Ceramic bond grinding tool

A ceramic bond and abrasive tool technology, applied in abrasives, grinding devices, manufacturing tools, etc., can solve the problems of uneven structure, difficulty in meeting use requirements, uneven pressure transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

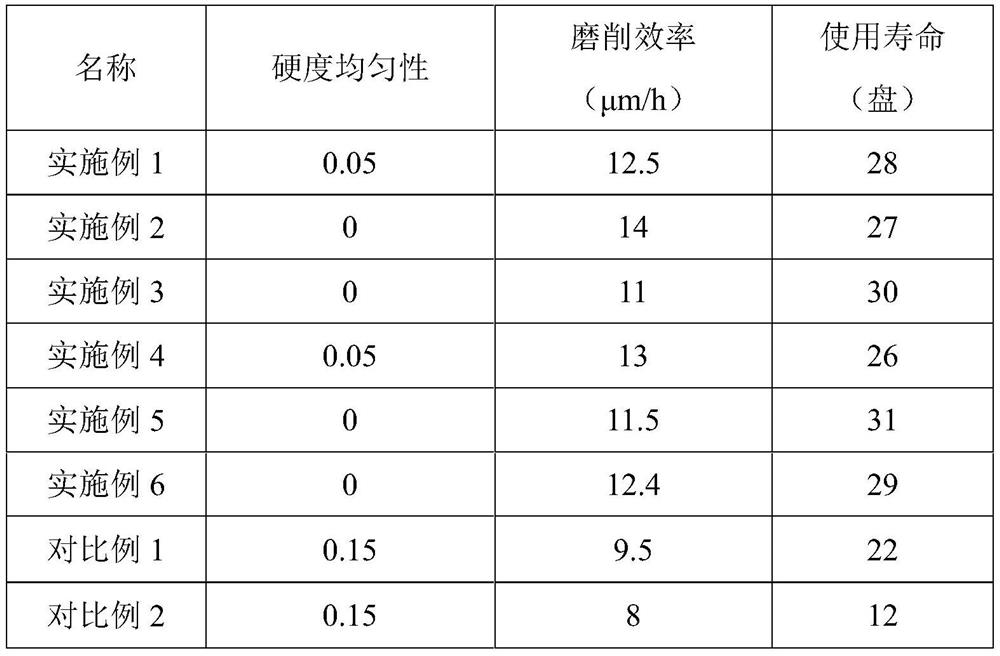

Examples

Embodiment 1

[0018] The vitrified bonded grinding tool in this embodiment is a vitrified bonded grinding wheel, which is made of the following raw materials in mass percentage: 20% silicon carbide, 30% corundum, and 50% vitrified bond. The vitrified bond used is composed of the following components by mass percentage: 17% of kaolinite powder, 2% of low-melting glass powder, 3% of nano silicon dioxide, 12% of pyrophyllite, and the balance is feldspar powder. When preparing the vitrified bond, take the formula amount of each component, mill it in a ball mill for 2.5 hours, and then sieve it. Among them, the low melting point boron glass powder is composed of the following components in mass percentage: 36% silicon dioxide, 11% aluminum oxide, 31% boron trioxide, 7% potassium oxide, 15% sodium oxide; low melting point glass powder The refractoriness is 570°C. The average particle diameter of nano silicon dioxide is 600nm.

[0019] The vitrified bond grinding wheel of the present embodiment ...

Embodiment 2

[0021] The vitrified bonded grinding tool in this embodiment is a vitrified bonded grinding wheel, which is made of the following raw materials in mass percentage: 20% silicon carbide, 32% corundum, and 48% vitrified bond. The vitrified bond used is composed of the following components by mass percentage: 17% of kaolinite powder, 2% of low-melting glass powder, 3% of nano silicon dioxide, 12% of pyrophyllite, and the balance is feldspar powder; During preparation, each component in the formula amount is ball milled in a ball mill for 2.5 hours and then sieved to obtain the product. Among them, the low melting point boron glass powder is composed of the following components in mass percentage: 36% silicon dioxide, 11% aluminum oxide, 31% boron trioxide, 7% potassium oxide, 15% sodium oxide; low melting point glass powder The refractoriness is 570°C. The average particle diameter of nano silicon dioxide is 600nm.

[0022] The vitrified bond grinding wheel of the present embodi...

Embodiment 3

[0024] The vitrified bond grinding tool of the present embodiment is a vitrified bonded grinding wheel, made of the raw materials of the following mass percentages: silicon carbide 18%, corundum 32%, vitrified bond 50%; the vitrified bond adopted consists of the following mass percentages Component composition: 17% kaolinite powder, 2% low-melting glass powder, 3% nano-silica, 12% pyrophyllite, and the balance is feldspar powder; when the vitrified bond is prepared, take the components of the formula After ball milling in a ball mill for 2.5 hours, it is obtained by sieving. Among them, the low melting point boron glass powder is composed of the following components in mass percentage: 36% silicon dioxide, 11% aluminum oxide, 31% boron trioxide, 7% potassium oxide, 15% sodium oxide; low melting point glass powder The refractoriness is 570°C. The average particle diameter of nano silicon dioxide is 800nm.

[0025] The vitrified bond grinding wheel of the present embodiment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractoriness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Refractoriness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com