Intelligent grinding equipment for plastic pipe production

A plastic pipe, intelligent technology, applied in the direction of grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems that the pipe cannot be rotated, cannot be polished, etc., and achieve the effect of improving comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

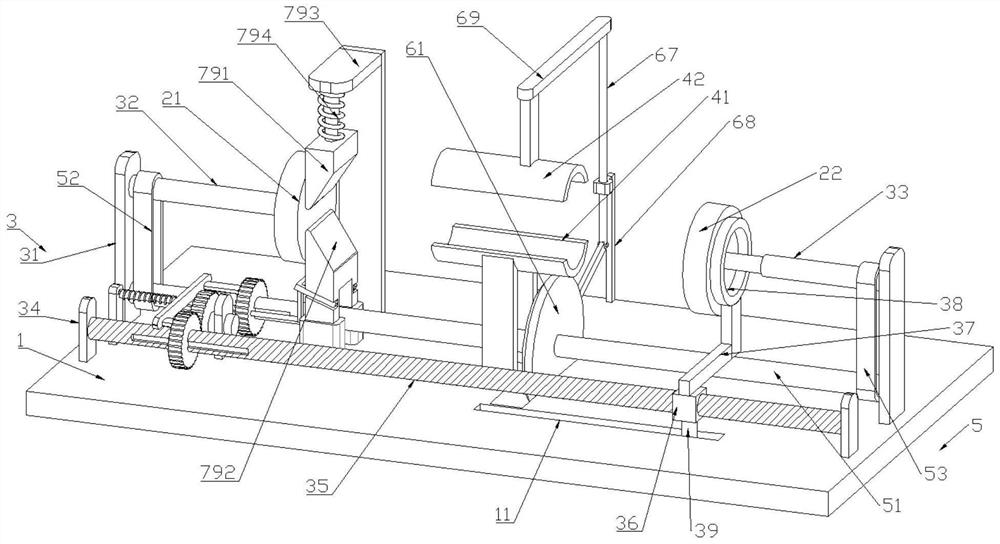

[0029] see figure 1 , the present invention provides a technical solution: an intelligent grinding device for plastic pipe production, comprising a base 1, and a first circular grinding disc 21 and a second circular grinding disc 21 and a second circular grinding disc located above the base 1 for grinding both ends of the plastic pipe Grinding disc 22, above the base 1 is provided with a positioning and clamping assembly 3 for driving the second circular grinding disc 22 to move to the side close to the first circular grinding disc 21 to clamp both ends of the plastic pipe, above the base 1 A first arc-shaped polishing plate 41 and a second arc-shaped polishing plate 42 are provided for polishing the surface of the pipe, and the first arc-shaped polishing plate 41 and the second arc-shaped polishing plate 42 are located on the first circular polishing plate 21. A support column is fixed between the first arc-shaped polishing plate 41 and the base 1 between the first arc-shaped...

Embodiment 2

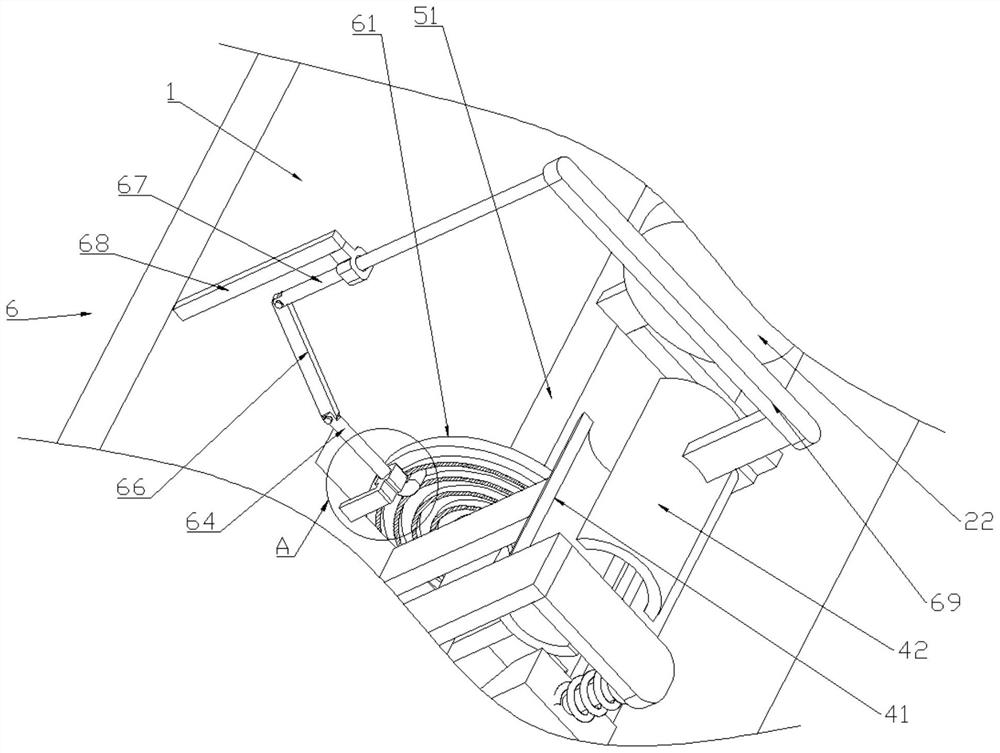

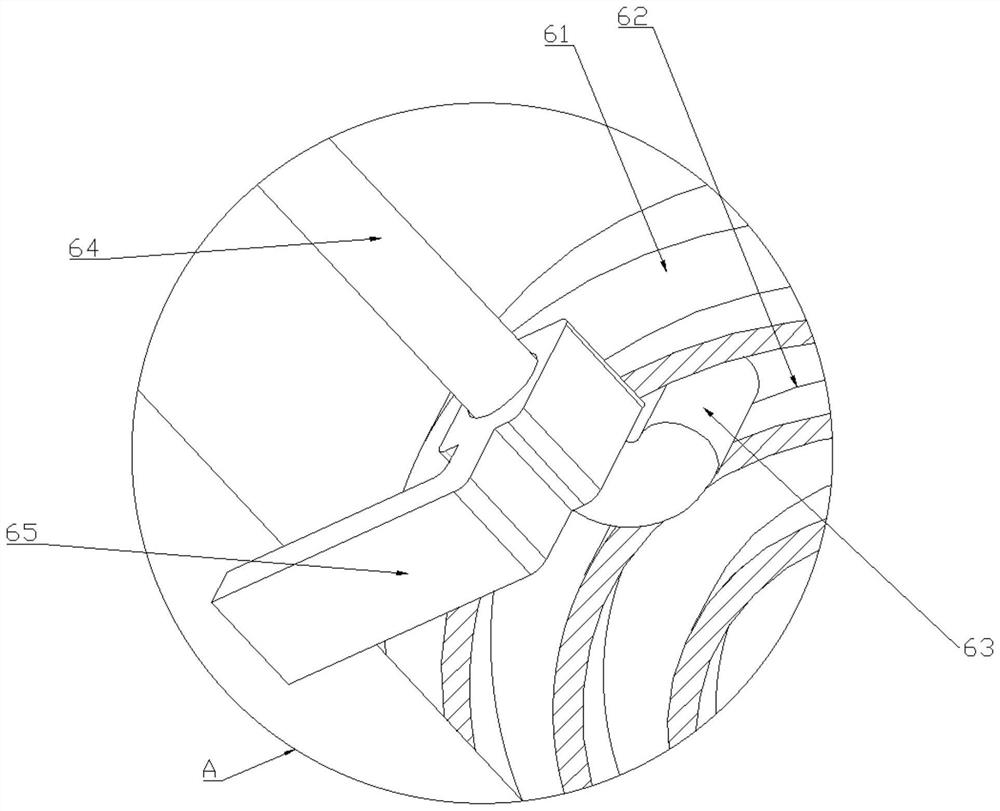

[0034] see Figure 1-Figure 3 , On the basis of Embodiment 1, further, above the base 1 is provided a grinding assembly 5 for driving the first circular grinding disc 21 and the second circular grinding disc 22 to rotate at the same time, and a grinding assembly 5 for driving the second circular grinding disc 21 and the second circular grinding disc 22 to rotate at the same time. The linkage assembly 6 in which the arc-shaped sanding plate 42 moves downward at the same time.

[0035] In use, by setting the grinding assembly 5, it is convenient to drive the first circular grinding disc 21 and the second circular grinding disc 22 to rotate after clamping the plastic pipe, and drive the plastic pipe to rotate accordingly, so that the plastic pipe is The outer surface can be polished by the first arc-shaped polishing plate 41;

[0036] The linkage assembly 6 is provided, so that when the first circular grinding disc 21 and the second circular grinding disc 22 drive the plastic pi...

Embodiment 3

[0042] see Figure 4-Figure 7 On the basis of the second embodiment, further, a drive assembly 7 for driving the threaded rod 35 and the rotating shaft 51 to rotate alternately is arranged above the base 1 , and the drive assembly 7 includes a first A gear 71, the first gear 71 is driven by an external driving device.

[0043] The external driving device is a motor.

[0044] In use, the drive assembly 7 is provided to drive the threaded rod 35 to rotate first. After the first circular grinding disc 21 and the second circular grinding disc 22 clamp both ends of the plastic pipe, the threaded rod 35 stops rotating. , and then drive the rotating shaft 51 to rotate to grind the pipe.

[0045] The surface of the threaded rod 35 is sleeved with a second gear 72 , the surface of the threaded rod 35 is provided with a first strip groove 351 , and the second gear 72 is integrally provided with a sliding fit with the first strip groove 351 The slider, the second gear 72 is intermitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com