Copper-based powder metallurgy brake pad material as well as preparation method and application thereof

A technology of powder metallurgy and brake pads, which is applied in the fields of copper-based powder metallurgy brake pad materials and its preparation, and brake pad materials and its preparation, can solve the problems that the comprehensive performance of brake pad materials cannot meet the requirements of high-speed train brake friction pads Achieve excellent plasticity, improve stability, and reduce adhesive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

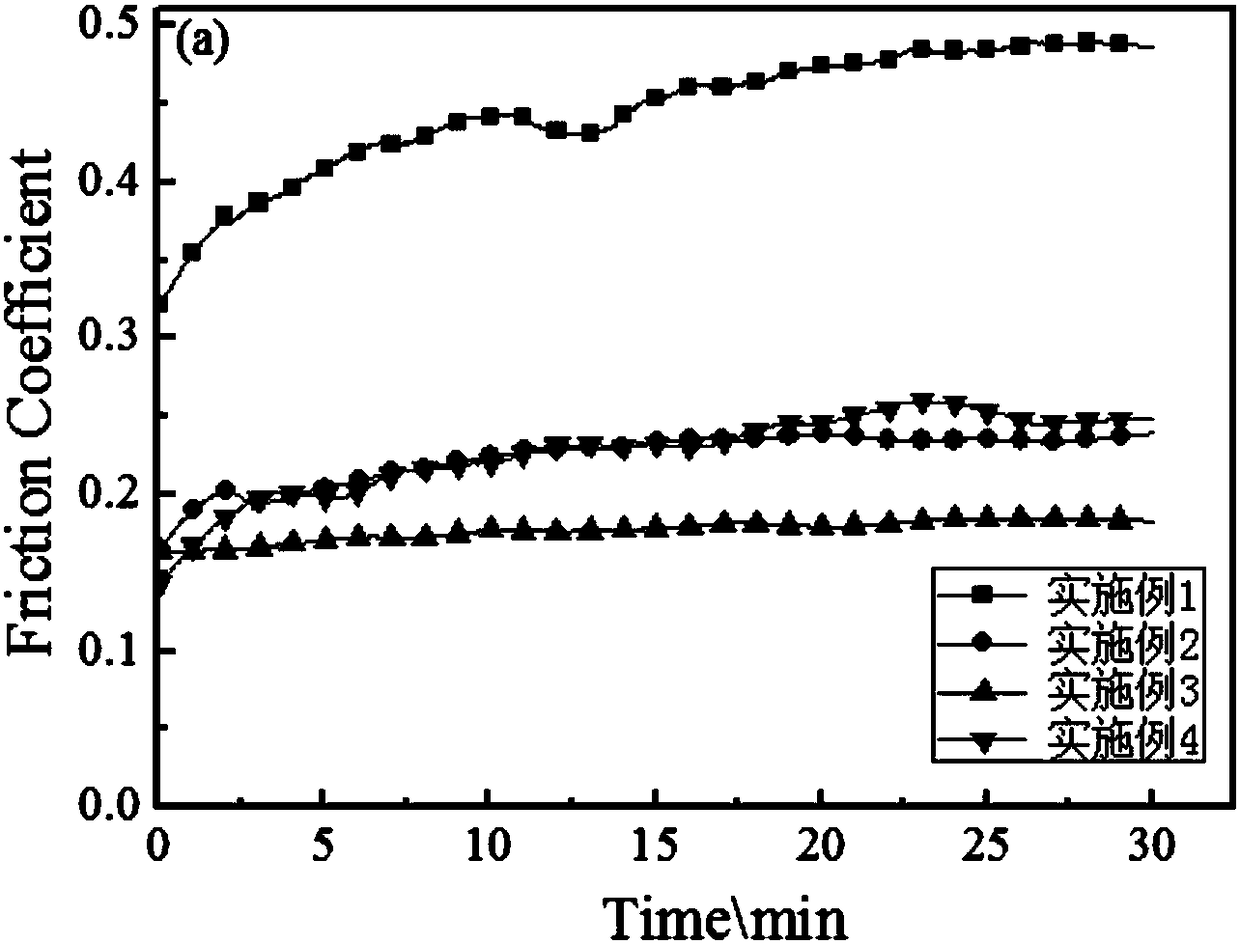

Embodiment 1

[0021] A copper-based powder metallurgy brake pad material is made of the following raw materials in proportions by weight:

[0022] Copper powder 67wt%,

[0023] Graphite 13wt%,

[0024] Iron powder 4wt%,

[0025] Fe-chromium alloy 14wt%,

[0026] SiC 1wt%,

[0027] Silica 1 wt%.

[0028] The particle sizes of the above materials are respectively:

[0029] Copper powder 400 mesh,

[0030] Graphite 0.2~0.8mm,

[0031] Iron powder 40 mesh,

[0032] Iron chromium alloy 200 mesh,

[0033] Silicon carbide 500 mesh,

[0034] Silica 5 μm.

[0035] Weigh the powder raw material according to the above raw material ratio, put it into the mixer and mix evenly; put the mixed raw material into the graphite mold, control the sintering temperature in the discharge plasma sintering furnace to 800°C, and the heating rate to 100°C / min, the holding time is 20min, the pressure applied to the mold is 50MPa, and the vacuum is maintained during sintering and cooling; after the preparati...

Embodiment 2

[0038] A copper-based powder metallurgy brake pad material is made of the following raw materials in proportions by weight:

[0039] Copper powder 67wt%,

[0040] Graphite 13wt%,

[0041] Iron powder 10wt%,

[0042] Fe-chromium alloy 8wt%,

[0043] SiC 1wt%,

[0044] Silica 1 wt%.

[0045] The particle sizes of the above materials are respectively:

[0046] Copper powder 400 mesh,

[0047] Graphite 0.2~0.8mm,

[0048] Iron powder 40 mesh,

[0049] Iron chromium alloy 200 mesh,

[0050] Silicon carbide 500 mesh,

[0051] Silica 5 μm.

[0052] Weigh the powder raw material according to the above raw material ratio, put it into the mixer and mix it evenly; put the mixed raw material into the graphite mold, control the sintering temperature in the discharge plasma sintering furnace to 810°C, and the heating rate to 100°C / min, the holding time is 20min, the pressure applied to the mold is 45MPa, and the vacuum is maintained during sintering and cooling; after the prepar...

Embodiment 3

[0055] A copper-based powder metallurgy brake pad material is made of the following raw materials in proportions by weight:

[0056]Copper powder 58wt%,

[0057] Graphite 13wt%,

[0058] Iron powder 17wt%,

[0059] Fe-chromium alloy 8wt%,

[0060] SiC 2wt%,

[0061] Silica 2wt%.

[0062] The particle sizes of the above materials are respectively:

[0063] Copper powder 400 mesh,

[0064] Graphite 0.2~0.8mm,

[0065] Iron powder 40 mesh,

[0066] Iron chromium alloy 200 mesh,

[0067] Silicon carbide 500 mesh,

[0068] Silica 5 μm.

[0069] Weigh the powder raw materials according to the above raw material ratio, put them into the mixer and mix evenly; put the mixed raw materials into the graphite mold, control the sintering temperature in the discharge plasma sintering furnace to 820°C, and the heating rate to 100°C / min, the holding time is 20min, the pressure applied to the mold is 40MPa, and the vacuum is maintained during sintering and cooling; after the prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com