Juicing method of juicer

A juicer and juice technology, which is applied in the field of juicing of a juicer, can solve the problems of increasing the juice yield, affecting the size accuracy of filter holes, increasing production costs, etc., and achieving the effect of improving the juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

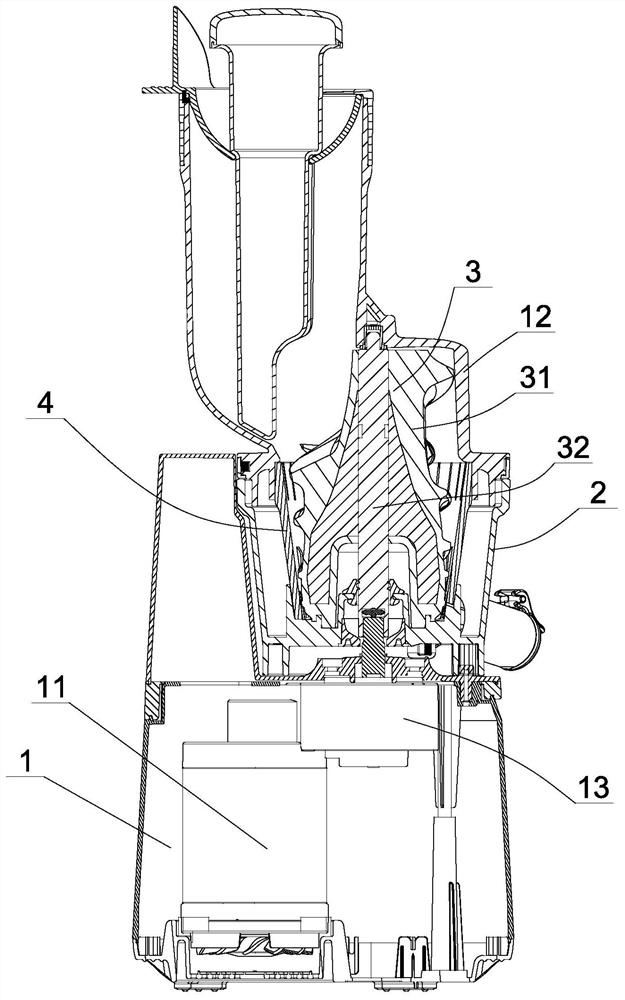

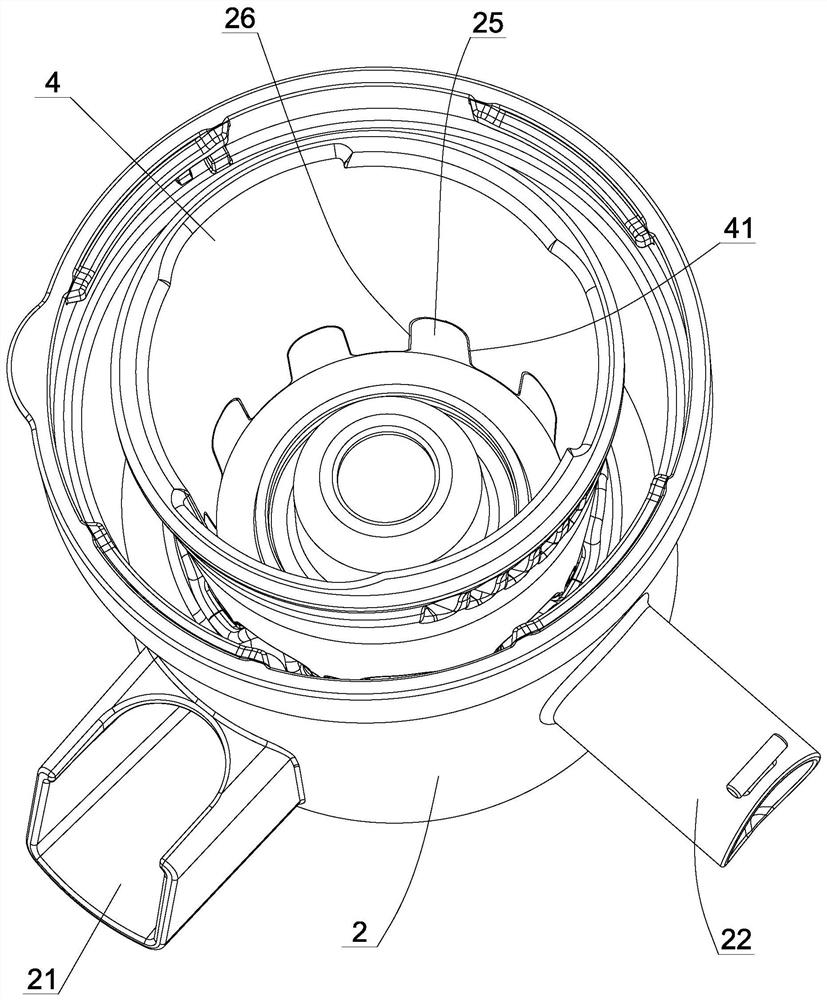

[0052] Embodiment 1: A method for extracting juice with a juice extractor, wherein the juice extractor refers to a household juice extractor that produces fruit and vegetable juice by means of physical pressing. like figure 1 , figure 2 As shown, the juice extractor includes a machine base 1 with a motor 11 inside, a juice collection chamber 2 connected to the machine base, a screw 3 longitudinally arranged in the juice collection chamber, and an upper and lower opening between the screw and the juice collection chamber. Extrusion cylinder 4, a top cover 12 with a feed hole is arranged at the upper opening of the juice collection chamber, the screw includes a screw body 31 with a spiral on the surface and a screw shaft 32 in the screw body, and the motor is connected with the screw shaft through a transmission mechanism 13 , which can drive the screw to rotate.

[0053] In addition, the screw body includes a crushing section, an extrusion section, and a grinding section fro...

Embodiment 2

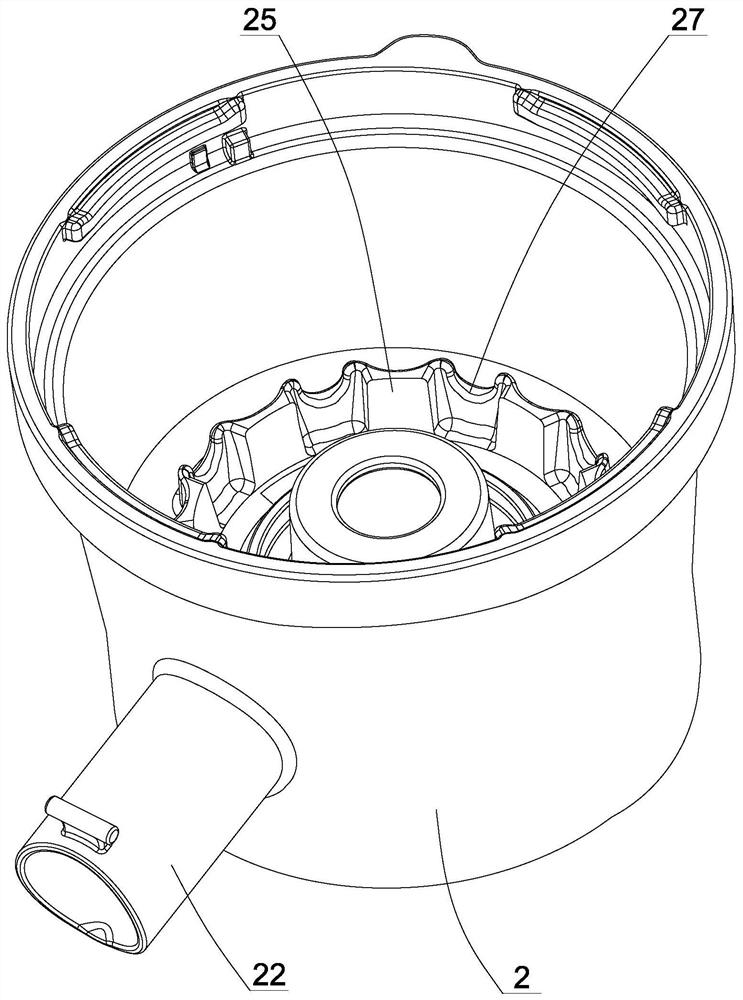

[0074] Embodiment 2: as Figure 5 As shown, the upper part of the extrusion cylinder in this embodiment includes a juice outlet 43, and several upper juice outlet slits 44 arranged side by side and extending in the axial direction are arranged in the juice outlet. , its juicing method also includes an upper filtration step between the shearing step and the squeezing step:

[0075] Part of the juice formed by the spiral shearing of the material in the shearing step flows out directly through the upper juice outlet gap, and the other part of the juice that has no time to flow out flows down along the inner wall of the extrusion cylinder.

[0076] That is to say, the height and axial length of the upper juice outlet gap correspond to the crushing section of the screw rod, so as to ensure that the juice flows out through the shortest path, so as to increase the juice outlet speed as much as possible. Since the materials in the shearing step basically exist in the form of small pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com