Copper-clad steel wire production fabrication process

A copper-clad steel wire and manufacturing process technology, applied in the field of metal products processing, can solve problems such as affecting electroplating copper, surface moisture increase, working environment and human body influence, etc., to facilitate replacement and cleaning, avoid absorption saturation, reduce surface The effect of humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

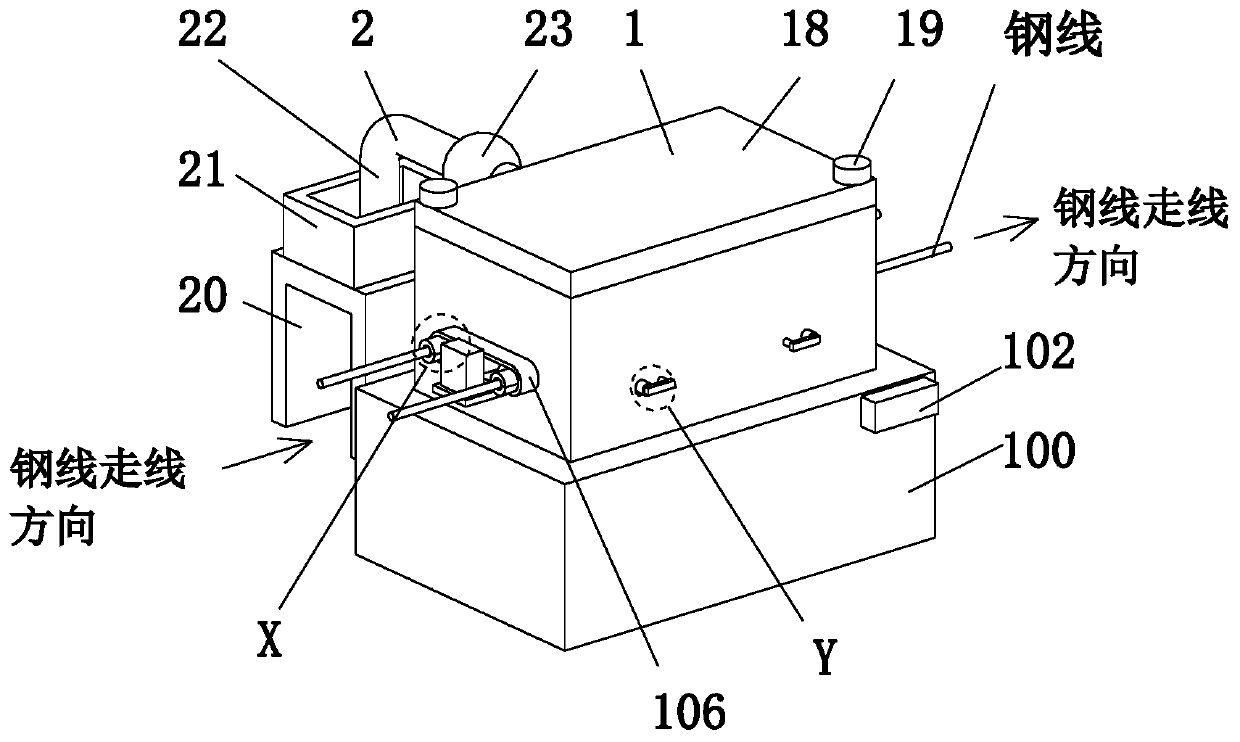

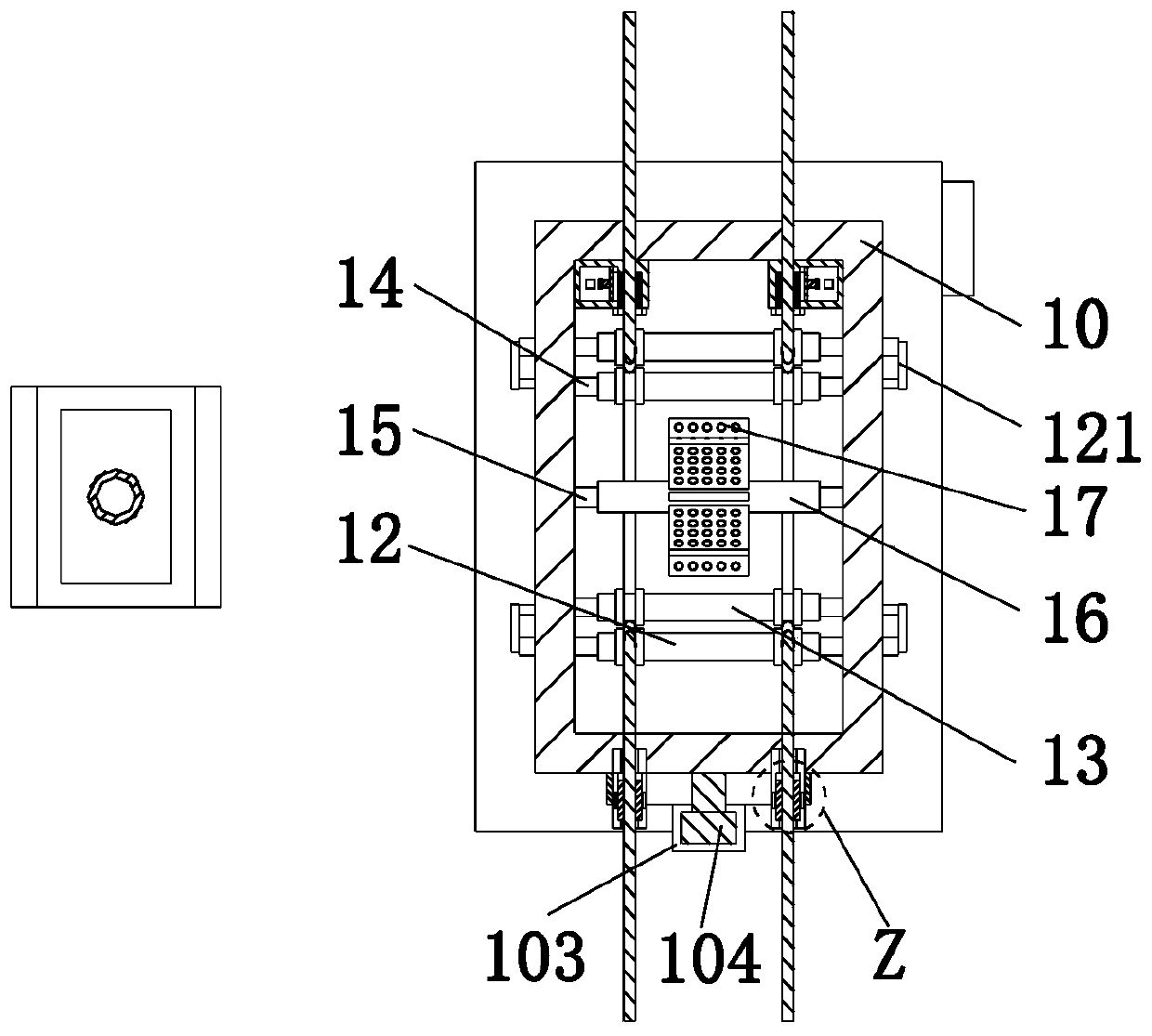

[0034] Such as Figure 1 to Figure 9 As shown, a copper-clad steel wire manufacturing process uses a copper-clad steel wire manufacturing device, the copper-clad steel wire manufacturing device includes an electroplating mechanism 1 and a processing mechanism 2, and adopts the above-mentioned copper-clad steel wire to produce The specific manufacturing process of the manufacturing device for copper-clad steel wire production is as follows:

[0035] S1, electroplating copper: the steel wire passes through the No. 1 ring shaft 12 and the No. 2 ring shaft 13 in turn and runs from left to right in an S-shape. After the steel wire is routed, manually tighten the bolt 19 to fix the top cover 18 and the Electroplating box 10, during the course of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com