Polishing equipment for mobile phone screen production

A technology for mobile phone screens and equipment, applied in the field of screen polishing, can solve the problems of unfavorable use, easy attachment of small debris, low work efficiency, etc., and achieve the effect of reliable and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

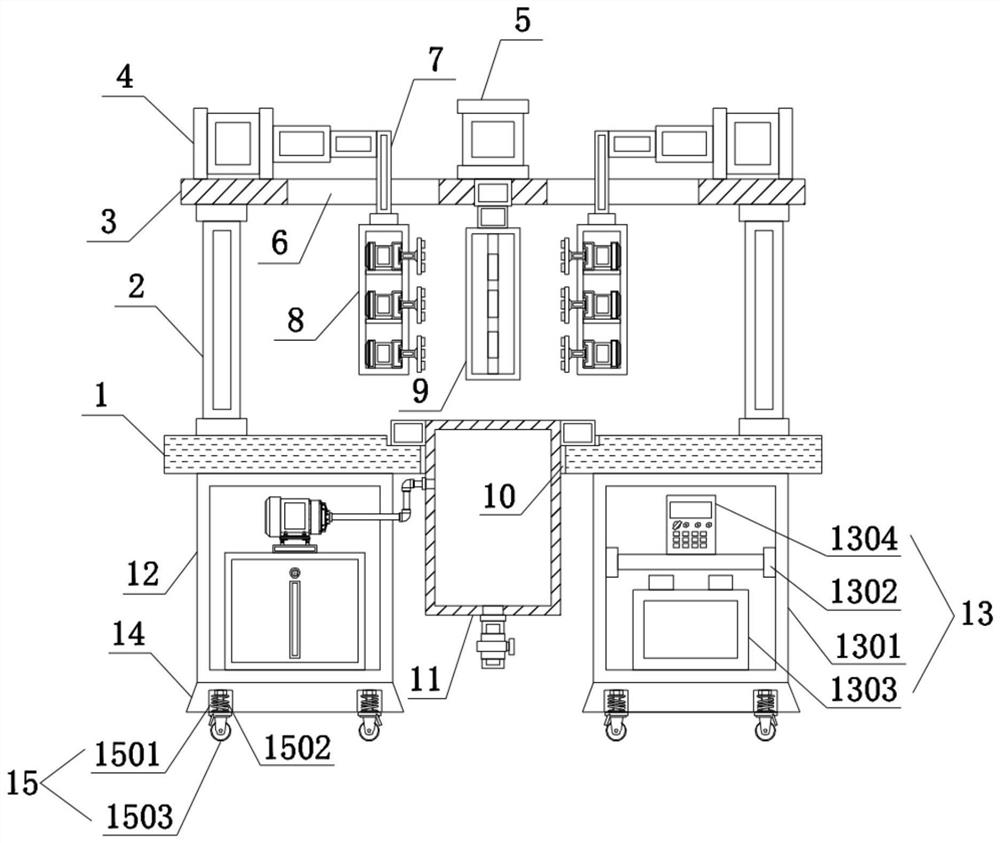

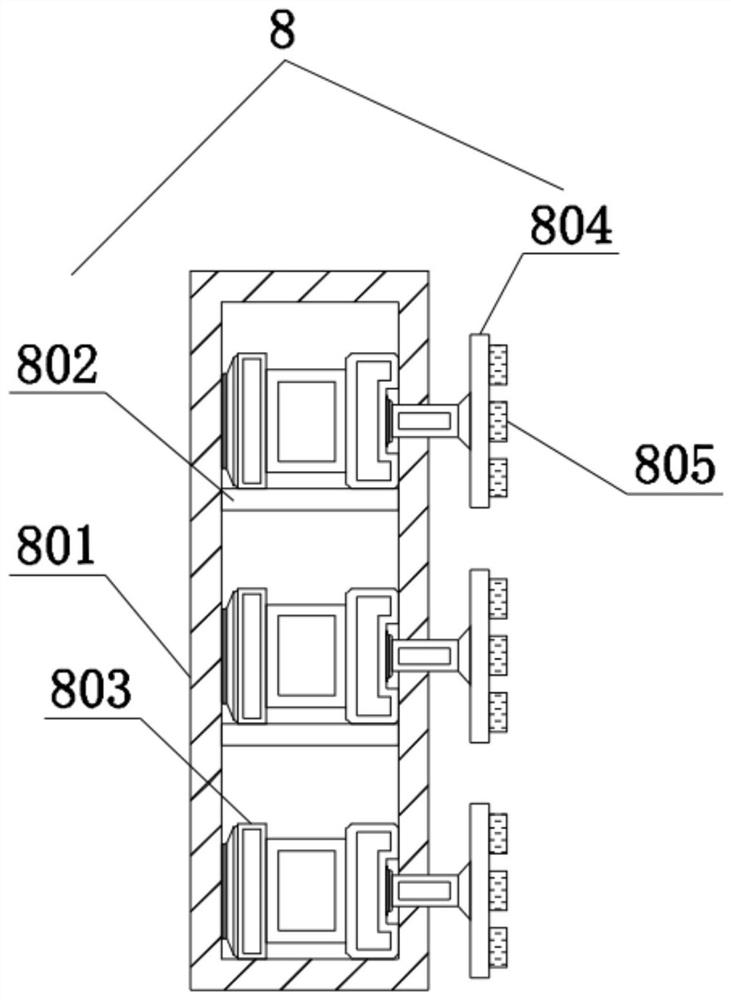

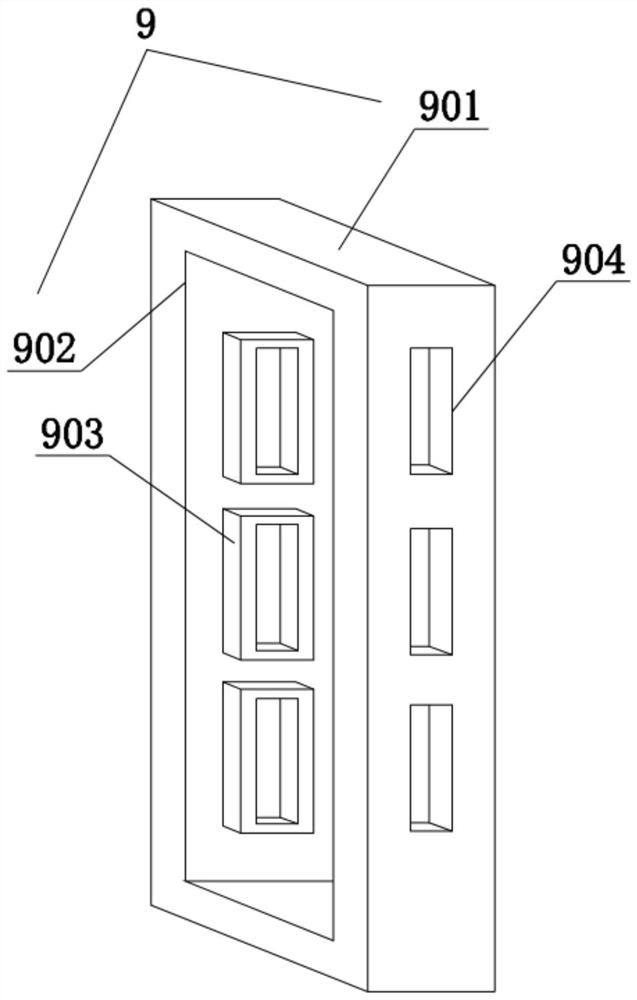

[0034] see Figure 1-5 , a kind of polishing equipment for mobile phone screen production, comprising a working platform 1, the top, left and right sides of the working platform 1 are fixedly connected with supporting columns 2, and the tops of the supporting columns 2 are fixedly connected with mounting plates 3, so The left and right sides of the top of the mounting plate 3 are fixedly equipped with an electric push rod 4, and the middle end of the top of the mounting plate 3 is fixedly mounted with a telescopic cylinder 5, and the top of the mounting plate 3 is located between the electric push rod 4 and the telescopic cylinder 5. The position between is provided with strip notch 6, and the output end of described electric push rod 4 is fixedly connected with connecting plate 7, and the bottom of described connecting plate 7 passes through strip notch 6 and is fixedly connected with polishing mechanism 8, The output end of the telescopic cylinder 5 passes through the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com