Preparation method of toughened high-temperature-resistant insulating heat-conducting composite material

A technology of insulation and heat conduction and composite materials, which is applied in the field of thermal management materials preparation, can solve the problems of high brittleness, insufficient toughness, poor thermal shock resistance, etc., achieve wide use temperature range, improve high-temperature sintering performance, mechanical properties and heat resistance Excellent shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

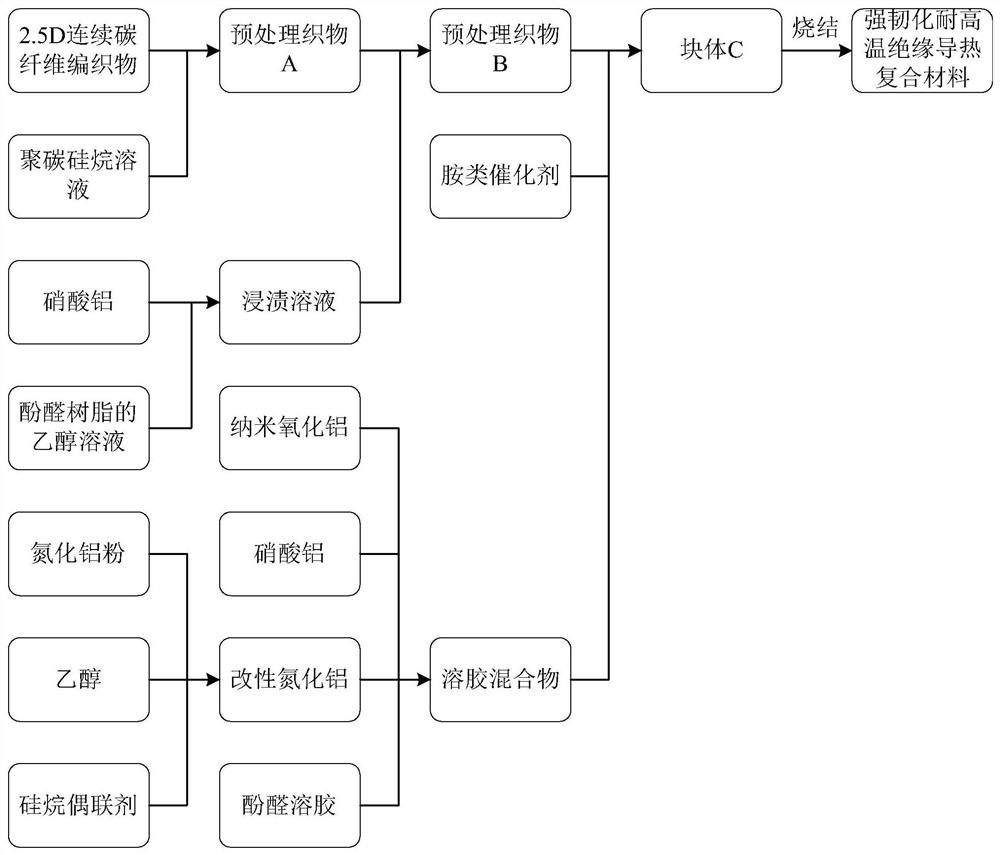

[0028] The invention provides a preparation method of a strong and tough high temperature resistant insulation and heat conduction composite material, such as figure 1 As shown, it includes the following steps:

[0029] (1) The 2.5D continuous carbon fiber braid with an elastically compressible structure was dipped in a polycarbosilane solution, taken out, and dried to obtain a pretreated fabric A. In order to ensure the impregnation effect of the polycarbosilane solution on the fabric, the drying conditions are: drying at room temperature for 1-10h (can be any value within this range, such as 1h, 2h, 3h, 4h, 5h, 6h, 7h, 8h, 9h, After 10h), at 50-150°C (can be any value within this range, such as 50°C, 60°C, 70°C, 80°C, 90°C, 100°C, 110°C, 120°C, 130°C, 140°C, 150° C.) for 1-10 hours (can be any value within this range, such as 1 h, 2 h, 3 h, 4 h, 5 h, 6 h, 7 h, 8 h, 9 h, 10 h).

[0030] (2) Add the aluminum nitrate into the ethanol solution of the phenolic resin, mix evenly...

Embodiment 1

[0038] (1) Take out the 2.5D continuous carbon fiber braid after dipping in the polycarbosilane solution, and obtain the pretreated fabric A after drying; in order to ensure the impregnation effect of the polycarbosilane solution on the fabric, the drying method described in step (1) can be further Preferably: after drying at room temperature for 1 hour, vacuum drying at 50°C for 10 hours;

[0039] (2) Aluminum nitrate is added in the ethanol solution of phenolic resin, after mixing uniformly, impregnating solution is obtained, for subsequent use;

[0040] (3) The pretreated fabric A obtained in step (1) is taken out after soaking in the dipping solution obtained in step (2), and the pretreated fabric B is obtained after drying; in order to ensure the impregnation effect of the pretreated fabric A, step (3) ) The drying method can be further preferably: after drying at 30°C for 5 hours, the temperature is raised to 90°C and the drying is continued for 10 hours;

[0041] (4) Alu...

Embodiment 2

[0047] (1) Take out the 2.5D continuous carbon fiber braid after dipping in the polycarbosilane solution, and obtain the pretreated fabric A after drying; in order to ensure the impregnation effect of the polycarbosilane solution on the fabric, the drying method described in step (1) can be further Preferably: after drying at room temperature for 10 hours, vacuum drying at 150°C for 1 hour;

[0048] (2) Aluminum nitrate is added in the ethanol solution of phenolic resin, after mixing uniformly, impregnating solution is obtained, for subsequent use;

[0049] (3) The pretreated fabric A obtained in step (1) is taken out after soaking in the dipping solution obtained in step (2), and the pretreated fabric B is obtained after drying; in order to ensure the impregnation effect of the pretreated fabric A, step (3) ) The drying method can be further preferably: after drying at 50°C for 2 hours, then heat up to 150°C and continue drying for 5 hours;

[0050] (4) Aluminum nitride powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com