A kind of preparation method of inner lining for microcrystalline alumina high temperature rotary kiln

A kind of alumina and rotary kiln technology, applied in the direction of overall lining, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of low pollution, low scouring service life, and the lining of microcrystalline alumina high-temperature rotary kiln is not resistant to erosion, etc. , to achieve the effect of improving life, reducing pores and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The preparation method of a tabular corundum and mullite composite prefabricated lining for a high-temperature microcrystalline alumina rotary kiln according to the present invention comprises the following steps:

[0070] (1) Weighing and preparing raw materials;

[0071] (2) Knead the prepared raw materials evenly, add 4-6wt% of the total weight of the raw materials, and stir evenly in an environment at room temperature of 5-25 degrees Celsius;

[0072] (3) Pour the mixed material mixed with water into the model to obtain a blank;

[0073] (4) The blanks are baked at a low temperature until they are shaped, and then transported to the demolding mechanism for demoulding;

[0074] Wherein, the raw material described in step (1) contains the following components according to mass fraction:

[0075] Tabular corundum particles with a particle size of 10-5mm are 10-20wt%;

[0076] Tabular corundum particles with a particle size of 5-3mm are 10-20wt%;

[0077] 10-20wt% o...

Embodiment 2

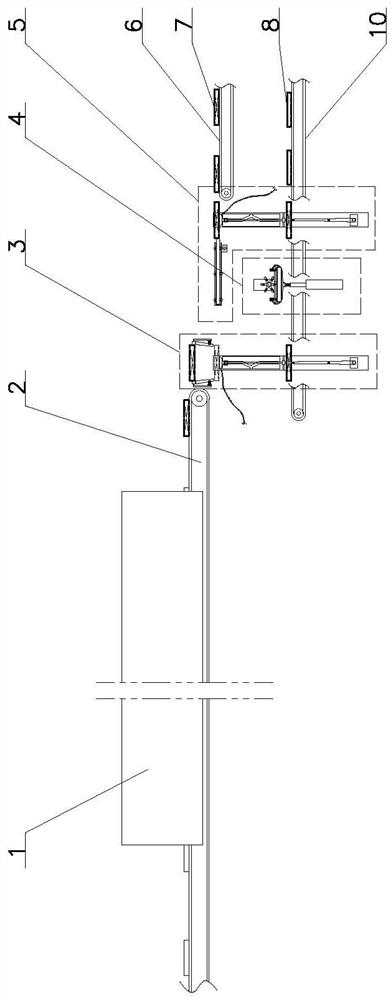

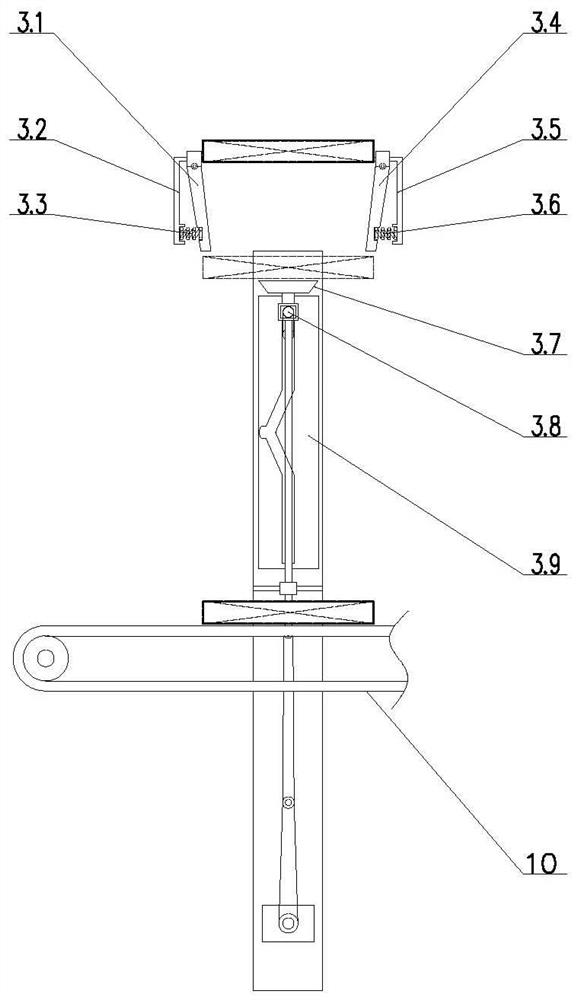

[0100] like Figure 1-4 As shown in the figure, in this embodiment, the demoulding mechanism includes a demoulding frame, a feeding functional part, a demoulding functional part and a material distributing functional part. It is installed on the demoulding frame in sequence backwards. The upper bearing station of the feeding function part is connected with the conveyor belt at the discharge end of the low-temperature roasting machine; the lower bearing station of the feeding function part, the demolding function part and the parts The lower material distribution stations of the material function part are connected by the lower conveyor belt; the upper material distribution stations of the material distribution function part are connected to the upper conveyor belt.

[0101] The feeding function part includes a front inversion conveying device, which includes a front inversion driving device, a front inversion arm and a front inversion suction cup. The front inversion driving d...

Embodiment 3

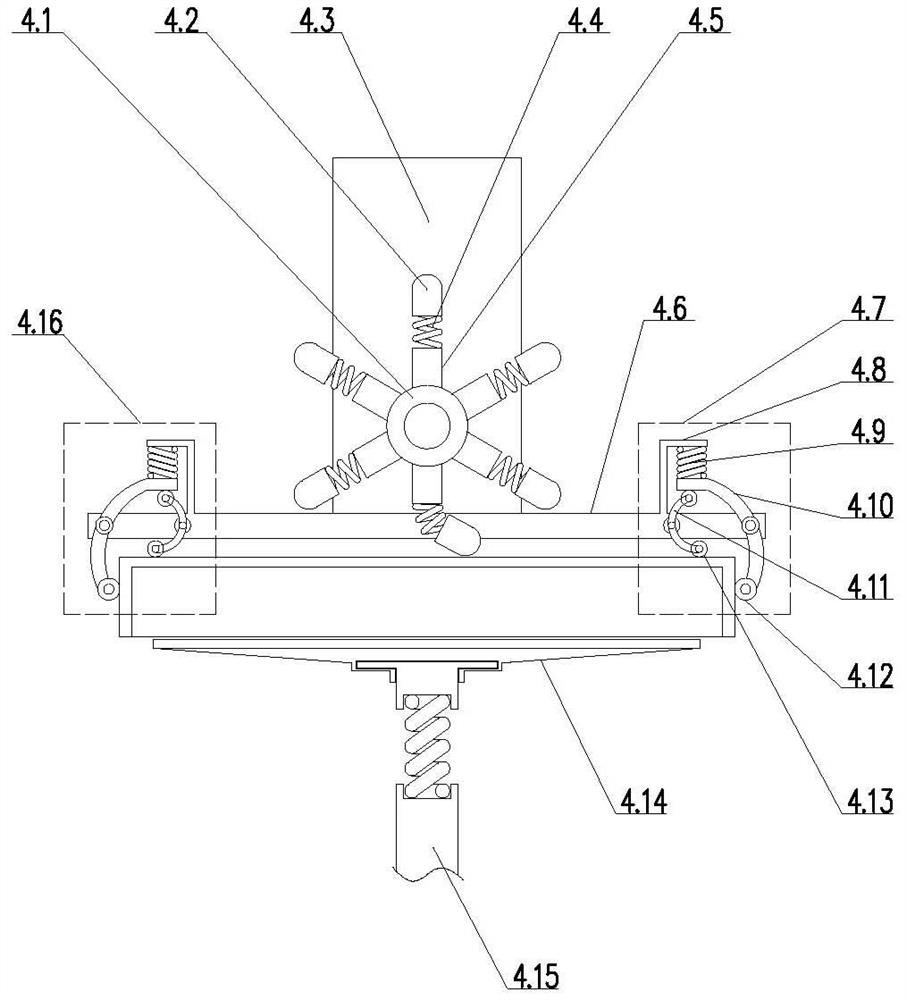

[0111] like Figure 5-7 As shown, in this embodiment, the front flipping driving device and the rear flipping driving device each include a set of flipping functional bodies; the flipping functional body includes a vertically arranged fixed vertical plate, and a guide rail is fixed on the upper part of the fixed vertical plate The vertical plate, a "﹛"-shaped reversing guide slot is opened on the vertical plate of the guide rail.

[0112] The front flipping arm and the rear flipping arm each include a first connecting rod, a second connecting rod and a third connecting rod; a guide sliding block is inserted into the reversing guide groove, and the extending end of the guide sliding block is vertically connected to the first connecting rod. One end of a connecting rod, the other end of the first connecting rod is vertically connected to one end of the second connecting rod, the other end of the second connecting rod is vertically connected to the third connecting rod, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com