Electrocatalytic coating composition, dimensionally stable anode, preparation method and application

A coating composition and electrocatalysis technology, applied in chemical instruments and methods, electrodes, electrolysis components, etc., can solve the problem of affecting catalytic effect, current efficiency and electrode life, weakening the precipitation of cluster grains, and uneven catalyst coating. and other problems, to achieve the effect of inhibiting excessive growth, inhibiting crack growth, and improving flatness and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

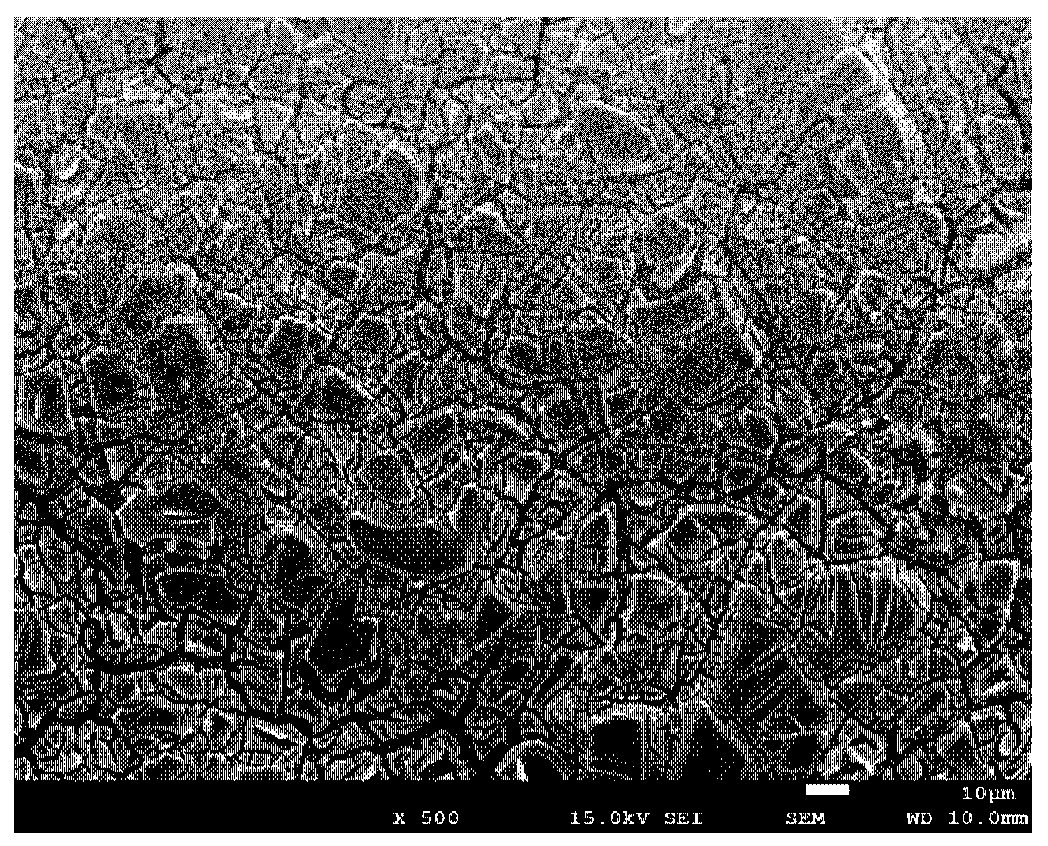

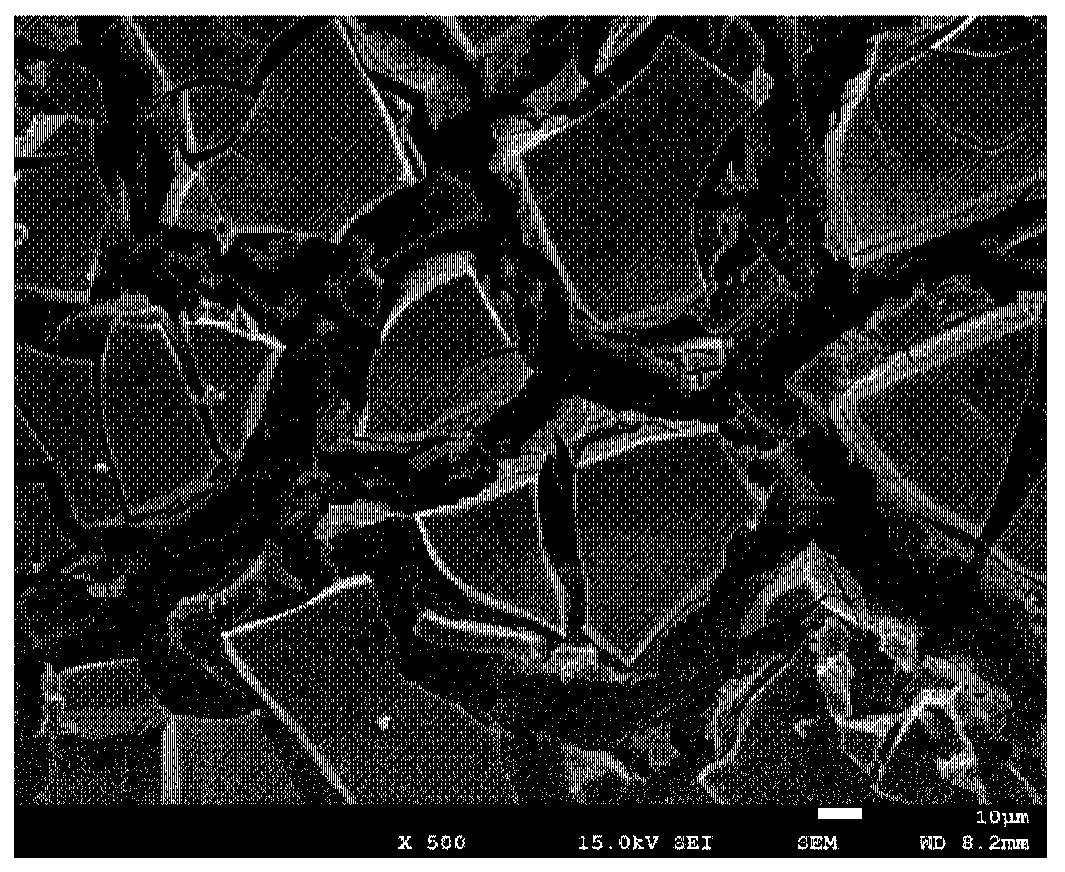

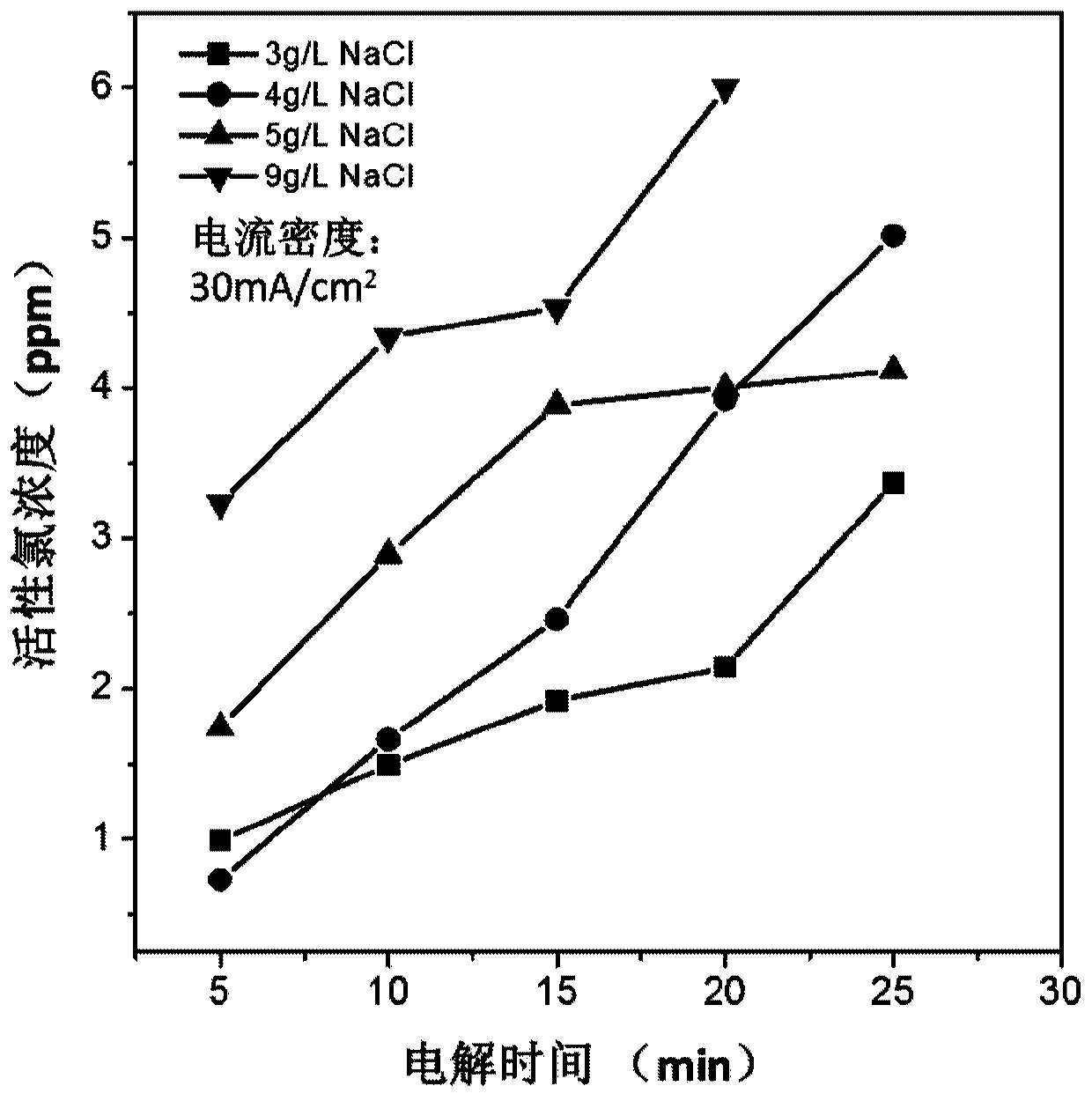

[0055] Polish the metal titanium sheet with 800-grit sandpaper, and then polish it with 2000-grit sandpaper; rinse it with ultrapure water, soak it in acetone to degrease; rinse it with acetone twice, and dry it; after that, put the metal titanium sheet into Soak in 3% oxalic acid solution at 90°C for 2 hours, then rinse with water for later use. According to the molar ratio of the three metal salts is Sn / Ru / Ti=x / (3-x) / 7 (x=0.01), the total concentration of the three elements (Sn+Ru+Ti) is 0.4mol / L and weigh TiOSO 4 、RuCl 3 , SnCl 4 And add an appropriate amount of pure water to dissolve to obtain a mixed metal salt precursor solution (referred to as solution A1). Configure 0.05mol / L citric acid solution, measure a sufficient amount of citric acid solution according to the molar ratio of (Sn+Ru+Ti) and citric acid 3:1; COOH / -OH=0.5 Weigh polyethylene glycol with a molecular weight of 1000 and add it to the citric acid solution; obtain a mixed solution of citric acid and gly...

Embodiment 2

[0057] Polish the metal titanium sheet with 800-grit sandpaper, and then polish it with 2000-grit sandpaper; rinse it with ultrapure water, soak it in acetone to degrease; rinse it with acetone for 3 times, and dry it; after that, put the metal titanium sheet into Soak in 3% oxalic acid solution at 90°C for 1 hour, then rinse with water for later use. According to the molar ratio of the three metal salts is Sn / Ru / Ti=x / (3-x) / 7 (x=0.5), the total concentration of the three elements (Sn+Ru+Ti) is 0.3mol / L and weigh TiOSO 4 、RuCl 3 , SnCl 4 And add an appropriate amount of pure water to dissolve to obtain a mixed metal salt precursor solution (referred to as solution A2). Configure 0.08mol / L citric acid solution, measure a sufficient amount of citric acid solution according to the molar ratio of (Sn+Ru+Ti) and citric acid 2:1; COOH / -OH=0.8 Weigh polyethylene glycol with a molecular weight of 800 and add it to the citric acid solution; obtain a mixed solution of citric acid and ...

Embodiment 3

[0059] Polish the metal titanium sheet with 800-grit sandpaper, and then polish it with 2000-grit sandpaper; rinse it with ultra-pure water, soak it in acetone to degrease; rinse it with acetone for 2 to 3 times, and dry it; after that, put the titanium sheet Soak in 3% oxalic acid solution at 90°C for 1 hour, then rinse with water for later use. According to the molar ratio of the three metal salts is Sn / Ru / Ti=x / (3-x) / 7(x=1), the total concentration of the three elements (Sn+Ru+Ti) is 0.2mol / L and weigh TiOSO 4 、RuCl 3 , SnCl 4 And add an appropriate amount of pure water to dissolve to obtain a mixed metal salt precursor solution (referred to as solution A3). Configure 0.1mol / L citric acid solution, measure a sufficient amount of citric acid solution according to the molar ratio of (Sn+Ru+Ti) and citric acid 1:1; COOH / -OH=1 weighing molecular weight is 600 ethylene glycol, and add in the citric acid solution; Obtain the mixed solution of citric acid and dibasic alcohol (re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com