Metal cutting machine tool for cleaning iron chips during cutting

A metal cutting and cutting machine technology, which is applied to metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of affecting processing accuracy, increased tool vibration, and tool rotation friction, etc., to improve processing accuracy, Reduced friction rate and vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

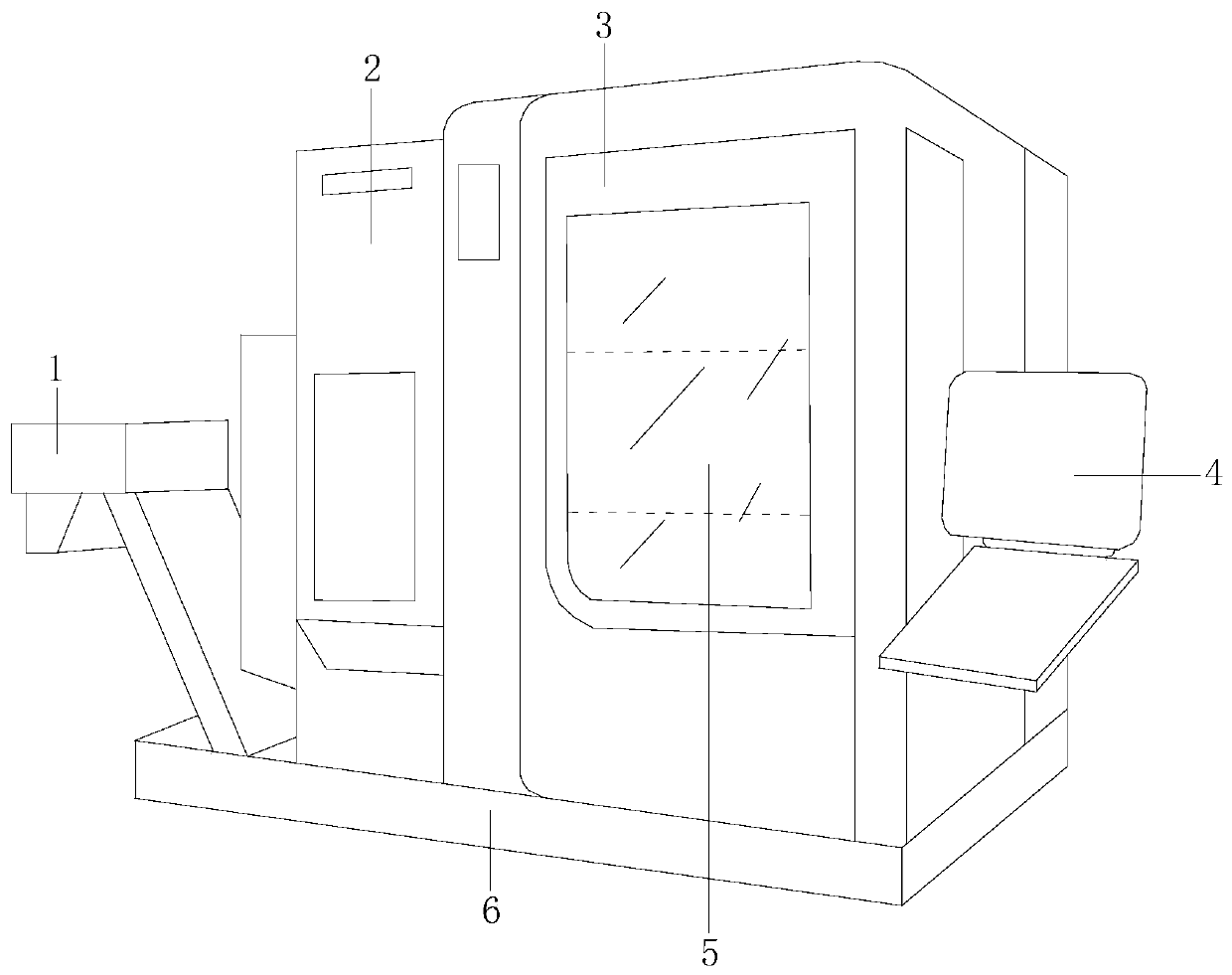

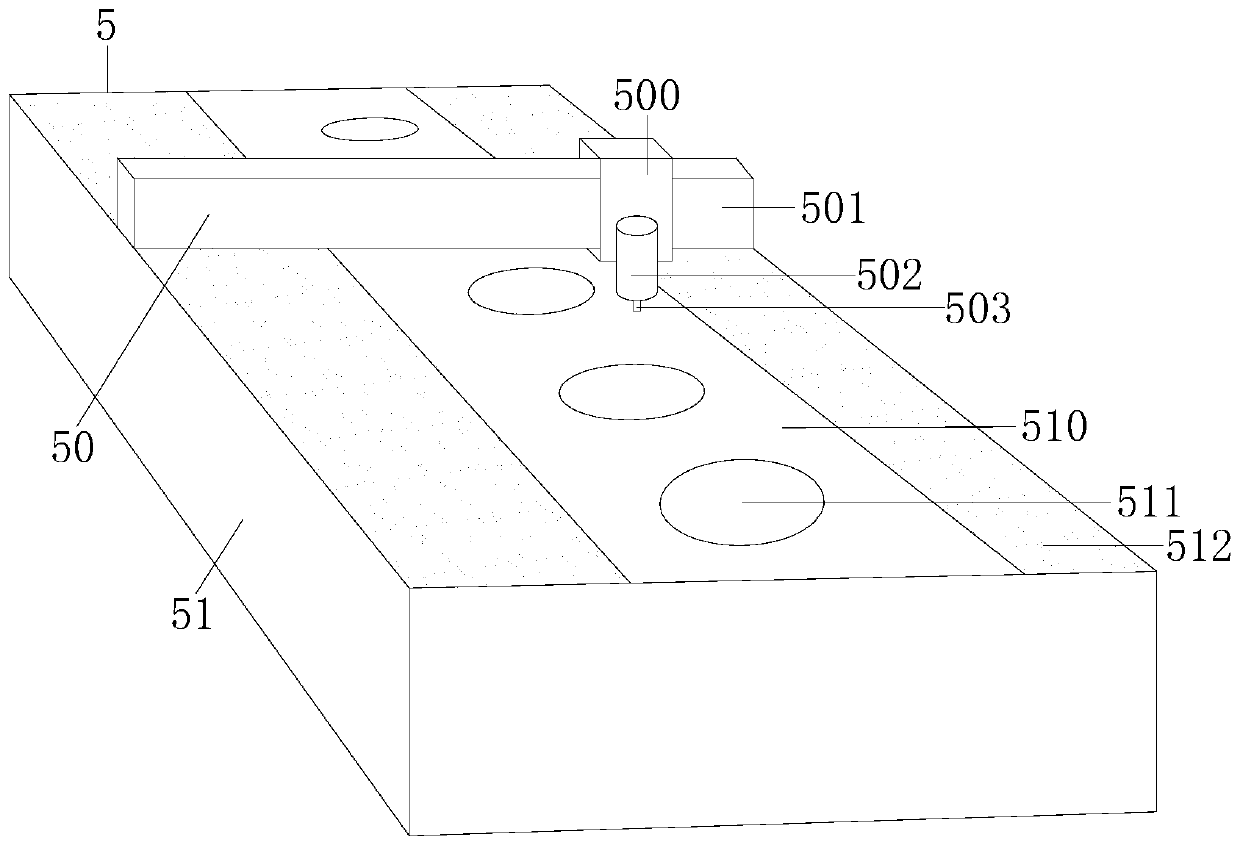

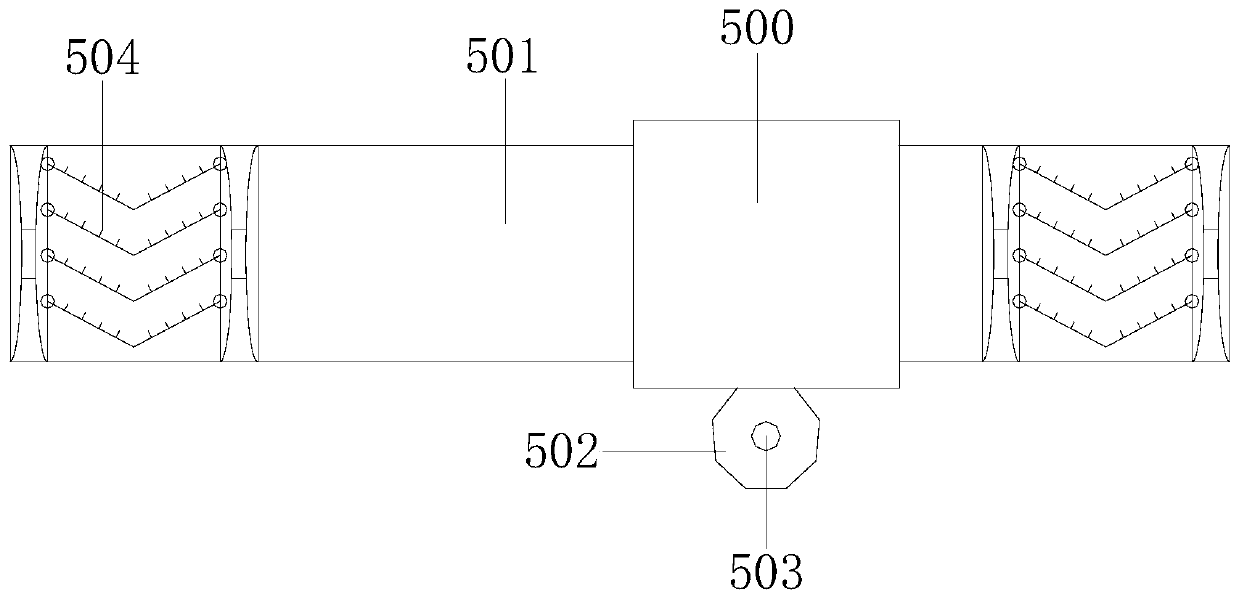

[0027] Example 1 see Figure 1-6 , the present invention provides a technical solution for metal cutting machine tools for cleaning iron chips during cutting: its structure includes a feeding rack 1, a cutting fluid storage rack 2, a cutting chamber 3, a control machine 4, a cutting machine 5, and a base 6. The cutting fluid The storage rack 2 is used to cool and lubricate the cutting tool and the workpiece. The feeding rack 1 and the cutting fluid storage rack 2 are installed on the base 6, the cutting chamber 3 is locked with the base 6, and the control machine 4 is locked in the cutting chamber 3 Above, the cutting machine 5 is installed on the cutting chamber 3, the cutting machine 5 is composed of a cutting head 50 and a workpiece frame 51, the cutting head 50 is connected with the workpiece frame 51 track, and the cutting head 50 includes Mobile machine frame 500, cross rail 501, cutting machine barrel 502, cutting machine drill 503, and dust attachment device 504. The m...

Embodiment 2

[0029] Example 2 see Figure 7 , the present invention provides a technical solution for metal cutting machine tools for cleaning iron filings during cutting: the structure of the dust attachment device 504 includes a bezel 90, a turning shaft 91, and a dust attachment structure 92, and the bezel 90 and the turning shaft 91 are locked , the turning shaft 91 is axially connected with the dust attachment structure 92, and the rotation of the turning shaft 91 drives the lifting of the dust attachment structure 92, which can pinch and clean relatively thick iron filings in a targeted manner. The dust attachment structure 92 It includes a turning shaft circle 920 , attached scales 921 , and mounting strips 922 , the fitting strips 922 are axially connected to the frame 90 through the turning shaft circles 920 , and the attached scales 921 are installed on the fitting strips 922 .

[0030] The bezel 90 cleans the iron filings at the dust attachment plate 512, the horizontal rail 501 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com