A sepiolite-alumina composite carrier and a high temperature resistant sintering methanation catalyst using it

A composite carrier and alumina technology, which is applied in the direction of carbon compound catalysts, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the complicated preparation steps, the decrease of specific surface area, and the limitation of heat resistance and other problems to achieve the effect of improving the collapse of the pore structure, improving the stability and stabilizing the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

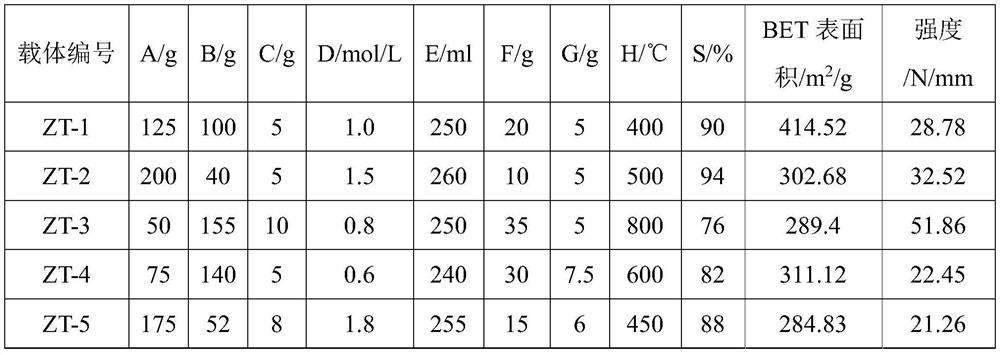

[0044] Preparation of sepiolite-alumina carrier: Mix (A) g of sepiolite, (B) g of aluminum hydroxide powder and (C) g of squid powder in a kneader, and (D) mol / L dilute nitric acid (E) ml was added to the above mixture and kneaded for 30 minutes, then (F) g of pseudo-boehmite was added to the above mixture, and kneaded for 10 minutes. Dry the obtained solid mixture in a blower dryer at 120°C for 2 hours, grind and granulate, sieve through a 24-mesh standard sieve, add magnesium stearate (G)g of the total amount of material, and form into tablets, with a size of Φ5 *5-7mm, about 240g of sepiolite-alumina composite carrier was obtained after roasting at (H)°C for 3 hours. The specific preparation parameters and physical adsorption data are shown in the following table: The water absorption rate of the carrier is measured by taking 20g (W1) of the carrier, soaking it in deionized water at room temperature for 2 hours, filtering out the excess deionized water, and then drying the...

Embodiment 2

[0052] Preparation of sepiolite-alumina carrier: the carrier ZT-1 in Example 1 was selected.

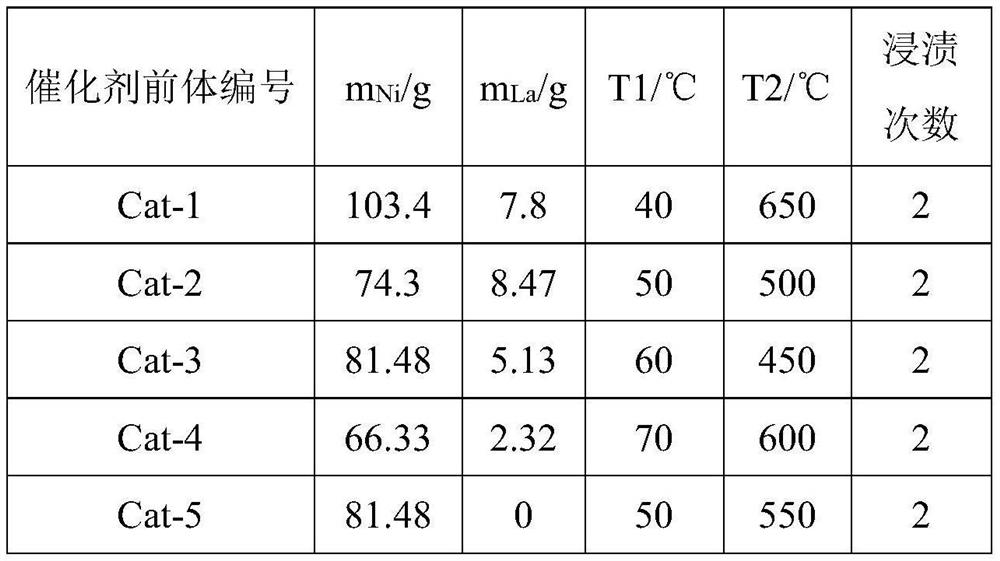

[0053] Preparation of catalyst precursor for nickel-based methane synthesis: Weigh 50g of the carrier, weigh 91.76g of nickel nitrate hexahydrate, and 9.84g of cerium nitrate hexahydrate, dissolve them in deionized water together, and prepare 100ml of immersion solution, and heat the immersion solution in a water bath To a temperature of 65°C, pour the carrier into the impregnation solution, impregnate for 2 hours, filter, dry in a blast drying oven at 110°C for 5 hours, and after two dipping and drying, bake in a muffle furnace at 600°C 4h to obtain the catalyst precursor.

[0054] The preparation of nickel base methane synthesis catalyst: according to the method for embodiment 1, the catalyst precursor is flowed in the H of 500ml / min 2 In the hydrogen-nitrogen mixed gas atmosphere with a content of 80%, the reduction is carried out under the conditions of a reduction temperature o...

Embodiment 3

[0056] Preparation of sepiolite-alumina carrier: the carrier ZT-1 in Example 1 was selected.

[0057] Preparation of catalyst precursor for nickel-based methane synthesis: Weigh 50g of the carrier, weigh 68.12g of nickel nitrate hexahydrate, and 4.38g of samarium nitrate hexahydrate, dissolve them in deionized water together, and prepare 100ml of impregnation solution, and heat the impregnation solution in a water bath To a temperature of 65°C, pour the carrier into the impregnation solution, impregnate for 2 hours, filter, dry in a blast drying oven at 110°C for 5 hours, and after two dipping and drying, bake in a muffle furnace at 650°C 4h to obtain the catalyst precursor.

[0058] Preparation of nickel-based methane synthesis catalyst: According to the method of Example 1, the catalyst precursor was reduced in a pure hydrogen atmosphere with a flow rate of 500ml / min, the reduction temperature was 600°C and the reduction time was 5h, and then passivation was carried out. Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com