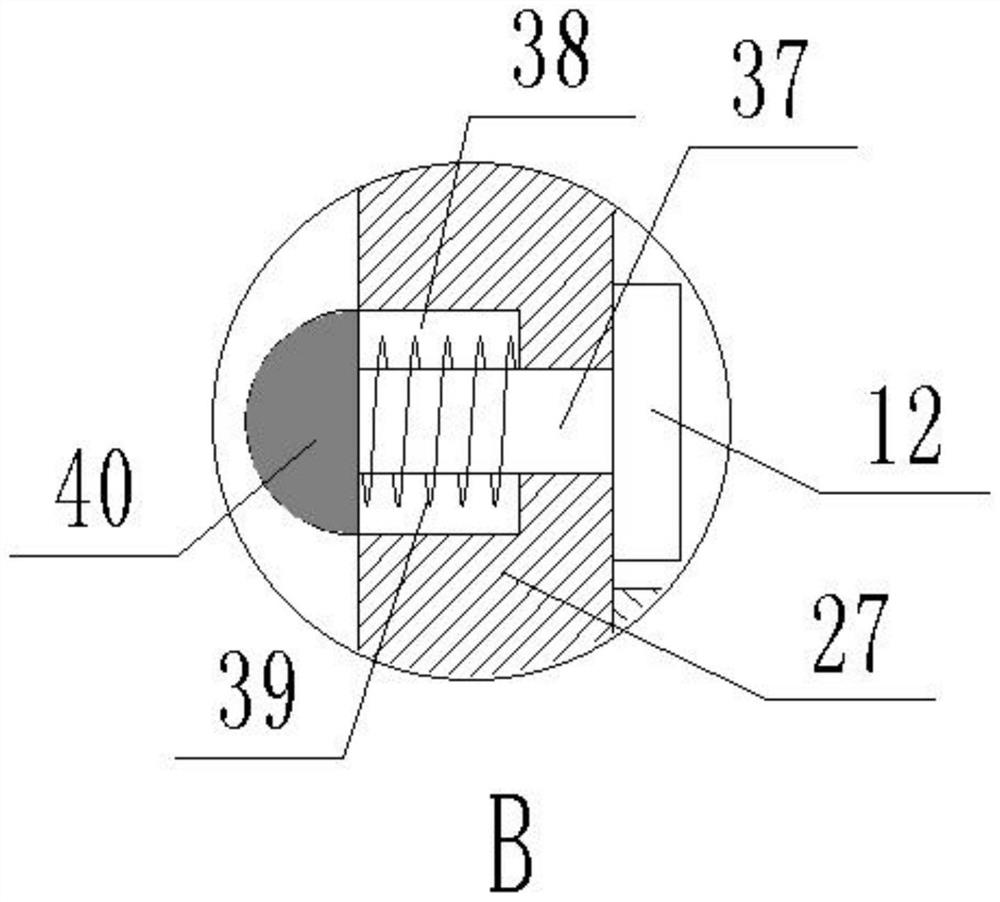

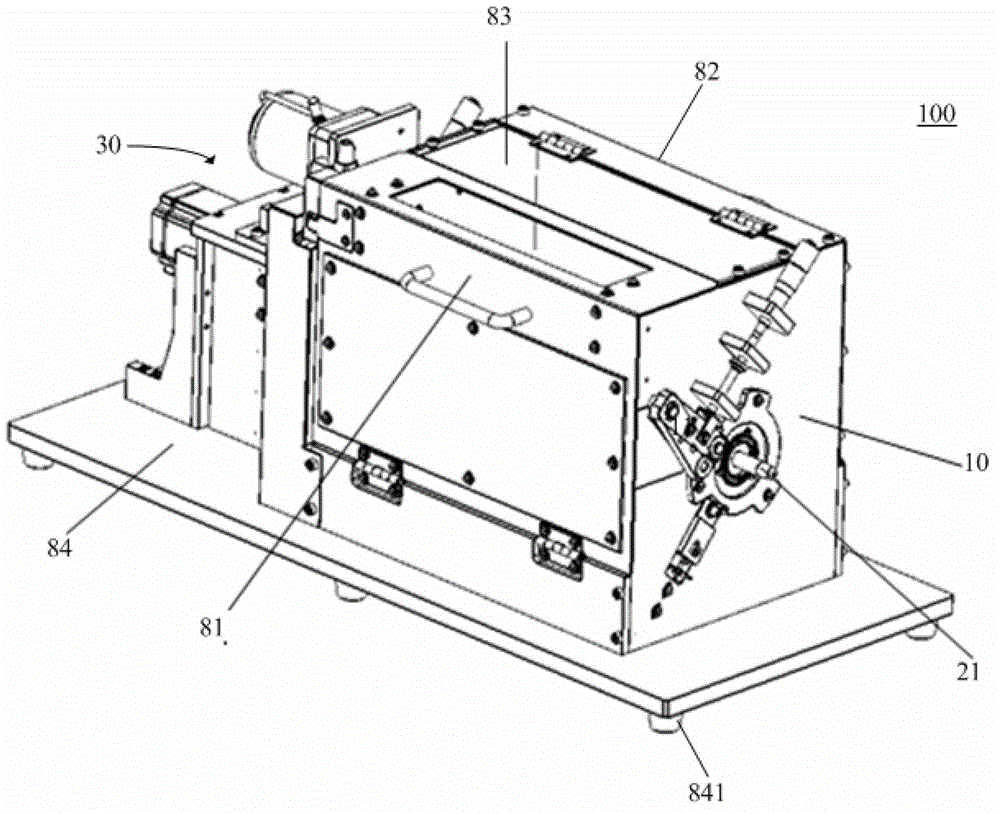

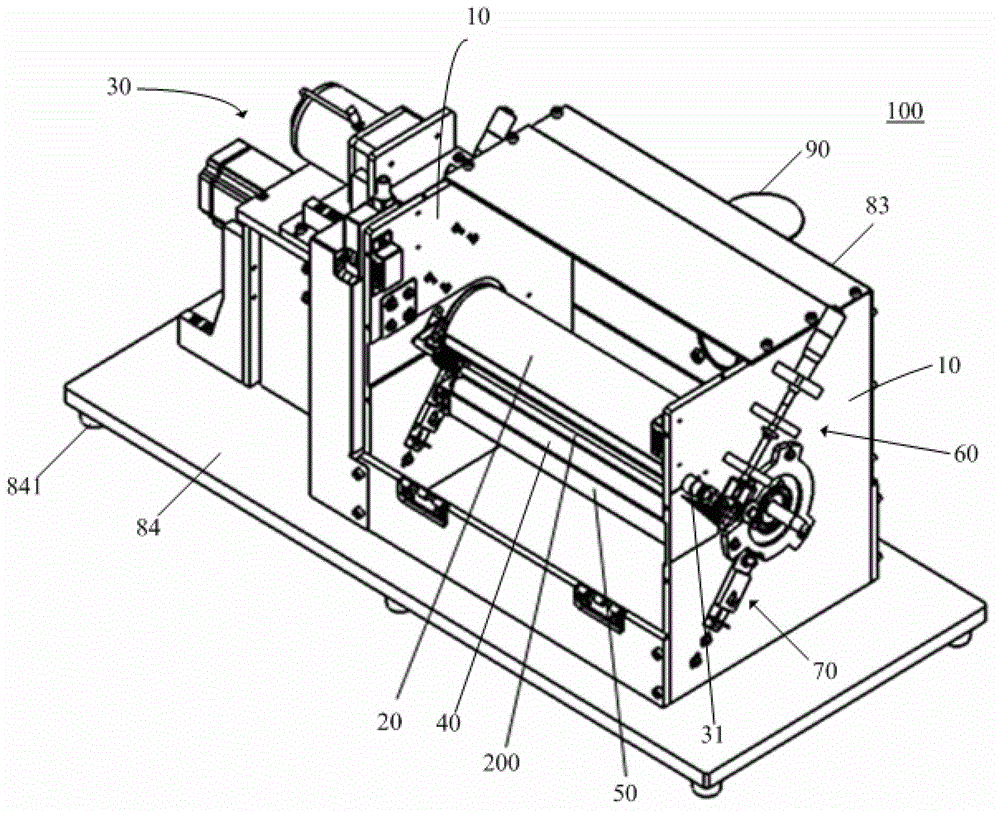

InactiveCN113021117AHigh dimensional accuracyAffect the installationEdge grinding machinesGrinding drivesHigh densityScrew thread

The invention relates to a manufacturing and machining device and a machining method for a high-density polyethylene HDPE double-wall corrugated pipe. The device comprises a workbench and supporting frames symmetrically arranged at the centers of the front end and the rear end of the bottom of the workbench, wherein an outer grinding device is arranged above the supporting frames, an inner grinding device is arranged above the workbench, and a cleaning device is arranged between two sets of rectangular baffles. According to the device, guide rods, bidirectional screw rods, first grinding rollers and first arc-shaped plates are matched so that the two sets of first grinding rollers can move oppositely under the thread driving of the bidirectional screw rods and the guide action of the guide rods, the corrugated pipe to be machined is jacked to the position above the workbench, burrs on the outer wall of the corrugated pipe to be machined are ground, the first arc-shaped plates rotate along with the first grinding rollers, the burrs in grooves in the outer wall of the corrugated pipe to be machined can be ground, the size precision of the corrugated pipe is improved, the situation that the burrs in the grooves are not removed, and consequently installation of the corrugated pipe is affected is avoided, and the labor intensity of workers is relieved.

Owner:南京绪风科技有限公司

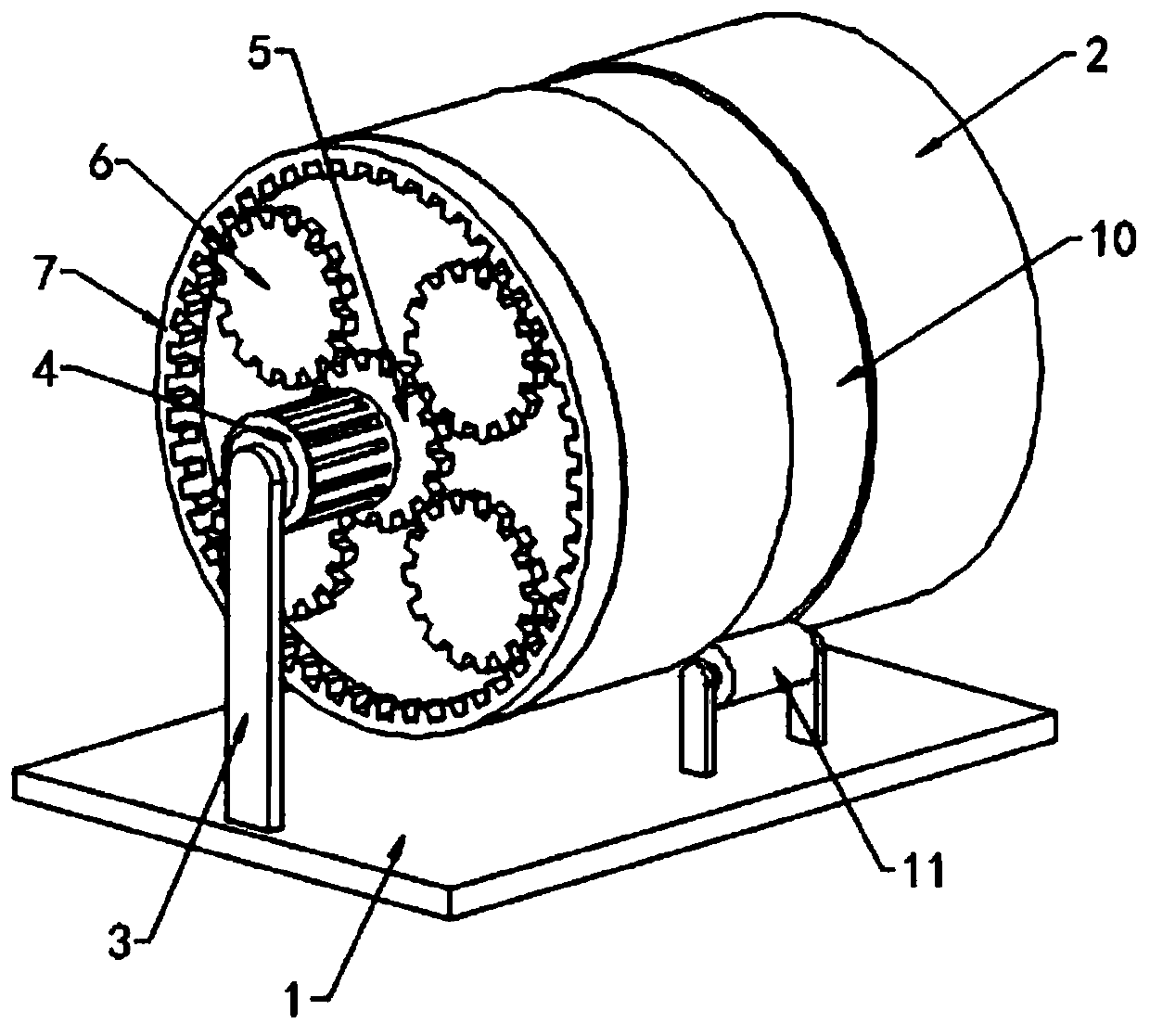

Engaged rotary crushing machine for rice

PendingCN110449204AImprove uniformity and finenessImprove stabilityGrain treatmentsPulverizerRice flour

The invention discloses an engaged rotary crushing machine for rice. The engaged rotary crushing machine for rice comprises a table plate, wherein a barrel body is arranged at the top of the table plate, and a fixed plate is welded to one side of the top of the table plate; a motor is connected to the top of the fixed plate through a bolt; and a drive gear is in connected to an output shaft of themotor in a transmission manner. According to the engaged rotary crushing machine for rice, a plurality of crushing rolls are arranged in the barrel body, the plurality of crushing rolls are connectedwith a drive gear and a driven gear separately, and a plurality of lugs are arranged on the inner wall of the barrel body. With the adoption of the design, the engaged rotary crushing machine for rice has the following advantages: the motor drives the drive gear to rotate, and then the driven gear and a gear ring are driven to rotate, so that the barrel body and the crushing rolls are rotated; the plurality of crushing rolls are mutually engaged, rice grains are thrown to be among the engaged crushing rolls along with the rotation of the barrel body, and then the rice grains are grinded intosmall-particle rice flour; and meanwhile, the lugs and the crushing rolls on the inner wall of the barrel body are also capable of playing the role of grinding, and then the uniformity and fineness ofrice crushing are improved.

Owner:通道福香米业有限公司

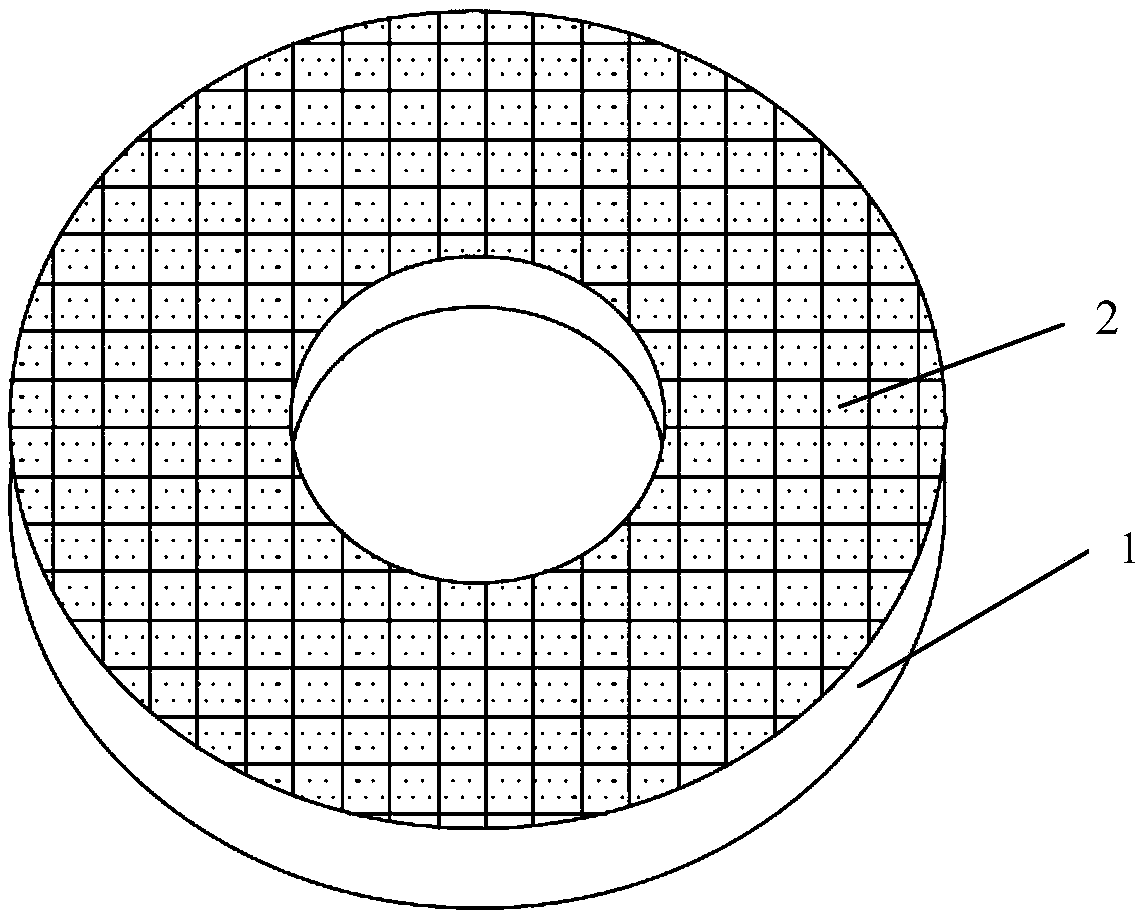

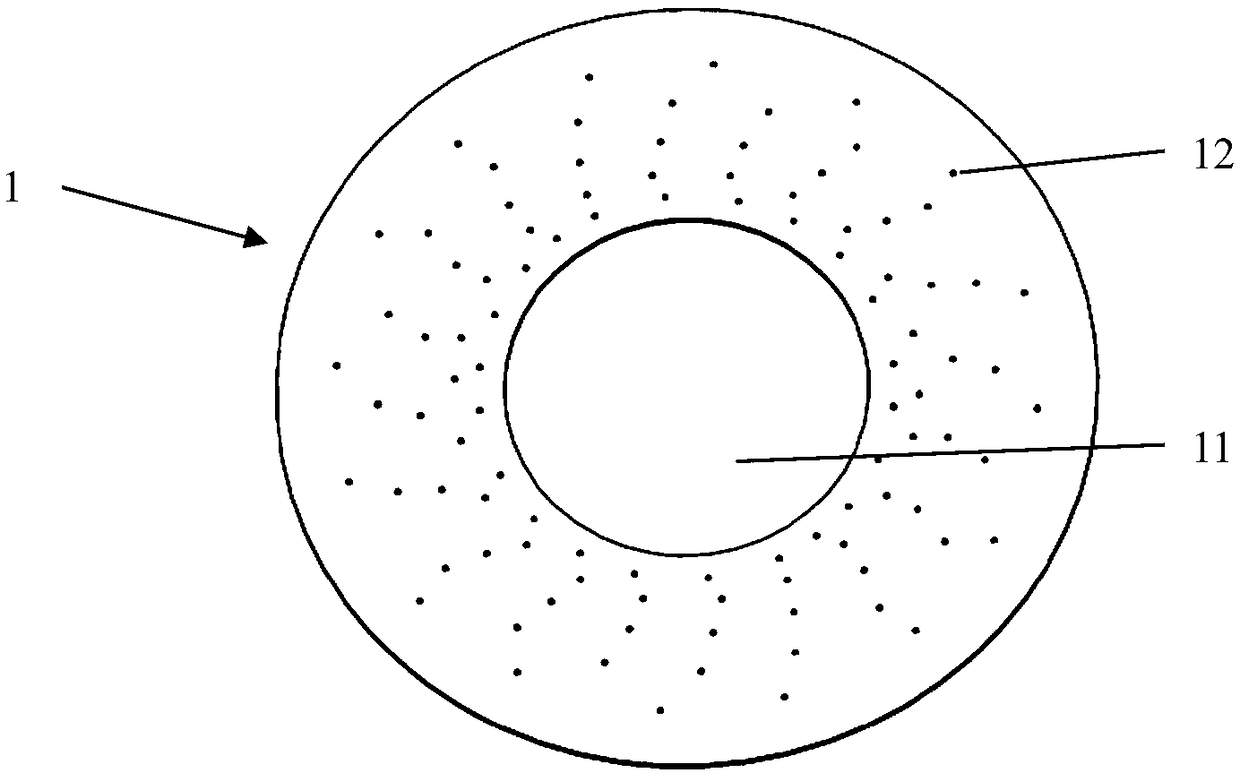

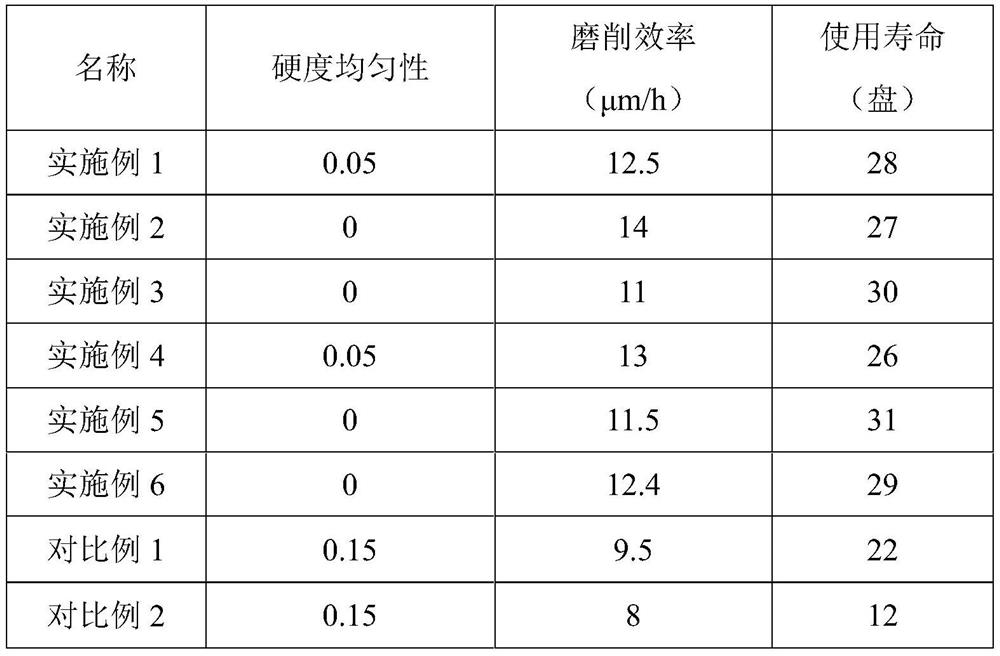

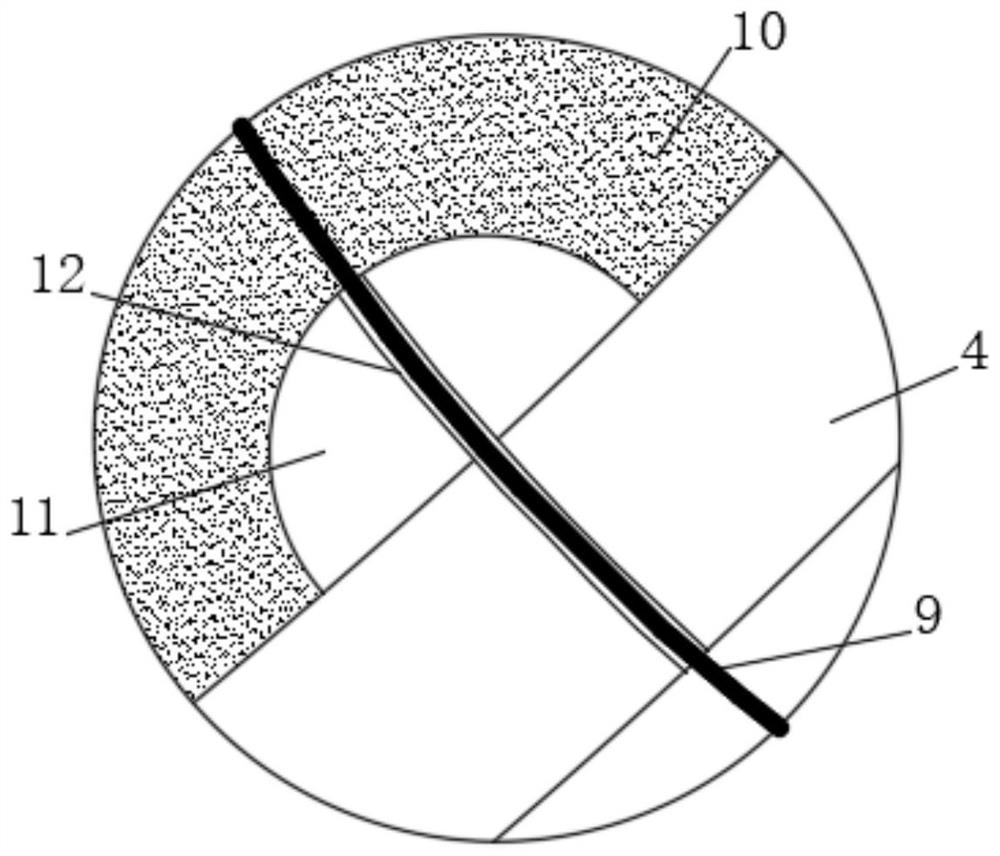

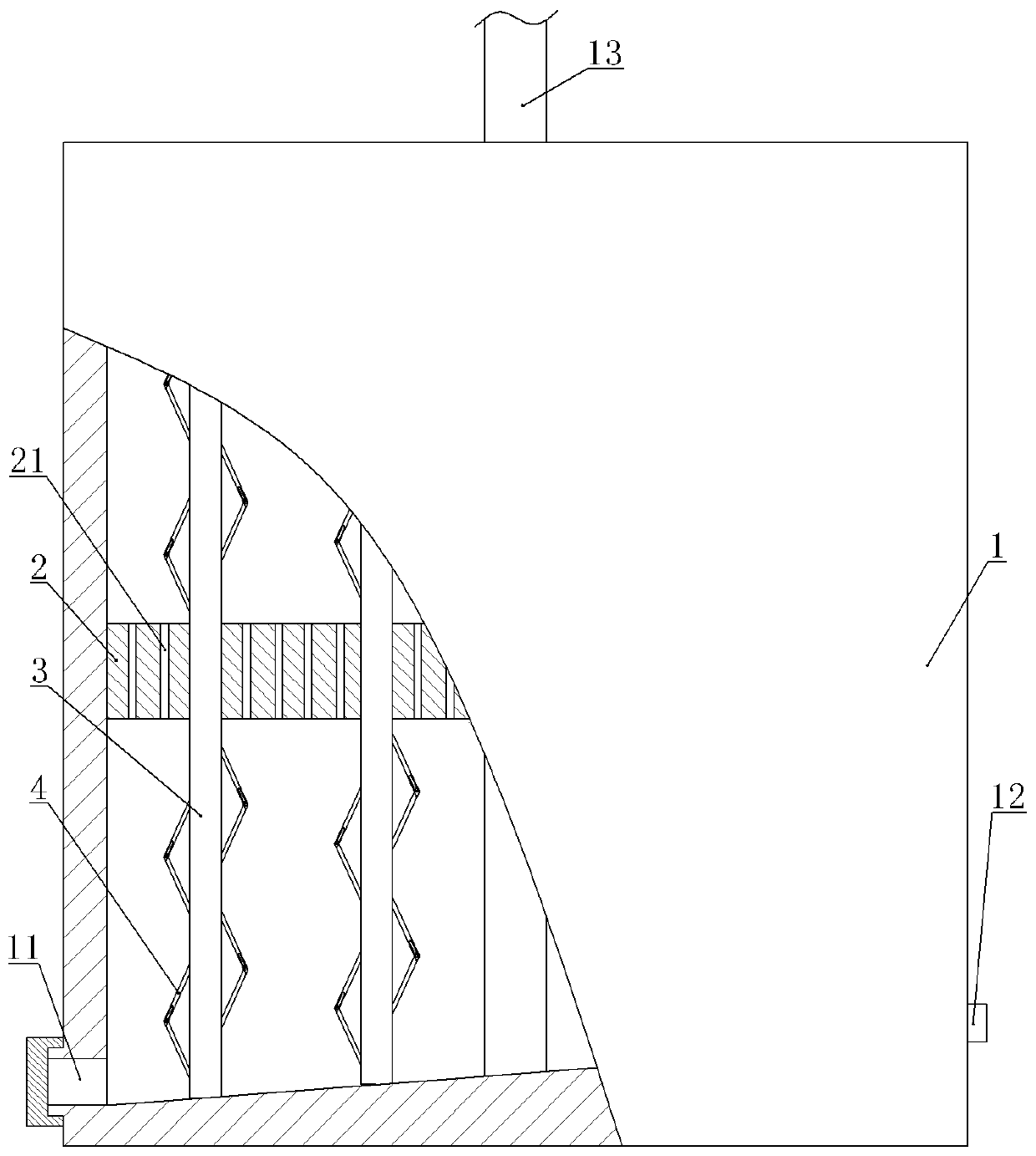

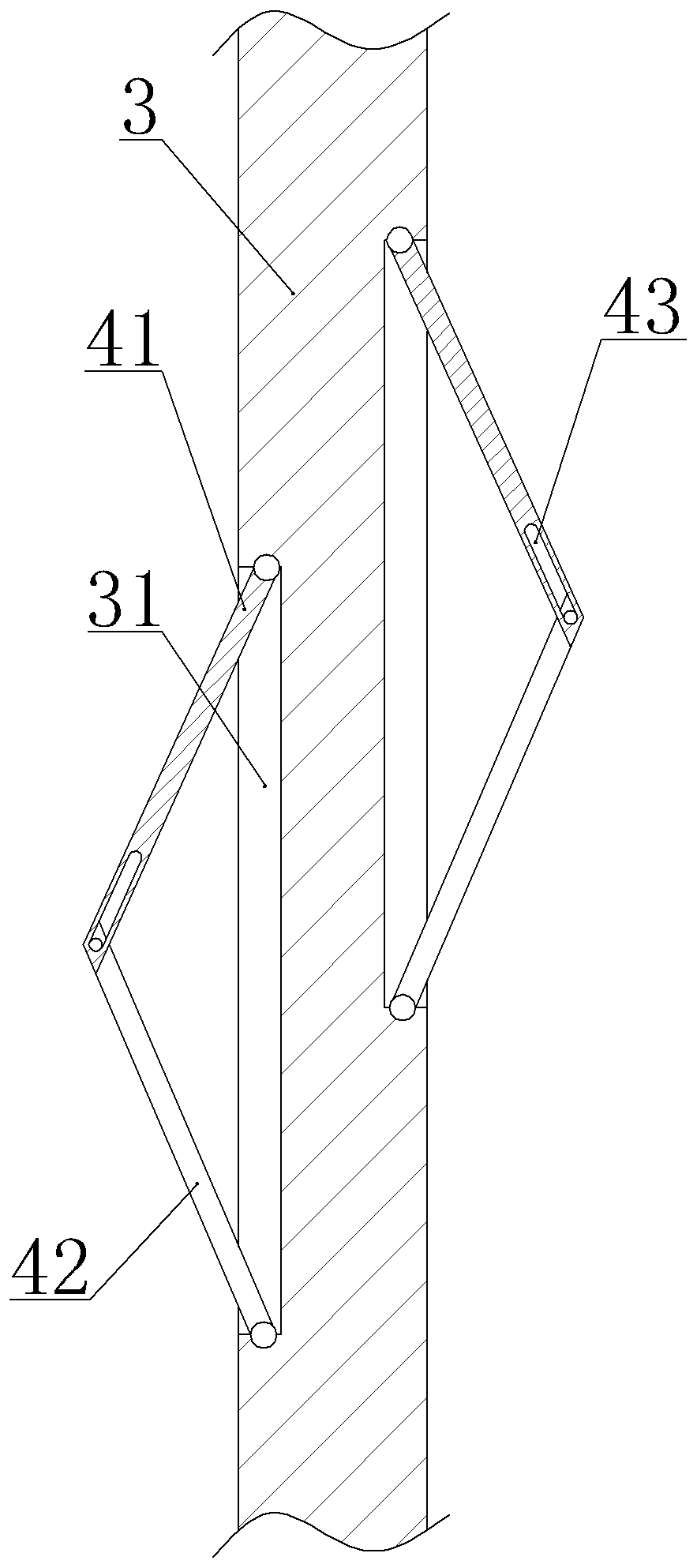

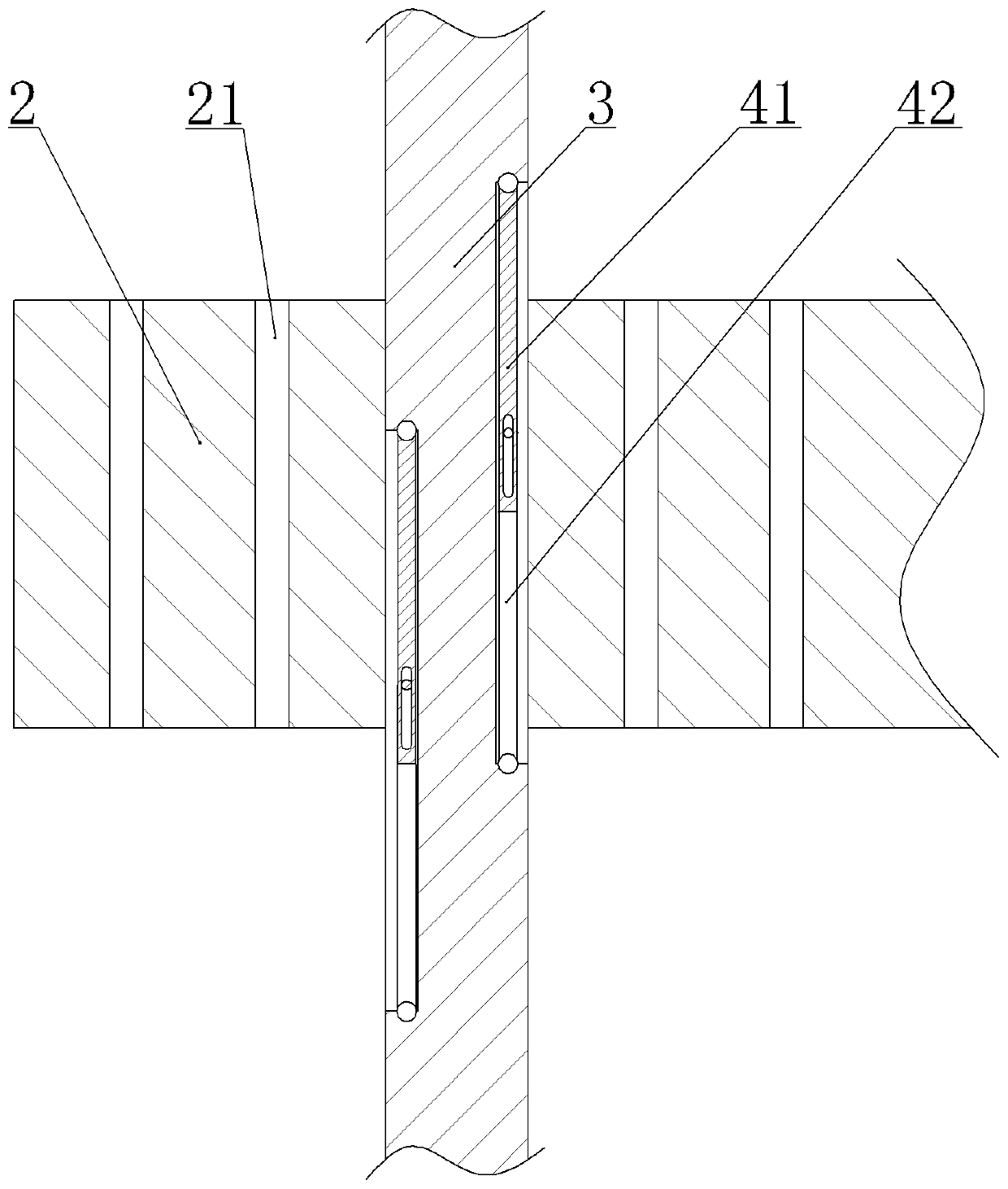

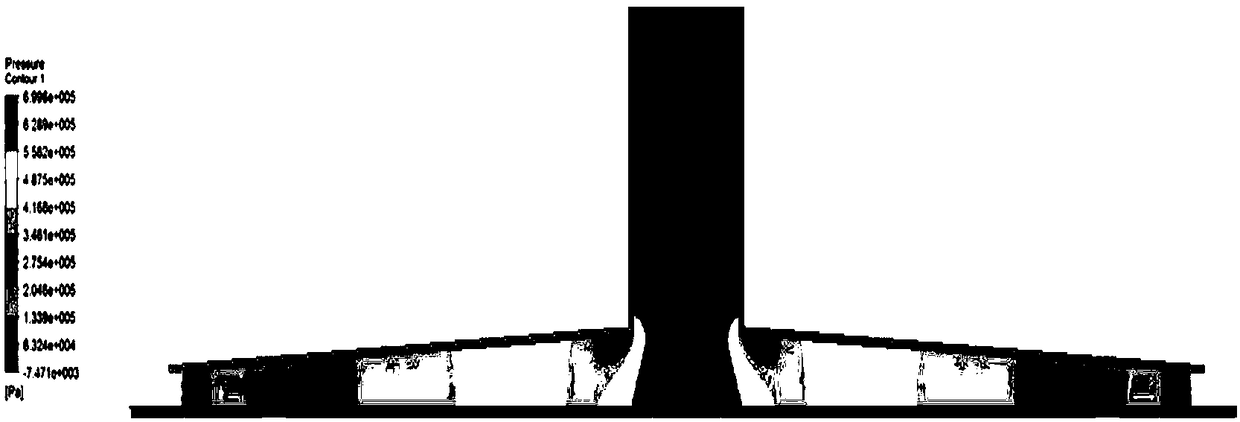

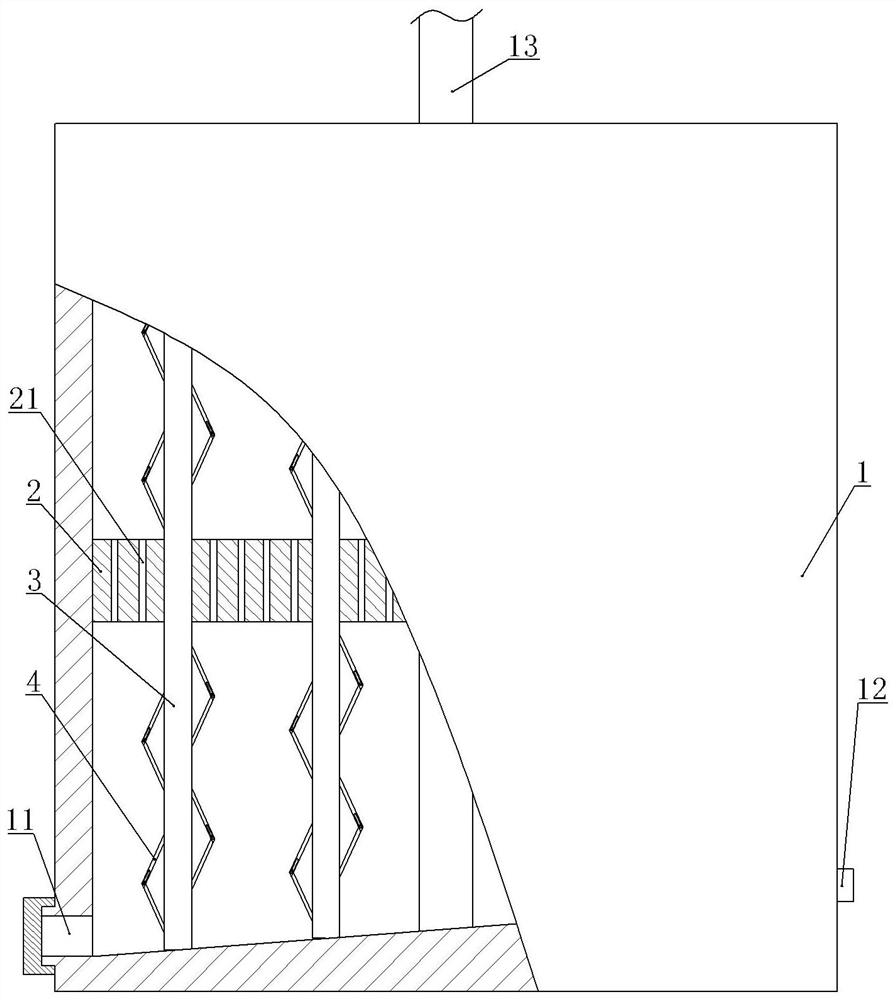

Semi-solidified grinding disk for semiconductor substrate grinding, and preparation method and application thereof

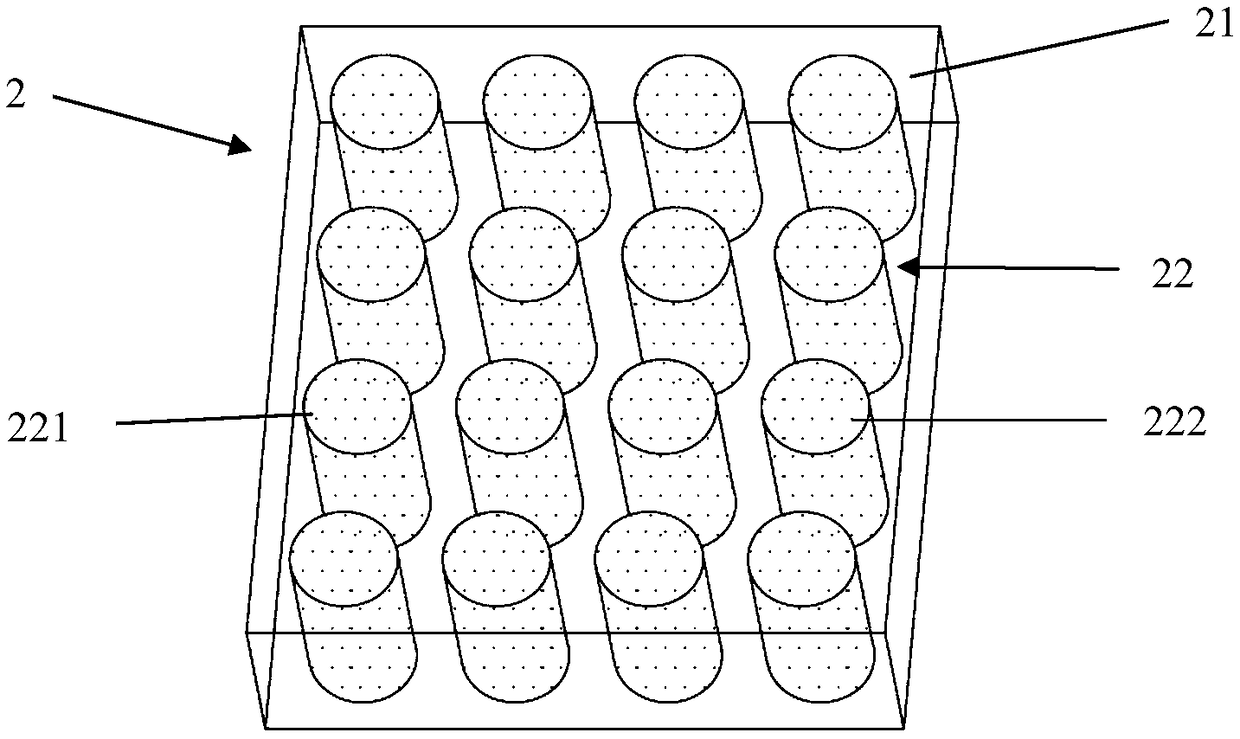

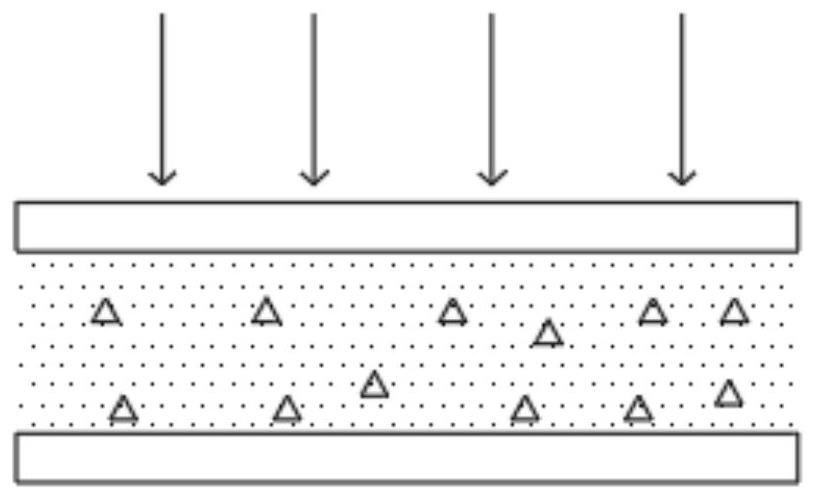

PendingCN109048645AIncrease stiffnessReduce distortionGrinding devicesLapping toolsHardnessSemiconductor

The invention discloses a semi-solidified grinding disk for semiconductor substrate grinding, and a preparation method and application thereof. The semi-solidified grinding disk comprises a base diskand a plurality of grinding slices. Each grinding slice comprises a skeleton and a semi-solidified grinding medium containing abrasive particles, wherein the skeleton is uniformly provided with a plurality of holes penetrating through the upper and lower surfaces of the skeleton, and the holes are filled with the semi-solidified grinding medium containing the abrasive particles; the hardness of the skeleton is higher than that of the semi-solidified grinding medium. The lower surfaces of the grinding slices are fixedly connected to the base disk. The upper surfaces of the grinding slices jointly form a grinding working surface. Flow channels are formed between the adjacent grinding slices. The novel structure semi-solidified grinding disk for semiconductor substrate grinding can achieve the good surface quality and high grinding efficiency, meanwhile, can improve the surface figure accuracy of substrates and can also be used for precise grinding machining of semiconductor substrate parts having the high requirement for the surface figure accuracy.

Owner:HUAQIAO UNIVERSITY

Ceramic bond grinding tool

ActiveCN113894710AGuaranteed abrasive rateImprove high temperature sintering performanceAbrasion apparatusGrinding devicesPyrophylliteKaolinite

The invention relates to a ceramic bond grinding tool, and belongs to the technical field of abrasive grinding tools. A ceramic bond adopted by the ceramic bond grinding tool is composed of the following components of, by mass, 17%-27% of kaolinite powder, 1%-3% of low-melting-point glass powder, 1%-5% of nano-silica, 7%-12% of pyrophyllite and the balance feldspar powder. The ceramic bond grinding tool has high structure uniformity and quality stability, the pyrophyllite is hydroxyl-containing layered aluminosilicate, the chemical formula of the pyrophyllite is Al2[Si4O10](OH)2, the pyrophyllite has good pressure transmission capacity under large pressure, and the structure uniformity and the quality stability of the ceramic bond grinding tool can be further improved; and in addition, the nano-silica can improve the high-temperature sintering performance of the bond and improve the self-sharpening performance of the ceramic bond grinding tool, and therefore the cutting efficiency is improved.

Owner:白鸽磨料磨具有限公司

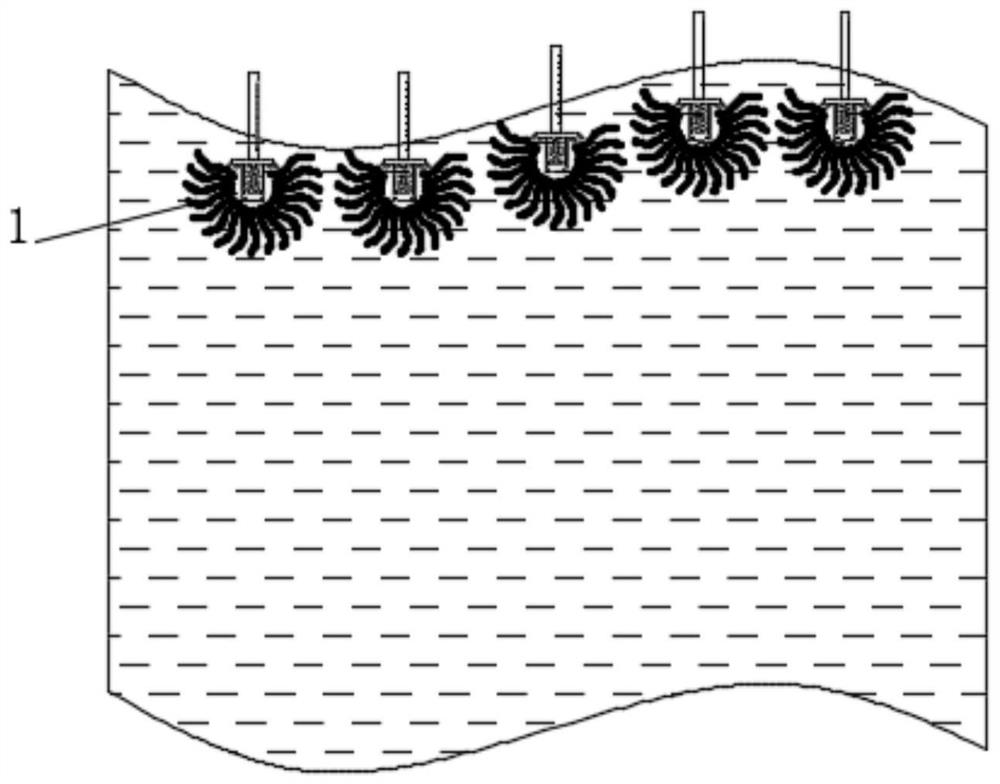

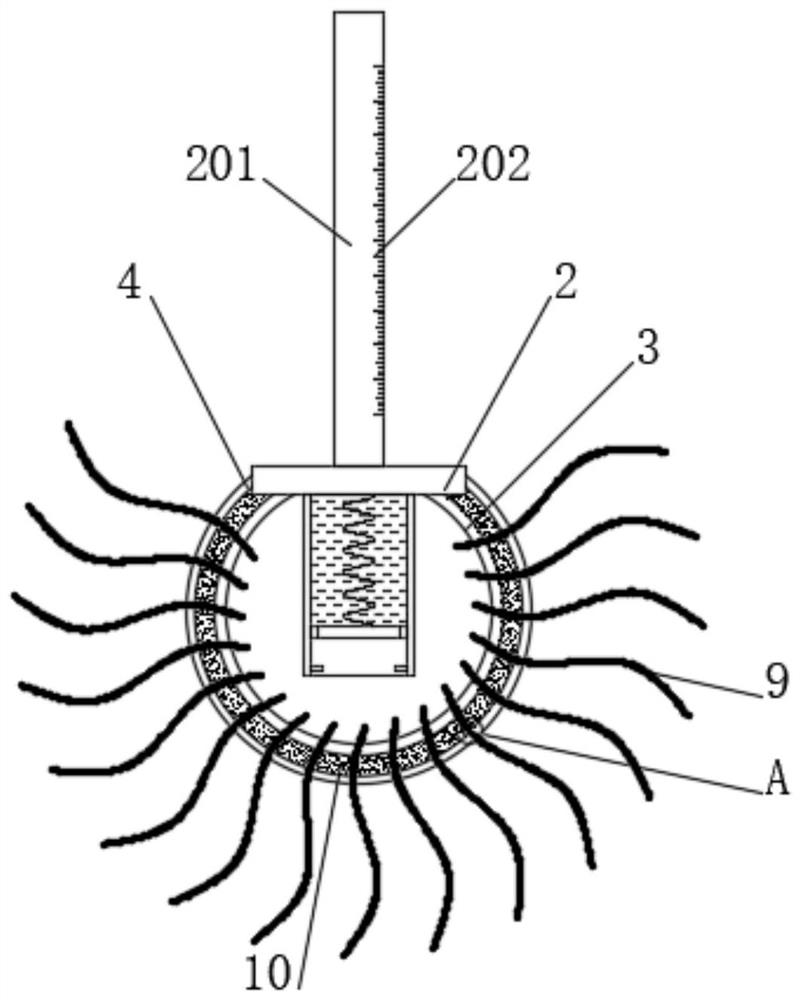

Jellyfish-like printing and dyeing wastewater fiber adsorption device and use method thereof

InactiveCN111847753AMove quicklyIncrease temperatureWater/sewage treatmentMultistage water/sewage treatmentFiberHot melt

The invention discloses a jellyfish-like printing and dyeing wastewater fiber adsorption device and a use method thereof. The invention belongs to the technical field of textile industry. According tothe scheme, an inner elastic balloon, adsorption tentacles and fiber impurities are respectively simulated into the umbrella-shaped body, the tentacles and the food of the jellyfish, the fiber impurities are absorbed by simulating the predation process of the jellyfish, the fiber impurities are adhered by using a hot melt adhesive layer arranged on the surface of an outer spherical wrapping frame, and when the adsorption tentacles expand outwards, part of the brought-out reaction powder reacts with water to generate sodium hydroxide and water, and a large amount of heat is released. First, grease dissolution can be promoted, the grease content in the printing and dyeing wastewater is reduced; by means of the generated heat, the escape amount of carbon dioxide in the carbon dioxide aqueoussolution can be increased, meanwhile, the temperature around the outer spherical wrapping frame is increased, so that the viscosity of the hot melt adhesive on the surface of the outer spherical wrapping frame is improved; and in addition, by means of the generated oxygen, the fiber impurities inside can be promoted to rapidly move and are forced to be fully adsorbed by the adsorption tentacles.

Owner:罗培佳

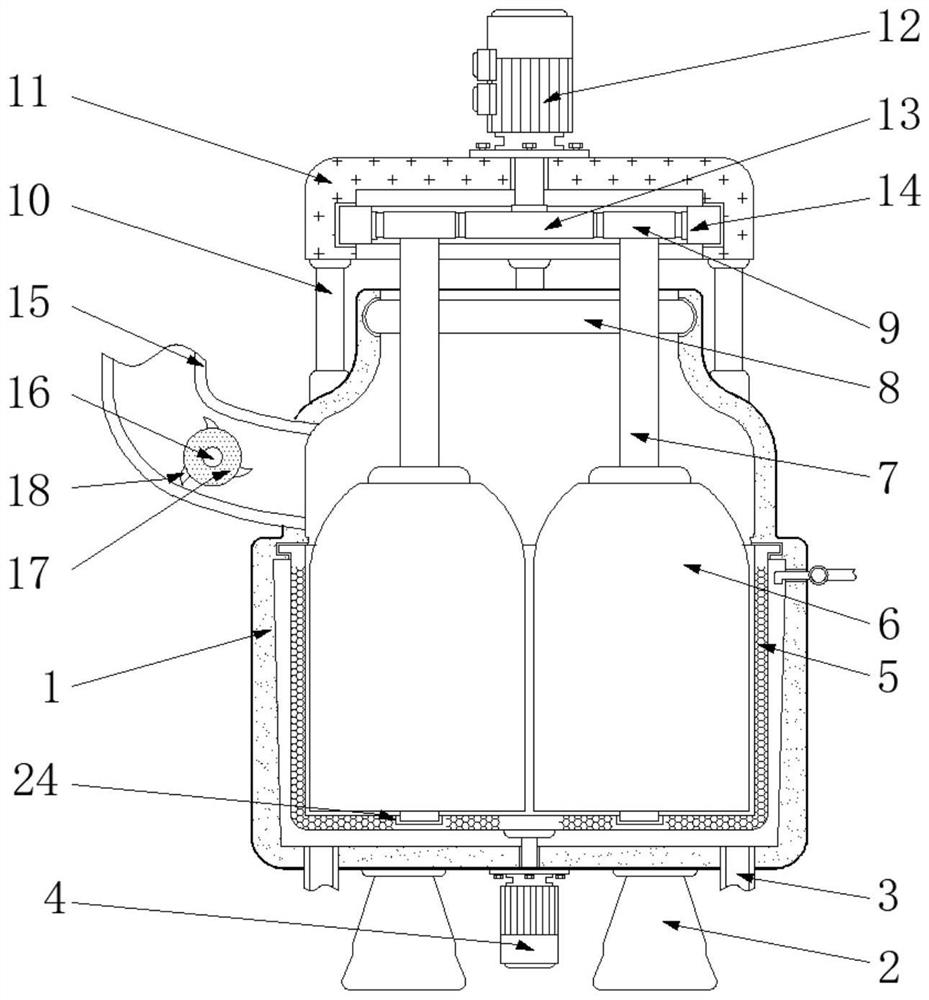

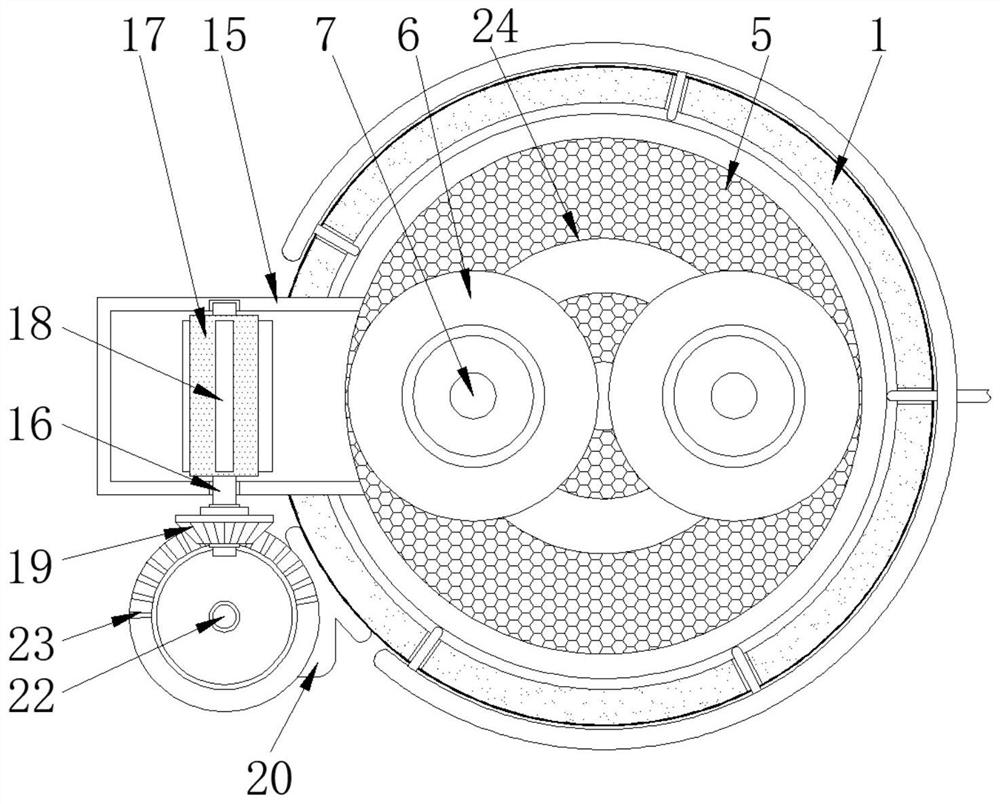

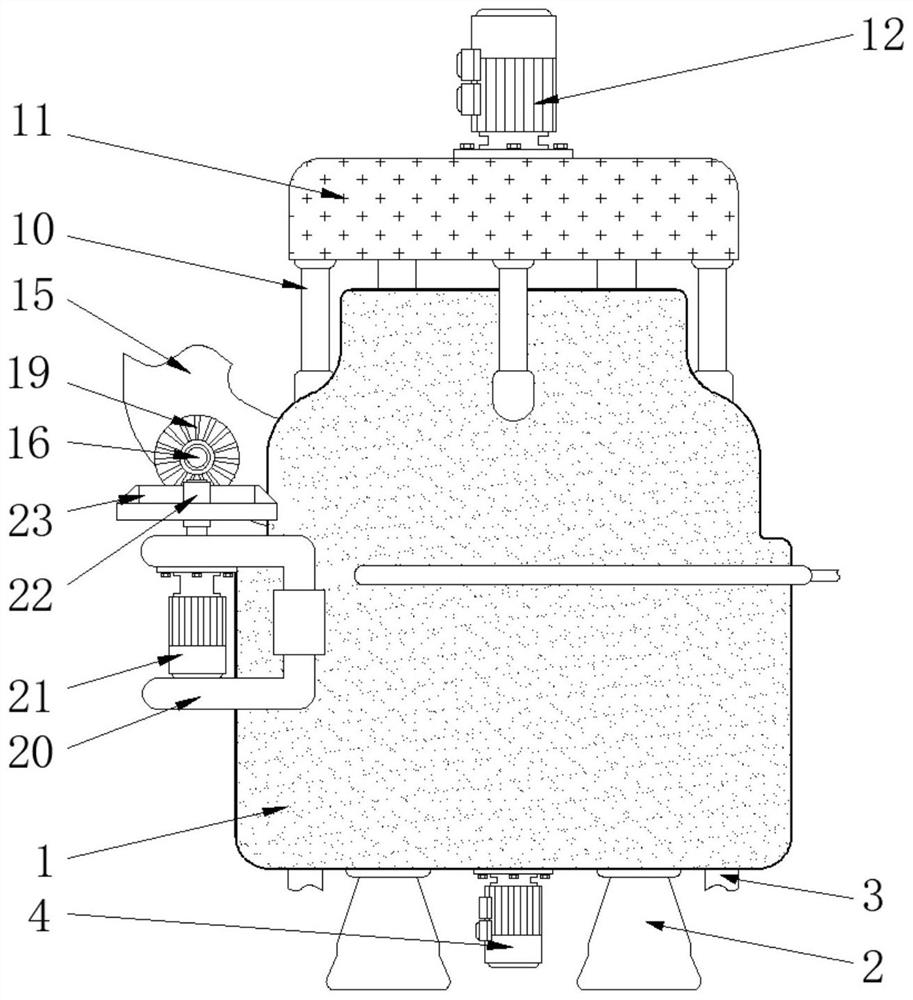

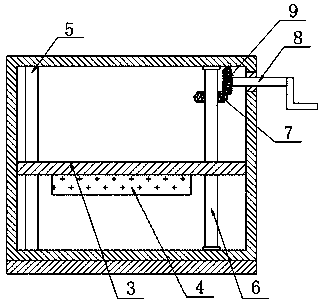

Kitchen waste treatment device and method with improved dry-type anaerobic fermentation effect

ActiveCN113278514AGood magnetic conductivity and heat transfer performanceEasy to recycleBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringWaste treatment

The invention discloses a kitchen waste treatment device and method with an improved dry-type anaerobic fermentation effect. The device comprises a fermentation tank, a stirring assembly, a sensing assembly, a control assembly, a heating assembly and an adsorption assembly, wherein the adsorption assembly comprises an electromagnetic coil arranged on the outer side face of the fermentation tank, and the heating assembly comprises a heating sheet which is arranged on the outer side face of the fermentation tank and is adjacent to the electromagnetic coil; the sensing assembly comprises a first temperature sensor and a second temperature sensor, the second temperature sensor is used for sensing an internal temperature of the fermentation tank, and the first temperature sensor is used for sensing a temperature of the heating sheet; and the control assembly can be used for controlling independent make and break of the electromagnetic coil and can also be used for controlling simultaneous make and break of the electromagnetic coil and the heating sheet according to a sensed result of the sensing assembly. According to the device and the method, a stable-temperature uniform-heated fermentation environment can be provided for anaerobic bacteria in the fermentation tank, the problem of dead corners for stirring is effectively solved, and the efficiency and quality of decomposition of the anaerobic bacteria to kitchen wastes are improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Extraction device for multi-layer extraction of effective components in Chinese herbal medicine

PendingCN111974023AImprove efficiencyReduce the number of reprocessingSolid solvent extractionFiltration circuitsChinese herbsStructural engineering

The invention discloses an extraction device for multi-layer extraction of effective components in a Chinese herbal medicine. The device comprises a processing tank, a motor, a material pump, a support plate and a discharge pipe, wherein a feeding hole is formed in the right upper corner of the processing tank; the motor is mounted at the left upper corner of the processing tank through bolts; a motor shaft is connected with a movable cylinder through a first belt wheel mechanism; a supporting ring is fixed to the lower end of a connecting shaft; an extraction tank is movably installed in theprocessing tank and located on the outer side of the connecting shaft; the outer side of a connecting hole is sleeved with a sleeve block; the motor shaft is connected with a movable pipe through a second belt wheel mechanism; balls are fixed to the outer surface of the extraction tank; and a partition plate is arranged on the inner wall of the lower end of the processing tank. According to the extraction device for multi-layer extraction of the effective components in the Chinese herbal medicine, the effective components in the Chinese herbal medicine are extracted in a solvent extraction mode; and meanwhile, the components in the Chinese herbal medicine can be fully separated out in a rolling mode, so extraction efficiency can be improved.

Owner:山东药品食品职业学院

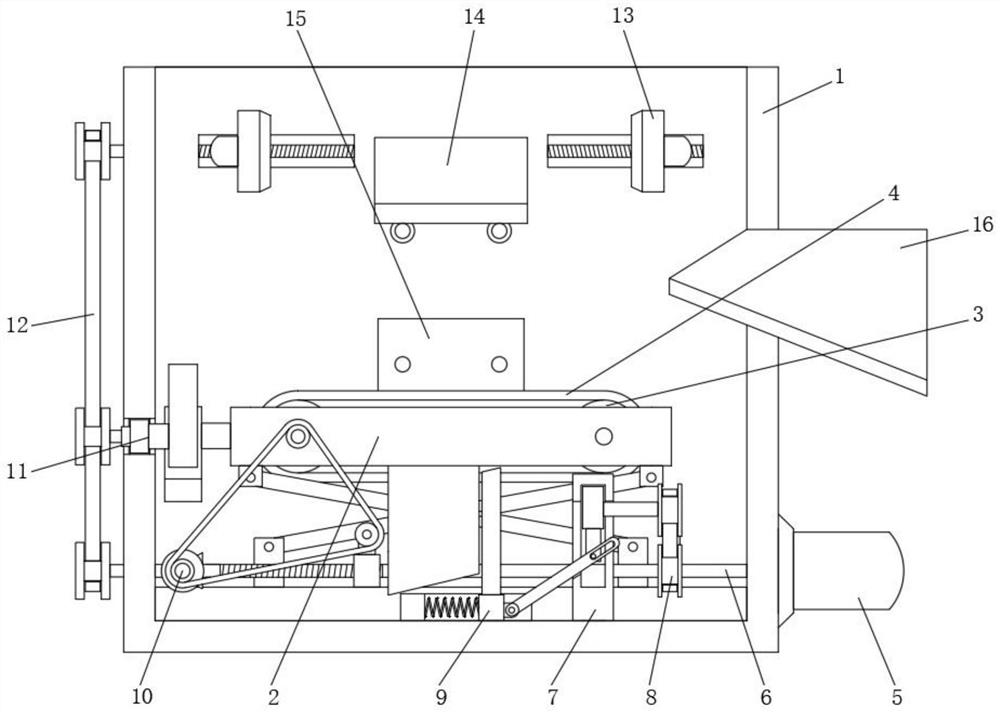

Grinding device for processing wooden door

InactiveCN110774078AHeight adjustableAvoid regrindingGrinding carriagesGrinding feedersStructural engineeringMechanical engineering

The invention discloses a grinding device for processing a wooden door, and particularly relates to the technical field of wooden door grinding. The grinding device comprises a supporting plate. A grinding frame is arranged on the top of the supporting plate. A grinding mechanism is arranged in the grinding frame. The grinding mechanism comprises a movable plate. A grinding brush is arranged at the bottom of the movable plate. Limiting rods are arranged at the four corners of the top of the movable plate correspondingly. The top ends of the four limiting rods are all fixedly connected with thetop of an inner cavity of the grinding frame. The bottom ends of the four limiting rods all penetrate through the movable plate and extend out of the bottom of the movable plate. The bottom ends of the four limiting rods are all fixedly connected with the bottom of the inner cavity of the grinding frame. A threaded rod is arranged on one side of the movable plate. By designing the grinding mechanism, the height of the movable plate and the grinding brush can be adjusted, the grinding brush at the bottom of the movable plate can always make contact with a door board so as to have a grinding effect on the surface of the door board, the door board is prevented from being repeatedly ground, and meanwhile resources are saved to a certain extent.

Owner:徐州世纪华腾木制品股份有限公司

Environment-friendly water-based printing ink preparation and processing system

ActiveCN111871306AStir fully and evenlyAvoid drippingTransportation and packagingMixersEngineeringPrinting ink

The invention relates to an environment-friendly water-based printing ink preparation and processing system which comprises a stirring tank and a plurality of groups of stirring devices arranged in the stirring tank, and a driving device of the stirring device for driving is arranged outside the stirring tank; the stirring device is driven by the wheel disc to rotate, the bucket in the stirring device shovels up ink, the ink falls down from the material leaking hole, and the ink is scooped up and leaked for multiple times, so that the ink is fully and uniformly stirred, and the best use effectof the ink is achieved; in addition, a grinding mechanism is additionally arranged on the bucket, so that the roller makes contact with the inner wall of the square groove under the action of the elastic force of the spring, the roller is driven by the bucket to rotate, the roller makes close contact with sediment at the bottom of the stirring groove, and the sediment at the bottom of the stirring groove is ground; and secondly, the side plates also play a role in guiding the grinding mechanism, so that the grinding mechanism is prevented from being clamped at the top of the square groove.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

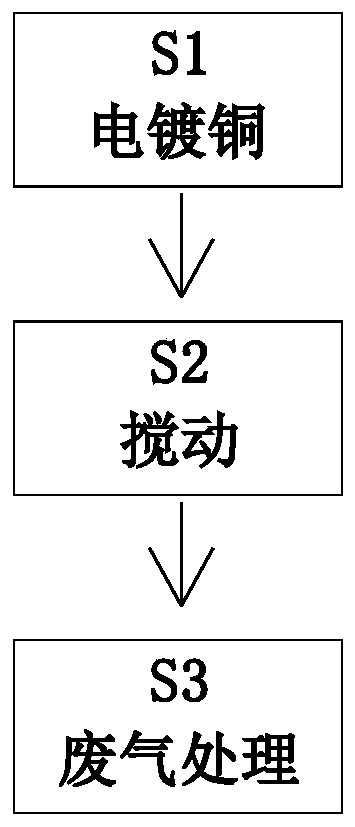

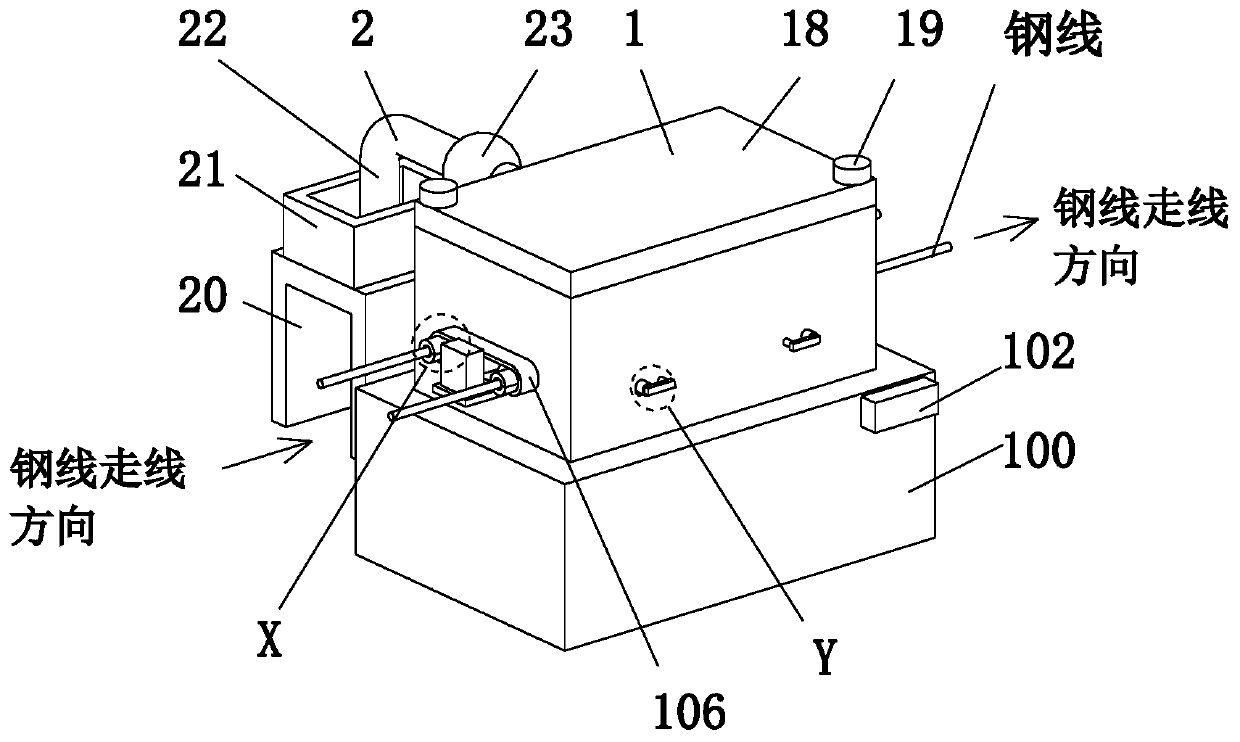

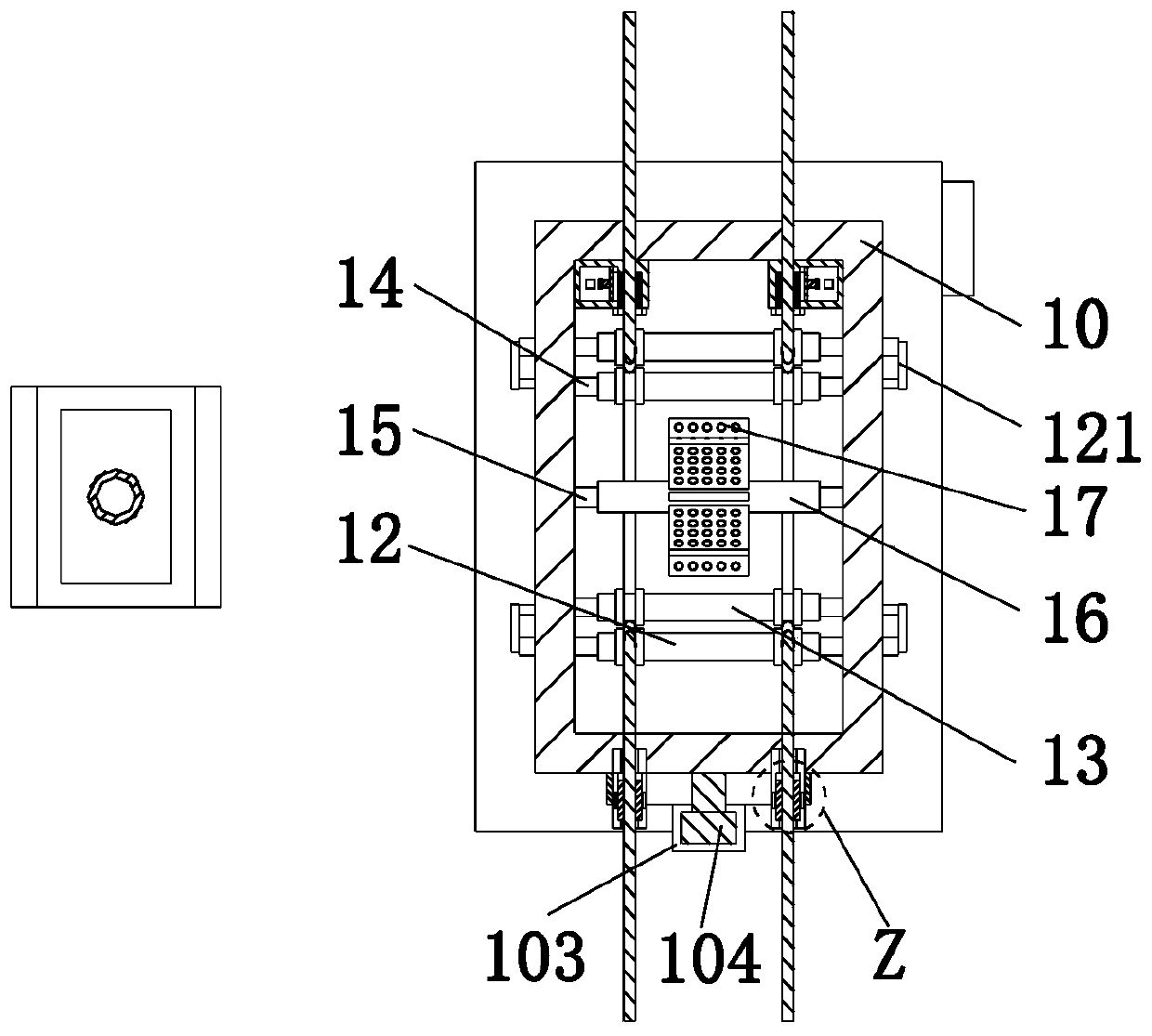

Copper-clad steel wire production fabrication process

InactiveCN111575758AIncrease current densityImprove copper plating efficiencyCellsElectrolysisCopper plating

The invention relates to a copper-clad steel wire production fabrication process. A copper-clad steel wire production fabrication device is used in the copper-clad steel wire production fabrication process, the copper-clad steel wire production fabrication device comprises an electroplating mechanism and a treatment mechanism, wherein the lower end of the electroplating mechanism is arranged on anexisting working ground, the right astern of the electroplating mechanism is provided with the treatment mechanism, and the lower end of the treatment mechanism is arranged on the existing working ground. According to the copper-clad steel wire production fabrication process, a design concept of combining electrolytic copper plating with environmental protection structures is adopted to perform copper-clad steel wire production fabrication, the treatment mechanism is arranged to absorb and remove waste gases generated in the electrolytic copper plating process in real time in order to upholdthe green environmental emission concept, meanwhile, a heating structure capable of performing real-time monitoring is arranged to perform appropriate heating treatment on electroplating liquid in anelectroplating box in order to improve the active degree of substances contained in the electroplating liquid, and then the steel wire copper plating speed and effect are improved.

Owner:合肥集知网信息技术有限公司

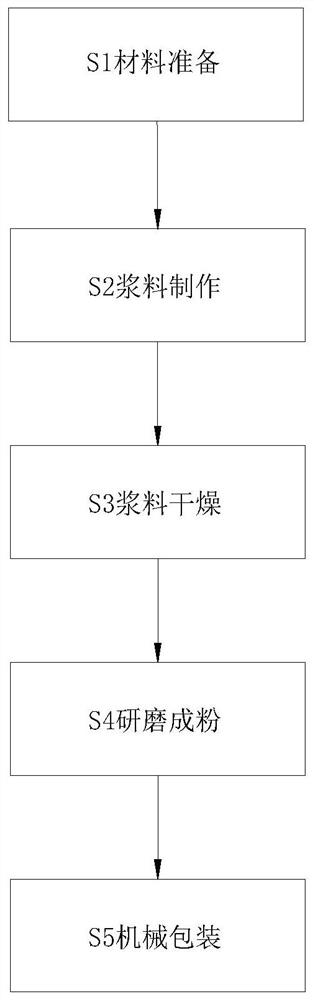

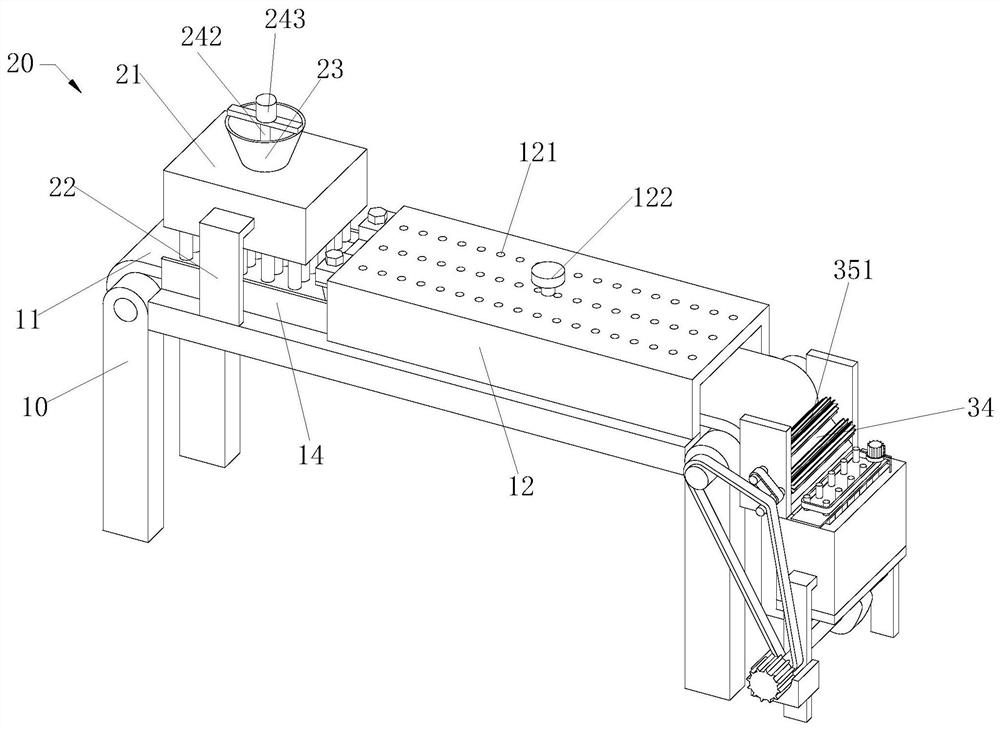

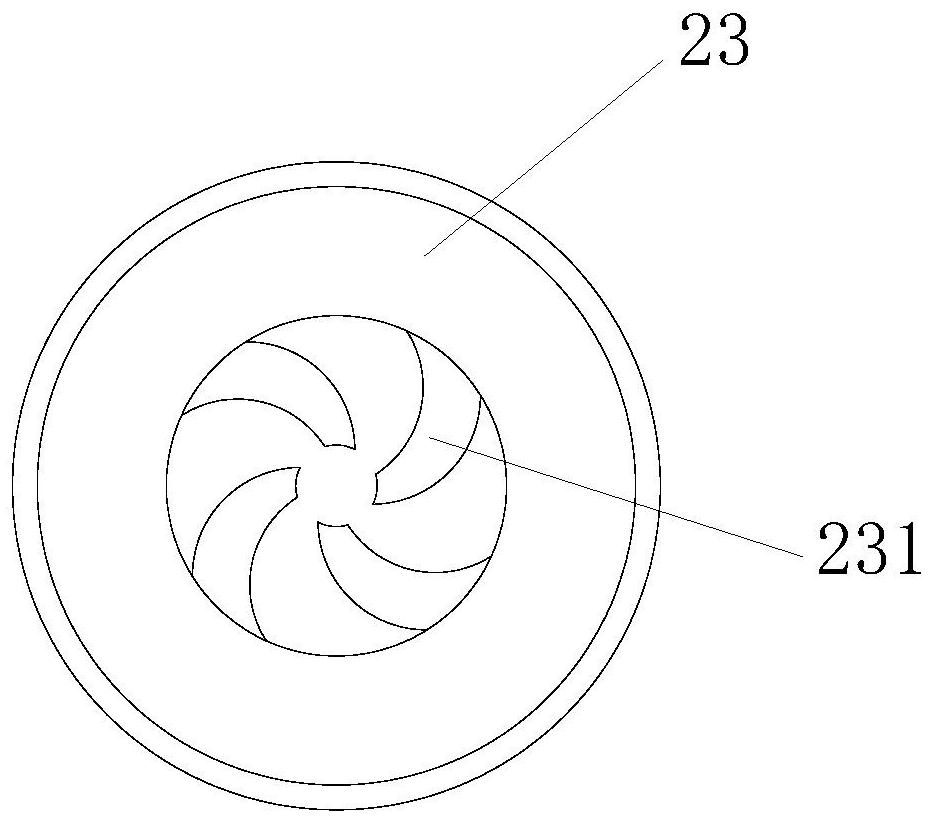

Skin care talcum powder preparation method

The invention relates to a skin care talcum powder preparation method which uses talcum powder processing and preparing equipment. The talcum powder processing and preparing equipment comprises fixed frames arranged in a bilateral symmetry mode and a conveyor belt arranged between the fixed frames, wherein a feeding device is arranged above the conveyor belt, and a grinding device is arranged on the right side of the conveyor belt. For the skin care talcum powder preparation method disclosed by the invention, by matching first blade plates with second blade plates, gaps between the first blade plates in each set can be gradually reduced and increased, at this time, slurry in a feeding hopper gradually flows out of the gaps between the first blade plates and the second blade plates, the discharging capacity is continuously changed, and the operation is repeated, so that intermittent feeding and discharging of the slurry by the second blade plate are achieved, and the phenomena that the slurry is accumulated due to continuous feeding, resources are wasted, the thickness of the slurry is increased, and the slurry is not prone to being fully dried are prevented.

Owner:徐俊

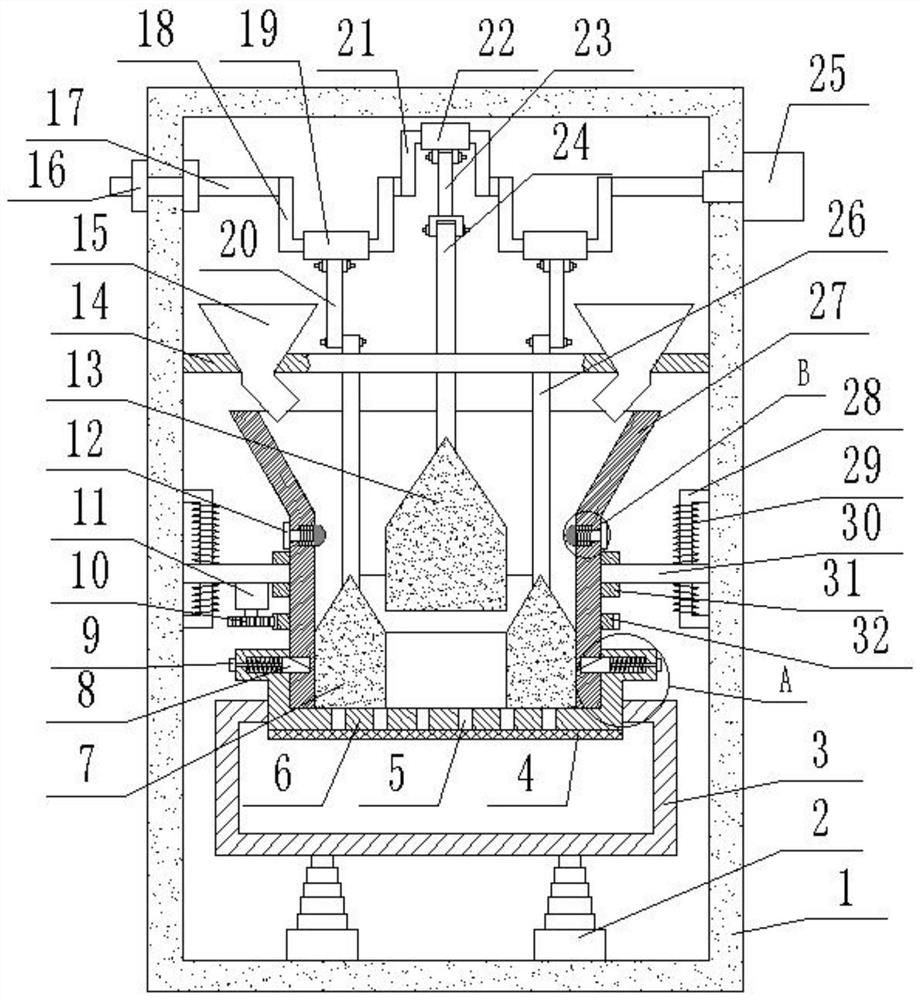

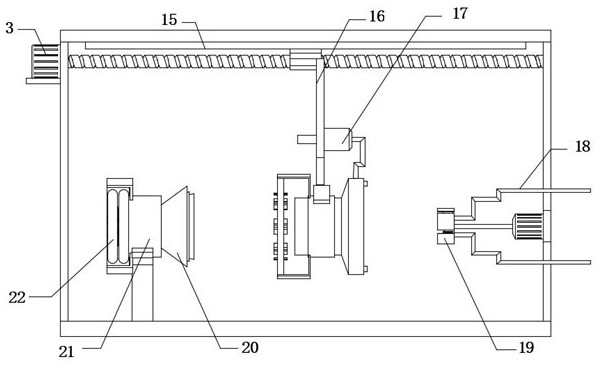

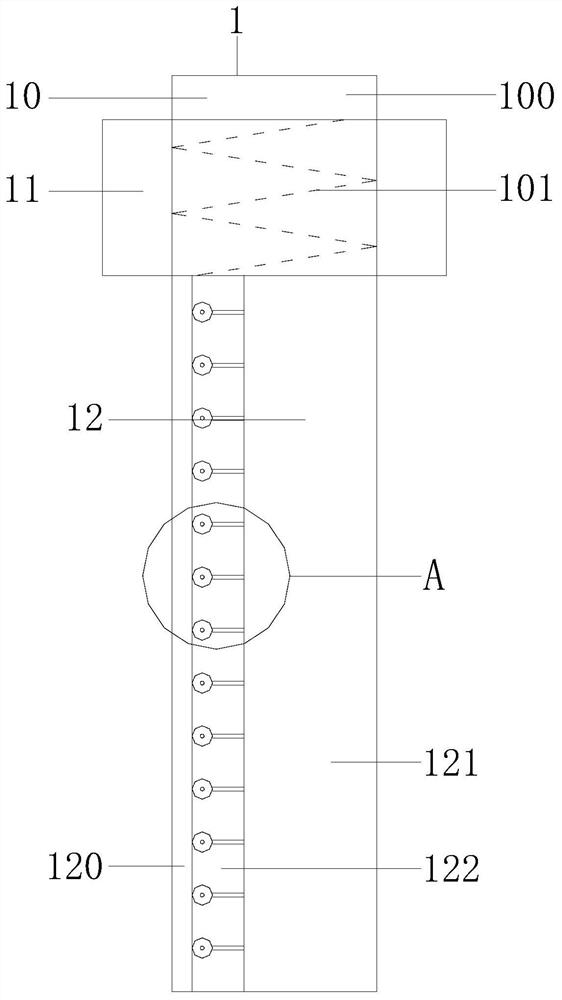

Medical efficient medicine grinding device

ActiveCN112588346APlay the role of grindingAvoid impact cleanupGrain treatmentsPharmacy medicineElectric machinery

The invention discloses a medical efficient medicine grinding device. The device comprises a box body, and a box door is hinged to one side of the box body. A second motor operates to enable an annular pressing block and a conical pressing block to alternately slide up and down, medicine falling into a circular groove is crushed, meanwhile, a first motor operates to enable a barrel and the circular groove to rotate, crushed powder is screened out through a filter screen, in addition, the medicine below the annular pressing block and the conical pressing block can be effectively ground throughrotation, large-particle medicine can be effectively rotated to the top face through rotation so as to be crushed conveniently, meanwhile, in the up-down sliding process of the annular pressing block,the barrel and the circular groove jolt under the arrangement of a first spring, medicine particles jolt and roll over, large-particle medicine is effectively rotated to the top face, crushed powderis rapidly screened out through the filter screen, and therefore it can be effectively avoided that crushed small particles are accumulated to influence crushing of large materials.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

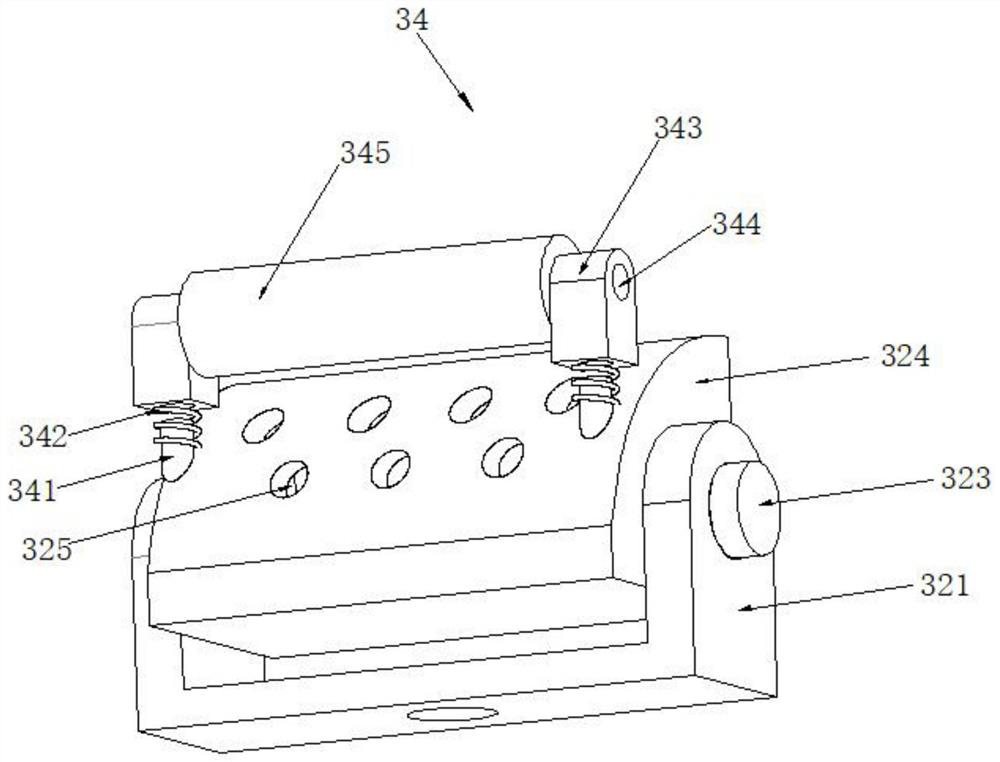

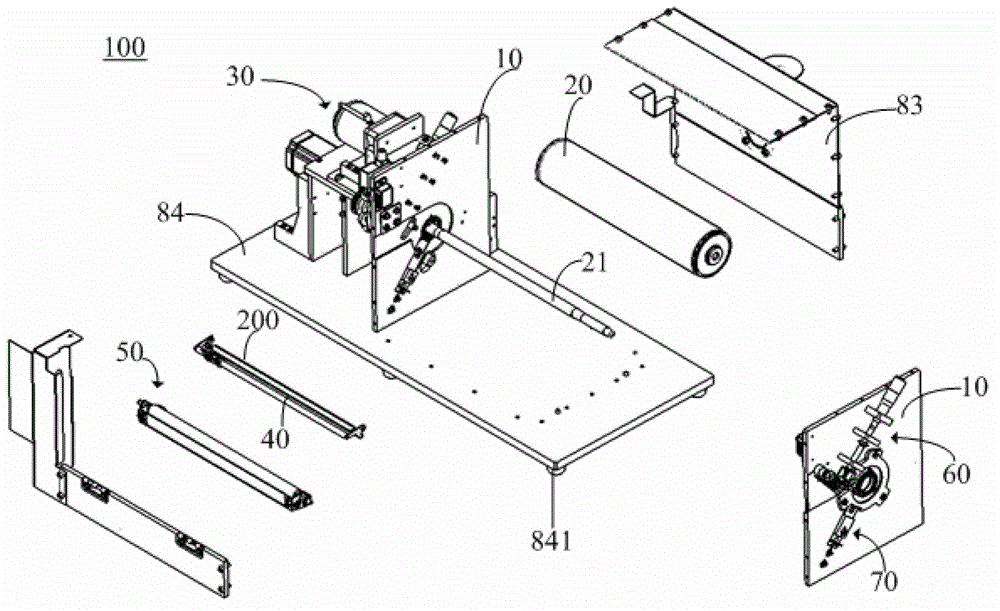

Scraper grinding device

InactiveCN103144000AReduce fine bumpsQuality improvementEdge grinding machinesElectrography/magnetographyDigital copyImaging quality

A scraper grinding device comprises two opposite support parts, a cylindrical rolling part, two positioning parts and a driving part, wherein the two ends of the cylindrical rolling part are rotationally located on the two support parts; the two positioning parts are located on the two support parts respectively and used for positioning a scraper; the driving part is connected with the cylindrical rolling part and used for driving the cylindrical rolling part to rotate; and when the cylindrical rolling part rotates, the scraper is ground. The scraper grinding device can grind the scraper; when the distance between the cylindrical rolling part and the scraper is appropriate, after the cylindrical rolling part grinds the scraper, fine bumps at the edge of the scraper are decreased; the edge precision is improved; correspondingly, when the scraper is applied to imaging devices such as a digital copying machine, no toner missing happens when a toner is cleared; and the image quality can be improved.

Owner:KONICA MINOLTA BUSINESS TECHNOLOGIES (WUXI) CO LTD

Raw material smashing device for brick making

The invention relates to the field of building and particularly discloses a raw material smashing device for brick making. The raw material smashing device comprises a smashing cylinder, a drive partand a stirring mechanism. The stirring mechanism is located in the smashing cylinder. The stirring mechanism comprises a rotating shaft, a plurality of stirring rods and a balance weight piston capable of sliding in the vertical direction of the smashing cylinder. The rotating shaft and the stirring rods penetrate through the balance piston vertically. The balance piston can slide in the verticaldirection relative to the stirring rods and the rotating shaft. The balance piston can rotate along the rotating shaft. The balance piston is provided with a plurality of through holes. The drive partdrives the rotating shaft to rotate. The smashing device in the scheme can avoid clay caking in the smashing process.

Owner:CHONGQING YONGCHUAN DISTRICT HONGDI BUILDING MATERIALS

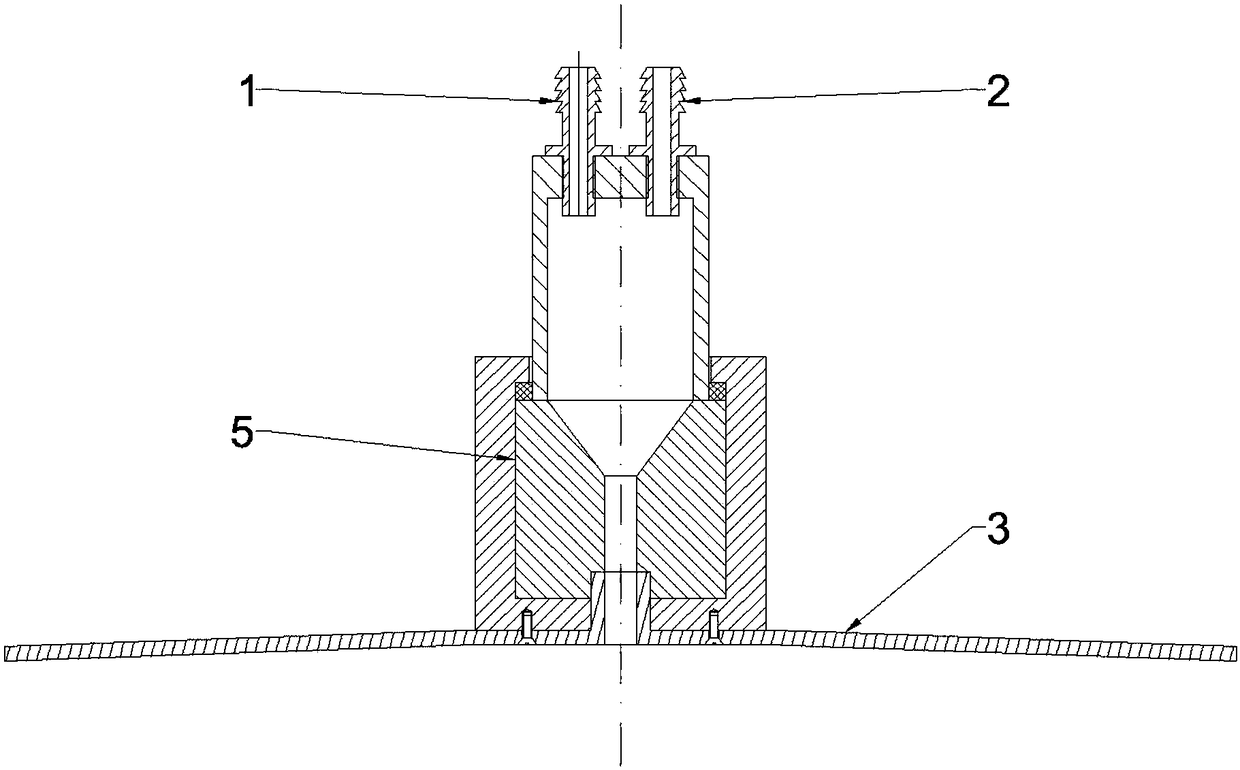

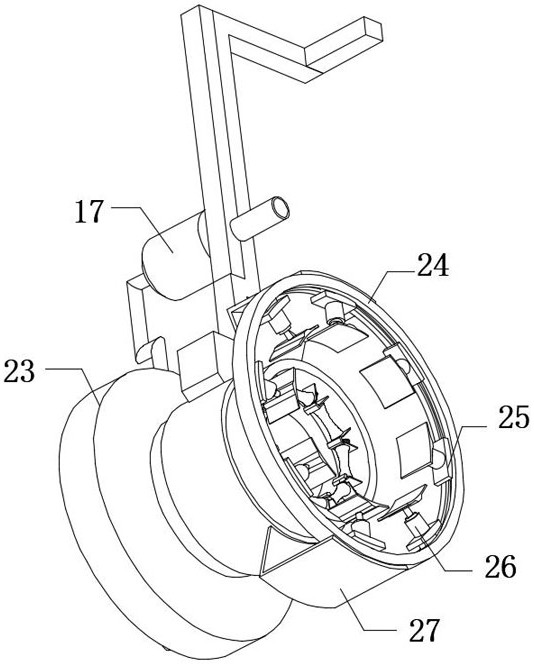

Blast shot spray gun device

InactiveCN108372471AIncrease roughnessPlay the role of grindingBlast gunsAbrasive feedersAtmospheric pressureNozzle

The invention provides a blast shot spray gun device. The blast shot spray gun device comprises a nozzle, an air inlet pipe and a blast shot inlet pipe, the air inlet pipe and the blast shot inlet pipe are inserted into a nozzle inlet, a flow guide plate is arranged on a nozzle outlet, the flow guide plate is in a curved face or arc shape, and the reflection frequency of shot steel shots or steelsand is increased; the flow guide plate is a conical face, the center line of the conical face coincides with the center line of the nozzle outlet, the taper of the conical face of the conical flow guide plate ranges from 1 to 3 degrees, the proportion of the bottom face area of the conical flow guide plate to the area of the cross section of the nozzle outlet is 30:1-50:1, the length of the air inlet pipe inserted into the nozzle is smaller than the length of the blast shot inlet pipe inserted in the nozzle, and air pressure losses are avoided. The grinding frequency in unit time can be increased, the air pressure failure speed can be controlled, the machining efficiency is improved, and the effective jetting strength can be effectively improved.

Owner:JIANGSU UNIV

Cold drawing equipment for stainless steel product machining

The invention belongs to the technical field of stainless steel product machining, and particularly relates to cold drawing equipment for stainless steel product machining. According to the scheme, the cold drawing equipment comprises an operation table and a fixing rod, and a pre-cold-drawing mold is fixedly connected to the outer wall of the bottom of the fixing rod. According to the cold drawing equipment for stainless steel product machining, through the arrangement of a molding cover, sliding blocks, hydraulic cylinders and molding plates, a guide groove is formed in the inner wall of the molding cover, in the pre-cold-drawing process of a stainless steel product, the hydraulic cylinders are adjusted to drive the molding plates to make contact with the outer wall of the stainless steel product, in the process of sliding on the outer wall of the stainless steel product along with the pre-cold-drawing mold, the molding plates extrude the stainless steel product, the cold-drawn stainless steel product is easy to deform, the outer wall of the stainless steel product is polished and molded through the molding plates, the situation that the outer wall of the stainless steel product is uneven is prevented, and in the process that the molding plates and the stainless steel product are mutually extruded, the sliding blocks slide in the guide groove, so that the molding plates realize self-rotation, and the molding effect on the stainless steel product is improved.

Owner:南通飞神金属制品有限公司

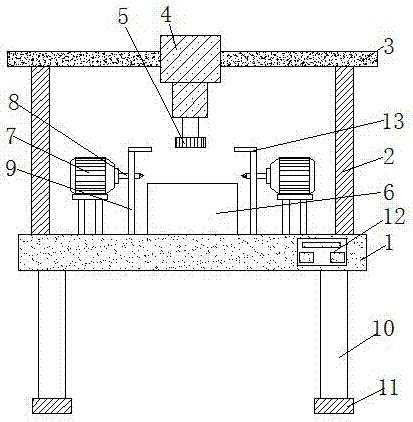

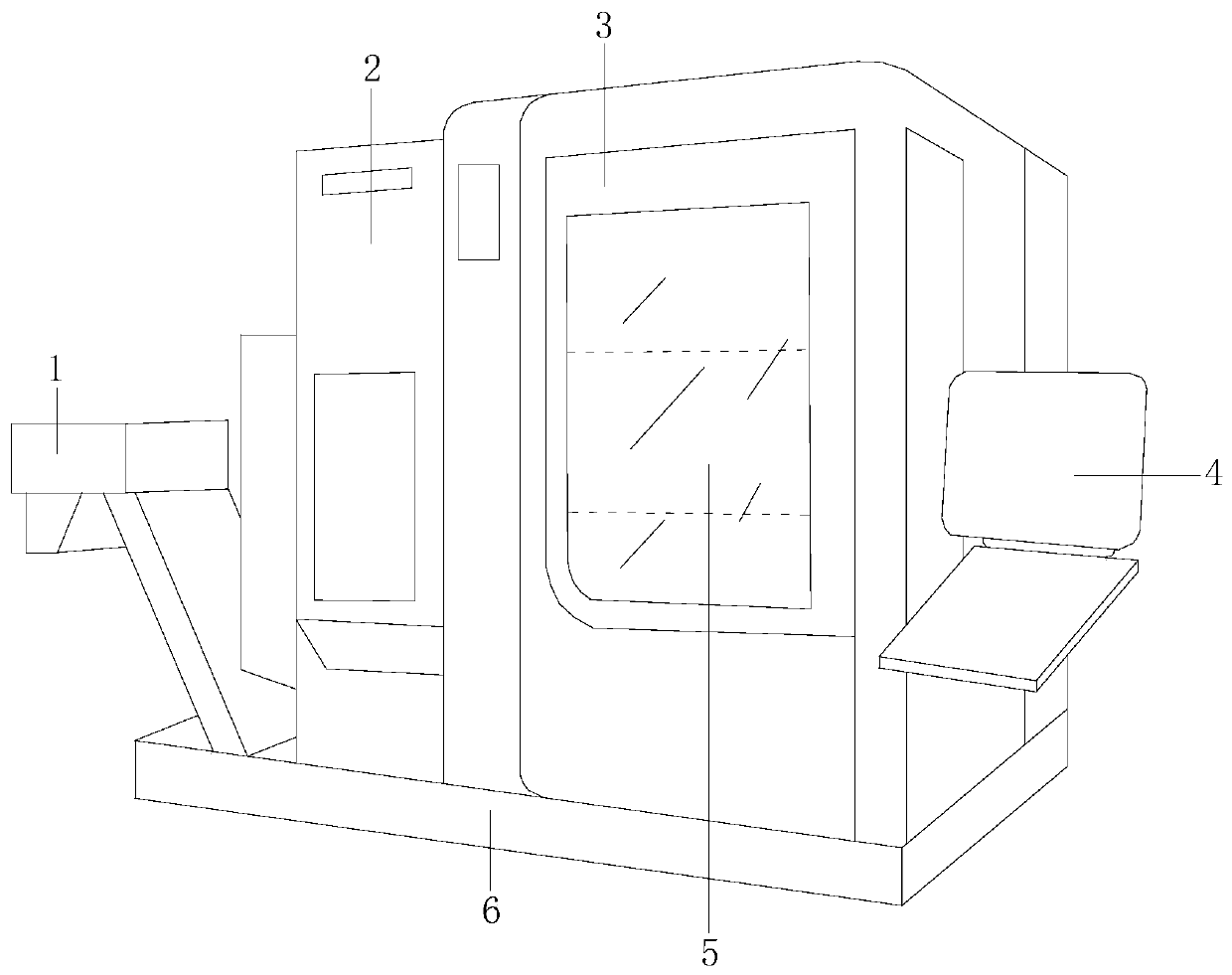

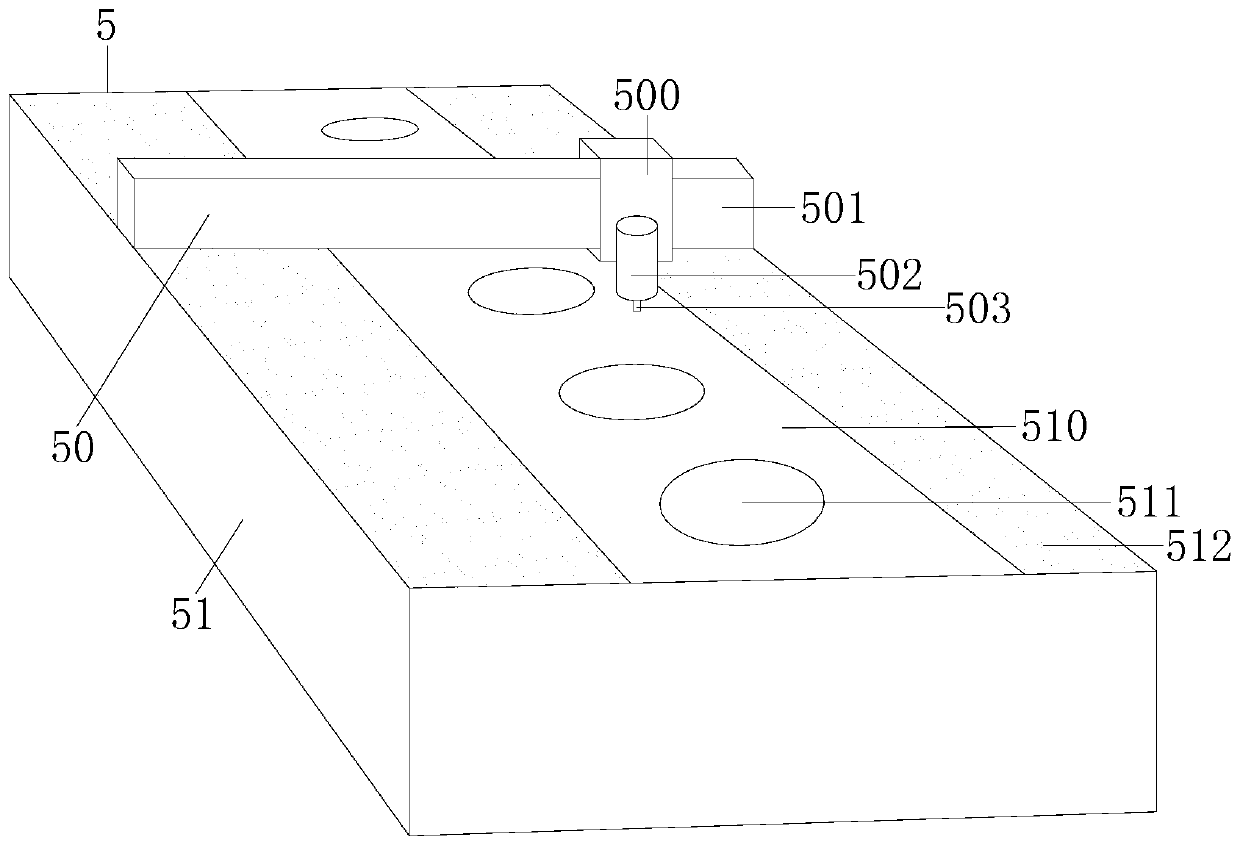

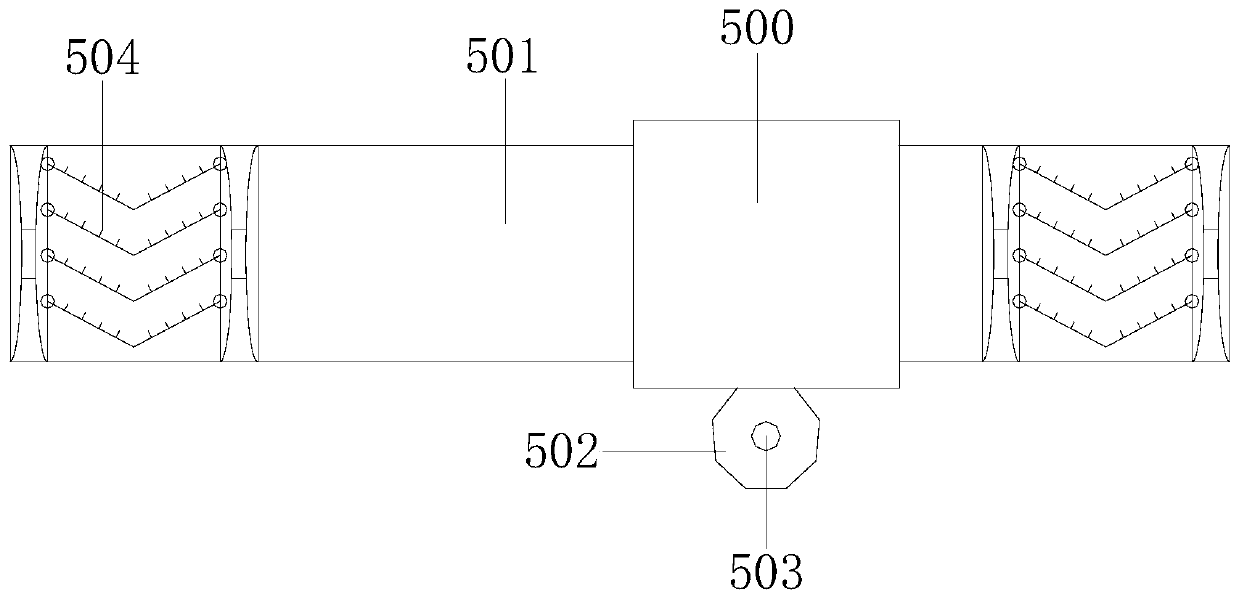

Metal cutting machine tool for cleaning iron chips during cutting

The invention discloses a metal cutting machine tool for cleaning iron chips during cutting. The metal cutting machine tool structurally includes a feeding frame, a cutting fluid storage frame, a cutting chamber, a control machine, a cutting machine and a base. The feeding frame and the cutting fluid storage frame are installed on the base, the cutting chamber and the base are locked, the controlmachine is locked on the cutting chamber, the cutting machine is installed on the cutting chamber, the cutting machine is composed of a cutting machine head and a workpiece frame, and the cutting machine head is in track connection with the workpiece frame. The cutting machine head includes a moving machine frame, a cross track, a cutting machine barrel, a cutting machine drill, and a dust collecting device. The moving machine frame is in track connection with the cross track, the dust collecting device is embedded in the cross track, the moving machine frame is welded to the cutting machine barrel, and the cutting machine barrel is connected with a cutting machine drill spindle. According to the metal cutting machine tool, the cutting machine drill collects and cleans the iron chips whileturning, the friction rate with the iron chips is reduced when the cutting structure is machined, the vibration is reduced, and the machining accuracy is further improved; and the iron chips accumulated around are further evenly cleaned by an embedded frame, so that the friction brake due to the thickening of the iron chips is avoided, and the equipment operates more smoothly.

Owner:安徽佰易智能精机制造有限公司

Polishing equipment for mobile phone screen production

InactiveCN112318351APlay the role of polishingEasy to usePolishing machinesGrinding drivesEngineeringMechanical engineering

The invention discloses polishing equipment for mobile phone screen production, and belongs to the field of screen polishing. The polishing equipment comprises a working platform, supporting columns are fixedly connected to the left side and the right side of the top of the working platform, a mounting plate is fixedly connected between the tops of the supporting columns, and electric push rods are fixedly mounted at the left side and the right side of the top of the mounting plate; a telescopic air cylinder is fixedly mounted at the middle end of the top of the mounting plate, strip-shaped notches are formed at the positions, located between the electric push rods and the telescopic air cylinder, of the top of the mounting plate, the output ends of the electric push rods are fixedly connected with connecting plates, and the bottoms of the connecting plates penetrate through the strip-shaped notches to be fixedly connected with a polishing mechanism; and the output end of the telescopic air cylinder penetrates through the mounting plate to be fixedly connected with a clamping mechanism, and a through hole is formed at the position, corresponding to the clamping mechanism, of the top of the working platform. By arranging the clamping mechanism, the clamping mechanism plays a role in fixing the mobile phone screen, so that the polishing mechanism polishes and grinds the mobile phone screen from the two sides.

Owner:DEQING HANGZHOU SHELL INTELLIGENT TECH CO LTD

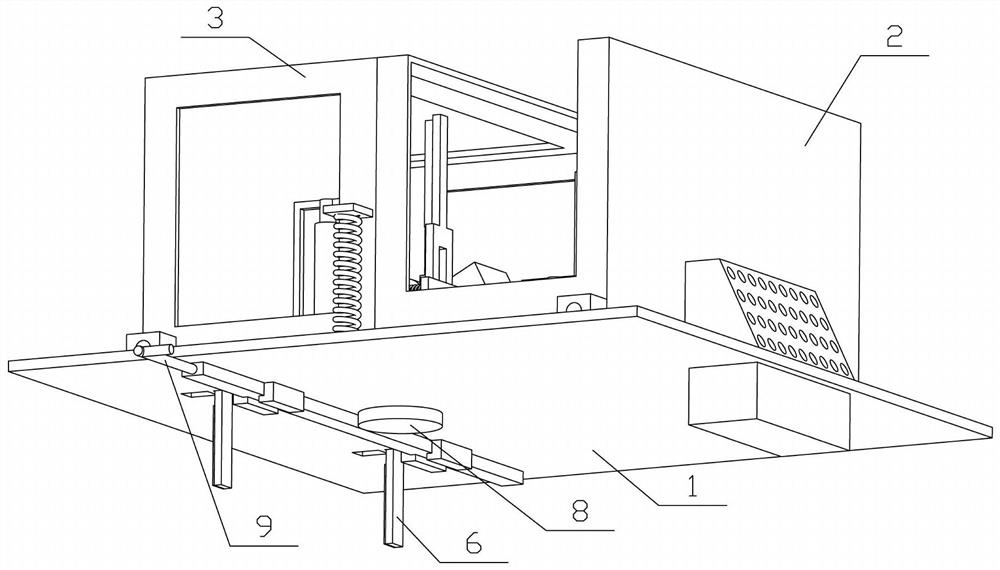

Industrial model manufacturing device

PendingCN114211363AMeet the needs of useImprove efficiencyBelt grinding machinesGrinding work supportsElectric machineryMachining

The invention relates to the technical field of model manufacturing, and discloses an industrial model manufacturing device which solves the problem that manual auxiliary operation is needed in the polishing process of existing model manufacturing polishing equipment, the industrial model manufacturing device comprises an equipment shell, a lifting U-shaped frame is arranged in the equipment shell, and two rotating rollers are installed in the lifting U-shaped frame; a grinding abrasive belt is installed between the surfaces of the two rotating rollers, two motors are installed at the bottom of one side of the equipment shell, a main rotating shaft is installed on one side of the bottom in the equipment shell, the output end of one motor is connected with the main rotating shaft, and a second transmission mechanism is installed between one side of the main rotating shaft and the lifting U-shaped frame and the inner wall of the equipment shell. In the using process of the industrial model manufacturing device, assistance and participation of workers are not needed, the workers only need to place the model on the device and control equipment to start, and therefore the efficiency and speed of model manufacturing and machining are effectively improved.

Owner:武汉印合科技有限公司

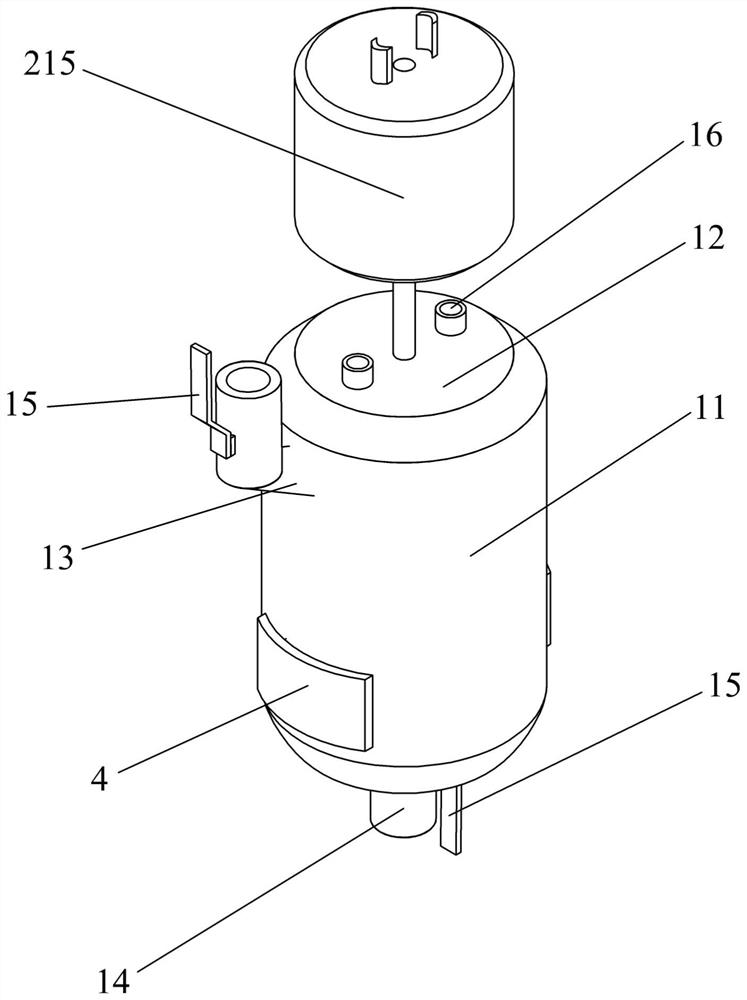

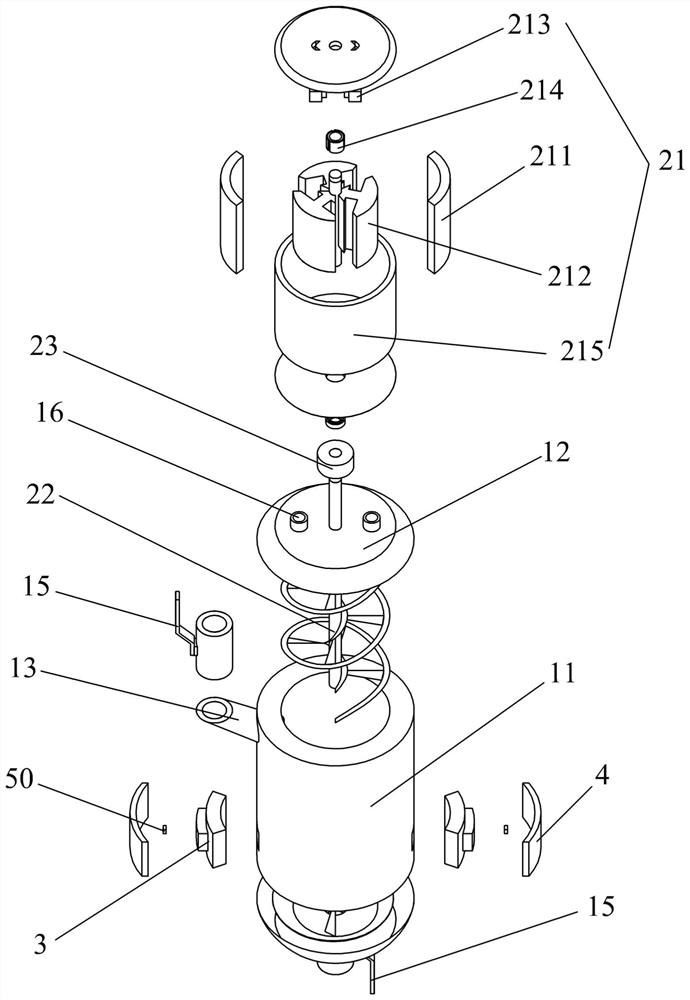

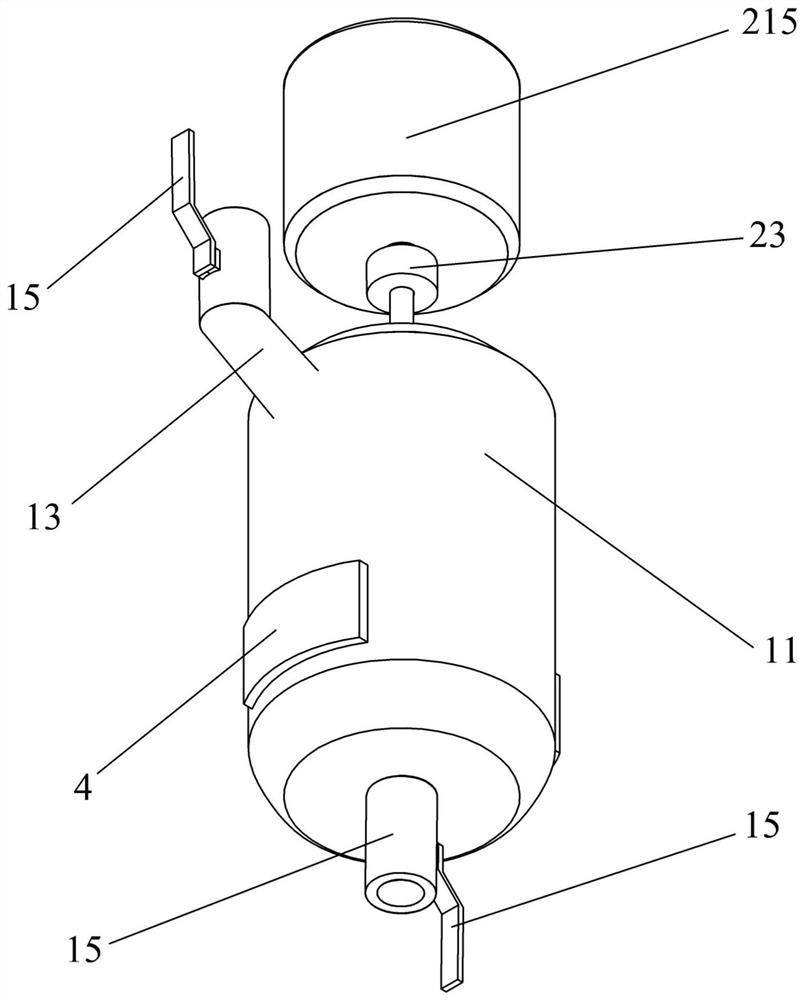

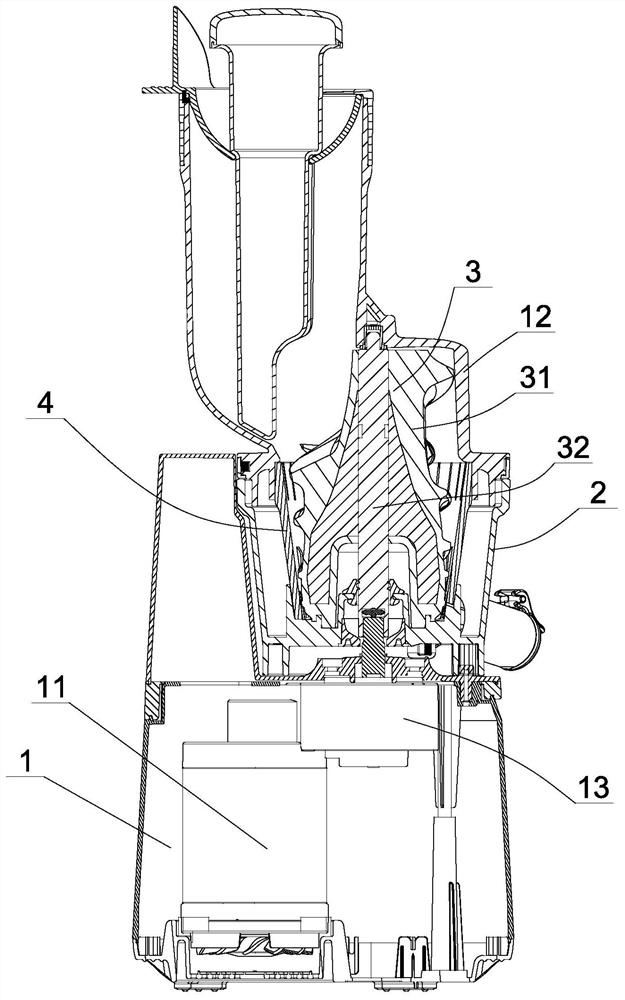

Juicing method of juicer

Disclosed is a juicing method of a juicer. The juicer comprises a machine base, a juice collecting cavity formed in the machine base, a screw rod arranged in the juice collecting cavity and an extrusion cylinder located between the screw rod and the juice collecting cavity, the screw rod comprises a crushing section, an extrusion section and a grinding section from top to bottom, a gap between thescrew rod and the extrusion cylinder is gradually reduced from top to bottom, and the lower part of the extrusion cylinder is matched with the bottom of the juice collecting cavity in an inserting manner to form a lower juice outlet gap. The juicing method at least comprises the following steps: a shearing step: shearing and crushing materials into small blocks by the screw of the crushing section to generate juice; an extrusion step: spirally pushing the material to move downwards to a grinding section while rotating, extruding the material by a screw rod and an extrusion cylinder, discharging juice, and enabling the juice to flow to the bottom of a juice collecting cavity; and a grinding and filtering step: pushing the material to the lower part of the extrusion cylinder by the screw, grinding the material by the grinding section to form pomace and juice, and enabling the juice to flow out through a lower juice outlet gap. According to the invention, the juice yield and the juice outlet speed can be increased, and the juicer is convenient to manufacture and clean after being used.

Owner:JOYOUNG CO LTD

Crushing and refining device for ore processing

PendingCN114011551AShorten the break timePlay the role of primary fragmentationGrain treatmentsPulverizerMechanics

The invention relates to the technical field of ore processing, in particular to a crushing and refining device for ore processing, which comprises a first connecting shell, a supporting plate is fixedly connected in the first connecting shell, a leak hole is formed in the supporting plate, and a second connecting shell is abutted against the supporting plate. A crushing mechanism is arranged between the first connecting shell and the second connecting shell; the first connecting shell is connected with a supporting frame through a connecting mechanism, and a rotating shaft is rotationally connected with the supporting frame through a bearing. The device has the characteristic that the crushing time can be saved.

Owner:安徽鑫玉精细材料科技有限公司

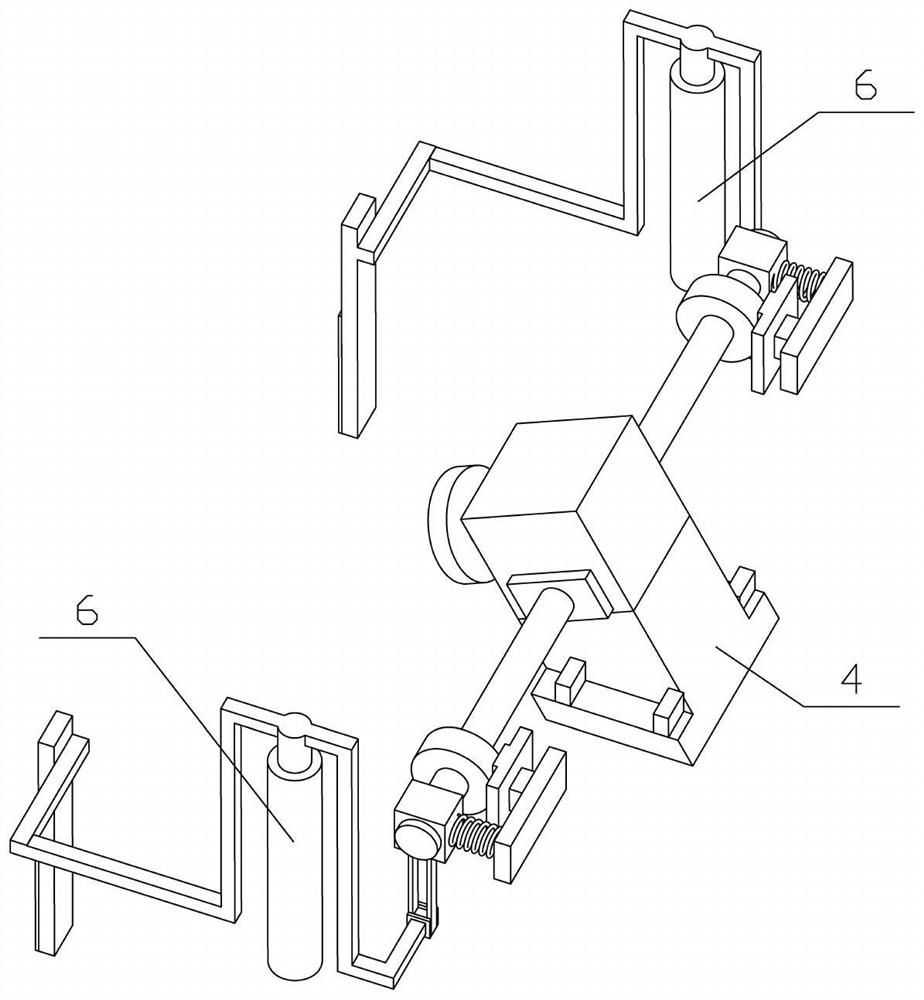

Industrial grinding machine

ActiveCN112497045AEasy to cleanPlay the role of grindingGrinding drivesLapping machinesTool bitEngineering

The invention relates to the technical field of machinery, in particular to an industrial grinding machine. The industrial grinding machine comprises a bearing device, a fixed box, a rotating box, a grinding device, a locking device, lifting devices, a clamping device, a workpiece and an adjusting device. The right end of the upper portion of the bearing device is fixedly connected with the fixedbox, the left end of the upper portion of the bearing device is connected with the rotating box in a hinged manner, and the grinding device is installed on the bearing device. The grinding device andthe bearing device can be fixed through the locking device, the front end and the rear end of the upper portion of the bearing device are symmetrically and fixedly connected with the two lifting devices, the two lifting devices are both in sliding connection with the bearing device and are both in engaged transmission connection with the rotating box, and the two lifting devices are in sliding connection with the front end and the rear end of the grinding device correspondingly. The clamping device is rotatably connected to the middle of the bearing device, the workpiece can be clamped throughthe clamping device, and the adjusting device is in sliding connection to the bearing device and is in engaged transmission connection with the clamping device. The industrial grinding machine has the function of conveniently cleaning a grinding tool bit.

Owner:湖南嘉顺华新材料有限公司

Raw material crushing device for brick making

ActiveCN109731655BWon't uniteWon't hinderClay processing apparatusGrain treatmentsBrickClassical mechanics

Owner:CHONGQING YONGCHUAN DISTRICT HONGDI BUILDING MATERIALS

Thread break preventing device for textile machinery

ActiveCN111926451AAvoid accumulationSmall diameterWeft knittingWarp knittingStructural engineeringMechanical engineering

The invention discloses a thread break preventing device for textile machinery, which structurally comprises an upper thread column, a main frame, a bottom thread column, a thread grinder and a threadoutlet frame, wherein the upper thread column is mounted on and connected with the bottom thread column, the main frame is locked with the thread outlet frame, and the thread grinder is mounted on the main frame; the main frame is composed of a main frame body, frame holes and an outlet plate, the main frame body is welded with the outlet plate, and the frame holes are formed in the main frame body; the thread outlet frame comprises a thread outlet frame body, a thread frame hole and a thread frame port, and the thread frame port and the thread frame hole are formed in the thread outlet framebody; and the upper thread column comprises an upper thread-feeding head, an upper thread-feeding cover and an upper thread-feeding rod, and the upper thread-feeding head and the upper thread-feedingrod are embedded in the upper thread-feeding cover. According to the invention, the conveying stability is improved due to multi-position winding and conveying of spun threads, the spun threads are combed when being conveyed by the upper thread-feeding rod, and an upper trajectory and the thread grinder are capable of adjusting the opening size according to the thread thickness, thereby avoidingthread knots and thread accumulation, and meanwhile, the diameter of a thread knot is reduced by grinding, so that the conveying smoothness of the spun threads is improved.

Owner:河南世贤纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com